-

Posts

888 -

Joined

-

Last visited

-

Days Won

2

Content Type

Profiles

Forums

Blogs

Events

Gallery

Downloads

Store

Everything posted by Jersey

-

Thanks madkaw. I've thought about making a set of those HM det cans, just haven't got around to it. No knock sensor installed unfortunately. Safe travels.

-

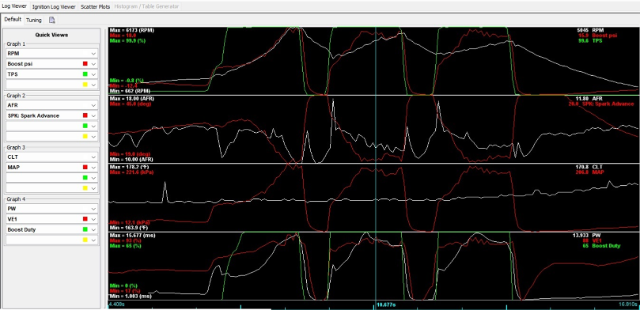

Thanks awd, madkaw. 1st start went great last week. She fired up instantly and ran it @ 1500-2000prm for about 20 minutes to break in the cam. Since then, made a few changes to the VE, AE, WUE settings and also ditched the unstable manual BC & enabled the EBC. Ran some data logs and it stays close to the AFR table I've set up, boosting to 15psi. Still a bunch of tuning to do but so far, it seems ok and pulls pretty dang hard without any detonation that I can hear. True madkaw, it was nerve racking. I did need to make a bunch of changes to the GR tune before 1st start or, it really had no chance at starting. GR had all my motor specs and purchased all the MS components through them, but it almost seems like they left most, if not all of the settings they had for their test motor as the current tune. No big deal since I figured it all out before I turned the key but, worth mentioning if someone else goes down this road. Their assembled unit and wiring harness are very nice which made the install pretty painless. I also converted from hydro lifters to solid during the MS install and need to do a quick write-up on that at some point. After installing the time-serts and solids, cranked it a bunch without the rockers and the lifter oil ports on the P90A head were moving a lot of oil past the smaller headed solid lifters. Found some copper metric washers to use which sealed the small oil ports almost completely. With the amount of oil getting past the lifters at cranking speed, I wasn't comfortable leaving it like that since I'm sure there would be a lot more blowby at higher RPM's, possibly starving the crank bearings, cam & bearings, etc. Also picked up some .160 lash pads which put the wipe pattern perfect with the Delta regrind. A little to the lifter side which creates a little more lift, which is good. North-eastern NJ, Morris county madkaw. Thanks for the replies guys. Now I need to find a Dyno and a tuner in NJ that knows MS because I'm sure I'm leaving a lot on the table since this is the 1st time I'm ever tuning, especially in the ignition table dept. If anyone knows of someone they trust in my area, please let me know.

-

Thanks Jon. Nice to hear from a familiar member. Guess we'll see how this .443, 212° @ .050 w/260° of duration works out for now. This whole cam dilemma just became a bump in the road when I started the Megasquirt install. Received the solid lifters and time-serts today, hope to do the wipe patterns tonight to see which lash pads will be needed. Once I get this all sorted, back to figuring out how to tune this MS! Wish there wasn't so many variables but, is what it is. I do like your way of thinking though... Go big or go home!

-

We shall see. Thanks Brad.

-

Thanks Brad. Solid lifters, mousetraps and time-serts on their way. Figured the hydros were going to bite me sooner or later, might as well make the switch now. From my measurements, looks like he took just about .060 off the base. Hoping I wont need to go larger than .160 pads so I’m able to keep the stock retainers. He did say this grind would work with either the solids or hydros, but didn’t have the ramp angle spec. Might be time to get a dial indicator because now I’m curious and could pass this info along to others.

-

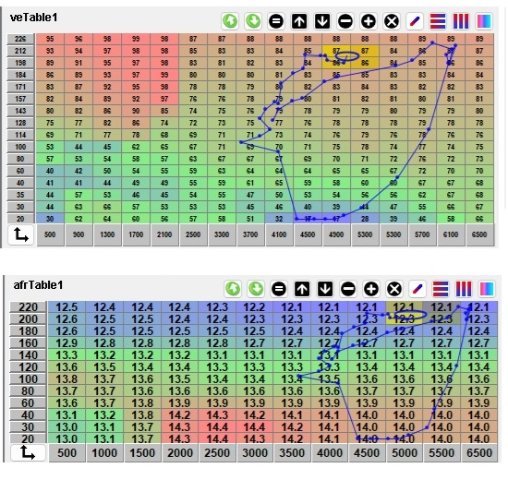

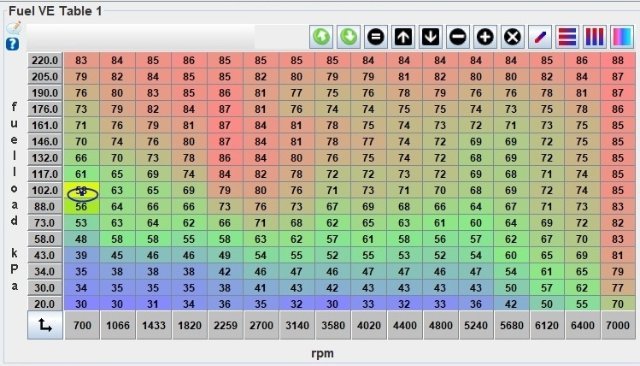

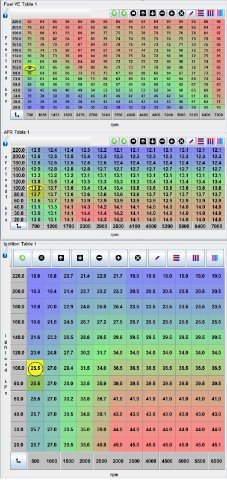

Ok, thanks. Whew, thought I wrote something that offended or against new rules or something. Yes, Moby's posts were some of the first few thousand on MS setup I read before talking my cousin into MS'ing his 77. And I've also read a bunch of your posts, the most recent in helping Flak280z back in April with his setup. Your help and replies are much appreciated. It's just that a lot of the posts and stickies are from 10-15-20 years ago and there's a whole bunch of different setups so, I just wanted to see if someone could comment on the tables I've set up for this build before the 1st start to make sure I'm not way out of line. Granted, every motor is different, and tunes will need to be tweaked even if builds are exactly the same, which I understand. Anyway, thanks for the reply and enjoy the long weekend.

-

Morning all, Please don't take this as I'm complaining, I'm just curious if I posted something out of line? Maybe my setup or settings are so far out of whack that nobody wants to comment on or possibly this subject has just beat to death? Granted, I haven't visited this site much in several years since my Z's been laid up so maybe members aren't as active as they used to be when I joined over 20 years ago? If you'd rather not comment publicly, please feel free to PM me. Thx - Jersey

-

Ken couldn't really suggest which pads would be right since the base circle was cut and I also had him resurface the rockers so, understandable. From the measurements I took if I were going to use the hydro lifters, it looks like I'd need something in the .190 range, and that's with guessing @ .020 preload on the lifters. Couldn't find the exact amount of preload that they should have but @ .170, the rockers were tight up against the cam. Time-serts, mechanical lifters and with springs are on their way. Ken said the grind was a "260" Stage 1, 212 @ .050 w/443 duration.

-

For some unforeseen issues, I may be switching gears on this once again and swapping over to mechanical lifters & time-serts in the P90A head. Question is, can I use the original Hydro cam that Delta just shaved down for me if i go this route or would i need to go with a solid cam/spray bar setup? I've read a few times now about the "clearance" or "opening" ramp being too aggressive on the hydro cams and will cause a noisy valvetrain and probable rocker/cam lobe damage if used with mechanical lifters. True? Untrue? Over thinking? Thanks.

-

-

Hi all. I just finished installing an MS2 v3.57 from Godzilla Raceworks and will be installing the Delta reground cam tonight. I'm hoping once I get the wipe patterns correct and get it all back together, I can get it up and running to about 2k rpm as quickly as possible to properly break in the cam/mate the rockers. The motor is in solid condition and ran well before I started the MS install, other than being pig rich and dangerously lean with the stock ECU. I'm hoping someone could take a look at my config and the AFR, VE and Ignition tables I've added to the base tune GR sent to make sure I'm in the ballpark. I left all of the other GR base settings alone, just these 3 tables seemed to be set way rich and very conservative, which I'm sure is the safest option on their behalf. Any and all suggestions are more than welcome. MS is all new to me so please no flames! ha. Thanks in advance. ’83 L28ET Turbo motor MegaSquirt MS2 v3.57 F54 block P90A Head w/hydraulic lifters Ported N42 Intake 2mm Metal head gasket JE Forged Pistons T3/T4, 50trim E wheel, .63 Stage III clipped Bosch EV6 440cc Injectors - NEW 60mm 240sx Throttle Body Walbro 255LPH Fuel Pump SS 3/8” Fuel Supply Line Pallnet Fuel Rail - NEW Aeromotive FPR - NEW AEM Wideband O2 - NEW NPR Intercooler Allstar 40,000v High Performance Ignition Coil - NEW Electronic Boost Control - NEW, but not enabling yet Greddy BOV Custom DP w/3” Exhaust Dual Perma-Cool Electric Fans

-

Yes, think he said something in the 260 range. I will definitely ask which pads he recommends once he's done with the grind, thanks Brad. I'm assuming something close would be the stock .160 pads, plus the amount of material removed from the base circle should put me in the ballpark? And then I'll need to check wipe patterns when installing to be sure. Great, now I need to learn how to check wipe patterns! LOL. See, told you I was green when it comes to cam selection and all that's involved. It's like a black art to get it all right! Appreciate the time and info.

-

Thanks. I spoke with Ken @ Delta earlier and I'll be sending him the P90A cam for a regrind and a slight mod (stage 1?).

-

Thanks AZ. I think I'm leaning toward sending this P90A cam to Delta for a regrind for now. Don't really want to do any head work at this time, that might be the winter project once we pull the motor to get body work done. Anyone have a suggestion on what specs I should give for the regrind considering the mods I've posted above? Sorry, I'm real green when it comes to this as I've never done it before and I know a bunch on here have. Again, not looking to go crazy, mainly streetable with occasional blasts when needed Jersey

-

Thanks for the reply Brad. Are you saying it wouldn't be beneficial going with an aftermarket cam from like Isky or Schneider with this build?

-

Morning HybridZ'rs. Just received our (working on cousins '78 w/'83 turbo motor) Godzilla Megasquirt order and while doing some motor checks and cleaning up before starting the install, I noticed the compression on cylinder #4 was a little out of range compared to the others. It was at 150psi compared to 167-172 for the rest. Pulled the valve cover and noticed the #4 intake cam lobe is scored pretty bad and the rocker has a larger groove compared to all the rest. So... time for a new cam, rockers, pads, springs and possibly lifters. Haven't determined exactly what happened but it's been sitting for a while over the past few years with occasional starts so my best guess right now is/was an oiling issue. I really didn't want to modify anything else at the same time while installing the MS but now I've got no choice. I'll list the specs below of the current setup and of the MS specs I'll be installing. If anyone could recommend a cam/spring/rocker combo that would work well for what we have, that would be much appreciated. Not looking to go wild as it needs to be streetable but I do know from all I've read that the stock cam runs out of breath around 5500 and with the mods we've done on his car, a little more lift/duration should definitely help. Really appreciate the advice in advance. Current setup: 1978 280Z ’83 L28ET Turbo motor/Stock ECU F54 block, P90A Head (hydraulic lifters), N42 Intake ported to match P90A head 1-2mm (?) Metal head gasket (I'm thinking 1mm since compression #'s on the high end) JE Forged Pistons T3/T4, 50trim E wheel, .63 Stage III clipped 370cc Ford SVO Fuel Injectors 60mm 240sx Throttle Body Walbro 255LPH Fuel Pump SS 3/8” Fuel Supply Line Custom Aluminum Fuel Rail Modded stock Fuel Pressure Regulator NPR Intercooler MSD Blaster Ignition Coil Manual Boost Controller Greddy BOV Custom DP w/3” Exhaust Dual Electric Fans (Yes, we've been rigging the setup with the stock ECU for far too long, why it was time to go MS!) Installing from Godzilla: MS2 v3.57 kit with a base tune from the specs we gave them above Wideband O2 Retaining Single coil (for now) Pallnet Fuel Rail Bosch EV6 440cc Injectors Aeromotive FPR Electronic Boost Control Think that's about everything. If any additional info is needed, please let me know. Thanks - Jersey

-

Thanks again G-Tech. Worked out good. Front 16x7 +4, 225/50/16 & 16x8 +4, 245/50/16. No spacers or longer studs needed. May eventually space the front out about 1/4" just to get it a little closer to the inner fender lip but IMHO, it needs to be lowered a little first, then we'll go from there. He's real happy with the look.

-

Thanks much for the quick reply G-Tech. No, power isn't anywhere close to your Z, which is very very nice BTW. If I have to stick an 1/8" or so spacer up front to get the space needed between the tire/strut, so be it. For the rear, +4 will bring the wheel in a little more but running a 245 (10mm more than you) should put the outside edge of the tire just about where yours is at. No (stock) strut/spring rubbing issues you see running +4 with a 245 in the rear? Hopefully I've got these calculations right, just hate to have him spend $ on a setup I incorrectly suggest. Again, thanks.

-

Hi all. Sorry for another question on this already beat down subject but, I'm trying to help my Bro-in-law with a new set of wheels/tires on his '83ZX NA. I've set up a bunch of S30's in my life but I know visually and from reading through 1000 different posts that the S130's wheel/tire specs are a bit different. Stock suspension, slightly lowered. He wants to run a 16" wheel, not have to roll his fenders and have the tire close to inside lips without rubbing. He likes the look of the RB-R's so here's what I'm thinking... Front: 16x7 +4 offset running 225/50/16's Rear: 16x8 +4 offset running 245/50/16's If I'm understanding correctly from what I've read, the fronts should fit without issue and should fill out the wheel well nice and a 235 would be too wide without rubbing or addition mods. The rears with 16x8 +4 w/245's may need a thin spacer to get the wheel away from the perch and out more toward the inner fender lip. I've tried to get him to go with the staggered 17's but he wants 16's so, that's out of the question. Any help is appreciated. I'm just trying to get him set up right so i can move on and start working on my '73 again!!! lol. Thanks.

-

Hey all from NJ. I'll be building a rotisserie in the near future for my '73 240 and just was hoping i could get a couple of questions answered from those who have done it. I've read and accumulated pages of info on building one but want to be clear on these items before i start welding. My Z is a '73 240 with the entire drive train, front & rear suspension, tank, doors, hatch and interior removed. Front glass and dash will remain. I'll be using 2 engine stands that will bolt to the front and rear bumper mounting locations. I'm sure this is slightly different for all setups but best guess from experience - Is 4" above both the front and rear bumper mounts about right for the center of the pivot point? I'll be connecting the 2 engine stands together for stability. Will 40" from the ground up to the center of the pivot point be enough to allow the Z to rotate 360 degrees without hitting this connection between the 2 stands? Thanks, Jersey

-

Rust on drivers side is/was pretty bad. I've already replaced the passenger side floor and support rail with Zedds pieces, halfway up the firewall, under the battery box & both front frame rails already. Right now, the drivers side floor, outer rocker and dogleg are cut out. I've even got the new tabco outer rocker and dogleg to replace but the lower half of the inner rocker is wasted, and knowing how much the rocker is considered structural, i'm just hesitant in tackling. May just come down to sucking it up and doing it. Thanks for the eyeballs out there in Idaho but i'm thinking the shipping cost from that far west would put me over what i'd like to spend. Thanks for the replies.

-

Hey all. I'm looking for an S30 shell with minimal rust. Unfortunately, my 240's just about unrecoverable and thinking a full swap to a cleaner chassis may be my best bet. Feel free to send me a private message with what you have and what you want. Thanks in advance, Jersey

-

Thanks. I did see his posts a while back and may contact him if nothing pans out here. Appreciate the heads up. - Jersey

-

Looking for the DS inner rocker, front to rear. I know, long shot but thought i'd ask. Any donor cars around here in NJ? Thanks in advance, Jersey