Dat73z

Members-

Posts

756 -

Joined

-

Last visited

-

Days Won

3

Dat73z last won the day on March 18 2023

Dat73z had the most liked content!

Profile Information

-

Location

CA

Recent Profile Visitors

5553 profile views

Dat73z's Achievements

-

Had to take a break for a couple of months and go on a bunch of family trips. A few left to go but long lead-time parts are trickling back in. Had my vintage SK50s fully restored by Kyusha House as the older castings are better suited for the surge tank, they look fantastic. Once I get back in from traveling will see what it'll take to get the custom intake manifold cnc'd.

-

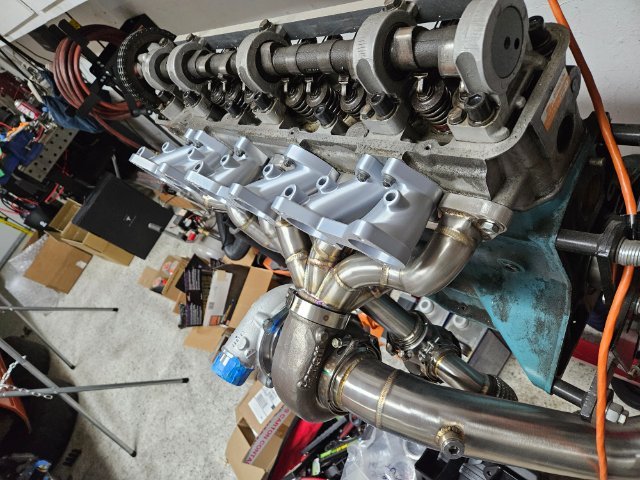

I had a couple of hrs this morning so I stripped out the old turbo setup and started mocking up the new Vband G series and wastegate. There is a lot of fabrication work ahead and it starts with mocking up all the hard parts in the car.

-

Life got busy but I recently started working on the build again. Since the last post I've been cleaning out the garage and figuring out where things are at. All of the new suspension is on and I pulled the midpipe to begin refabrication around the new turbo setup. I also sent the vintage SK 50s out for restoration and started assembling my wheels with the 245s for more traction.

-

It has been a ridiculous month and I had to take a break from the project due to working insane hours and balancing family time, but I'm back at it again. Since the last update I wrapped up the bulk of the suspension and brakes upgrades and started tearing back into the turbo aspects. I need to fully mock up the new manifolds and turbo setups into the car before we continue with the new cnc intake manifold setup so I've started tearing everything back out again. This will also allow me to refabricate my midpipe to downpipe connection.

-

After disassembly it was apparent what had happened. The dust shield lip somehow caught on a couple of areas of the KW powdercoated strut assembly. After some beating with a hammer things looks better. I'll ensure there are no raised edges on the strut assembly or dust shield, throw a coat of paint on everything, and re-reassemble. Hopefully I can get it back together this next week or so, the general mechanical work is easy but time consuming. I'd like to get back into some welding and fab work.

-

This evening I had an hr so I packed and pressed the rear end together with new OE bearings and seals. Unfortunately, one of the stubs was extremely difficult to turn when pressed on. This is a new one on me, apparently the dust shield was binding with the strut assembly. Fortunately I have a couple spare dust shields but I'll try and lightly bend this one out first before pulling all the studs out and starting over.

-

I thought I'd get a break but apparently I'm working again this weekend. Still planning to squeeze some time into the Z between family and other obligations. I've been working with an exceptionally talented designer on the intake manifold. The 2nd print came in so I did some more mockup. I think this weekend the objective will be to get the rear end back together as the parts I painted have cured for a week or so now. It'll be nice to get the car back on the ground or at least on dollys

-

Just a quick update I got the steering coupler re-painted. Looking it over, the ujoint seems ok but maybe I should replace it at some point since everything else is new (it's the later staked type). I'm going to focus on cleaning up my workspace as it would probably be good to let things continue curing out, but I think it's mostly just reassembly from here.

-

Likewise I'm not pushing it 11/10 on the streets in my typical driving but I am considering maybe putting a OE ZG or early 240 rear bar on but we'll see once I get the new setup dialed in. I actually sold 2 former track toys this past few months so maybe the Z will get some more use if I don't end up getting another fun/daily car...getting tired of having multiple projects. That's some good points on the trans mount. I couldn't find my other OE mount but I seem to recall I dinged my t3 crossmember due to trans movement under high load/boost but otherwise it felt like a good match with the milkfab poly engine mounts which basically cut the engine rotation down to 0 and there was minimal cabin noise. The poly trans mount is too harsh and there was basically 0 movement of anything with a lot of gear noise being transmitted to the cabin. Maybe I'll try filling the OE trans mount with window weld or find some lower durometer inserts for the poly trans mount. It would be interesting to set up a camera and see what direction(s) things are moving.

-

More parts trickling in. I'm going back to the OE trans mount for now. For some reason I seem to recall the moulding was a lot beefier, where this new OE mount the moulding seems super thin. I'll need to do some digging to find the OE mount I was using before and compare.

-

Finally caught up on measurements. This AM I got my rear stubs painted in under the solar eclipse...I was wondering why it was so dark out 😂 I think I'll let these cure out over the week while I address other brake system items.

-

@Zetsaz it's the OE front bar powdercoated with poly bushings and endlinks. I had considered bigger sway bars but they seemed more trouble than they're worth. I made AL spacers for a rear bar in the past which could likely help in your situation, just get some flat plate and drill some holes

-

Just a quick update got the rear 280z stub axles stripped tonight and ready for paint tomorrow. More parts trickling in this next week but making steady progress, trying to do 1 thing per day again against the daily schedule. Some house renovation projects as well in the background and maybe the garage next, remove all the cabinets from the 60s and redo the floors and walls. I'd love to open the ceiling and install a lift.

-

Last week I modified the 280z rear stub axles for the ZCG stoptech brake kit. The cast nubs need to be ground down to clear the machined AL rotor top hat, an issue not present with the cast rotors from the t3 wilwood brake kit. The stub axles material is extremely hard. Later this week time permitting I will paint them and continue the suspension refresh/reassembly.

-

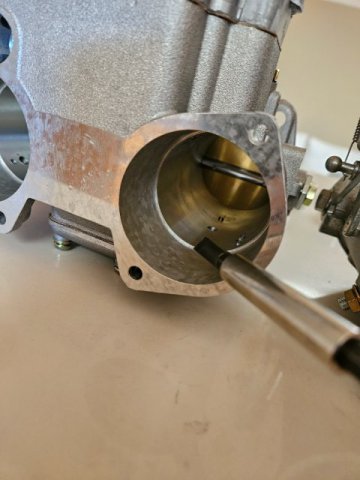

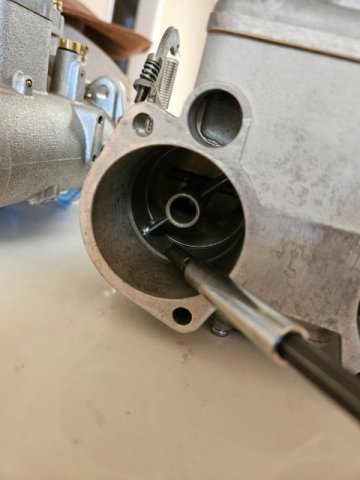

Some additional SK/OER reference pictures as there isn't much information on these carbs out there especially since they're boost friendly. Comparing the vintage SK 50mm bodies to the newer production OERs. It is apparent the vintage castings are of higher quality also with more attention paid to machining steps. For example on the newer OERs the barrels just have an abrupt step to the aux venturi whereas the vintage bodies have a nice chamfer machined in. This attention to detail carries throughout, I would assume due to cost cutting. If you have the vintage bodies in good shape/configuration (chokeless) it would be worth restoring them over the new production.