Dave

-

Posts

350 -

Joined

-

Last visited

-

Days Won

2

Content Type

Profiles

Forums

Blogs

Events

Gallery

Downloads

Store

Posts posted by Dave

-

-

Oh, and since you're doing this, I found a battery distribution block to be a very neat thing to have. In case you are putting your battery in the trunk or so that is...

I did not mention it in the starting post but there is a distribution block with a 5/16" stud on the firewall that is used for the lead to the starter and the power tap for the add-ons. I plan to move the battery later and I will start at the distribution block. For the time being the battery is in the stock location.

With the lead to the starter that is hex crimped there is no room for solder, and I don't think soldering and crimping is the way to go. When I bought the welding lead and lugs they offered to crimp them and the finished product looks well done.

-

In the process of making my battery cables because I can't find ready made ones I really like. I have fine strand welding cable that I will use but when it comes to lug crimping I see that some solder, some crimp and solder and some are crimped only. I would think crimping alone would be good enough but I see 3 different crimp styles, indent crimping tool that uses a hammer and there's a diamond crimper that gives a square crimp and the last one is a hex crimper that is 6 sided.

What have others been doing to put both ends on their battery cables.

-

Is there someone in or close to Sarasota that can help me

get something small shipped back to Oregon? PM me and I

have further details about what the seller does not want to

ship.

-

Hey,

Got any guesses on when I'll get the items I paid you for back on 25 Feb ?

Datsun 240z,260z,280z Rear Brake Line 3 Way Connect NOS

Datsun 240z,260z,280z Upper Corner Door Rubbers - NOS

Thanks

I was going to buy that same 3 Way Connect from him until I found it was still available

from Nissan for less than $12. It seems that a lot of his stuff is from Nissan at 3X the price.

-

-

I have noticed items with the same SKU on the cover at one price, and the same SKU with a different suffix inside the catalog for 2X as much!

It pays to read carefully...

I saw the different prices also, I bought the 6" stainless digital calipers for $7.99 last weekend. I have 2 different catalogs with 2 different prices, $19.99, $17.49 and then found a internet price at $9.99 all the same SKU. I had a 20% off coupon that got it down to $7.99.

I have several of the HF stores here in town and not al of them will honer the Internet price, but one store always has.

-

I have bought tools from HF, some were good and some were so-so.

I see that they have a Inside Track Club Member area that is just less

than $10 a year that is supposed to give discounts/specials not available

to the general public. Does any one here belong to it or have a commercial

account? I could also open up a commercial account.

I am looking for someone that has personal experience with either a inside

track club membership or a commercial account.

-

Wow... I just tried smith and my 97220 zip and it gave me a bunch of items a Michele Smith bought

-

So if i take off the gaurd and bag... then I should be ok?

I personally would not do it. If you have a harborfreight near you buy one of their cheap reciprocating saws $39 (sawzall knock off) and it can handle all you want to do. My best guess is the wood miter saw is going to be damanged because it is not really made to do that.

-

Sawz-All and my grinder with a cutoff wheel. I'm going to try using my friends crafstman mitter saw with a cutoff blade on it. Then I can get some awesome compound cuts.

Also a bench grinder.

Not a wood working miter saw!!!! The sparks and heat from the abrasive cutoff wheel will melt the plastic blade guard and all the plastic that is close.

-

That deal from K&D tools sucks. I had one, and I broke it within two attempts at uses. Quite honestly your better off marking and cutting with a sawzall.

IMO horizontal bandsaw is the way to go. I like Austin's solution but I am willing to bet its well out of my price range.

Evan

I looked at this milwaukee unit, this looks just like a standard chopsaw with a $150 blade... Austin can you elaborate on the differences?

I have the Makita version of that saw, it's a 12" cold cutter with the tripple chip carbide blade. The big difference between the cold cutters and abrasive cutter is the rpms, cold cutters spins at a slow 1300 rpm and the abrasive cutters are 3800 rpm.

-

A foot switch would be amazing, thats a great idea. Since I will be changing to a bigger motor anyway.

Evan

Once the part your drilling comes after you the foot switch will make a believer out of you.

-

When I bought mine years ago I replaced the motor with a reversable one so I can drill/tap stuff and then back the tap out. I also put a foot switch on it to free up both hands. The time will come when your part that your working on will get away from you and you wished you could turn the drill press off real fast. With the foot switch I can just tap it for better control and the motor has a lot more torque when on the starter winding

A cross slide vice is very usefull as is a V block.

http://www.harborfreight.com/cpi/ctaf/displayitem.taf?Itemnumber=32997

-

I had some inquiries about this on another post, so I thought I would post a separate summary of a mod I did to remote-mount my Master Cylinder (MC) reservoir.

I needed to do this because the stock ones were going to interfere with one of the twin turbos I am mounting on my 350 Chevy V8 Paul

Paul, Did you get the brakes working? and did they bleed OK? I was going to mount my PV in the same location but was not sure if running the line above the MC and back down would create a area for a air pocket to develop.

-

I like your idea of installing it where you can adjust it from inside. FYI, I installed mine near the master cylinder. I can adjust it by opening the access door on the drivers side. I disconnected the line that goes from the MC to the rear brakes and re-attached it to the output of the proportioning valve. I then installed a new, short line from the PV to the MC. I replaced the stock PV with a union that came with the kit from Flyin Miata.

Looking at your picture of your PV I see that you have a couple caps on your master cylinder with hoses leading to the reservoir. What are they from?

-

Hey Ron! I stopped by ESP (largest parts supplier in Eugene) and Carquest, but no luck at either. I'll try Napa, as they are often good for "odd ball" stuff, but didn't think they'd be the place for those. I'll find out tomorrow and if not, I'll have to check around some more. Thanks for the input!

This is the AGS (American Grease Stick) part numbers for the 10mm X 1.0

Japanese flare nut. Still going to be hard to find, but with these numbers

they may be able to cross them over.

BLF-40C-5 - Carded (5 fittings per card/10 cards per case)

BLF-40B - Individually Bagged (1 fitting per bag/10 bags per case)

BLFX-40 - Bulk/Boxed (100 fittings per case/box)

BLF-40 - Bulk/Bagged (10 fittings per case/bag)

-

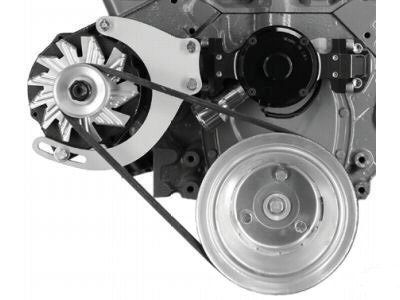

My 240Z has a 12SI that is mid mounted on a 70's 350 with a Alan Grove bracket designed for the electric water pump. I am upgrading to a CS144 140 Amp alternator because with everything running there is not any reserve left with the 12SI.

The CS144 adjusting ear misses the adjusting slot in the bracket. I can make another bracket using just the water pump holes and the mounting/pivot hole at the top, that will be the easiest. I then have to make some kind of adjuster. What have others done to make this all go together with the least amount of fuss? The first picture is a 12SI installed, the CS144 will need to have the adjusting slot lower. The second picture is a Alan Grove mount for the rear of the alternator for a small block without bolt holes in the head. Kinda looks like with spacers it can be used for the front of the alternator. But I still need a belt adjuster of some type.

-

I was removing the front left brake line and while i was loosening the line the metal line the runs from the hose to the rear of the caliper broke because it was really worn out. Where can i get a replacement? If possible.

Ya talking about the S shaped bridge tube?

-

Hey guys!!! I just purchased a 280z yesterday for like 1800.

and im freakin happy like craaazy.

aanyways for that price, its bound to have little problems here and there.

For starters, Both of my mirrors on the 1977 280z keep loosening up. So when im driving, the mirrors are basically pointing really down, all the time.

can anybody help me????

or should i just buy new mirrors. haha

thanks!!

Are they the chrome mirrors? If they are the dealer installed mirrors or black pearl mirrors this link may be of help.

http://www.v8-240z.com/Files/Datsun/Mirrors/Z_Car_Mirror_Repair.htm

-

Great link. Thanks.

Push button wipers... Hmmm... Version of todays "mist" control.. Not a bad idea for an occasional windshield wipe without having to twist, then untwist...

With the mist control "switch" in the foot rest.

-

It is best to take the ground cable to the block using the same size cable as the positive. If you do run the negative to the body as a ground you need a ground from the block to the body that is the same size as the positive cable. I see that some even ground the head or heads to the block with a cable. If you don't have the block to body ground you will find the clutch lines, throttle and choke cable will start acting as grounds.

How about a Stainless braid fuel line acting as a ground as the car is being started? As 2eighTZ4me said "The Z (earlier S30's) are known for crappy wiring and poor grounding" just don't make it worse.

-

I will have a few extra of the metric fittings if you need one.

Thanks for the offer, I got lucky with the last trip to True Value hardware, I found they have AGS brand brake line in different lengths and their 8" Japanese line was $.99 each, so I bought a bunch of them.

-

Dave,

I bought the brake line kit from ebay and they had the proper metric fittings. The lines are copper with a coating, the fitting I am putting on are standard to the proportioning valve-3-8/24 I believe.

You have the easiest line there is to work with and all the fittings are correct. It is just a matter of getting the flaring tool to work. Are you still working with the Autozone loaner tool? It just may be too trashed to work well. If your doing the flares in the car try to clamp the tool halves together with a large C-clamp.

I left the tee because Dave (AZC) didn't specify to remove it.[/Quote]I asked about the tee because I need to find another one and have not found one other than on eBay for $35 (Ouch) I had a extra one here but it seems to have vanished. The 10mm X 1.00 flare nut is not easy to find either.

-

Dave,

I will take some pics Sunday, I put the proportioning valve and the hydraulic brake along the console on the passenger side. I probably dumped a cup full of brake fluid on my floor with my first attempt bleeding my brakes since my flares sucked so bad. Of course I didn't notice right away where the fluid was going:oops:

When you cut the lines and flared them did you use a SAE nut for 3/16" tube? The brass fittings in the propotioning valve and ebrake valve are not for metric flare nuts they are SAE. The 10mm X 1.0 nut that fits the rest of the Z's braking system will bind up before it bottoms out on the fitting. You might want to look at the seat in the brass fittings that are screwed in the 2 valves. They are soft and may be damaged from the crooked flares. The fitting is a 1/8" male pipe thread by 3/16" SAE inverted flair and should be stocked just about everywhere.

Is the tubing your working with steel or is it stainless steel and did it come with the Japanese 10mm X 1.0 nuts? Did you reuse the tee in the back that splits the brake line?

The ultimate cruse Rambo Style

in Non Tech Board

Posted