-

Posts

302 -

Joined

-

Last visited

Content Type

Profiles

Forums

Blogs

Events

Gallery

Downloads

Store

Posts posted by zlalomz

-

-

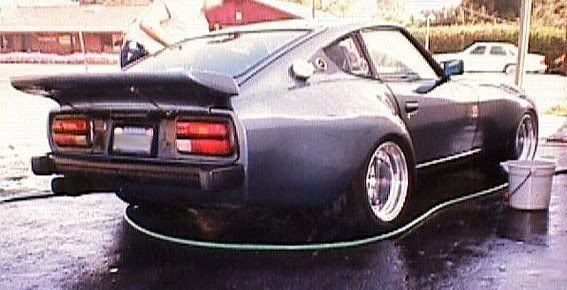

Here are a couple of styles that are no longer made.

The first are Ronal Racing 16 inch 3 piece wheels on my brothers Z which he built in the 80's. Ronal has since discontinued the 16 inch size. The second ones are Wheel Specialities. They are 2 piece wheels that are glued together with some NASA glue! This style wheel was used by Andy Craig to win the FP solo 2 nationals years ago against a tube frame TR-8.

-

-

I tried to get "ctrl z" or "ctrl zz" but they were taken. Maybe just "ctrl" and let them figure out the Z. Auxilary would be the only one to figure it out though.

-

Would that be Thorin Oakenshields namesake? From the furry feet I would have gone with Frodo or Bilbo.

-

The UV leds work great illuminating vaseline glass marble eyes too! 3 months 'till Halloween.

-

You had me fooled for a minute until I saw the Koala in the eucalyptus trees. That's just a picture from Australia.

-

Ooh, judging by the no secret compartments behind the seats it looks like an early series one, so nice and lightweight.

-

Autoweek.com has a screensaver of the crash.

-

http://www.teamjamoto.com/dixeregionpage.htm#v8301600

Even Nascar crews can't get 4 wheels off this fast.

-

Here is Bill Coffey in Florida's car. I also thought Ferrari 550 Maranello style headlights would look great with the YZ.

-

Why so big for autocross, is this a track car too? I am using a 3 gallon drag "cell" from summit.

-

I am trying to help the original owner to locate this car.

More info can be found half way down this page.

-

Well TonyD, if you need a fourth fan or more fans for target practice you can get them at Clarks Corvair Parts. Around $26 used and $98 NOS. They also buy used parts if you need more ammo money.

Do you notice how the back sides of the fans look like 4th? gen Corvette wheels?

Do you notice how the back sides of the fans look like 4th? gen Corvette wheels? -

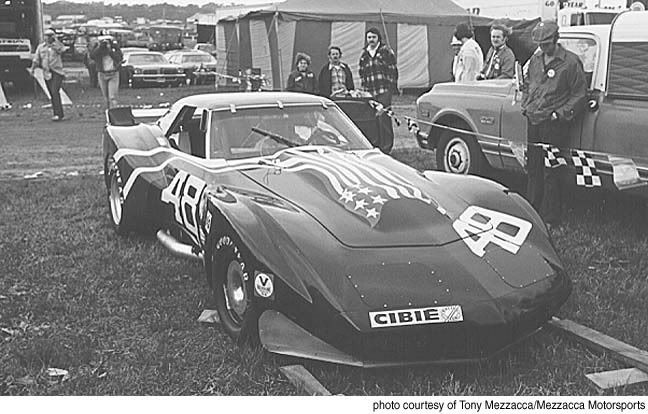

SCCA Corvettes used to use fans from the tops of Corvair air-cooled engines on their wheels. My first car was a Corvair so I would point this out with pride to my friends when we went to races at Laguna Seca. They would then tell me that the fan was the only race-worthy part from my Corvair. The fans on the 65-69 'vairs are made of magnesium.

From the Greenwood Corvette website,

“On the front wheels, Greenwood ran a very early version of the air extractor fans -- he used cut-down Corvair fans bolted onto the wheel to help move air across the brake area.”

-

Sign up and then you can vote. I voted, good luck!!

-

The piano's been drinking, not me.

-

T/C rods have a history of breaking with stiff bushings front and rear. If they move the mounting points to the brackets it should work.

http://forums.hybridz.org/showthread.php?t=70931&highlight=t%2Fc+breaking

-

Stunning fabrication work!!! This should be one incredible Z. Is it just me though or is that T/C brace limiting the independent movement of the T/C rods? Shouldn't the brace go to the mounts and not the rods themselves?

-

It looks like the old Jim Cook Racing kit. http://www.jimcookracing.com/catalog/page13.html

scroll down to bottom left pic. The rear view with a whale tail is on pg.11 of the catalog.

-

I always wondered what to do with that spare shell on the side yard…wall art!!!

The pics are from http://www.auto-active.co.uk/

-

And now back to the exploding booth myth. Since you are drawing overspray through the fans is there a spark problem when using cheap fans? I remember reading of a certain kind of fan with an insulated motor.

-

I put a 1 1/2 tube as close as I could tell where your bar is to check the clearance. I have the short Mikuni manifold. My large ITG filter won't fit with the bar there but maybe a custom airbox will work for you. The stock throttle linkage looks to be in jeopardy so something fancy or a cable throttle. My engine is in the stock location with newer stock motor mounts (no sag). I checked when I built my orange car front tubes and it cleared but this is because of the freakishly high dash bar that Rick at Rebello built. It worked for clearance on the engine bay bars but made my door X bars too high. I modified the driver bar for easier access.

-

-

Excellent, and when they are both in the container you can ship it to my house.

The counterweight is just a rectangular tube and a post welded on, a lot less work than many I have seen. I lock it in place with a nut welded over a hole on the spinning shaft. I just tighten the bolt to clamp it down. It doesn't need much tightening to lock in place. I have been inside the cockpit with the car sideways and did not need to lock it down. I would just move it a little to get access to the hard to weld tubes.

The counterweight is just a rectangular tube and a post welded on, a lot less work than many I have seen. I lock it in place with a nut welded over a hole on the spinning shaft. I just tighten the bolt to clamp it down. It doesn't need much tightening to lock in place. I have been inside the cockpit with the car sideways and did not need to lock it down. I would just move it a little to get access to the hard to weld tubes.

240, 260, 280z hoods all the same?

in S30 Series - 240z, 260z, 280z

Posted

There is a thread over on ClassicZcar about series one hoods and their differences from later hoods.

http://www.classiczcars.com/forums/showthread.php?t=27591&highlight=hoods