-

Posts

60 -

Joined

-

Last visited

Content Type

Profiles

Forums

Blogs

Events

Gallery

Downloads

Store

Posts posted by col10see

-

-

Wow this is old...but....updates or where is the other half?

-

Found this

http://forums.hybridz.org/topic/45414-gulp-fmu/page-3

Im not surs if the people are using na injectors or turbo

Acording to this theory and my math I need to run a 12:1 fmu and be into the 130s psi @ 10psi boost(i dont have my paper with me I will edit this with my info.... But according to what the guy says to be at 95psi @ 11psi boost, I would really want like a 6:1Use the pressure ratio to determine how much more fuel you will need. This is how Corky Bell does it in his turbo manual.

For example: if you are going to run 8 psi of boost then the pressure ratio is (8 + 14.7) /14.7 = 1.544. So you will be making 54.4% more power and will need 54% more fuel. (In theroy).

So....

(pressure ratio x pressure ratio) x 36 psi = FMU pressure needed.

FYI, 36 psi is Z full throttle fuel pressure.

(1.544 x 1.544) x 36 = 86 psi.

86 psi will be a good starting point, but you need to check a/f during boost and make adjustments. 85 psi doesn't take into account boost acting on the injector or a turbos need for more fuel/hp. Corkey Bell says the FMU is only good for 10 psi because the fuel pressure gets to high after that.

You will need a fuel pressure gauge in the car to check the pressure when driving. That pressure may be hard to hold during high fuel rates.

I have run as low as 65 psi with 8 psi and 85 psi with 12 psi of boost, but the a/f ratios were about 14:1 which is not the best to make power and reduce detontion.

I currently run 11 psi of boost with 95 psi of fuel pressure. I had run 13 to 14 psi of boost with that fuel pressure, but recently turned down the boost a little to get more favorable a/f ratios and haven't noticed a lost of power.

Also note the compression ratio given at example... I used the comp ratio of 8.3

-

I guess so. Gabriel replacements from ghetozone.. not OEM from nissan.

-

-

Same here new alternator fixed it up... it was like 50$ from autozone and had a lifetime warranty...acdelco I think but no problems since

-

Im thinking I want to lean it out a little low end any pressure recommendations for the turbo injectors. From what ive gathered its 36psi at idle with no vac...

Also if I do that im guessing I want to get a fmu what ratio for 13 psi. 5:1?

Hopfully soon I can find some doner dished pistons and rebuild the motor.

Also heres a pic of the the turbo blanket..

-

Between the afm and the inlet of the compressor. In the long run I would like to route my intake/air filter in front of the radiator to start with cooler air in stead of sucking in hot air right off the radiator. Though it may be a negligible air temp diference by the time it passes through the turbo. And I would also like to put the afm near the stock location so I can get easier access if I need to tweek it a little.

-

Air moving into the inlet side of the compressor housingThe rest didn't make sense to me. When you say air coming in, where is it "coming in" to?

I also get that the bov needs to be on the pressurized side of the compressor side of the turbo, to release pressure, thats why I put it on the pressurized side of the compressor.

-

So I tightened the afm spring about 7 cogs.And noticed a pretty big drivability difference. Less hesitation after shifts and it doesn't smell like someone is chasing me with a can of gas. And I am also getting better readings from my a/f guage I did however turn up the fuel fressure to about 36psi idle and it hits about 50psi under full boost without dropping out of rich territory under wot.

I would like to redirect the bov after the afm to see if this will help fight false air flow readings and help the rest of the hesitation after shifts under lighter boost or no boost. At 3-10psi, it doesn't seem to matter as I think that the turbine is spinning high enoungh that the air coming into the compressor doesn't hit a "wall" of slowed air via the slower compressor blades because of more time in between shifts and longer time with the throttle body closed.

If anyone has pics of how they did it or links feel free to post up....the more info out there the more it helps others too not just me;)

Also having the blanket on the turbine housing helped a lot! When it comes to heating up the intake manifold and the turbo seems to be spooling up a little faster.

I may need to cut a little off to fit around the waist gate mechanism to better hug the housing.

Pictures to come

-

I wrapped my dp with dei header wrap back to were the flange will go for the cat so I can remove it whenever and it will make it a little easier to do exhaust work come tim to put in a 3" exhaust.

This stuff works great. Im going to wrap the manifold when I switch out the pistons.

And I am waiting for my turbo blanket to get here as well ill ad pictures of that once I get it on.

-

Im an idiot I left my cooling fan control switch unbolted when I put in the ic tubing. And go figure it grounded out.. I fixed the problem that it caused. But just wanted to post this in case something like this happens to anyone else...

So the switch is direct to pos+ on the battery and when I unbolted it I though I had secured it well enough... not so, it ended up grounding out on the fenderwell and now the battery wasnt charging above 12v and the dash lights were staying on as if i hadnt started the car but would turn off after like 4min and the come back on at idle... probley not even charging wile driving maybe very little. Wtf! . I checked the fuse links all good there. So I looked up the price of a replacent voltage regulator(internal I know) 100+ BUCKS at the parts store. So I looked at the price of an alternator 49$ no brainer. So I installed the new alternater and problem solved.

Just felt I should document it in case anyone needs the help or ideas.

-

Just an update so far no issues been about 200miles or so and no issues. Also I replaced the bolts on the driveline with some new ones and the shakes are gone too. So out of the whole mess it ended up working out.

Thanks for all the help!

-

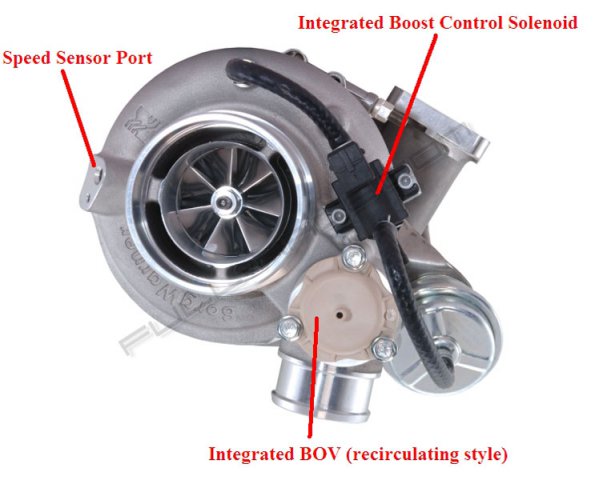

I saw this and found it interesting were borg warners efr turbos have their bov's....

http://www.full-race.com/articles/borgwarner-efr-turbos.html

I will probably end up moving the some things around as I clean up the piping and sillicone and get a bigger intercooler.

Here is a shot of the of the rest of the piping.

Also I added the voodo III manual boost controller and turned it up to 10 sounds normal on reg gas so, so far so good.

-

Good luck with the build be sure to document it. Im interested to see how it goes...

This is mine maybe it will help... maybe not but feel free to post any questions.

http://forums.hybridz.org/topic/112511-my-550-280zx-na-to-turbo-adventure/

-

Drain the tranny fluid. Look for metal or shiny stuff in the fluid. If nothing I say fill it up again.... make sure you can loosen the fill plug first though or else you are screwed....

Is it possible the clutch may be slipping? They have rivets in them that will sound maetalic and it could also be causing the slippyness under hard accel

-

Did you reconect the ground in the harness at the manifold or is it possible the manifolds contact to ground is dirty?

-

Yea ive had the tubo on for a little bit. But I just the intercooler in. Just getting caught up on putting it on the interwebs when I get a chance. Yea silly cone j pipe had been run about week with no issues until the tranny went berzerk on me.

Next to the radiator is kinof a messy hole I should have hole sawed it but thats hindsight.

As far as the bov not by the compressor, Just curious why?

I figured it would be better to blow off hot air instaed of cool air so I didnt heat soak the intercooler as much... but I dont know just went with my gut.

I will get some more pics of the piping

-

Got the intercooler in.

I couldnt get a good picture of the other side it just does a 90 behind the radiator and goes to the bov and to the compressor outlet of the turbo...

Oh yea, thats right, more silicone fittings. Ha ha ha

Heres a picture as it is today. Been rust hunting so it looks a little beat not that you can tell with the light..And I removed the door bumpers too because I think it looks better.

-

Yea that what ive read. Im only at 5 now... well holding 5 psi now! Because when I clocked the turbo I didnt adjust the waistgate right.

But yea im workin on installing the intercooler.

-

Lol, right so ghetto but it will do till I cut the hole to run the ic tubing on the other sideLol at Jpipe made of silicone.

Do you have pics of your car? interior and exterior, action shots etc.

Good to know ill keep it at 10.

Action shots... I wish someone could have recorded it or I had the go pro when I spun off the road in january in frosty road conditions showing off for a kid who had never seen a 280zx started fine put it in second and gunned it. Next thing I knew I was sliding sidways looking the face of the kid...oh sh**! oh sh**! oh sh**!!! I let off the rear tires hooked up and I spun the other direction off the road, up a snow banked curb right in between two electrical poles... that would have been a solid action shot.. hope I painted a good enough picture.... im going to try to find the picture of when I got it, and some other shots.

-

-

Has anyone made a shift pattern plate for the z like the fuhrarreeez. Lol

-

Also have a stock set here likewise

-

Love the build keep it up

my 550$ 280zx na to turbo adventure

in S130 Series - 280ZX

Posted

All together minus intercooler 40 $ eBay, I'd say less than 600$ all diy fab except the alum bends and couplings turbo was like 250 $ worked like a charm..

I had less than optimal compression so it didn't spin tires uncontrollably. It only spun if I made it.

I recently sold it though:( but I got a nice well taken care of old man's 350z instead:)... I miss it now and then.