-

Posts

346 -

Joined

-

Last visited

-

Days Won

17

markrolston@mac.com last won the day on January 4 2023

markrolston@mac.com had the most liked content!

About markrolston@mac.com

- Birthday 04/06/1969

Contact Methods

-

Website URL

http://www.rolston.me/NewSite/Z-car.html

Profile Information

-

Gender

Male

-

Location

Austin, Texas

-

Interests

https://www.youtube.com/feed/my_videos

Recent Profile Visitors

The recent visitors block is disabled and is not being shown to other users.

markrolston@mac.com's Achievements

-

Progress on my insane VQ35HR 240Z project

markrolston@mac.com replied to markrolston@mac.com's topic in Nissan V6 Forum

For the most part I've just been driving the car on the track, working out the kinks, and getting used to the car's particular dynamics. The bosch ABS is a game-changer in terms of keeping up with modern cars. It's easy to make any car fast but it's a real art-form to get it to stop. I did finally get around to working on the new splitter. And I started on a new project to create some "race-fenders"- essentially some fenders to pop-on for track events that relieve a lot of front-end air pressure. Since the body is CF over a tube frame it's easy to swap these particular panels out. -

Progress on my insane VQ35HR 240Z project

markrolston@mac.com replied to markrolston@mac.com's topic in Nissan V6 Forum

ABS is working. Really nice to have on track. I'll really get to test it out at COTA on July 15th. I'm now working on a track specific front splitter. The original is fine for street use but the car has some front end lift at speed I'd like to cure. So I'm working with some Klegicell structural foam, plywood, and carbon fiber to make a splitter with some 3D features. I'll also model and print some new canards to fit the new form. The shape is a best-guess from reading/watching as much as I can about the subject along with a little aesthetic constraint. Right now the shape is just getting worked out and then I'll apply a finishing layer of carbon. -

Progress on my insane VQ35HR 240Z project

markrolston@mac.com replied to markrolston@mac.com's topic in Nissan V6 Forum

here are a few images. The dashboard was originally a matte black fiberglass repro and we covered it with carbon fiber. -

Progress on my insane VQ35HR 240Z project

markrolston@mac.com replied to markrolston@mac.com's topic in Nissan V6 Forum

thanks. I'll report back how it feels. This one is new so I'm not worried about bent parts, but a good feel and no slack will be important. -

Progress on my insane VQ35HR 240Z project

markrolston@mac.com replied to markrolston@mac.com's topic in Nissan V6 Forum

dward steering rack. They will custom build to your specs or you can use one of many pre-built setups. If you're not using electric power steering their servo allows you to change the force level of the assist but doesn't have any production car damping. Jon went this route on his car. Awesome news on the Bosch motorsports ABS. Totally jealous of that purchase. Please do share- what's not nice about the Coleman racks? They were one we found that fit and had a lot of options for steering ratio. Certainly the hardware looks pretty robust in hand. I think we looked at Woodward and something didn't work out. I can't recall atm. Also, not going to make it to Zcon. Will try and make it to Znationals though. -

Progress on my insane VQ35HR 240Z project

markrolston@mac.com replied to markrolston@mac.com's topic in Nissan V6 Forum

Activity here may slow down quite a bit since the car is mostly finished. However, I am doing small bits of work to refine the car. The original steering rack was one I bought from Morrison and it is really set up for big hotrods. It's too slow. So I bought one that allows for custom ratios. This is a much faster ratio so I can do full turns without taking my hands off the wheel. Also, Andris, who builds race cars at the shop had a 4th gen Bosch motorsports ABS kit available that he had pulled from a car so we are installing it into the car. True motorsports ABS is a game-changer. And a few changes to oil breather and fuel venting exhaust plumbing will tidy things up. Then lastly I started some early work mapping out a more aggressive front splitter for the track. -

Progress on my insane VQ35HR 240Z project

markrolston@mac.com replied to markrolston@mac.com's topic in Nissan V6 Forum

sorry. did not make that event. But just ran COTA on 12/19 and had a great time. Car ran great. I did take it a bit easy just to get through the day without any surprises. I posted a video of the last session. My brother rode along, getting to experience the track for the first time. https://www.youtube.com/watch?v=RKw4UNuSOoM -

Progress on my insane VQ35HR 240Z project

markrolston@mac.com replied to markrolston@mac.com's topic in Nissan V6 Forum

Use painters plastic sheets to protect everything. Even then it’s super messy. But it’s so cool to fab this way. I recall someone building a full custom dash by using expanding foam to make a form then shaving it down, -

Progress on my insane VQ35HR 240Z project

markrolston@mac.com replied to markrolston@mac.com's topic in Nissan V6 Forum

I took the car to Zcon in Colorado Springs a few weeks ago. Nice to see so many z-cars in one place. While I was there Larry Chen did a quick video about the car. It was cool to do a complete walkthrough of the build. -

Progress on my insane VQ35HR 240Z project

markrolston@mac.com replied to markrolston@mac.com's topic in Nissan V6 Forum

Took one last picture before loading the car up tomorrow. Looking forward to Zcon, especially getting some track time now that the car feels sorted. -

Progress on my insane VQ35HR 240Z project

markrolston@mac.com replied to markrolston@mac.com's topic in Nissan V6 Forum

-

Progress on my insane VQ35HR 240Z project

markrolston@mac.com replied to markrolston@mac.com's topic in Nissan V6 Forum

extraction: hood vents and the fact that the entire front end is just a tube frame. If that doesn't do it then down the line I'll put in some side vents and wheel well vents. But at the moment, I'm confident that basic shielding of the turbos will do the trick. -

Progress on my insane VQ35HR 240Z project

markrolston@mac.com replied to markrolston@mac.com's topic in Nissan V6 Forum

I got some serious track time last week. It turns out the turbos and downpipes create some serious heat on the hood, despite the open space in the engine bay. I'm going to have to wrap them and come up with a nice shield. Too bad since it looked cool uncovered. Anyone going to Zcon in Colorado Springs this coming August? I'm trailering the car up there now that it's more or less finished. -

Progress on my insane VQ35HR 240Z project

markrolston@mac.com replied to markrolston@mac.com's topic in Nissan V6 Forum

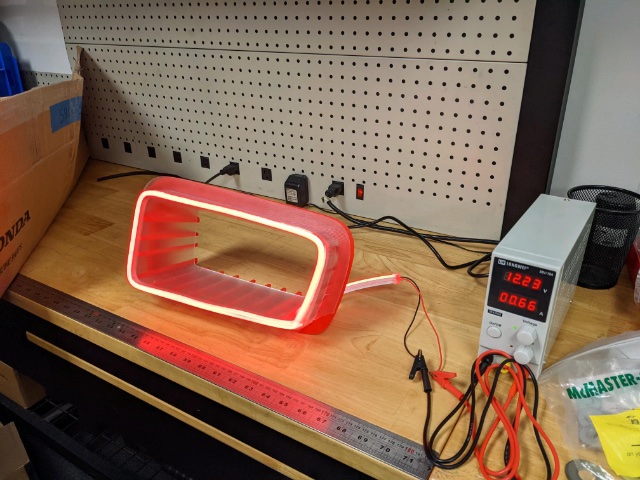

Still working on the lights. Rest of car is done. Going to make some videos soon to walk through the build. Also just registered to bring both Z's to the August Zcon in Colorado Springs. Should be fun. -

Progress on my insane VQ35HR 240Z project

markrolston@mac.com replied to markrolston@mac.com's topic in Nissan V6 Forum

thanks for the advice. I'll certainly do some testing first. Anything I do will first need to be subtle enough to not force a drastic change in the classic form of the car. I'm trying to tread a narrow path between modern tech and an old-school car.