-

Posts

35 -

Joined

-

Last visited

-

Days Won

2

Content Type

Profiles

Forums

Blogs

Events

Gallery

Downloads

Store

Everything posted by KidandhisCar

-

Im using the original cam for this build,still trying to find out if thw .030 shims under the tower will effect anything negatively.i've seen posts where people have shimmed it up and ran without issue,and i've seen some stating thicker pads,or longer valves are an absolute must

-

Seating 14mm O-rings into oem manifold

KidandhisCar replied to KidandhisCar's topic in Fuel Delivery

It seems like the 14mm lower ring will fit circumfrence wise, but the bores do not seem deep enough to get them all the way in to where to rings seat on the untapered part of the bore.i have a feeling that is because the factory injectors seal from to to bottom,so the bore was never originally intended to be deep enough to have an o ring seal on the wall of the bore -

My injectors cam in yesterday.ls1 units with 14mm upper and lower o-rings.How are you guys sealing the pintle end of the injectors to the manifold? I tried with the pintle cap removed,but there is not enough depth in the bore for the o-ring to seat,i haven't been able to find any information on this,is it standard practice to have the bore deepend?

-

When shimming the cam,am i going to have to get thicker lash pads? I imagine not,but i dont know if the now higher cam,in relation to the valve stems will give me any problems?

-

Just checked around,msa has 30 thou shims,ill tell my machineist to take 15 thou off the block,and everything will sit pretty. Thanks much for the info,i knew i was missing something

-

Sorry,what i meant was total shaving combined,block plus head before i have to worry about using a thicker head gasket. The head has been milled down .015,if the block gets milled .015 for a total of .030 total material loss,will that be a large enough inscrease in compression to warrant a thicker head gasket? Assuming in trying to keep stock compreasion ratio? Engine is bone stock l28et out of an 82

-

Side topic,whats maximum overall mill i can have on ap90 head and f54 block,before worrying abour compression being increased,and need ing a thicker head gasket? My machone shop had to take 15 thousands off of the head to get it flat,and the block will be getting done tomorrow. Thanks in advance.

-

Thanks for the input,i am just going to hold off until i can afford a proper turbo.evem if it means the engine will have to sit a bit on the stand

-

I have another question , i was recently given a turbo off of a 3.9l perkins at work,the engine and turbo have less than 50hrs on it,and were on a stand used for classes for apprentices.they decided to junk the engine to clear up space,so i nabbed the turbo. Anyway the turbo is a garret air research ta3107. No waste gate,it is identical to the stock turbo,uses the same oil lines,only there is no waste gate,and the compressor wheel is about 10mm smaller.(measured with a mic) The stockers cartidge is junk,tipping the turbo over results in oil leaks out of the intake and exhaust,and has enough vertical shaft play to let either wheel touch their housings. Can i use the perkins unit for my build? If people are maxing out flow on the stockers,in my minds eye i think i would be alright without the waste gate. I doubt this would flow anymore than the stocker,but my main want to use this is it was free,and i recently bought another car to give me more time on the z,as the z was my dd,wich ruined the money i had saved for the turbo. Ive read that people say running without a waste gate will cause excessive boost,and overspeed the turbo during spool? During spool the wastegate should be closed to send all gases throufh the turbine,and then open once desired boost is reached. So if my turbo maxes out of flow before max rpm i should be ok correct? Please advise,and thank you

-

I want to keep this build under 300hp,as this is my DD,and I just dont have the money,to go through the transmission,upgrade the differential,or the Cv's. The absolute main reason I want MS3Pro is for the sequential injection,and spark. As far as I can tell,MS3 and lower,offer only wasted spark setups, wether batch fired or group fired. For some reason,I just can't wrap my head around a plug lighting off at the wrong point in it's cycle.It just bother the hell out of me haha. Plus I feel like that could somehow increase my chances of a detonation related kill..

-

Full specs here,more than i'll probably ever need, but i'd rather have it and not need it, then need it and not have it. http://www.ms3pro.com/ms3-pro.html

-

There's a few, Smaller more compact size over the MS3,also the full sequential fuel control,and ignition drivers,(im planning on individual Coil packs,one per cylinder.) MS3 has these features only with the msx board installed. It also has a bunch of outputs, for fuel pump control,Fan control, and Iac control. And the price difference isn't excessive.

-

Exactly the information I'm looking for thank you. I've heard the stocker runs out of breath right around 12psi just like you said. When you say you lost the lower end,i'm assuming detonation had a hand in it? There's alot of other stuff for the build thati didnt list, one of wich is a wideband Air fuel monitor.

-

Hi gents, I''ve been getting everything in order for my L28 build. Notes for the build: F54 block,and P90 head (Engine comes from a running parts car) Lower end,and top end will be stock minus the camshaft. Lower end,and top end,will be refreshed during the build (new bearings, rings Etc) Going to an aftermarket fuel rail,and Individual coil packs. Higher flow injectors,and MS3 Pro for fuel and ignition delivery. I'm looking to make between 200-250WHP. There are a bunch of very informational threads on turbo selections for 400hp+ builds. but I haven't been able to find much information on a turbo sizing for a build in the lower hp range. I'm only looking to make around 20psi maximum,shooting for around 15psi for normal driving. I havent had much luck finding a turbo just a little larger than stock that will suit my needs. would anyone have any experience in this department? I know i'm looking at a t3/t4, but in what trim? I appreciate the input.

-

Well,today i found the cause of my woes(presumably). Inspected and re-loaded the wheel bearing,Nothing looked out of normal.When I went to pick up my wheel with the new tire installed. The gentleman there told me there was a small finishing nail in my tire,wich i was unaware of. I mounted the new wheel/tire onto the hub and checked my clearance. Had about 1/8 gap,maybe slightly less, much more then when checking the day before,Even though I had massaged the lower spring perch a little. Anywho, I suspect that the tire may have been low enough on air due to the slow leak of the nail to cause the tire to "sag" ,and let the side wall balloon out just far enough to touch. I went today and bought two 1/4in wheel spaces and mounted them both on the fronts,to ensure this wont bite me again. I much appreciate the input gents!

-

Bearing slop was measured by hand with the wheel on the car,and and with the wheel off,shaking it in all directions,and not with a dial indicator or anything of that nature. Tomorrow before I remount the wheel,I will re-preload the bearing,and double check my work in there. The kit Includes, 2 rotors off a ford GT500 redrilled to match the front 280zx hubs,(car is an 82',it's in the original post) 1992 toyota 4 runner 4 pot calipers. Custom mounting brackets for the calipers,Spacers that go between the outside rotor face,and inside inside hub face,to align the rotors center to the caliper,Stainless front lines,and new hardware all around,and ceramic pads. I'm not keen on adding another wheel spacer,even if its a thin one, as the car already has spacers to get my 17in enkies to fit,also I don't know how having one wheel,(even though minutely) farther out from the hub on one side would affect steering.(I'm thinking it could affect the ackerman),but not positive. Also I fixed the link to the silvermine kit. I much appreciate your input

-

Hi all, Last weekend I installed the silvermine front brake upgrade on my 1982 280zx NA this one, http://www.silverminemotors.com/nissan/nissan-280zx/brake-kits-nissan-280zx/stage-4-front-brake-upgrade-kit Anywho,quality of the kit is flawless,everything mounted perfectly,and car stops beautifully, Today however i removed my front wheels,to double check tightness,and fitment of everything. Came to find my front right tire is rubbing on the shock now,sidewall is just barely touching,and where the tread starts at the edge of the tire,was severely rubbing,on the lower spring perch. FWIW suspension is completely stock to my knowledge. Wheel bearings where not replaced during the brake kit install. but were cleaned thoroughly(along with the spindles)and bearings repacked,and as it sits now the bearings have no slop in them.I did notice the ball joint on the passenger side has a little bit of slop when the suspension is unloaded. Crudely since this is my dd,I took a hammer to the lower spring perch,to remedy the issue..for now.. Suspension will be replace,after i get my engine build done and engine in. Added some pics to help with any ideas, In the overall picture i added red sqaures to indicate where the tire was rubbing. and also added a picture of the front left with the suspension load to show the clearance on that side (roughly 3/8 of an inch), while the passenger side has none. Any input is greatly appreciated since this is my dd. Thanks in advance.

-

Here's what im doing with the center caps, Modifying them to sit in the center caps for my enkei 18's Left is the stock enkei centercap,Center is with the Z one epoxied in,and the right one is sanded and primered ready for the paint shop.

-

I pm'd you borini,and the car was driven here from AZ after the guy got a divorce,he was starting a new life in florida,and had it on the local craigslist.It's a beater,needs paint. but is 99% rust free.

-

My savior!, Will get in touch with you tomorrow,and send My info,and the money, Funny thing, I noticed you're in arizona, the 82 that these are going on,is an arizona titled car.What are the odds? (im in florida btw haha)

-

Difference Between L28E Auto and manual Crankshafts??

KidandhisCar replied to KidandhisCar's topic in Nissan L6 Forum

Meant to reply to this, a long time back, a light tap on the edge with a deadblow and it came right off, Engine has been in the car since april,and is running like a top, Thank you all for the replies -

Looking for 2 280zx Center caps,Willing to pay 50$ plus shipping for some that are in good condition. Looking for the style in the picture below,thanks for your time. Edit: They dont have to be super shiny (like in the pic), they will be stripped and repainted before installation, just don't want any that have deep gouges or scratches in them.

-

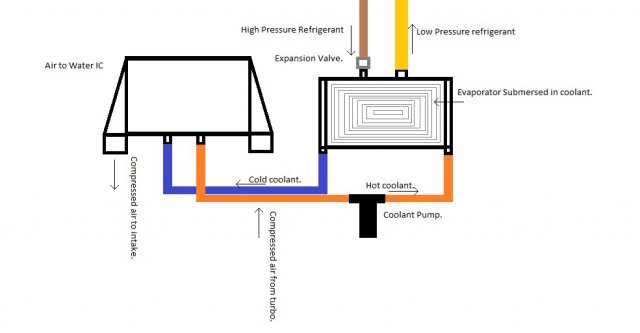

Evening gents, I have been thinking of this for quite some time. The system is based off of three main parts,an air to water IC,an evaporator inclosed in an aluminum tank, and your typical R134 AC system. The idea is as follows, Coolant circulates between the outside of the evaporator, to the water side of the IC,and back to the evaporator tank. and the evaporator is cooled by your typical AC system. A couple of key points,if this ever comes to fruition, the evaporator tank would be added on to the side of the IC,wich would further more promote cooling and lessen the amount of fluid in the system. The way I'm thinking is that with less coolant in the system, it will take less time to cool, (also less to heat up as well though). I've seen multiple threads throughout the web that have had ideas with the evaporator being mounted inside of the inlet airstream, but the ruling has been that the air isn't dense enough to be cooled quickly off of the evaporator at high cfm rates I know there are some brilliant minds here on hz, and was curious on input and if this would be a plausible way to bring intake temps down,or if the constant drag by the compressor would negate any net gains? Picture attached below for a visual.(MS paint warning). Thanks much.

-

Difference Between L28E Auto and manual Crankshafts??

KidandhisCar posted a topic in Nissan L6 Forum

]Hi gents,first time poster long time lurker. Long story short two weeks back I had the engine in my 82 280zx sling a rod, (stock l28E AFAIK). Found a local guy with a L28E pulled to be replaced with a V8, engine is in good running condition. so I bought it. Now here is my problem.. My car is a 5 speed, and the replacement engine came out of an auto, When attempting to mount to the flywheel from my engine onto the replacement engine i noticed that the fly wheel sticks out about 1/4 farther from the rear engine plate,then it did on my engine. I also noticed that the tail end of the crankshafts are different. the one on my original engine has a shoulder that the flywheel sits on. The one on the replacement engine does not. I can still bolt the flywheel to the end of the replacement engine is just sits about 1/4inch farther from the rear engine plate,than it did on my engine. Both are F54 Blocks,and P79 Heads, All stock. Please Advise. Old Engine Crank Old Engine w/flywheel mounted Replacement Engine Crank Replacement Engine W/Flywheel Mounted