jonbill

-

Posts

184 -

Joined

-

Last visited

-

Days Won

1

Content Type

Profiles

Forums

Blogs

Events

Gallery

Downloads

Store

Posts posted by jonbill

-

-

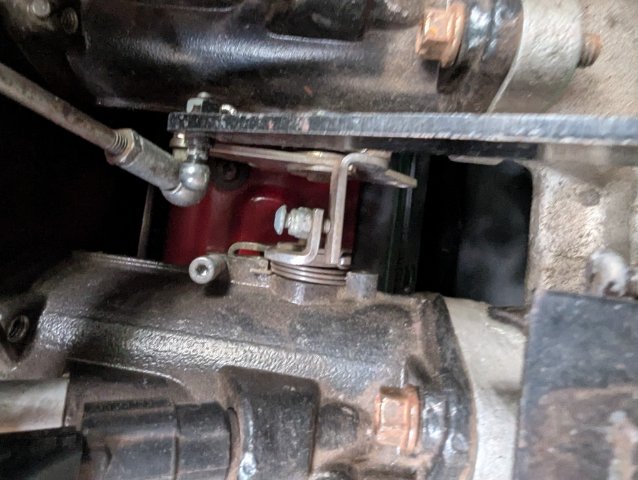

There should be adjuster like this

between each, to make each pair flow the same, and the bleed screw is to balance flow within a pair.

between each, to make each pair flow the same, and the bleed screw is to balance flow within a pair.

If the bleed screws don't have enough, then hold the throttle body up to the light with the throttle closed. You'll probably see the butterfly isn't perfectly centered because they weren't assembled very carefully. So they flow different amounts of air.

You can slacken the two fixing screws and recenter the butterflies to balance them.

But.... Why does the first need more air on yours? That doesn't sound right.

-

I don't really remember I'm afraid, but I know there wasn't a lot of adjustment available. Have you looked at recentering the throttle plates to see if you can get more consistent air flow when closed?

-

Yes I did on the FAJs, I just about got the amount of adjustment I needed.

-

It's a welded p90a. I think the ports are 38mm. I think they must be as big as they can be since the head bolt holes broke through when we drilled them for m12 bolts.

-

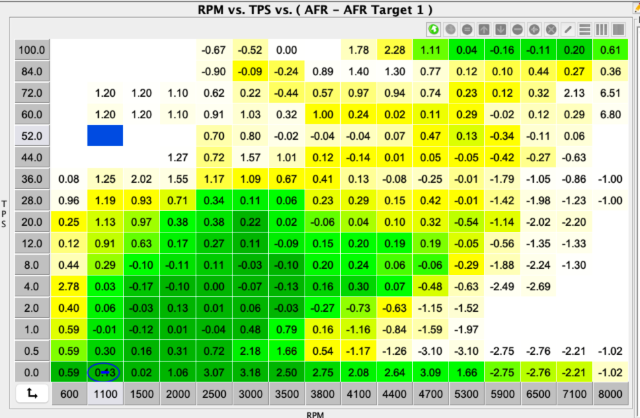

the most valuable tuning tool for me has been this MLV histogram - I can drive around all day logging, and then load this and in one view I can see how close the tune is to where I want it to be.

-

7 hours ago, madkaw said:

Are you running Tunerstudio? Either way would you share some screen shots of your tables ? Curious how efficient you have the motor running as far as power vs mpg ?

45’s to small or looking for more power ? I think my small port head will like the smaller ITBS .

You have a thread I can read up on ?thanks

yes, Speeduino uses Tunerstudio too - I'll share some screenshots and the tune.

I'm switching to 50s because this engine doesn't rev out like my previous 2.9 did - it would zip round past 8000 but this one is more powerful below 6000 but isn't so keen to rev past 7000 at all. It might just be the longer stroke, but it could be the 45s are too small so I have to find out.

on the motorway it does about 35 mpg (UK gallons, so prob 30mpg US). and I'm confident it's well more than 300bhp (but never proved it, because that costs money :))

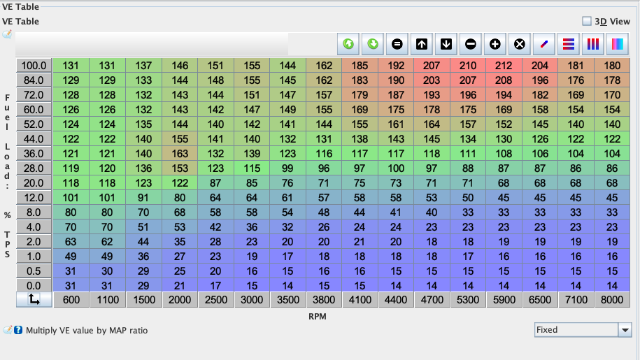

VE table:

Spark table:

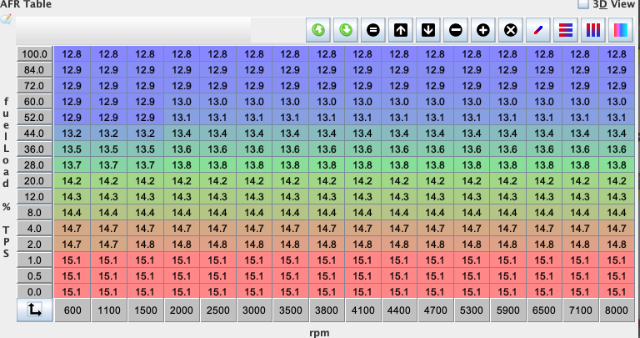

AFR table

I only use closed loop o2 control at low throttle openings. Above that, it does hit the target AFRs quite well, after years of logging and histogramming with MLV.

-

I run pure Alpha-N on my engine with Speeduino. 3.2 stroker with a diesel block. FAJS 45 ITBs. I have it working very well everywhere.

Idle is managed with Speeduino's ignition advance idle control. It starts on the key from cold and hot without touching the throttle and idles at 1100 throughout.

Its in bits at the moment, but when it goes back together it'll have 50mm Sherryberg ITBs.

-

What kind of a car and engine is "this beast"?

If you're idling an l6 in an s30 with an unvented bonnet and no heat shielding on the exhaust, the injectors may well be heat soaked.

But then again, if as you say you can add fuel until it stumbles and it still reads lean, then it sounds like a duff sensor or an air leak in the exhaust.

Is it a genuine Bosch LSU4.9? Where did you buy it?

-

What sensor and wb controller is it?

-

Sounds like a duff sensor.

-

Thats almost invincible.

-

A couple of things that might help:

When a cylinder doesn't fire, then the wbo2 reads full lean because the gas passing over it is atmospheric air. None of the oxygen has been used to burn fuel.

This happens whether the misfire was because the mixture was too lean or because it was too rich.

So when you're at 11 afr and go richer, it wont burn and so it shows lean.

Telling TS that you have bigger injectors when you haven't changed them will make it leaner, because the calculation assumes that it can deliver the required fuel in a shorter time. Assuming your injectors are big enough for your power level, when you're maxed out on the VE table values (as your are) a larger required fuel value will give you more head room.

-

Pull the cam out and get it reground to a more aggressive profile. You'll get more power (maybe) and more lash clearance.

Win win.

-

-

Just to be a bit contrary:

IF you can find someone competent with dual sidedraughts, I guarantee it will be a lot cheaper to get the webers spot on than to supply, fit, tune ITBs and EFI

-

I'd look at where the throttle plate is, in relation to the progression holes.

You want it to start uncovering a progression hole at the first movement of the throttle. I think it is possible to setup idle by keeping the idle bypass screws shut and opening the throttle to the first progression hole, but you've then got a fair way to go to the next progression hole.

Correct way is to have idle on completely closed throttle and idle air supplied by the bypass screws.

-

I expect the missing bit is in the sump.

I'm sure you'll be able to epoxy it all back together.

The cam lobes look ok, thats the main thing to check out with the spray bar broken.

I've never seen those bits made of cast ally, mine have all been pressed steel.

-

Maybe try the next size up idle jet, that might cover the transition hole, might richen it a little at wot too.

Also check the float levels if you haven't already.

-

I'd check that the accelerator pump is working correctly first. Take the carbs off and see if they squirt fuel out the back.

-

Will it get up to the higher revs ok if you don't give it so much throttle?

If it can accelerate up at part throttle without any hiccups, then its probably the accelerator pump circuit.

-

To ensure enough pressure and flow to the bottom end.

-

Mine is r200 with r200 moustache bar. is yours an r200 moustache bar? i believe they are different. Maybe not the wrong way round, maybe just the wrong bar....

-

Not sure what thats in reference to, so I may have the wrong end of the stick, but ignition timing jitter has been well measured in Speeduino and there's no problem (would be my conclusion).

-

Surely your moustache bar is back to front?

between each, to make each pair flow the same, and the bleed screw is to balance flow within a pair.

between each, to make each pair flow the same, and the bleed screw is to balance flow within a pair.

3.2 Build EFI N42 / MN47

in Nissan L6 Forum

Posted

I think thats a significant difference.

Adjusting the throttle stop on that carb will move the others. Have you got a pic of how the throttle bodies are linked?

I balance them by disconnecting the linkage and using air bypass to get each pair in balance with themselves and the throttle stops to get the 3 three balanced with each other. Then connect/adjust the linkage so they're still flowing the same at idle. They should then stay in balance as you open them.