Wedge

-

Posts

551 -

Joined

-

Last visited

-

Days Won

2

Content Type

Profiles

Forums

Blogs

Events

Gallery

Downloads

Store

Posts posted by Wedge

-

-

Lol in Canada Montreal area we are at 5.58 $ a gallon and people are "just" starting to bitch so if you guys think that 4 $ a gallon is alot then ignorance is bliss .

-

I checked out the file the previous owner had and when he had the motor rebuild he had the head sonic tested and rebuild completely so at least i can delete the water passage break up in the head . Im going today to check the thermostat and water pump that were changed in Nov. 2000 maybe ill see something thier . Ill check with a filler gauge if the head and bloc are in spec tolerance .

-

Well ok then , thanks Nick for the advise its very appreciated .

-

One question id like to ask if i put all back together and drive it like a grand'pa will blow again right away or ill be able to drive it around a bit ? My quest is yes but for how long .

-

Sorry took my papers out to be sure and compression is 11,5:1 still Very high . Ok then ill stop putting time on it and start thinking to what i will do . Thank you guys .

-

12:1 compression the previous owner did the work and i used premium ,here max octane is 91 ... Well if i have to put more then 500 $ on it its gonna wait i was goin for the RB swap anyway . Thanks guys .

-

Ok , now im starting to think i F*** it up i thot using a really fine grain sand paper was ok i almost cant tell where i sanded ? And no i dont really know why the Head Gasket blew i suspect the previous owner of reusing the same gasket when he opened it up and since i got high compresson pistons now it made sense it blew ?

And for the torque wrench its just a question of conversion from inch pounds to foot pounds and ill probably just borrow one .

-

Have your head pressure tested first to see if its cracked,usually can be done at the engineering shop and if its not cracked a quick skim will do.Any oil on the pistons when you took the head off? coz if there was you might be in for a set of rings and bearings....chances are you cooked the rings with the blown gasket.Any water in the oil pan or just in the water system(radiator etc.)?

No oil on any piston but i had water in the oil pan . I Flushed the coolant and the oil yesterday . The coolant was fine no oil anywhere . I cleaned the head and bloc the best i could to remove the old gasket took a 800 grit sand paper to get the very hard stuff out but the gasket remover spray was perfect . I only sanded the part where the gasket blew on the head and the bloc cuz the gasket was litterally cooked their .

Here are yesterdays pictures .

clean bloc

New gasket on bloc

Head back on the bloc

I had to stop there because my torque wrench wasnt strong enough it stops at 210 inch pounds and i need 648 (+) inch pounds to torque the head .

-

I would advise to get the Urethane one it has a way longer life span and it doesnt crac . My 2 cents

-

Thank you , Tom i didnt thought of that ! it makes prefect sense .

-

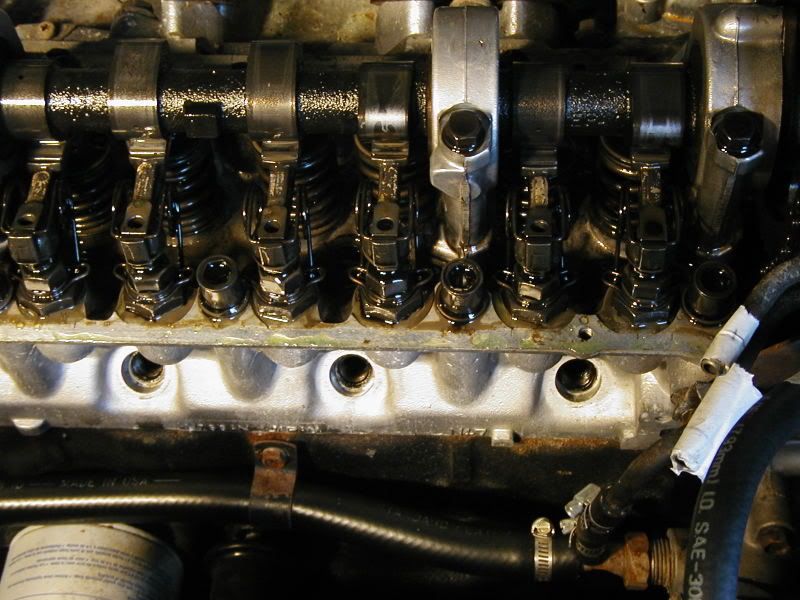

Finally took the head off this afternoon . The break in the gasket was at cyl 3 and its just a small tear . The not too funny thing tho is on the head side it looks like their is less carbon (black stuff) in cyl 3 chamber ? It was abit cleaner then the 5 others ? Does this tell me my injector is working proprally ?

Here are the pictures

Cylinder 6 was filled with prestone

picture off the head off

I had some kind of grim on the exhaust port and head on cyl 3 & 4

Do i have oil restrictors on ?

Yes i think so

Ok thats it if you spotted something i didnt please tell me !

-

Well its not opened yet so i may have other surprises but like Golum said and you can see on the first pictures their is coolant in the head i might have splashed in the intake plenum other then that i dont know what it could be i checked the inside of my intake plenum and it look like it doesnt have any coolant in it only the normal gunk the EGR makes . But when the gasket blew i remeber that when i opened the hood something splashed on the hood through the breather on the intake end couldnt tell if it was coolant or oil .

-

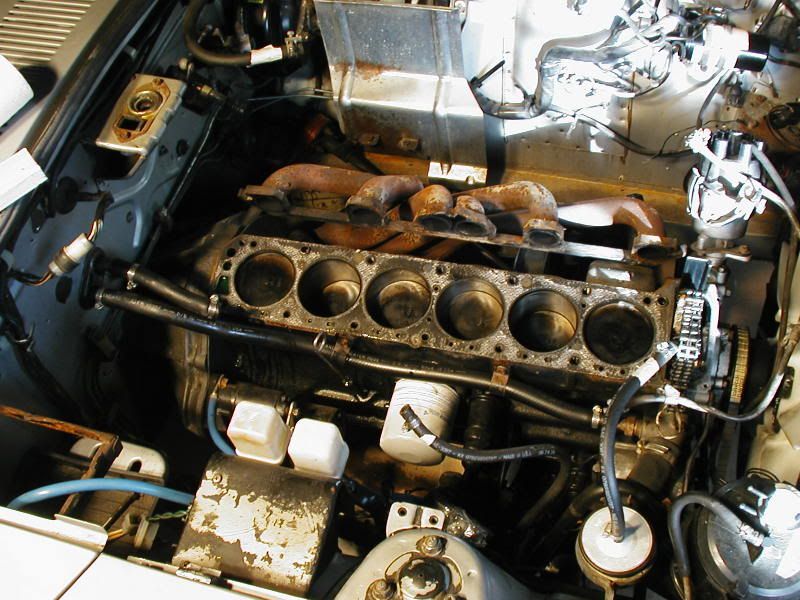

Yesterday Thursday 10 , i finally was able to take off the intake plenum and header . Let me start by telling you its a PITA when the motor is still in the car ! I am a big guy so i had to bend my arms in shapes i never thought was possible to get acces to the bolts but at least a the good part was that the bolt weren't rusted nor jammed . So here are the pics and ill follow with a quick question .

I broke some hoses i forgot to take off .

My question is The TDC in the manual isnt written in way that i understand it they say that a bright chin link reprensent TDC but i have 2 ? one with wrinting on it and that doesnt in both my book haynes and the FSM they dont say at wich mark they need it i got dots 1 2 3 on the cam sprocket and does it need to be on top or 45 degree to the right when i opened it up the silver link with writings was at 45 degree to the right and had dot 3 under it i wish i couldve taken a picture but i played with it i forgot to take a picture . I hope my question is clear if not tell me hehe .

-

Thank you guys ill update with pictures !

-

Thank you very much ! Thats what i did i cut the ring then cut the tube with a knife i may have to clean them they got durt in the tiny filters . I just took a picture injector 1 has rust on the barbs can i clean it or i need a new injector ?

-

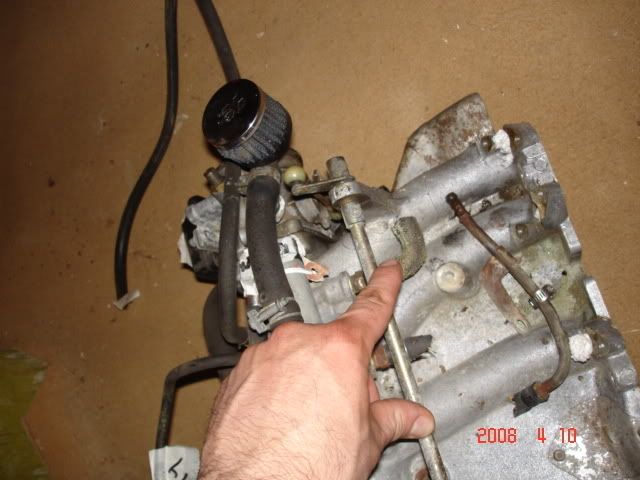

Hello all , as the title says i need some help top hook back my inj. i got a L28e and the inj. are 280z green units . I had to cut the lines so i just want to know if i can buy the metal ring at the bottom of the injector or can i just use a normal clamp .

metal ring pointed by pencil

can i use those type of clamps

i checked my FSM but they dont show anything about that installation .

Thanks for the help

-

How much do the Ebay unit flow compare to the treadstone one should be your question . Take the best flowing unit .

I just checked both unit and the ebay one that Jeffer has say they have 0.2 psi pressure drop that is great efficency but i doubt those numbers since treadstone being a well know companie has a 1.5psi drop ... im wondering who say the truth ?

-

Well yesterday and this afternoon i got some time to start disabling my Z to chabge the head gasket . I disconected everything and tag everything too ready to be lifted off with both manifolds on . Took a couple pictures .

As soon as i took the bolts off and pry the cover to lift it up i saw coolant coming out .

Then i took the cover off and found lots of water and oil .

And i stoped their for today took off the fule rail to , that bugger was stuck

had to cut the fuel lines . I got 2 bolts too that shred on me so ill need to find a way to take them out . Ill update more as i go along with this .

had to cut the fuel lines . I got 2 bolts too that shred on me so ill need to find a way to take them out . Ill update more as i go along with this . -

Happy B-Day Phil !

-

It was a dumb attempt to hide the plate lol what a dumb ass BTW its supposedly on CTV news lol

-

Biggest attention getter thread ever its EDIT: fun ! checking the 18 pages their are about to catch the dumb ass as i write this !

http://forums.beyond.ca/showthread.php?threadid=212943&perpage=40&highlight=&pagenumber=1

-

Great work on the bar but grind those welds a little to make it cleaner . BTW Monkey i love TIG welds they look so good .

-

Holy ♥♥♥♥. I dont even want to imagine how much that cage weighs LOL. Thats gotta be like 200lbs worth of steel!

I was thinking the same thing ! But as you wrote if its not a problem for you good job !

-

Boozt3d , how is the response on that setup laggy or highly responsive ? I guess its laggy but im still asking .

Gas prices are crazy! turbo biodiesel?

in Nissan L6 Forum

Posted

^^ Farmers here where i live uses heating oil in Tractors and other deisel farming engines ! works great and is real cheap .