-

Posts

35 -

Joined

-

Last visited

-

Days Won

2

Content Type

Profiles

Forums

Blogs

Events

Gallery

Downloads

Store

Everything posted by KidandhisCar

-

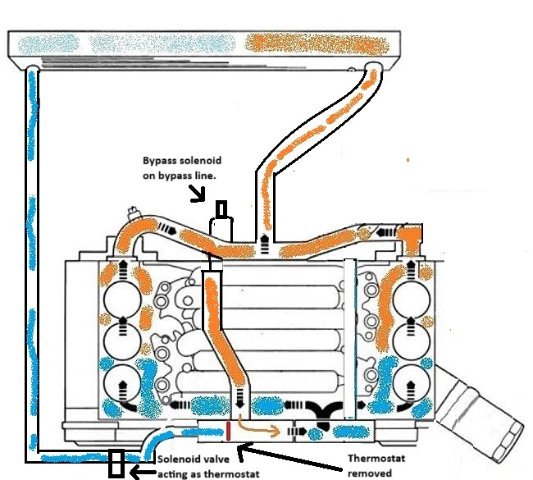

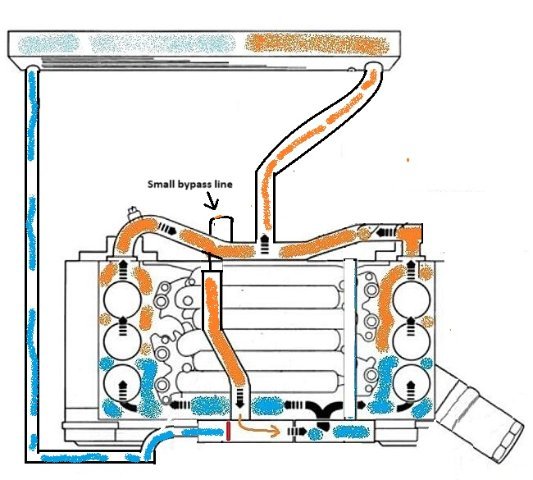

The orange pipes on the back of the head are metal, as well as the two that go under the intake to the front of the engine. I would cut/ weld as needed. As for where the original bypass is I don't know, I have the engine in a dirt buggy and don't have the car it came out of. I'm now considering removing the thermostat, and putting a solenoid valve on the hose that goes to the water pump inlet, and another one on the bypass line and using Megasquirt which is already running the engine, to control the solenoids via PWM based on coolant temp. So that the higher my coolant temp gets, the more it would close the bypass solenoid, and the more it would open the water pump inlet solenoid. This way it can actually regulate temperature, and not just be a hard on/off system. But now as I'm typing this I'm asking myself if there would be any benefit? I guess to maybe have true full flow through the radiator when needed?

-

The orange pipes on the back of the head are metal, as well as the two that go under the intake to the front of the engine. I would cut/ weld as needed. As for where the original bypass is I don't know, I have the engine in a dirt buggy and don't have the car it came out of. I'm now considering removing the thermostat, and putting a solenoid valve on the hose that goes to the water pump inlet, and another one on the bypass line and using Megasquirt which is already running the engine, to control the solenoids via PWM based on coolant temp. So that the higher my coolant temp gets, the more it would close the bypass solenoid, and the more it would open the water pump inlet solenoid. This way it can actually regulate temperature, and not just be a hard on/off system. But now as I'm typing this I'm asking myself if there would be any benefit? I guess to maybe have true full flow through the radiator when needed?

-

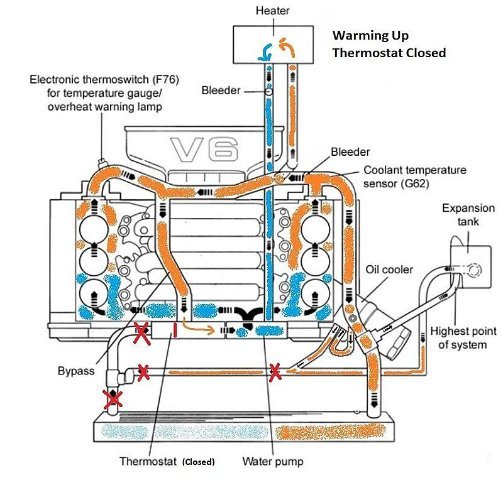

Hi guys it's been a while since over been on HZ, I'm working on a VW ATQ engine in a rail buggy. (its the engine in the early 2000s Passats V6) I'm here because some of the smartest people I've ran into are here on this forum, and I'm hoping someone can chime in and let me know if they think my proposed cooling setup will be ok. Radiator is rear mounted behind the engine, Oil cooler is getting ditched. It's pretty common knowledge amongst the VW guys they're about useless the way the are plumbed from the factory. I've attached two pictures, one is of the original cooling system, and the second is of my proposed one. Catch can isn't pictured but it feed off the radiator neck. Thank you.

-

Bump,still hunting

-

Looking for a turbo backing plate off an 81 through 85 turbo. The backing plate is the aluminum plate behind the compressor wheel with the 4 10mm head bolts in it. Need it for a draw through setup on a non z vehicle. Needed becuase it is a carbon seal backing plate,and will directly fit onto my garrett TA3107, (wich is a dynamic seal). Will also just buy an entire junk turbo, dont care if its trash bent fins etc, as long as the backing plate is in one peice, thanks guys!!

-

Hey guys, odd request... Im looking for a z or zx shell,anything between 70-83 would work. Looking for a bare shell if possible,can be rusty heavy,can have dents etc. My goal is to used the body as a temporary mold so i can build a fiberglass shell to fit onto my rail buggy.odd? Yea i know. Thought it would be kinda neat to pay homage to the vehicles that got me into cars 15 years ago haha. Thanks for your time.

-

Put it all on craigslist today for 300$ If there are any local hybridz-ers that are intrested ill them all go for 200$ Thanks for the kind words!!

-

A new way to bleed brakes?

KidandhisCar replied to KidandhisCar's topic in Brakes, Wheels, Suspension and Chassis

Thats the same way i came about using the rc pump,4 new calipers,new mc and hardlines/stainless line. It was kicking my ass when I first did it,so i used the rc pump and started at rear right and pump fluidnin through the calipers until no more bubbles came out the master,pedal was PERFECT. I was just thinking for easy of simplicity,plug the line onto the caliper check valve,run the pump until no more bubbles in the mc,move onto the next caliper.could make for some quick fluid flushes,and bleeds. -

Hi all, ive got toyota 4 pistons up front, yesterday i went to take the z out (81) After its been sitting for a few months,i quickly found my brake pedal went to the floor, upon backing the car up i found a wet spot in my dirt driveway coming from bleow the battery area,i was unable to find any wet lines or connections but im sure a leak is present,as the mc was empty. I tried filling the mc and pumping the brakes to find the leak but was unsuccesful,so im going to have to bleed the system find the leak,repair it,then bleed again. This got me thinking,the way i normally bleed my brakes is to use an rc plane fuel pump and pump the brake fluid in through each caliper with a pan under the mc,until no more air comes up out of the mc. Has anyone ever install check valves into the calipers where the bleeder niples wouldn go? So fluid could onlyngo into the calipers and not out when doing this? Ive already sourced some m10 x 1.0 check valves just curios what anyones thought are on this beforeni go through with it. And i dont mean "speeder bleeders",those only let fluid out of the caliperand prevent air from going back in,im looking for the opposite effect, fluid into the caliper but not back out,any thoughts?

-

Ive got a stock pile of junk,cams of all sorts,tons of gears that will be in my next table, a junk 302 marine block. Ive found that if you call local tranny shops and ask them if they have any old gear they want to offloaf theyll often let them go for free!!

-

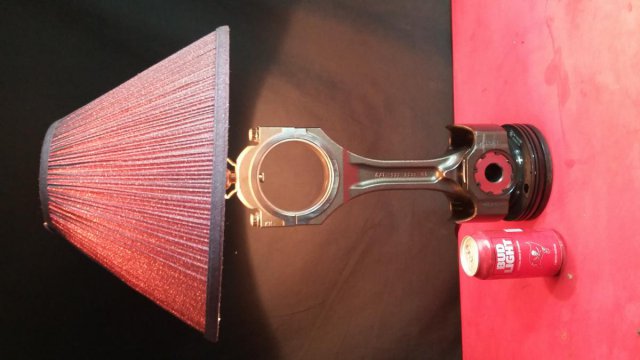

Finished this table today,pistons and rods are from a 302,the flywheel and stator at the top is from a 25hp kohler,the crank is from a l28 (badly spun bearing,had machine shop roll the journals down,and roll the snout down to fit it in kohler flywheel) Bottom flywheel is from a l28 n/a, and the very bottom part is a drive sprocket from a skidsteer. Also added pull chain sockets to the lamps,with little spark plugs. Just put the whole lot up for sale,here's to hoping they sell.

-

It doesnt change how far the valve opens, just how long it stays open. Its pretty neat,its only on the ohc engines,as on a pushrod engine the pushrod would fall out. Also,i said the actuator pawl pushes on the bridge,that was a typo,it pushes on a flat spot on top of the rocker,wich pushes on the bridge. You'll probably ask, what happens to the roller on the back of the rocker when it slams back onto the cam when the actuator lets off,well....thats probably why roller failure is pretty common on those engines haha. Edit: here's a pic of it

-

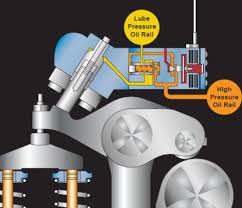

On alot of the midsize Cat truck engines,3406,3456 etc,they had single cam vvt. They worked by having a a "rack" over each set over cylinders(straight 6). The rack was fed with with engine oil,that when actuated by a solenoid in the rack,would push down a little pawl on the bridge for the intakr valves on that cylinder.Cat calls it VVA,variable valve actuation.

-

Ive got 2 of those lamps made now,and 8 more piston/rod combos.they came out a a 27 liter Cat engine. Ive got a table in the works using a l28na crank as the main upright I'll post pictures once its done. Thank you for the kind words man

-

-

Injector bung location on custom manifold

KidandhisCar replied to KidandhisCar's topic in Fuel Delivery

Josh,im an idiot,and dont know why didnt think of that. I was too caught up in the idea of cutting the bungs to a wedge shape at the end,and tring to figure out the correct geometry to place them where the flange and runner meet. Your idea is excellent and that is what ill go with, welding the bungs on then cutting to mate mate to flange.ordering flange plate tomorrow so i can get to work,thanks much. -

Injector bung location on custom manifold

KidandhisCar replied to KidandhisCar's topic in Fuel Delivery

As far as i can tell i cant place the bungs directly on the flat bar flange bc they with interesect to much with the runners if im trying to maintain factory injector location (where the pintle points into the notch at the top of the intake port on the head.) I will be using ms3pro when the time comes. The bar would be milled down to match the exhaust where the bolts that a hold down both intake and exhaust sit. The only reason reason for wanting to put the bungs on the runners is simplicity,and cost. A 1 inch think bar 2 ft long is 52$ average,while a half inch bar 2 ft long is 20$,both not including shipping. And the 1inch bar with have more machineing costs to put the angles face on it,and have the injector seats cut. -

Injector bung location on custom manifold

KidandhisCar replied to KidandhisCar's topic in Fuel Delivery

The only thing i can think that would need to be different is when the injecotrs fire in relation to when the intake valve opens. They would have to "fire" earlier,to make up for the time it takes the fuel to travel the longer distance to the intake valve correct? -

Hoping to soon be building an intake manifold.(l28 P90 head) My question is how detrimental is it that the injector bungs Be made into the flange? If i can get away with using 1/2 plate as the flange and just placing the bungs on the runners as close to the flange as possible, will this severely affect performance? If needed ill buy 1in aluminum bar,and have the edge milled down so that the injectors will we still sit right over the intake valves. Thanks guys

-

Im gunna say it,your car sounds great! Where abouts are you shifting?

-

Anyone ever thought of making and exhaust manifold adapter to adapt from and L series head to something along the lines of and RB,or similar i6 engine exhaust manfifold? Space issues aside does anyone think it could be done? 3/8in plate on the L head with very short pipes to another 3/8in plate that a non L series manifold could bolt to? It could make sourcing equal length tube manifolds easy.And with the availability of divided scroll manifolds for the RB series could open up alot of options.

-

CONFIRMED L28 with RB25 Flywheel and 350Z Clutch

KidandhisCar replied to 83turbo280zx's topic in Nissan L6 Forum

Was the t5 bell clearance ever checked?Nearing time for me to order a flywheel and clutch,and I've got a t5. Thanks -

Not sure if there are any distributors for them,best bet may be to make a cardboard template using the factory manifold as a guide,then take it to a machine shop and have tu2e cut it of whatever material you want,at whatever thickness for your application.

-

I've got my heart set on the 3X,and it's staying that way.still haven't gotten the rockers in,but the head and timing set is on.here's a pic from the other night,still much to do

-

Awesome,just got the pistons in the block tonight,and all but one valve back in the head,somehow even though everything was stored individually in labeled ziplock bags,im missing the outer spring seat for #2 intake.not that big of a setback as i have a spare head in storage i can steal from.once the head is on i'll report back.thank you much