-

Posts

64 -

Joined

-

Last visited

Content Type

Profiles

Forums

Blogs

Events

Gallery

Downloads

Store

Posts posted by ArizonaZ

-

-

Looks great! Do you happen to know what material it was printed out of? I would be hesitant of using anything but ABS.

-

I am currently running the CS130 alternator on my car, it takes a modified alternator mount and a new tensioning arm (turnbuckle), but it works great. I also have a champion 3 row that will be going into the car when I get it painted. I went down to the junkyard and grabbed a dual fan set-up from a Ford Contour, it fits the radiator almost perfectly and should be thin enough to fit with the L series. I cant find any solid numbers but internet lore states that the fans put out around 3500CFM at 30 amps.

-

The Kameari GT seats look very similar, but expect to pay a very high premium for them. Here's a thread talking all about these types of seats

-

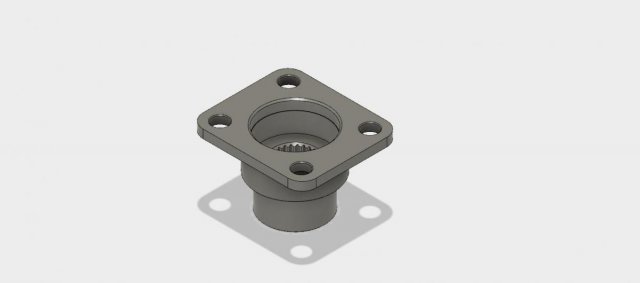

I don't know how accurate this is, but here's a model of one I picked up a while ago. Here's a link to my google drive for a .step file of it. I can't upload it directly to the forum.

https://drive.google.com/file/d/0B7QMuH0UuWYxX2tvR3diWEZNSHc/view?usp=sharing

-

Wow, that looks great! I did mine while ago, and I know that it takes a lot of work to get it to look that good. Great job!

-

What if you had a spacer on the face of the flange?

https://www.appletreeauto.com/CV-GREASE-RING-930-CV-AC525140-930/

That's 20 dollars, and has the added benefit of being able to grease the CV joint without disassembly.

That would bring you back up to 19mm of spline engagement.

That's about the only thing that I'm coming up with as well. It's just a bit annoying that there isn't a way to make it work without a spacer.

-

Speaking of which, any update if a smaller nut or something can be used for the Toyota flange?

I got the new flange in the other day and started doing some math with it. The problem isn't the nut sticking out, but the end of the stub axle. If you want it to be flush with the companion flange face, then you can only take off about 2.5mm from the splined side. This leaves only 16.5mm of spline engagement vs the 24mm that the stock flange has.

-

If you wanna pay shipping, I'll give mine to you since I won't be using it.

The link for the source is in the posts above.

Thanks for the offer! Just a little too late though, I already ordered one last night haha.

-

I measured the washer and the 280ZX self locking nut stack up and its about 19.5mm. I'm thinking the flange may still work if less or no material is removed from the end. Unfortunately I already started machining mine, so I will need to get another one to play with.

-

-

For anyone wanting to run 930 CV axles though, would modifying this flange be any different than just using these adapters?

https://zcardepot.com/driveline/rear-axle/billet-aluminum-axle-adaptors-930-cv-240z-260z-280z.html

For me the main advantage would be losing 8 fasteners in the axles. If you used the adapters on both sides of a single axle you would end up with 40 bolts in both of the axles! Getting that number down would be preferable to me.

-

I plan on using these flanges with 930 joints, but I think a small spacer will need to go between the joint and the flange accommodate the plunging of the axle. I'm thinking a 5/8" spacer should be plenty. The outer diameter of a 930 joint is 108mm, so there is plenty of room for them.

-

Yep, that would work. I was thinking about how to attach that sleeve, and my first thought was to use loctite that is meant for cylindrical parts. I also looked into new oil seals and you can find 72mmx38mmx10mm ones pretty easily for ~$4 as well.

-

Thanks Neverdone, I think that worked!

Here are the links for the downloads:

-

Also I forgot the mention that you can order the flange with either a differential or transfer case dust shield. I ordered mine with the differential one, and it is the exact same size as the original Datsun one.

-

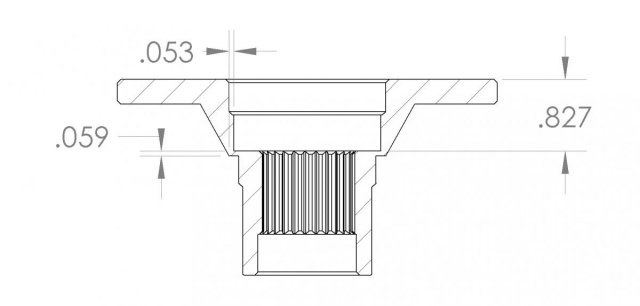

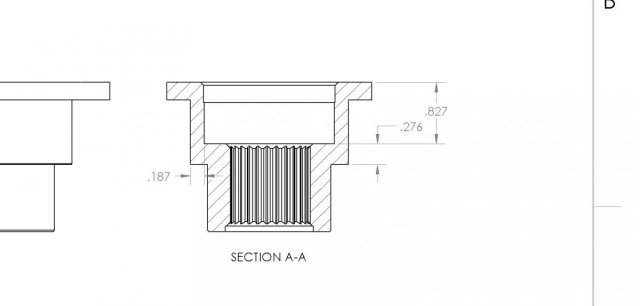

Here's the update. I received my blank flange today and got to measuring it. Before I did that though I test fitted it on my stub axle and I am happy to say its a direct fit in terms of spline count and diameter! There are a few things that will need to be modified to make the flange work though. As jthom said the splined portion is too long, long so it will need to be shortened about 10.4mm. The outside diameter is also 4mm smaller, so either a new oil seal will be needed or a 2mm thick sleeve will need to be put on the new flange. I drew up both flanges since I had them, and I will attach the 3D files for them. There are fairly quick measurements done with a cheap caliper, so please dont rush off to a machinist with the model and complain when they made something that doesn't fit. The splines are pretty accurate, but please treat them as just a visual representation as well.

If anyone is interested in looking at the models and doesn't have any program to open them with, I would suggest downloading Fusion 360 from Autodesk. It's what I modeled them in and its free to pretty much anyone unless you're a company that makes $100k+ a year.

EDIT: I am unable to attach the .STEP files. Does anyone know how to attach them?

-

Well I ordered a blank flange yesterday. I am in the process of putting on some ground control coil overs, so I can pull my stub axles and take some measurements. I am a machinist, so I should be able to modify the flange as long as the spline portions mate pretty well.

-

From what I was able to find online, the diameter of the Toyota bore should be 28mm or about 1.1". I could only find one reference to the diameter of the Datsun axle, and that put it at 1.09" or 27.69mm.

-

Does anyone know what the original flanges are made of? I bet that 5140 is probably a stronger material than what Nissan used.I also just ordered one to play with. If it works out I'll be using it for a 930 cv flange.

-

Do you have a part number or link to the wilwood kit that you used?

-

Rota's, I'm in for a cheap staggered rbr set.

+1

-

Any chance of you making glove box doors to match the fiberglass and carbon dashes?

-

The results may also be skewed because non contact infrared thermometers will read differently depending on the reflective of the surface. The gold tape will alter the results I'm betting.

-

I know that this is an old post, but I'm curious if there has been any more experience with these turbos. I see that the new EFR 7163 seems to be a great turbo for the Subaru guys. Looks like the performance of the 7064, but a spool time closer to the 6758. What do you guys think about fitting that on an L28ET?

Saturn Electric Power Steering In A Datsun 280Z

in Fabrication / Welding

Posted

Excellent write up! I picked up a Saturn motor at the pick a part a few months ago and will be using this when the time comes to put it in.