-

Posts

1201 -

Joined

-

Last visited

-

Days Won

7

Content Type

Profiles

Forums

Blogs

Events

Gallery

Downloads

Store

Posts posted by duragg

-

-

Dynojet in Phoenix at the NASA approved facility..

258 to the wheels was our best, but there were indications of detonation so we had to pull timing.

Final configuration for classing purposes with filters and safe timing on 100LL fuel will be 248 wheels (245+ from 6250 to 7500)

With a few weight changes and 275 tires gets me just perfect at the ST3 class limit of 9:1.

Motor is clean, dry, healthy and seems happy.

Did I want 275? yes I did.

Might need to revist Bob Reams system soon..

-

I haven't really started dialing in the carbs yet. They are perfect 11.5 to 12.5 at WOT and being a track only car, who cares about the rest. But i will make some new idle jets and probably reposition one of the Prog Ports with the Franck tool. Maybe..

-

My Team Manager trying out new motor.

"Don't bottom out on the fuel farm", I said... But he did and I had to comment

-

Some fail...

Drove the modified 1st and 2nd gear tranny tonite.

I was able to get a crunch in the 1-> 2 shift while pulling hard.

Not as bad as before tho..

For the record, I HATE the "short shifter".

Stock throw was just fine.

-

Oh and RebekahsZ why you selling those Tokicos? What you replaced with?

-

Ok, ok.

I will post once done. Sounds wikked. And the cam is gnarly looking.

-

Rebello L30 motor is in and running.

Feels like double the power of the old L28 (which was injured).

Wheel dyno next week and adjustments to stay in 9:1 (+.1 or -.3 depending on tires).

If you never see me post the dyno numbers you will know how it went...

-

Getting the trans rear extension on correctly so it can activate the fork rods is tricky.

You have to gently feel it go on, with your finger down in the shifter socket and work it in.

And don't mesh any gears until the front cover is on so the rods don't over extend.

Once I have it all bolted together, then I bench check to make sure all shifting feels about right.

It might feel clunky since there is no vibration or rotation to assist.

You may have moved a fork while putting on the cover and didn't get the actuator in the fork slots right.

-

Just 1983 is reverse thread iirc

It's real tight.

Get the staking well removed first.

I just got a brandy new Left Thread nut from Nissan, so they are still out there.

Take pics as you go. Stay organized.

-

-

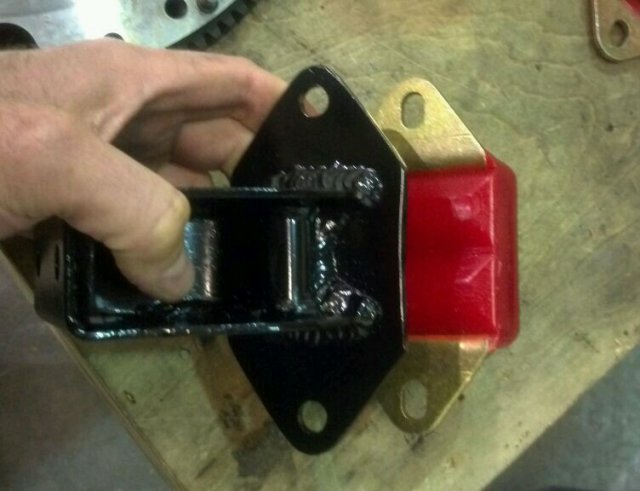

Got the motor in last night on the Jeep mounts.

Way stiffer,

Probably need to research a similar tranny (rear engine) mount since the energy will likely be moving somewhere (weaker link).

-

-

Height?

Well those jeep mounts are almost identical size.

Should be close to same I will double check pinions when it all goes back in.

-

That moustache bar setup looks like Monzster's L24 setup... I have photos of it somewhere. It was a nice solution especially when you have tubing or broken moustache bars laying around to use the bushing set!

...

....

... but you like mine too right Tony??

-

Mine is a track only thing so rough is good.

TJ

-

I almost broke my head doing all the alignment math last year when I was having vibes issues.

Do the best you can and if it doesn't buzz like crazy call it good.

-

Wait, wha?

Oh u want it slo-moe?

Cool:

-

-

Heres an old thread brought back to life. Can't see any reason for a new thread when the data is already here?

I ordered the Jeep mounts as referenced above and as indicated the tabs on the Jeep mount are way wider than the L28 mounts.

Initially i just enlarged the L28 mount holes and I think you could drill new holes in the ES Jeep mount and that would be fine... i guess.

But, I think I will cut off the bent ears on the L28 mount and weld on a new piece of 3/16" steel to the stock mount and match the shape of the ES Jeep mount and drill matching holes.

I will postemup some piks.

k.

Tj

PS> The ES Jeep mounts are beefy and will appear to be way more stifferer and about the same installed height. They might be a teence taller, but I can account for that (in theory) with the placement of the new welded on plate. In actuality, its gonna bee what it is.

-

-

I sense we have some like-minded people here that are relatively competitively racing the s30 chassis.

I am totally committed to the next 2+ years or more in the s30. Its the dimensions, the shape, the history, the balance...

s30 ain't quite ready for VARA in my book just yet... haha

-

Funny, I was just sitting at my desk and work stretching my 43 year old limbs and wondering: "Why do so many of them ache and creak".

Glad its not just me. Winter makes it worse that's for sure.

In Arizona the summer temps make everything better (except power)

-

Took tranny apart (again) and machined the slots in the 1st and 2nd gear synchros.

I took about 20 thou out of the slot making it that much deeper. Visually looks correct and so now should have solved the shifting issue for good.

I find a triangle shaped file about 3/8" width on sides works good. But the cut differently pushing / pulling so I used a die-grindr to cut it in half and used both directions to make the slot base even.

I can do that tranny in my sleep now.

Trick... to the left and right of your work stations affix 2 rods to the left (top and bottom) and 2 on the right. As you take parts off the shafts you can keep them in order and just hang on the rods.

-

Enjoying this thread immensely. I've got an RB-powered Z that's complete, and after all that work, she's "creaky."

When I started the build, my intention was to do a full stock restoration... but now that she has power and handling and braking, I really want the chassis to be as well-done as the rest of the car.

Almost thinking I'd like to find a clean rust-free shell, media blast it, incorporate ALL of the aforementioned efforts, and THEN swap everything over from my completed Z.

Just what I need.... another project.

I've just begun this very task with a 1970 shell.

As "rust free" as they come = just replace floorboards and delete spare tire pond

High RPM shifting dynamics

in Drivetrain

Posted

Some of this is just "the principle" of the battle.. I want to win.

What I DIDN"T do on this last round was to roughen the synchro cone so the brass can bite better.

I did that on 3&4 but frankly forgot on this last round.

The cone gets real shiny and if I had broken that glaze it might have helped.

I may do that someday in the future.

No, 2nd isn't used much on the track.

But I may want (need) to drag race the car some day and 2nd is helpful for that.

And I just want to be able to report 100% success to my Hybridz bretheren.