Dat73z

Members-

Posts

851 -

Joined

-

Last visited

-

Days Won

8

Content Type

Profiles

Forums

Blogs

Events

Gallery

Downloads

Store

Everything posted by Dat73z

-

Had a couple mins tonight and started mounting a new oil spray bar I had for a long time. My old one was held together by silicone. Surprised the valvetrain looks so great- that Walmart special Rotella T6 puts in work.

-

A question for the community: I believe the turbo studs are M10 x 1.5 and some rough measurements show the studs will need to be ~50-55mm long due to the 1/2" thick stainless flange I'm using to clearance the T40E/T3 from the exhaust manifold. Is anyone aware of a vendor/supplier that sells these studs in Inconel?

-

2nd Weekend Update: Had some time this morning before the wife and I do our Sunday thing. Pulled the gas tank out from storage and started cleaning/buttoning everything up. I feel bad that this thing has been covered in dust for so long. I'm going to set up the fittings for 6AN feed and 8AN return. It is a MONZTER copy gas tank so service plate up top, ATL blackbox with the Walbro 255 inside, modified OEM fuel level sender. Once the tank is bolted up I'll pull the trans and delete the old fuel lines and that one evap line which runs to the driver's side frame rail. I need to measure out how much stainless line to order. I am going to assume bending 6AN and 8AN stainless will be a bear, but it needs to get done. Huge shout out to Ivan @ Vintage Spirit Garage over in Albany (no affiliation). I don't have the means in my garage to fab this up so I called around a bunch of local race / custom fab shops in the bay area and nobody wanted to take on this project. I just dropped off the parts and the work was done to a high standard and in a timely fashion. You can check out their Instagram page here: https://www.instagram.com/vintagespiritgarage/?hl=en

-

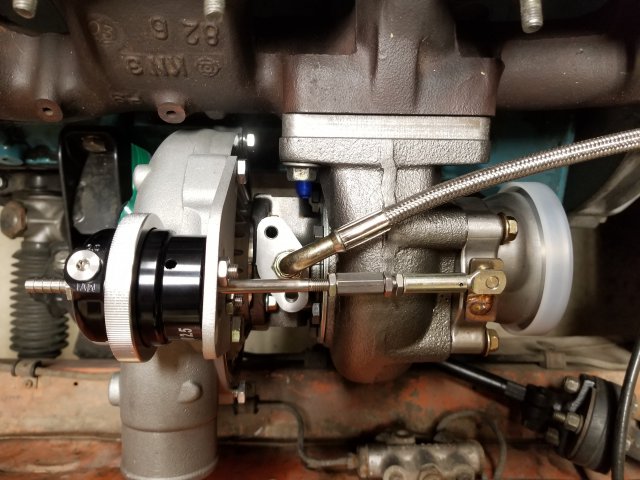

Weekend update: Test fit the wastegate actuator. It's a Tial MVI 2.5 unit with a 10lb spring. Tight fit and I'll need to fine tune the angle a bit more, but it looks it it will work.

-

Thank you. Your airbox looks great! Really original use of a spare valve cover 😉. Yeah the shorty manifold is a bear to install and the studs must be the perfect length. I've had to pull and install it a couple times now to get everything to fit so I'm getting pretty good at it. Good call on the heat shield material. I have been thinking this over and I'm partly considering just sending all of the hot side components to ATP for their inconel treatment. The HKS carb mounting is rather curious. The holes do not line up with 44s. My friend also just picked up a set of Mikuni 40 type 4's I'll try in a couple of days, but I was under the impression the casting between the 40 and the 44 were the same. Maybe the Type 1 Surge Tanks and SK units have it better. The motor is the #'s matching block which has been bored out and fitted with low compression pistons. I have no idea what it is, but the previous owner ran it on drawthrough turbo in the 80's and it was supposedly fast. The kit was in the trunk when I bought the car and the RAYJAY turbo was about the size of my head if that's any indication. Much longer term once I'm done lighting money on fire here I have a L28 block sonic tested good for a massive overbore in my garage along with a knife edged stroker crank from my friend Eric. Eric, if you're reading this I lost your contact- thanks again man and come over to hang out sometime.

-

Pre weekend update: Did a test fit of the linkage assembly. It is apparent that I will need to use shorter turnbuckle? arms, but overall everything works well and operation is smooth. Just used some stuff I had around in the parts bin and some I imported from Japan and a McMaster-Carr hardened stainless 10mm rod to complete the setup. The Japanese setups are interesting in that the linkage rods I've dealt with so far for Z setups at least (Kameari, OER/SK, Mikuni) are all 10mm (~3/8 being the largest "typical" US size for the couple of manifolds I've worked on). Most US items are this smaller diameter or even smaller which makes finding Japanese components stateside difficult. In the earlier pictures you can see I ended up pressing in and reaming out some 10mm oilite bushings for the linkage rod rather than running the teflon bushings. Also test fit the sandwich plate for the oil cooler. Either way, still just typical triple setup/parts so far so nothing crazy just yet which is good. I'll start fabricating the bracketry for the throttle cable setup which is already installed from my last triple setup this weekend. I'm going to attempt to streamline it all and run the shortest non-binding cable setup I can. Wastegate and more components comes in tomorrow and AN fittings/hose for coolant and fuel next week. Just a long wait now for parts to slowly trickle in.

-

Some quick project updates: The compressor side looks to work the best with the outlet facing about parallel to the ground. This leaves a lot of room for charge piping I hope. Clearances are tight but have enough information on measurements to order a wastegate actuator now and confirmed the measurements with a distributor so now another couple day wait for more components to come in. Although I enjoy the process, I wish I had a warehouse of everything so I could just test fit parts instead of measuring every detail and piecing together/fabricating everything to fit. The build goes on... Edit: Specific to the triple blowthrough setup on the HKS Version 2 Surge tank- you can see why I had to drill out the carburetors in these pictures with the hardware removed. I've checked a couple of carbs (Weber DCOE 40, Mukini 44 PHH Type 4, OER 47- the current carbs) and none of them have the appropriate spacing for the HKS Version 2 surge tank. So you need to drill out the front and rear mounting points to make everything fit. I've personally seen another set of Mikuni 44PHH drilled out for this setup as well with most of the drilling done at the inlet where the trumpets used to be. I tried to balance the drilling between the front and rear to leave enough material on both ends to seal appropriately.

-

Thanks for the tip! Didn't consider this but it makes sense will give it a try. Thank you. I had considered the possibility of crossfire when I was selecting the wires but not sure if I've experienced it yet. I daily drove the car for the past 2 years with no issues but it was only with triple sidedraft carbs. I suppose I could always build another set of wires over the valvecover as I still have the tools from the last couple of sets I put together including the one on the car currently. The coil is actually a MSD 8222 solid state unit. I had the red oil filled blaster type coil which I gave to my friend a couple of years ago I think the specs were fairly similar but I'll take a look again tonight and the part numbers you referenced. The ignition system is the 123 Ignition BT distributor running off a MSD 6AL Digital and the MSD 8222. I've never had any issues with this setup over the last couple of years but haven't run it yet with forced induction.

-

Also if anyone has any pictures of how they did their intake I would like to see (and it would be much appreciated!). I want to install AC with this setup and it looks like it will be tight if I mount the compressor where the old air pump used to be. Either way I'll need to fabricate a bunch of heat shields for heat management. Fortunately I have a bunch of 0.080 AL...hopefully it's not too thick for my wimpy sheet metal brake. Otherwise I'll need to get some thinner AL. The plan is once everything is fabricated and mocked up to pull all of the hot components off and have them swain coated before final assembly.

-

Test fit the turbo, it looks good. The 1/2" stainless flange I drilled out looks to be the perfect spacing. I'll need to do a bunch more fine tuning work with the fitting but at least this is a start. The 3" vband flange from the internal wastegate looks like it will work for the setup with a sharp 90 into a 3" exhaust.

-

Mid week update: Parts have been slowly trickling in. Started to mock up the oil and coolant lines and just received the turbo. It's a ball bearing T3/T40E 50 trim/63 AR so not much size difference from the factory T3 but it should meet my power goals easily. I'll use the factory T3 to figure out the relative orientation and true up the clocking on the car. So far so good.

-

The bottom hal The bottom casting amazingly is actually perfect with no pitting. How much are you asking? Feel free to send me a PM. Thank you!

-

Looking for a 3 bolt thermostat housing cover in good condition. Mine looks pretty corroded and chipping away where the upper radiator hose connects so looking for one which is solid throughout. Thank you. Edit: Added picture of what I'm looking for circled in red. I believe this is a thermostat housing from a 280zx turbo but I'm not sure if that matters (or if all of the 3 bolt covers are the same).

-

Going with a new turbo sounds like the right move for the price. You'll need to figure out your wastegate situation, but there are options.

-

Hello fellow HybridZ members, Over the years this community has been great and provided tons of info on my rebuild, build, and build again. For context: my initial rebuild was to recondition the entire car mechanically (all new suspension, driveline, powdercoat everything, etc.) and fix all of the rust on the car to make a reliable and fun daily driver which has been a smashing success this past 2/3 years. Afterwards, the first build was pretty basic and focused on improving the driving experience- triple carbs, header, exhaust, some interior, etc. In searching around I haven't found a ton of info online for triple blowthrough setups for the L-series and so far as I know there are only a couple of cars here in the Bay Area which are running this setup currently. I've been collecting the components and slowly tackling the projects associated with this sort of build over the years but am finally at the point where I have most of the pieces in place to make this a relatively straightforward project. I've decided to chronicle this process to keep me on track and hopefully provide info for those curious about this setup in the future. A couple of weekends ago my buddy who is a fellow s30z fanatic drove my car for half a day and liked my last setup so much he bought my triples, manifold, exhaust, header, fuel system, etc. We pulled everything off the next morning and so the 2nd build began. Here is the short list of what's been done so far: Drill carburetors to mount to surge tank and manifold Mount manifold to head ATL black box installed into OEM fuel tank with -6AN feed -8AN return 123 Ignition BT Here's (a long list) of what needs to be done: Set up linkages/throttle cable Run new -6AN and -8AN fuel lines and fuel system Mount electric fans and install fan controller ARP head studs, new headgasket (it has become apparent this past year that my headgasket is leaking fluids all over my block) Install turbo and plumb oil / coolant Install charge piping / intercooler Install downpipe, exhaust Install vacuum lines Some tuning

-

The cost of rebuild and upgrade is not insignificant. I believe I was quoted somewhere around $695 before shipping by gpopshop to upgrade the stock 280zx T3 to T3/T04E 50 trim before some other options like ceramic coating, upgraded bearings, etc. but ditched that idea after removing the OEM wastegate housing and finding my turbine side had some significant cracks. You're basically in new turbo territory at that price point.

-

Thanks guys, that makes sense. I don't have experience with either the 50 or 57 trim t3/t4e, just what I've read and looking at the compressor maps. In terms of real world performance how does the spool on the 50 versus 57 compressor on a 63AR turbine compare? If you're looking to retain the internal wastegate this may be viable: https://www.atpturbo.com/mm5/merchant.mvc?Screen=PROD&Product_Code=ATP-WGT-023&Store_Code=tp

-

Reading through this thread is there a reason why the T3/T4E 57 trim is recommended over the 50 trim? I haven't looked at the compressor maps for a while but I was under the impression that the 50 trim compressor is more ideal for the L28?

-

I believe that is the same radiator. Yes, people are willing to cut the shroud, but it's fairly expensive here in the bay area. What I ended up doing was having some 0.080 AL sheared in the correct size. I will cut out the holes for the fans with a jigsaw maybe later this week. Should be a fairly straightforward project.

-

No problem- to be clear, this shroud looks like to would work great with slightly smaller diameter fans and on those 3 core radiators where the cooling fins are flush with the endtanks to direct all of the cooling air into the fans. If you want to run the twin 12 spals it would be better to fab your own shroud. I'm talking to some folks now to get this cut on a waterjet to hopefully get a better finish than I can with tin snips.

-

Thanks, yeah realized that yesterday as well when researching if there was an optimal air gap between the fans and cooling fins for a shroud. I was looking around and it looks like most aftermarket radiators have the cooling fins coming out to almost flush with the endtanks. The Mishimoto which is what I've been running has the cooling fins ~1/4" inset behind the endtanks I think because it's a 2 core so may be able to net another 3/4" clearance there. Going to measure and see this weekend/week or next when I get everything on. Found this pic of a Mishimoto radiator from their site where they welded on a shroud for the s30z radiator.

-

For the curious, here is what twin SPAL 30101522 12" fans look like on a ZCarDepot shroud. The fans are slightly over 1" thick at the edges and taper to slightly over 2" thick at the motor. This matches the drawings from the SPAL website of course. The shroud is a bit undersized for these particular fans and feature a step at the edges. I'm not sure of the functional purpose of the step, but it adds roughly 3/4" to the assembly height or as I'd mentioned before ~1" if I consider the 1/4" step inwards on the Mishimoto radiator. Likely I'll fabricate my own flat AL shroud to better fit the radiator and fans.

-

Another way to look at this is you need fans either way and you already have the intercooler piping kit. You could always get a larger single or the dual 12's and decide after mocking and measuring up if you want to fabricate or purchase a shroud. Best of luck on your install. Edit: Just purchased the 2x Spal 30101522 Puller Fan (12" Medium Profile) ~1300 CFM ~2.5" thick so I guess I'll know in a week or so.

-

240z Turbo- interesting points on charge air density and piping diameters. I had not considered that. If at all possible I'd like to go 2.5" and be done with it but I'm thinking packaging will be the issue. Do you think the 2.25" piping on the hot side would make a noticeable difference in boost/turbo response at these power levels ~300whp? Albatross Cafe- I have yet to mount my electric fans. I have been running a Mishimoto radiator with the mechanical fan/clutch for years which has been working great in my weather and recently picked up the ZCarDepot 12" dual fan shroud. I have yet to purchase my electric fans but I'm looking at running the following SPAL models: Spal 30101522 Puller Fan (12" Medium Profile) ~1300 CFM ~2.5" thick Spal 30100467 Puller Fan (12" Low Profile) ~ 900CFM ~2" thick So far as I can tell I'll need the twin 12" medium profile fans for >2000 CFM to match the factory mechanical fan (or a combination of one medium, 1 low profile). Really the main constraint for me will be running the hot side pipe across the front of the engine with the fan shroud and electric fans. I could probably just mount the fans directly to the radiator and save an inch or so that way but would prefer to run the shroud as it gets over 100*F over here on summer days. Also I've been in contact with Craig @ Simtec (really nice and knowledgeable guy). He'll be fabricating the piping for me but I'll need to get him the measurements of my setup once I have it all mocked up.

.thumb.jpg.17c51a97a0c0b914b94f3a004d2dab6a.jpg)

.thumb.jpg.311d3c8a9611de3f8848261507358d63.jpg)

.thumb.jpg.0b9cd28b7d9c088a47436ef737cdfd53.jpg)

.thumb.jpg.535f3b10f1770a0c899d70a35ecdde04.jpg)