-

Posts

787 -

Joined

-

Last visited

-

Days Won

2

Content Type

Profiles

Forums

Blogs

Events

Gallery

Downloads

Store

Posts posted by Nigel

-

-

Had a solid mount in my '73 Z for one lap around the block and it came out. The gear whine was way too loud for my taste and my Z isn't exactly quiet. Glad I did because I've since seen pictures on this site of front cross members torn up from using these. Eventually switched to the RT mount with the Energy Suspension poly GM trans mount above and nothing below. There's an exhaust hanger bracket welded to the tunnel that people partially cut away to make the RT mount fit, but it only takes a bit of hammering to recess it enough that the RT mount fits fine. No point potentially weakening the bracket unnecessarily.

I sanded the GM trans mount down to match the profile of the nose of the diff to apply the proper pre-load to the mount, and I shortened the supplied bolt that goes in from the top. it was a little too long and it was hitting the metal plate embedded into the poly. I suspect not sanding the mount and the too long bolt may be potential causes of the issues some people have had with this setup.

I had no way of checking the drive shaft angle, But I have a 240SX 5 speed with the shorter driveshaft, and if drive shaft angle was an issue, this setup should have exaggerated it. However, I haven't had any driveline vibration issues.

This has been my setup for the last 7 years behind an L28 turbo. It's held up fine through mixed use of drag, road course and street driving. So, overall the RT mount is one of the few things I'm content to leave as is.

Nigel

-

The drag strip is the only dyno that can't be disputed.

Who's driving?

-

I did overlook the oil filter bypass valve, which would still allow some oil to circulate. But, then the filter would be bypassed. Still not good.

Nigel

-

Yes, but the kits is only for a 1978 according to the Arizona site, so was there no change from the 280z of 1978? for the front and back braking system.

Or is this another kit and for the fronts only?

AZC sells brake kits for more than just '70 to '78 S30's. Go look at the AZC website again.

Nigel

-

I am preparing a L28Et for installation in my 240Z. The motor has a factory oil cooler and I would like to block it off for now to simplify the installation. I bought adapters and AN blockoff caps to replace the factory banjo bolts. It just occurred to me that I don't know if the motor need to flow oil through the oil cooler fittings for proper oiling. Does anyone know if it is safe to block the cooler lines?

The oil cooler is in series with the oil supply galleys to the crank and head. Cap off the oil cooler lines and kiss your engine goodbye. You can loop the inlet to the outlet on the block adapter. But as Lance Vance suggested, just remove the block adapter, put a filter nipple in the block, and screw the filter to the block just like every other Z without a cooler. Piece of cake to put the block adapter back on when you're ready.

Nigel

-

Does this kit fit on a S130?

280ZX = S130

-

I run a single Walbro pump (currently, planning on going to a dual pump system), fed from the drain plug in the bottom of my 240Z tank. The fuel pump is mounted about where the original electric pump would be in a 240Z (Just inboard of the right rear wheel, and several inches above the tank bottom). I've been doing so for 6 years without issue.

Have you tried this on a road course yet?

-

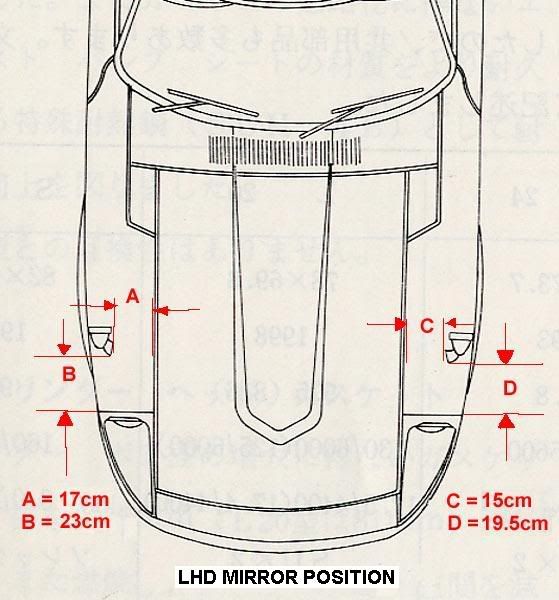

For the mirror, I use LHD version. Somehow I had RHD version image here.

That's a relief!

Looking really good! That's the same white I used on my Z.

Nigel

-

Thanks Alan T., aka HS30-H. for sharing information. I follow his instruction to drill holes.

http://forums.hybridz.org/topic/50023-fender-mirror-install/?p=549483

I hope you reversed the dimensions in that picture for a left hand drive Z? Here's a left hand drive picture:

Also, if you want more in-depth info on the FS5W71C swap, here's a link to my very detailed write-up:

http://www.motortopia.com/cars/1973-datsun-240z-11118/car-pictures/240sx-transmission-swap-14041

Good luck!

Nigel

-

Mine is an 83 stick and has an oil cooler.......

Are you sure it's the OEM cooler. Is your car a European import? Have you had the car since new?

-

Tate s130, I don't mean to hijack youre post, but, One quick question...what year supra injectors are you using? and roughly how much for all six? thanks..Rob Also, are you aware that our turbo zx's already come with an oil cooler? or are you just wanting a bigger one??

IIRC, only the automatics came with an oil cooler.

Nigel

-

This is not correct. Bolts are never in shear unless they are loose. Bolts force two surfaces together and it is the friction between those two surfaces which transmits any forces. The bolts are always in tension.

While on this issue, be sure not to apply excessive paint to any mating surfaces as it will compress over time and reduce the tension, and thus the friction, between the surfaces.

You're right. Referring specifically to the bolts being under shear load was a mistake. The point I was trying to convey is that the 'assembly' is under more of a shear load than tension.

Nigel

-

I wonder if one would have enough threads on the steering rack after pushing the wheel out? I'm kinda borderline on thread engagement already.

The steering knuckle is still attached directly to the ball joint. It doesn't get any further away from the rack.

Nigel

-

Surprisingly, based on a recent study by Lotus, who were commissioned to investigate the impact on handling and ride comfort when a 66lb electric motor was added to a wheel, unsprung weight doesn’t matter nearly as much as conventional wisdom dictates. They found that while adding that much mass does degrade handling and ride quality somewhat, it is of their opinion that this could be offset through normal suspension re-tuning. Consequently, in the grand scheme of things, I wouldn’t be particularly concerned about a 2 pound weight difference relative to all of the other factors to take into account during design.

http://www.proteanelectric.com/wp-content/uploads/2011/12/protean-Services3.pdf

Nigel

-

I used to have one of these on my Z. Wasn't a big fan of it. It looked too narrow when viewed from the front.

Nigel

-

Wow, 13" rear rotor, really? I've taken rotor temps at the track and could not imagine ever needing anything close to that, especially on the rear.

I think you may be missing my point, nothing wrong with upgrading brakes IF YOU NEED TO. But if you are going to spend $700-800 on an axle, why is giant better than just a little bigger? All those big brake kits sold could be even lighter if sized more reasonable. Every pound counts out on the corners.

Like most everything, it’s a compromise. The Modern Motorsports Xtreme rear brake kit uses probably the lightest rear calliper with an integrated parking brake there is out there. However, it’s not particularly “powerful.” Consequently, the leverage of a 13” rotor is needed to generate adequate brake torque, not because of its heat dissipation ability. Yet, by using a two piece rotor, the weight is kept in check, which as you point out, is beneficial.

In regards to front brakes, I think you’d be hard pressed to have too much heat dissipation ability. So, a larger diameter rotor is advantageous in that regard, and again, weight can be effectively managed with a two piece rotor. However, where I believe you can easily get in to a situation of overkill is calliper clamping torque. The AZC kit has the largest pistons available for that calliper, and the resulting brake torque they’re capable of is not that far off of what you get on a Nissan GTR, a car that weighs nearly 4000 lbs! Still, if you've got big, sticky rubber on your Z, they work really well and the AZC kit is a great value for the money. But, on a Z with, say 215 wide all-season tires and stock rear drums, they're pointless, if not dangerous.

For a street/track car not running fat rubber, I'd still stay with 12" or even 13" 2 piece front rotors, but ideally, it would be helpfully to go to smaller diameter calliper pistons in the same Wilwood calliper (they're already very light) to bring the brake torque down to a level that's more easy to modulate.

Nigel

-

As a point of comparison, I weighed a "giant" Modern Motorsports, two piece, 13" rear rotor, and a stock 11.81" Mustang rear rotor.

13" rotor: 11.695lbs

11.81" rotor: 12.705lbs

1.19 inch bigger rotor, yet 1lb lighter.

Nigel

-

Nothing wrong with insurance. You could put in a 500lb Nascar cage too. Those giant rotors are just not worth the unsprung weight gain for me.

The giant rotors with aluminum hats weigh less than many smaller one piece rotors.

Nigel

-

It's been a few months since the kits shipped out. Anybody other than KyleG have theirs up and running yet?

Nigel

-

A little off subject, but Wilwood makes a caliper that is compatible with a cable parting brake. I would have pursued that caliper, but the mechanism is external and there is no way that it would clear my 15" drag/landspeed wheels. I am eager to see somebody develop a kit using that caliper but it would probably be only something that could be used by folks with 17" wheels. It kind of sucks not to have a parking brake.

If you're referring to the Wilwood "Combination P-Brake Caliper," I investigated those when I was developing my rear disk conversion (http://forums.hybridz.org/topic/113199-yet-another-rear-drum-to-disk-conversion-option/) and ultimately rejected it in favour of the Jaguar XJ8 rear caliper. The largest piston available for the Wilwood is still ~2mm smaller in diameter than the Jag, which doesn't sound like much but makes a difference. Weight wise, they're exactly the same. They both require similar wheel clearance. The biggest difference is in the price. The Wilwood sells for $240 each, but you can pick up a reman XJ8 caliper for as little as $100. So, paying a $140 premium just to have the Wilwood name on the caliper and zero advantage in performance made no sense.

Regarding the front brakes, it doesn't look like Datsun Parts is offering anything more for the extra $150 you have to pay for their Stage 3 kit compared with AZC's front kit? They appear to be pretty much the same.

Nigel

-

Bad fan clutch, retarded timing and failing water pump are all good possibilities. Regarding the fan clutch, it's typically not an obvious failure. With the engine running, you'll see the fan spinning away and think that everything is fine with it. But it will actually be moving very little air. With the engine off, rotate the fan by hand. It should feel quite stiff. If it's easy to turn, replace the clutch. After you replace it, you'll suddenly notice that it sounds like there's a jet engine under the hood.

Nigel

-

Is the dipstick still in its hole? Have you tried boost yet? .

LOL!

Elishallen, just to be clear, you've connected the crank case vent directly to the J-pipe with no check valve? And by J-pipe, you're referring to the pipe that connects the turbo to the throttle body? Also, what do you mean by "behind the throttle?" Behind the throttle would be in the intake manifold, but if you have it connected to the J-pipe, that would up-stream, and therefore, ahead of the throttle.

To answer your question about airflow through everything, it is very important. The factory service manual does a very good job of explaining how it all works.

Nigel

-

I suppose machining an o-ring groove is doable, but I suspect it would be tricky to set up, and consequently costly. A T-bolt clamp may do the trick. I think they can be torqued up quite a bit tighter than a standard hose clamp, particularly those wire clamps. I just want to get the car running right now though, so I'm not in any hurry to go back to the Tilton reservoirs. Thanks for the retrobright suggestion.

Nigel

-

I installed the Tilton reservoirs after reading this thread a few years ago and I've just now had to go back to the original reservoirs, which I thankfully kept. I ran into the same problem as mr jdm. The Tilton reservoirs were not sealing on the master cylinder. The stock reservoirs are a tight fit on the MC, but because the Tilton reservoirs are meant to be used with a master cylinder with an o-ring groove for an o-ring seal, they are a looser fit. Consequently, I had to tighten the heck out of the clamps to get them to finally seal. This worked for a few years, but then I noticed yesterday that brake fluid was leaking again.

Turns out that despite being very conscientious about the positioning of the clamps, the upper wire of the front reservoir clamp slipped up slightly and was squeezing the sleeve of the reservoir just above the aluminum boss of the MC. Because I had to tighten the clamps so much, this eventually caused the reservoir to crack and fluid was leaking out. Also, the hose clamp screws stripped when I loosened them to remove the reservoirs.

It's too bad because I liked having nice, white reservoirs and black plastic screw-on caps instead of the old, yellowed reservoirs and rusty caps. But without a better way to get the Tilton reservoirs to seal, I don't think I'm going to try them again. So, for those that have them installed or are considering it, keep my experience in mind. Thankfully the black POR15 base coat I painted the chassis with is very resistant to brake fluid. But by the time I realized the reservoir was leaking again, the white urethane top coat had completely bubbled up on the inner fender and all across the top of the frame rail. The paint wiped right off, leaving the POR15 exposed under it so it looks like crap now.

Nigel

Our new D Brinkworth flares are ready

in Body Kits & Paint

Posted

Do you have any pictures of the car from a distance? It's hard to tell from a bunch of close-ups if they compliment the overall style of the car. Also, what about wheel and tire specs that work without rubbing?

Nigel