-

Posts

270 -

Joined

-

Last visited

-

Days Won

2

Content Type

Profiles

Forums

Blogs

Events

Gallery

Downloads

Store

Everything posted by wfritts911

-

Dropped the parts off at the powder coater today. He said they should be done on Tuesday of next week. If I can get them Tuesday I am going to try and have them packed up and ship either Tuesday or Wednesday morning that way I don't have to wait til after thanksgiving. I will be sending PM's out to those getting one of these sets sometime today, got tired last night lol. -Will

-

Well I was finally able to get my welder to finish everything up. I am going to run taps through all the holes to ensure all the holes are good after welding. I also have to clean up the mustache bars, the aluminum sheet had sat on a shelf for a while, so its a bit dirty. The burrs you see on the aluminum spacers will also be cleaned up. As soon as I start to get payments I will order all the bolts for the swap, you shouldn't need anything else to bolt this together other than the parts listed. Its pretty late now but I plan on getting everything ready to go to the powder coater tomorrow morning. Their lead time is 2-3 days and they only operate Monday-Thursday(They have it figured out). So It will probably be Monday or Tuesday before I get parts back. Then I will package everything up and ship them out. At this time I would like everyone to send payments in full for everything other than shipping, as stated before you will pay true shipping costs plus a small fee for packaging materials. I will be PM'ing those getting one of these first 5 swaps the actual amount you need to Paypal me. Now enough talk. Some of them are repeats, but this is everything other than bolts. I will be making "instructions" showing which bolts go where and what each piece is that I will be emailing out. Thanks for being so patient guys, I know this has been a long drawn out process, but I think everyone will be satisfied with the results. I hope it goes without saying that if you have any problems with fitment or quality when you get the parts to let me know ASAP. I want to ensure everyone is satisfied and the parts fit as they should. I will post pictures of the parts powder coated once I get them back and will post pictures of packaged boxes as well. -Will

-

Well my welder worked 101 hours last week...so needless to say he didn't get a chance to weld up any of my stuff. I talked to him today and he should be able to weld everything up tomorrow afternoon. He had some family stuff he had to do today. So hopefully he can get them welded up tomorrow. Once again I apoligze for the hold up here at the end, I want this stuff done as bad as y'all do I promise lol. As far as the cobra calipers/rotors go, does anyone have dimensions on the rotor/caliper for the cobra stuff? Can you get the cobra stuff at Autozone(Or other parts stores)? They say they have a "cobra" one, but is it really a cobra one? It looks the same as the non-cobras. If I can get one from a parts store to measure I might be able to make something happen. Or if someone wants to send me a caliper/bracket that would work too. -Will

-

No problem man, I could see how they don't seem like part numbers. The individual bearings have normal looking part numbers, but when you get the race and bearing in a set, that's how they are called out. From the sounds of it I will need to make a couple more sets of these. I only have 1 set at the moment. -Will

-

Are you comparing my axle swap to Rome? I'll take that as a compliment. But seriously, the parts are turning out really nice and I hope everyone will be more than satisfied with them. -Will

-

Joined the wheels-up club

wfritts911 replied to RebekahsZ's topic in Gen III & IV Chevy V8Z Tech Board

Just quit being a sissy and launch harder! I bet you won't bog with a 6k launch! We will fix your broken axle(s) afterwards. Seriously though, pretty awesome. Texis300 needs to hurry up and get his car running, that way I can at least say my parts are pulling the wheels off the ground haha. Looking good though, keep it up. -Will -

Well my welder is still getting overworked. Been working 14hr+ days since Monday...hard to convince him to do any welding when he gets home. Powder coating place said a lead time of 2-3 days. Sorry for the hold up guys, so close and getting held up by an hours worth of welding. -Will

-

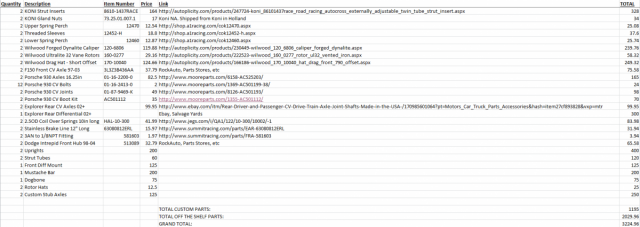

Guys, I just realized I posted the parts list on the first post, did y'all see it? The bearing part numbers should be the same as the Datsun front bearings as well. But the part numbers are SET 2 and SET 6 for the outer and inner bearing sets, respectively. The national seal part number is 340823. Please see the attached picture in the original post, it details out all the parts needed, vendors, and pricing. Sorry I was late getting back to you on this, been going from 6AM to about 2AM for several days straight, and tonight will be no different. Busy, busy, busy -Will

-

-

Got the rotor hats bored out to fit the hubs last night. You can see where I had to open them up. -Will

-

-

Ok so everything is pretty much done other than some finish welding on the axle flanges. My welder was going to finish tonight, but got held up with a last minute job at work so he is working pretty late tonight. Finished the strut tubes up Sunday night. Will be boring the rotor hats out tonight, had to get a new cutter insert that I couldn't get last night. Pretty much waiting on my welder to finish up which will hopefully be tomorrow, and I'll be dropping everything off at the powder coater. I will post some pictures shortly. -Will

-

-

-

Got the stub axles ready to weld. Uprights just need one small portion tig welded. Strut tubes are pretty much the only thing left to fab. I'll get some more pictures of uprights and everything else tonight. Finally got a new phone

-

Those of you buying one of these first 5 setups, check your PM's. As for updates, I gave the uprights and front diff mounts to my welder last night, he will hopefully get them knocked out tonight. Mustache bars just need the mounts drilled and tapped. I was going to do them today but I've got a lab report due tomorrow that I'm going to have to work on instead, but I might squeeze them in if I can. I have two axle flanges done but had to let someone else use the CNC so I wasn't able to make any more. Hopefully will be able to get on it this weekend to finish them up. Then its just a matter of getting the welded on. Will be finishing up the strut tubes this weekend, getting those welded this weekend as well. I purchased one Koni Yellow to use for mockup to ensure everything is 100% good again. I won't need it once I mock everything up though. If anyone is willing to purchase it from me that would be great, I'd knock a little off the new price and can send it with the rest of the goods. Still no pictures as my phone is inoperable and I haven't got a chance to dig the camera out of whatever box its hiding in. -Will

-

They look like they will work really easy if they are long enough. I had a couple pictures of what I plan on doing on my phone, but its broke now. Haven't had a chance to mock them up on the car yet, but I think they will be pretty easy to make work

-

Well phones been broken for a couple days so I don't have any pictures, but I have 8/10 uprights tack welded up ready for my welder to burn them up when he gets a chance. Other 2 will be getting tacked up today. The front diff mounts are tacked up as well. Had some hold ups with the stub axle flanges, the CNC mill's drawbar was missing a few threads on the bottom so it ended up dropping a collet with a carbide end mill out at ~3500 rpm . Hoping to get it fixed ASAP and get those made. -Will

-

Well you would only actually have to add 2 holes now, since you already have 2 directly across from each other. That is interesting though, I bought my hubs from RockAuto, they were one of the cheaper hubs they sell and they only had 5 holes. Interesting that the Timkens have 10 holes in them. Possibly try to return them and purchase some cheaper hubs. -Will

-

Sorry if I was confusion before, I would be taking material off of the caliper mounts, not the rotor hat. Yes .040 off the .25 thick hat is a little sketchy. I would be taking .040 off of the .500 thick backing plate, no big deal except for the extra labor. I think that is probably the best sure-fire way to make sure everything works. $273 is definitely not worth it, I can take some off the backing plate for significantly less than that and it will be perfect. Don't worry about the hat, we will take care of that. Try and see if you can find a local shop to redrill the hubs, that is the only part I would rather not handle. -Will

-

Well you can't shim the caliper. You would have to shim the rotor off the hat, which I suppose you could do. I guess I just don't like the thought of spacers. The caliper bolts to the back side of the backing plate, which means if you shim it, it makes the problem worse. Caliper shims would work fine the 5 lug hat to center it up perfectly, but its not needed. -Will

-

As far as staying 4 lug goes, the wilwood hat #170-6996 has a .73 offset, this is one of the only 4x4.5 bolt pattern hats they have, and its pretty close. I am willing to bet the caliper will be able to take this much misalignment in the pistons and everything will be fine. This would mean that the only thing needed to stay 4 lug would be purchasing this hat and having the hubs redrilled. With that in mind, I can face off the backside of the rotor mounting surface .040 to make the caliper and rotor be centered on each other. I could do this for an extra 20 bucks or so. This would ensure there would be no problems. I will be carrying the rest of this conversation to PM with the people that I know are staying 4 lug, but anyone else interested in staying 4 lug this is the solution. Please PM me if you would like to pursue. If you are trying to stay 4 lug, send me (2) of Wilwood #170-6996 hats. And we will figure out a solution. -Will

-

-

Ok, got busy with school yesterday so I haven't had a chance to check the parts list yet, will be getting it done and repost it after dinner in a bit. As far as the rotor hats, the one I listed is good and works for a 5 lug setup. I will check tonight on a 4 lug hat to see if there is an off the shelf one which will work. I have believe I have everyone's axles except one persons. I bet that drivetrain place is wondering why there has been a sudden spike in explorer axle sales lol. Will hopefully start getting flanges cut tomorrow and can start getting things welded up this weekend. My front door on Wednesday. Another set of axles showed up today. With some luck I'm hoping to have things ready to ship out next Friday, but that might get held up by the powder coating place. -Will