nmehdikh

Members-

Posts

82 -

Joined

-

Last visited

Profile Information

-

Location

Los Angeles

Recent Profile Visitors

3278 profile views

nmehdikh's Achievements

-

I'll have both the intake and exhaust machined flat, but pulling the head to machine it again is quite a large time and money investment. Is this the oem gasket you are talking about? Do you happen to know the nissan part # so I can try and get it locally? https://zcardepot.com/products/manifold-gasket-intake-exhaust-oem-280z-280zx?_pos=8&_sid=3cfbea7cf&_ss=r Is this it? https://www.nissanpartsdeal.com/parts/nissan-gasket-manifold~14035-n3500.html

-

Hi guys, I've been battle exhaust manifold leaks since I've had the car. I can't drive with the windows down or else I get a immediate headache from the fumes. The head has been rebuilt and head side is definitely square/true. If you look at the photos, you'll see I am leaking from a few separate places. I am open to any and all suggestions, so please help. The intake side is custom ITBs that don't seem to be leaking anywhere. The exhaust is a header set from "Top end performance". The flange on the intake is much thicker than the exhaust, so I have a custom step down washer on the shared bolts, it is unclear how well this is working. Tomorrow, I will check the exhaust flange for squareness / true. And I will also get more pictures with the gasket (copper) removed, so we can see if there are marks on the head side. 1) Cylinder #1, exhaust leakingout from the top (towards thermostat) and downward/forward. 2) Cylinder #2, exhaust leaking straight up 3) Cylinder #3 and #4 leaking straight downwards. 4) Cylinder #5, leaking towards both sides 6) Cylinder #6, leaking in all directions. My gut is telling me the exhaust isn't square/true. I don't think this is from not getting the bolts tight enough, their torque spec is so low. Looking at most of the leak paths, and how this exhaust bolts to the head, it doesn't seem like tightening bolts would really help any of these issues. My plan of attack : 1) Check the exhaust manifold for squareness, and machine flat. 2) Check intake manifold for squareness, machine flat, and thin out sections (to match exhaust manifold thickness) that share stud with the ehxuast 3) Replace studs with allen head bolts and lock washers to make wrench access easier. A couple of the studs are very difficult to get tightened. I am aware studs are less likely to break, but I just can't tighten some of these studs down. 4) Replace gasket? What do you guys recommend? I previously went with the copper because it came highly recommended. Should I be using any sealants? Photos: Cylinder #1 Cylinder #2 exhaust Cylinders #3 through #6 With intake Cylinder #1 and #2 Cylinder #3 through #5 Cylinder #5 and #6 Exhaust leaks blasting intake manifold Thanks,

-

Looking for interior door panels for an early 240z. Car is a 1973. A lot of places used to stock reproductions but everyone I've talked to is on back order with no date on re-stocking. Does anyone have anything for sale? Used or reproduction are ok.

-

New diff. New Ujoints. New bushings. Rear end clunks. Oh joy.

nmehdikh replied to nmehdikh's topic in Drivetrain

I didn't place in a circlip, there was already one in there. However, the axle did not slide in very easily, so I wouldn't expect to slide them out by hand, even if they weren't seated. I had to use a rubber mallet to get them in, and I don't know if I get them all the way in. I can try prying them out and see if I get any movement. Or trying to hit them in further. Do we have a measurements of how far the flange should be from the diff body? I could measure it fairly easily. If they weren't fully seated, do you think they would be causing the source of the noise? Looking at pictures of the LSD taken apart, looks like the axles play no part in the diff's operation. Like you'd be able spin the diff without any axles installed and it should operate normally -

New diff. New Ujoints. New bushings. Rear end clunks. Oh joy.

nmehdikh replied to nmehdikh's topic in Drivetrain

1) I'm using silverminemotors side axles. I'm not sure how to check if they are properly seated in the LSD. I tapped them in with a rubber mallet until they didn't seem like they were going in any further. I'll get photos in the next couple days https://www.silverminemotors.com/datsun/datsun-240z/drivetrain-26/lsd-r180-sti-out-output-flange-conversion-stub-axels Not the best photo, but its what I have on my phone off hand. Looks like the side axle is all the way in to me. Compared to what "moelk" posted on classiczcars a couple years back: Bad Good 2) yes, halfshafts have been driven on, which is why I'm ruling them out. 3) LCAs were swaped with T3 arms and have new bushings. Along with the rest of the suspension (new coilovers etc) 4) I plan on lowering it for the next set of testing. -

New diff. New Ujoints. New bushings. Rear end clunks. Oh joy.

nmehdikh replied to nmehdikh's topic in Drivetrain

On the topic of ujoint binding, how much angle is too much angle? Now that I think about it, the coilovers haven't been adjusted yet, so the car is sitting relatively high (probably 2-3 inches higher than stock). So even when the car was on the ground and rolling, maybe that was still too much angle for the ujoints causing it to bind? -

New diff. New Ujoints. New bushings. Rear end clunks. Oh joy.

nmehdikh replied to nmehdikh's topic in Drivetrain

Sorry, the clunk occurs when applying power. Not just when shifting gears. Next weekend I'll try moving the jackstands and loading the drivetrain with the ebrake on. -

New diff. New Ujoints. New bushings. Rear end clunks. Oh joy.

nmehdikh replied to nmehdikh's topic in Drivetrain

The jackstands are under the body, not on the suspension. Before I had the differential out to take to the shop, I put the car down and went up and down the driveway. Still clunked hard. Also, if they were binding, I'd feel it while rotating the wheel by hand correct? I've rotated the wheels multiple times and there is no obvious spot its hitting/binding either. The clunk can instantly be reproduced by engaging the clutch, it doesn't even have to go a full revolution. -

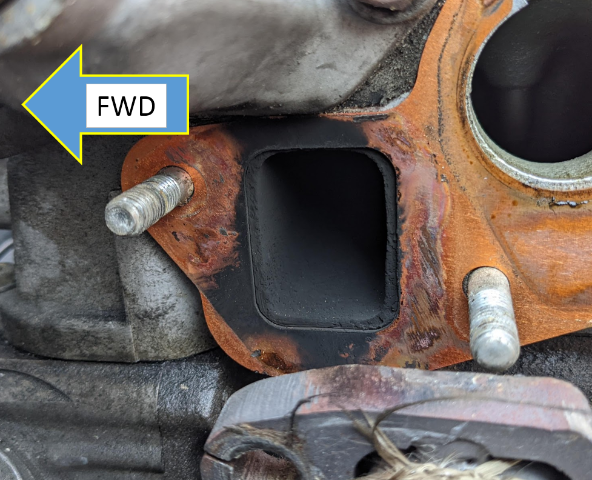

I have gone down the rabit hole of rebuilding my suspension and driveline. Car did not have any noises like this before I started. I installed a Subaru R180 out of a 2011 STI, with torsen LSD. Sitting on jackstands, going through the gears, there was massive clunking and banging coming from the rear end. Very apparent when going on and off the clutch. Checked to make sure everything was tight, no luck. Removed the differential, and took it to a specialty shop to check it out. The differential has a clean bill of health. If you hold the differential input, and try to turn the output, there is a bit of play. Differential guys said this is normal. Put the differential back in, hooked up the driveshaft only, no axles. Sitting on jack stands, going through the gears, clunking noises GREATLY reduced. Like down to 5% what it was before. You really have to listen for it. Hooked up passenger side, clunk is immediately back. Wheel off, clunk is gone. Wheel on, clunk is there. Wheel is not loose and has no play. Got annoyed and didn't bother testing the drivers side just yet. Things I've done before the clunk appeared: 1) While welding on coilovers to the rear spindles, I noticed the stub axle had some play back and forth. Further examination lead me to fine the peened nut had come loose. I replaced both sides with a new locknut from MSA, torqued the spec (close to 200 ftlbs) and the play was completely gone. Did not remove the stub axle or mess with the bearings in this process. Just took the nut off and put a new one on. 2) All 4 rear axle u-joints were replaced about a year ago. Car hasn't gotten many miles on it since, but they don't have any play. 3) New T3 suspension installed, including new mustache bar and drop mounts. I've also installed a Ron Tyler diff mount about 2 years ago on my old R180. The diff is in there solid, and there isn't any play when hearing the noise. I've tried jacking up the diff at different points and it doesn't budge. Thoughts / Ideas 1) I'm leaning towards maybe a driveshaft u-joint. With just the driveshaft hooked up, the noise is faintly there. With the added rotational mass of the wheel, it might be exasperating the problem. 2) My dad is convinced its a rear wheel bearing issue. I'm not buying it as I'd expect a consistent grinding/whirring noise. Not sudden chassis shaking rumbles. 3) Poorly fit splines somewhere: a) Differential input : factory subaru piece, just drilled to match the 240z driveshaft. Splines went it tight with no slop. b) Differetnail output : got output flanges from silverminemotors , they went in tight with a rubber mallet. Didn't appear to have any play c) Stub axles spines are worn out. I can't feel any play moving the two flanges relative to each other, but maybe the force from the engine is enough to cause some play. Any ideas on what the hell I'm chasing down here?

-

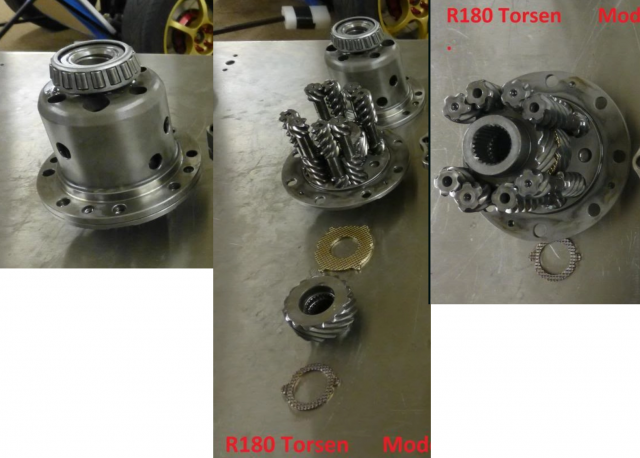

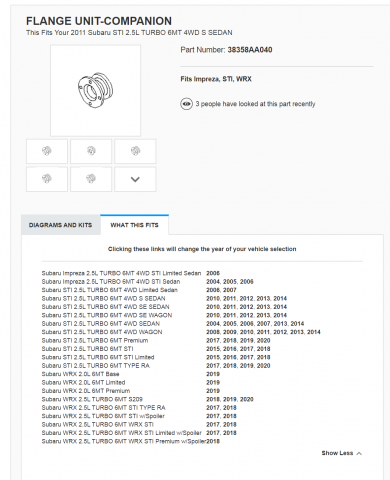

Yeah I cracked it open. It was as expected a 3.55:1 Torsen diff. Had all the proper markings on the outside as well. It also had the temp sensor built into the fill plug. Looking through the subaru parts diagrams, the companion flange appears to be the same throughout the model years. Part #38358AA040 Maybe there are differences in the Datsun R180 input flanges through the years?

-

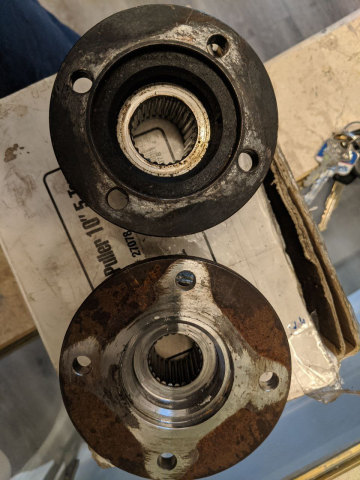

I bought a 2011 Subaru STI R180 recently with the intention of putting it in my 73 240z. I got the different stub axles, and they fit fine. However when I went to swap the pinion flange from the Datsun R180 to the Subaru R180, I was surprised to fine it doesn't transfer over at all. The Datsun pinion flange bore is much larger than the Subaru, by about .5" in diameter. So it doesn't engage with the splines at all and just rattles around. Am I missing something here? I was under the impression it should just swap over. My solution was to just take the Subaru flange and drill the Datsun pattern on it. Datsun flange on top. Subaru flange on the mill

-

240z with L26 - ITBs, EFI, megasquirt

nmehdikh replied to nmehdikh's topic in S30 Series - 240z, 260z, 280z

Had some time this weekend to buff the paint and start putting it back together. Still need to get the front end put together. -

240z with L26 - ITBs, EFI, megasquirt

nmehdikh replied to nmehdikh's topic in S30 Series - 240z, 260z, 280z

-

240z with L26 - ITBs, EFI, megasquirt

nmehdikh replied to nmehdikh's topic in S30 Series - 240z, 260z, 280z

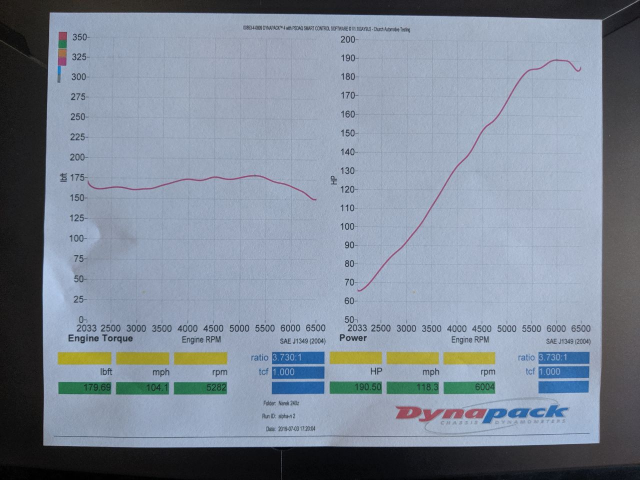

I don't know anything about the bottom end of the engine, just that the block is stamped L26 and it has flat pistons. The head is a N42 that I only had rebuilt and got a Isky L-490 cam on, as well as new valve springs etc. Didn't do any head work. The header is a "Top end performance" 6-2-1, with mostly a straight section with followed by a relatively small magnaflow muffler. Besides that its just the whole EFI / ITB setup. I'm honestly very surprised how much power it made, I was expecting 160-170ish. -

240z with L26 - ITBs, EFI, megasquirt

nmehdikh replied to nmehdikh's topic in S30 Series - 240z, 260z, 280z

Finally hit the dyno, made 190 horsepower to the wheels. Very happy with the results. https://photos.app.goo.gl/qB5vufWp9q44WQiA9