Zcardude

Members-

Posts

43 -

Joined

-

Last visited

Content Type

Profiles

Forums

Blogs

Events

Gallery

Downloads

Store

Everything posted by Zcardude

-

Also, looking at the cooling systems diagram thread a bit longer, I do see that turning off the heater on an earlier Z would essentially block coolant flow from the back of the head so now I am thinking this is likely a fine setup to run on the dyno Thursday. Just trying to cross my t's and dot my i's.

-

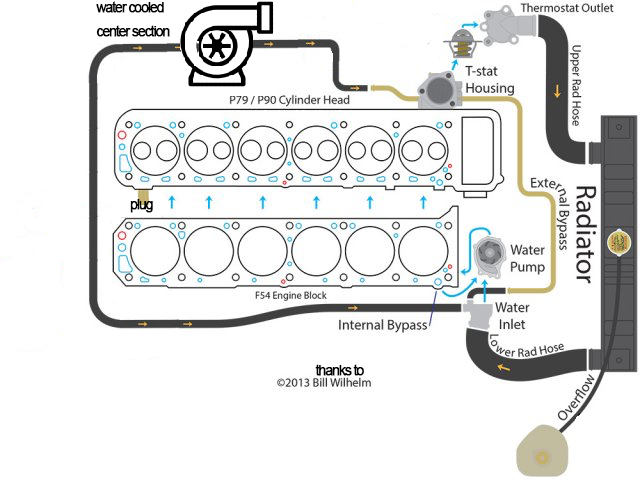

I just realized after looking at my car a bit longer that I have no bypass between my thermostat housing and lower water inlet. Here is an updated drawing to reflect my setup:

-

-

I think the way it's actually working is that I'm pulling from the thermostat housing and going in to the lower radiator hose. I'll post some actual pictures for better explanation So do you mean actually an inlet on the water pump itself, or do you mean using the lower radiator hose? So that would actually mean tapping a part of the water pump then? So this plug is actually okay? I was thinking it might be trapping coolant in the back of the head, and I would be better off allowing it to flow out of the back of the head and back into the cooling system

-

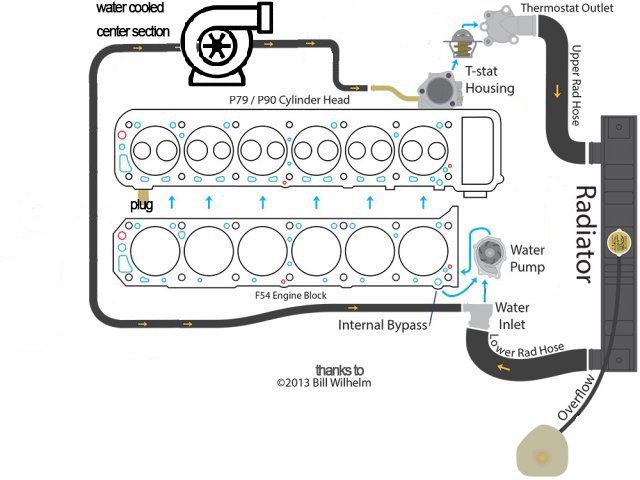

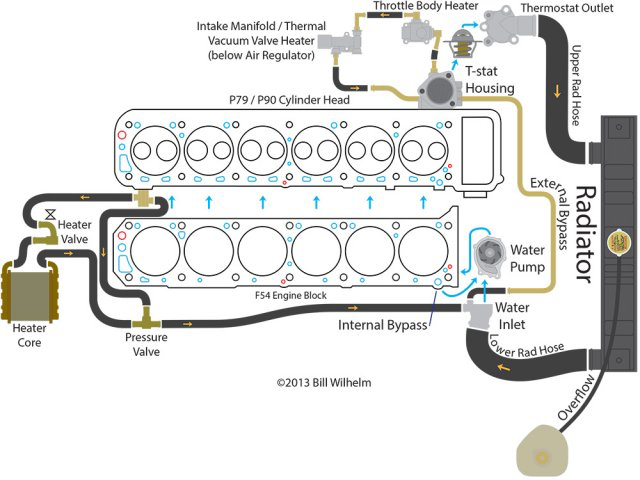

I'm looking for some feedback on how my cooling system is currently laid out. I got the car this way and have been tracking down one issue after another and have it running pretty good. One of my mechanic buddies (not a Datsun specialist though) said this layout is fine because it would essentially be the state of things when the heater valve is closed, but I am not sure that is correct as that is not what things look like in pics that I have seen. I am taking my car to the dyno on Thursday so want to make sure things are "right" before I have any issues there as I know dynoing the car will stress the engine to some extent. My Z does not overheat or anything but I have a large arizona Z car radiator and large electric fan, and the temperature does start climbing under load if I do a pull in 3rd higher gear, but comes back down relatively quickly after I am running an L28ET with a P90A head, F54 block, water cooled turbo. I have no heater core, but some of the coolant lines that went to my heater are rerouted to the water cooled center section on my turbocharger. The coolant passage after port #6 on my head is just plugged which concerns me. Here's a drawing of how things are laid out in my car which I suspect is bad: vs this "correct" layout from the coolant system diagram thread: What do people here think? It seems to me that at the least I should put some kind of a T valve in the back of the head, and route the coolant from the back of the head in to the hose going between the upper t stat housing and the water inlet. Has anyone else deleted their heater core and re-used some of the lines for a turbo? How did you do it? Any and all feedback appreciated. Thank you!

-

Need help diagnosing boost control issue

Zcardude replied to Zcardude's topic in Turbo / Supercharger

Yeah definitely this thing could use more intercooler but I am happy keeping things around 120F at the moment with my new CAI. I want to redo all of my piping and do a larger core intercooler that enters and exits on opposite sides of the engine bay and a proper CAI and I'm sure I too can strive for 20F over ambient. I don't mind the boost creep at all - I think it should be totally manageable with tuning and I am probably not going to be doing anything about it. I'm fighting what I think is a bit of an ignition issue at the moment but it seems to hold ~17psi pretty well after a small spike when using a boost controller which is a good target for this current setup. I'll shoot for more when I get a bigger intercooler -

Need help diagnosing boost control issue

Zcardude replied to Zcardude's topic in Turbo / Supercharger

Update! Boost-wise, things are looking much better. It looks like it makes positive pressure at about 1800rpm, full boost at 3k, creeps by a few psi by 4k and tapers back to wastegate by 6k where it is pretty much out of steam. So this was likely caused by a combination of some boost leaks and a non-working wastegate actuator but the boost curve now looks totally normal so I think my original questions were resolved! I hope others find my troubleshooting useful. Outside of that, the car sounds and feels a bit better, seems like it is not working as hard to do what it's doing, but it is extremely rich under boost (saw high 9 afr's at some point when glancing at the gauge?) and a little stuttery and not making a ton of power because of that. I'm going to manually remove some fuel from the fuel table before attempting to let autotune do its thing and will go from there. Also wanted to note: Realized my last datalog the other day where I was complaining about the temperature jumping to 200 under load is because the electric fan wasn’t on. I definitely need to get this under megasquirt control. Today I had the fan on and the temperature held steady. I have a skillard front splitter and I think that the radiator and engine bay gets very little cooling without the electric fan pushing in air so this is really really important. -

Need help diagnosing boost control issue

Zcardude replied to Zcardude's topic in Turbo / Supercharger

I ended up not driving the car tonight but I did retest the system and the BOV no longer leaks air by. Instead of driving I spent the evening building a cold air intake out of extra intercooler piping while I had things apart, so hoping to see reduced IATs as well as good boost on a drive tomorrow. 🤞 -

Need help diagnosing boost control issue

Zcardude replied to Zcardude's topic in Turbo / Supercharger

I hope people are enjoying my troubleshooting thread! I believe I fixed my wastegate actuator off the car. I then bent the actuator arm so it does not get cocked at a funny angle to reach the turbo. When retesting the car with the boost leak tester again, the wastegate now seems to go in and out as desired, and I also noticed... one more huge boost leak! The BOV piston is leaking under boost letting a ton of air by. I've disassembled the BOV and permatexed the crap out of it - hoping that it seals or I will need to get a new one. Will retest and post results shortly once the permatex dries. If it's not one thing, it's another! -

Need help diagnosing boost control issue

Zcardude replied to Zcardude's topic in Turbo / Supercharger

Okay another update: I yanked the actuator and hooked it directly to my compressor and it does not move at all. Instead all of the air seems to push around the outside of the diaphragm housing where it is crimped together. So seems like this is the issue and the boost just seems to do whatever it wants as the exhaust pushes the wastegate puck open -

Need help diagnosing boost control issue

Zcardude replied to Zcardude's topic in Turbo / Supercharger

Okay slight update: I just put my intercooler piping back together and it seems to be holding boost. I just retested my system with my compressor set at approx 25psi and am not getting bubbles anywhere. One thing of note is that I was watching the wastegate actuator as I was hooking up the compressor to the boost leak tester and it did not move at all with 25psi in the system. Would that point to a bad wastegate actuator? -

I'm working on a 73 240Z with an L28ET with a larger turbocharger running on a MegaSquirt II running msns2e. Honestly not sure the type of car is all that important as I think this is more of a general turbocharger issue that I've never crossed paths with before. The car runs pretty well and is fun to drive but is doing something sort of funny with regards to the turbocharger and boost control. Here's a graph of a 3rd gear pull from megalogviewer: Essentially what's happening is, when I go to full throttle, the turbo produces some boost (about as much as it was making previously at part throttle) and just... continues to slowly build more and more boost. Ideally It would hit some sort of boost level and hold it. Or even hit some boost level and creep up from there would be fine, I would be totally stoked to tune for that. Additionally the boost is getting a little hot - maybe this is expected but it feels like the turbo is working hard to achieve the given level of boost. I was seeing AITs in the 130 F at 70 F ambient range on this pull, with a small same-sided intercooler, hot air intake, and a windshield wiper sprayer hitting the IC with watermeth. This might be ok given the crappy intercooler setup, crappy hot air intake. Additionally coolant temps rose to approx 200F from my thermostat's 180F and quickly fall back to 180F over 15-20s - I'm thinking this might be a symptom of me using re-routed heater lines to the water cooled section of the turbocharger, essentially dumping hot water from the turbo directly on the coolant temp sensor but maybe a symptom of something else. I have a large arizona Z car aluminum radiator and shrouded electric fan and new water pump so the cooling system is sufficient unless something else is wrong. Since taking this datalog, I have fixed 5 very, very tiny pinhole boost leaks in some welds in my intercooler piping using a boost leak tester, but I am thinking it would take significantly more than that to produce this behavior so I am looking for more ideas. I will be re-testing with these very small boost leaks fixed shortly but don't expect that it will resolve the issue due to how tiny they were. When using the boost leak tester, releasing the line from my air compressor let a whoosh of air out the boost leak tester's fitting, telling me that the system held pressure pretty well and that the leaks were minor. I keep thinking maybe there is a wastegate problem. The wastegate is an integral dual port wastegate with a 7psi spring. I've run the vacuum line directly into a vacuum port before the throttle body to the top vacuum port on the wastegate, and also with a boost controller on that same vacuum line. In this run it was hooked up to a boost controller, but the same behavior happens without a boost controller and the boost controller did not make an appreciable difference in controlling boost. The wastegate actuator can be moved by hand and has good tension and seems to shut fully (I can hear it kind of "clack" shut if I release the spring by hand. Maybe there could be a problem with the diaphragm in the wastegate however? The arm on the wastegate actuator is threaded, so I could also try tightening it up. The arm also goes to the wastegate from the actuator at a slight angle and is not 100% straight. Happy to answer any other questions that I can about the setup if it helps. The car otherwise drives great and is fun to take on spirited drives, doesn't smoke or anything weird, but I'd like to get some proper boost control in place here and start making some decent power, right now it's sort of underwhelming when you stomp on it. Also worth noting that the turbocharger and exhaust manifold seem tight, all the bolts that I can get to easily are snug, no large amounts of sootiness around anything.

-

L28ET Valve float and spring recommendations, aftermarket cam

Zcardude replied to Zcardude's topic in Nissan L6 Forum

Just took the car for a spin and it drives a lot better. Still not perfect but definitely having no problem spinning past 5000. I turned the boost down a bit to test with, but I am definitely able to rev over 6000RPM now thanks to switching my spark settings. I guess I should have started out in the megasquirt forum! The car still seems to sort of lay down a bit after 5000RPM but I am attributing that to the tune being way too fat (low 10s on my current tune) up there, and I can clean that up a bit with some more street tuning and then a dyno. If anyone is reading this and wondering what the heck I changed given my issues: I had a dwell type of fixed duty, with a dwell duty% of 50. Chickenman recommend that this was wrong and that MSD boxes like my Street Fire, actually can use a standard dwell, with a nominal dwell of 2 and a spark duration of 1. -

L28ET Valve float and spring recommendations, aftermarket cam

Zcardude replied to Zcardude's topic in Nissan L6 Forum

Ended up triple checking that piston 1 was at TDC and then not adjusting cam timing based on feedback from this thread. I just finished throwing everything back together and loaded up some different ignition settings on the megasquirt based on Chickenman's feedback. The car starts and runs fine but I have not driven it yet because it is late and I don't want to wake up the neighbors. This thing is bit loud I will report back with whether or not a simple tune change fixes the issue tomorrow! -

L28ET Valve float and spring recommendations, aftermarket cam

Zcardude replied to Zcardude's topic in Nissan L6 Forum

From the FSM, I believe it is retarded but I would love to be told that I'm wrong. My setup looks to be somewhere between these two: I was thinking that the notch on the sprocket should be to the right of the groove. Looking at my timing chain, I'm noticing any timing dots or shiny links. Possibly an aftermarket replacement chain? Here is what I see at the "1" position with the engine at TDC, same position that I took the previous pic of the cam timing mark at. Looks like there is some markings on the chain links, but they are on other links as well, notice the link before the "1" mark: I've never had it past 5k RPM. Ignition is controlled by the megasquirt, it is running an MSD street fire ignition box. I am getting pretty strong spark. New plugs/wires/cap/rotor -

L28ET Valve float and spring recommendations, aftermarket cam

Zcardude replied to Zcardude's topic in Nissan L6 Forum

Ok, it's late so I haven't gotten around to adjusting anything yet, but I set the engine at tdc and am thinking that the issue is not that the cam timing is off by a tooth, but due to a worn or stretched timing chain. The adjustment marks look like this: Looking at the haynes manual, I am thinking if I move the cam gear from position 1 to position 3 tomorrow, I should have the cam timing close to correct. I will try this out and report back unless someone recommends otherwise This is my first L-series and I have never had to adjust cam timing before, so some questions: Would this amount of mis-adjustment still cause my RPM wall near 5000RPM? Is it possible to be off by a tooth and have the timing this close to spec? It seems like this is an adjustment issue and not an issue with improper cam gear installation -

L28ET Valve float and spring recommendations, aftermarket cam

Zcardude replied to Zcardude's topic in Nissan L6 Forum

Thank you for your posts! I have not verified cam timing and I will do so before doing anything else. I guess I'm getting ahead of myself here. I'm really glad to hear of someone else having the same symptoms, I feel like this car is so close to being awesome just not quite there yet! I'll post back (hopefully with a resolution!) after verifying and adjusting cam timing -

I need some help doing a bit of troubleshooting determining if I am experiencing what I believe is valve float due to too much cam: I have an L28ET powered 240Z, running on MegaSquirt, with a t3/to4e turbo, lonewolf intake manifold, 2.25" downpipe to 3" exhaust, fmic, etc. After looking at receipts from the PO, I believe it has this cam: http://schneidercams.com/270-60F-14_LET6.aspx in a hydraulic P90A head converted to solid lifters, with new, stock valve springs. I believe the stock valve springs are very wrong for this cam. After lots of tinkering with wiring to the megasquirt, fixing grounds, new plugs, wires, cap, rotor, and some noise filtering in the megasquirt software, the car drives really well. I've been driving around for a few days, and cruising around, part throttle, and WOT. I start making positive pressure at 2000RPM, and get desired boost by 3500-4000RPM depending on gear and everything is dandy -- up to about 5000RPM @ 18psi, a little higher at wastegate, around 9ish psi, where it seems to hit a complete wall. When it hits this wall, it is able to maintain boost and holds stable AFRs (a little on the fat end - low 11s), but, I can hear what I think is the blow off valve going off a bit, and I am not really able to accelerate without shifting. It doesn't sound like it is having ignition break up or detonation, but it sounds sort of off. The Z is not very fast despite making a lot of cool noises What I believe is happening is that the cam is at the very limits of the lift that the stock valve springs are able to handle, and the valves are floating. Is that a reasonable thing to assume, or should I look elsewhere? The megasquirt was previously wired poorly, but I have it running so well now otherwise I am hesitant to blame it for the engine's current behavior. I am thinking that I should have no problem revving this engine to at least 6500RPM (7000 would be even better and a damn miracle) which would give me a reasonable power band - right now it isn't terribly exciting. I'm only in full boost for 1000RPM, then hitting a wall! Next, if that seems like a reasonable place to look, I was considering doing the Rebello outer valve springs and nothing else, as that seemed like the most cost effective way to get some better valve springs in place and test my theory: http://www.rebelloracing.com/nissan1.htm My questions are this: Is there any reason I should not do this? Is this enough valve spring to work well with my cam? Is there an even more cost effective solution? Should I hunt down a stock cam setup instead? Do you have any other suggestion for my performance issues? I'm trying to get this sorted out on the cheap, feeling like if I can't get this setup operating correctly, I am going to swap to a newer GM V8