-

Posts

270 -

Joined

-

Last visited

-

Days Won

2

Content Type

Profiles

Forums

Blogs

Events

Gallery

Downloads

Store

Everything posted by wfritts911

-

When I said ultimate IRS setup, I was refering to strength of the drivetrain components. My bad for any confusion, but when you start to blow drivetrain components up, this setup is the best. But yes, doing away with the struts I suppose would lead to the actual "ultimate" IRS setup. When you start selling those I will retract my "ultimate" title and you can have it The glory of this setup is the axle bars and both CV joints are off the shelf components. No custom axle bars that run 500 dollars plus. You could probably buy my whole upright setup and sell what you have and be cheaper than trying to find someone to make a custom axle bar to mate the nissan stuff to the porsche stuff. And then when you break that custom axle bar you are out a lot of money. My axle bars cost 220 a PAIR for chromoly axles. You can pick these up from any number of buggy/VW stores online. And if the chromoly stuff isn't good enough, 300M bars are under 500 bucks a PAIR I believe. My outer CV you can get brand new, from any parts store(They carry them in stock), for ~50 bucks. Inner CV is a very common porsche 930 unit. Parts stores stock the hub incase the bearings ever go bad. Coil over parts are off the shelf from A1 racing. I am also willing to bet the F150 outer CV is bigger and stronger than the Q45 stuff, and MUCH easier to find. -Will

-

I debated the front mount a LOT. I mean a LOT. There really isn't another good way to make it bolt on and be simple. Sean will be putting this setup through the works, and if there is a problem with it, I will correct it. If it was me, I would run a couple of weld beads along the tunnel and the mount, on the front side of the mount. It sits in the same location as the RT mount does, and should never need to come out. The diff can come in and out without removing the mount. Running a couple welds and the front part of the mount makes them "easy" to get to if it did ever need to come out. You could put a couple on the rear part as well, but its a little harder to get to I think. The mount I have been running only bolted to one side of the tunnel, and I welded it in. Granted I'm not making 600rwp nor did I ever get a chance to put some slicks on, but never had an issue with it. I will be coming up with pricing in the next couple days hopefully. And I would like to have some sets done before the end of the month(So I can take them to Z Fest up in Branson, MO), but that might not happen. Also will be working on a 5 lug front setup with some big brakes for Texis300 in the very near future, looking at either 6 piston or 4 piston calipers, 13ish inch rotor, z31 hubs probably. Planning on the only custom part being a caliper bracket and maybe a small spacer, so it should be reasonably priced -Will

-

Also please excuse the flux core tack welds, my MIG bottle wouldn't fit in the Datsun -Will

-

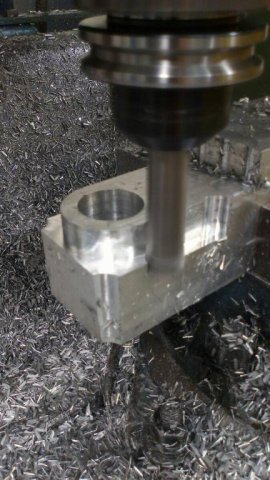

Sorry guys, fell off the map for a bit while I finished up with school. Got everything almost finished up yesterday. Will be mailing out parts Tuesday unless something happens. Front diff mount is tacked up just needs a jig built for it and finished welded. Uprights are fully welded. Strut tubes are tacked up, just need finish welded. Mustache bar is good to go except I have to shave a bit off the mounts to move the differential further towards the front by a hair. Stub axle adapters are fully welded. But enough talk, here are some real photos of what is going on. Mustache Bar Front Diff Mount Strut Tube Strut Tube Loaded Complete Upright Don't have any pictures of this exact setups axles, but mine are pretty much the same thing, but please excuse the crude other parts, I didn't have the fancy tools I have at my disposal back then. The second picture shows the F150 outer CV joint with the stock F150 axle bar still in it(Which is quite short). The first picture shows it on the car with the chromoly porsche 930 axle and the duct tape clips holding it in place hehe. Hopefully this clears stuff up and shows that this really is happening. This setup uses the Koni 8610-1437race strut insert. Off the shelf coil over pieces, stock top hat. Camber can be adjusted in the upright. Front diff mount similar to the RT mount. The lower piece captures it on the top and bottom(The lower brace is missing a piece of metal to go on the other side of the circle piece). 3/16 plate, waterjet and broke. Mustache bar is 6061 that is waterjet. The mount pieces use poly bushings and are CNC machined. Now that I'm done with school, I will have a lot more time to do work. Will be ordering metal sometime this week hopefully for 10 sets. Pricing to come this weekend hopefully. Questions/Comments/Criticism is welcome. -Will

-

All is ok as far as I can tell. Think some sheet metal got blown off my Dad's barn, but that's about it. Wish I could say the same thing for the rest of Vilonia, looks like they got hit pretty hard again. More damage than a couple years ago it seems. -Will

-

Here is a really awful picture of me rolling down a very steep drop off in the Suspension and Traction run. Dented to top roll bar and had to section it out an splice in a new one in the middle of a dust storm. Also here is the mustache bar fresh off the waterjet -Will

-

Alright, I apologize for not getting pictures like I said I would. Im enrolled in 17 hours in a Mechanical Engineering program, work 23+ hours a week, have a girlfriend with a baby, and was busting ass trying to get the Baja SAE car ready last weekend. Then I spent all last week destroying said Baja SAE car in the middle of a dust storm in El Paso, TX. I had hoped to get everything ready before I left, but the waterjet up at work was booked up and wasn't able to get the final diff mounts cut. I'm way to busy I'll admit, I beyond overbooked myself the past several weeks. I'll also admit I am the absolute worst at taking photos. I always intend to document my projects well, and then I get my hands dirty and in the zone, and I just build stuff and never stop to take pictures. Forgive me for prioritizing designing and building the parts vs spending time trying to market them. If I was better at marketing than engineering you all probably wouldn't want to buy my products, fortunately it's the other way around. Please be patient with me while I get this setup rolling, I was not ready to make a thread but it got brought up in a thread over on the V8 forums so I figured I better come clean over here. I was hoping to be done with it by now, but set backs happened. But I will post up what I have with me, sorry for letting everyone down and then running off out of town for a week. The setup is real and I have been running it for ~9 months, but like I said, never really photographed my setup when I built it. Here is the upright setup in the jig before it got tig welded CNC'ing the mustache bar mounting piece from some 6061 Aluminum This is the stub axle after it was tig welded. I CNC the flange and then weld it on the the stock stub axle after the CV cage area is cut off Here is an extremely awful picture of the mustache bar on the car holding the differential up Here is the brake setup on the base plate of the upright. Wilwood 4 piston calipers with 2 piece rotors. It's nice! I've got a test that I have to makeup tomorrow that I will be studying for late tonight. Hopefully I can get the new mustache bar and the front mount cutout today or tomorrow and will have a chance to get them done before this weekend. The uprights are welded up I just have to make the strut tubes. Hopefully this will hold you all over for a bit, Sean has been more than patient with me while I redo this setup. When I was doing the swap to my car i was pressed for time as summer break was ending and didn't quite do it like I should have, so I am redoing some things now.

-

Nice deal on the trak-lok. Only thing is, the SRA 8.8 differentials are slightly different compared to the IRS 8.8s. The difference being the way the axles go in. The IRS stuff uses circlips similar to the R200, the solid axle uses old fashioned c-clips. If you snap IRS axles in a SRA differential, you will have an incredibly hard time getting them out(Just getting them out of an actual IRS diff is hard). The spider gears need a bevel on the side of them to help compress the circlip, the easy way would be just to have a machine shop bevel them, and is probably worth it if you get a good deal on a SRA diff. Or at least this is what the internet has told me. Bout to head over to the car to get some work done. Uprights and stub axle adapters were fully tig welded on Friday. Rear mustache bar should be done, just need to mock up for fitment. Will try to get some photos posted up later tonight -Will

-

So as already stated, Upright is probably the proper term, so I will use that. Sorry for any confusion caused, I think I've been calling the upright multiple different names throughout this swap lol. My 6061 for the mustache bar came in today, so hopefully I will get that finished up tonight and will post pictures. -Will

-

Keith, the 8.8 uses a 31 spline inner stub axle. Cobra guys put a lot of power through these things. The Intrepid hub and the F150 outer CV are 33 spline. Sorry for the confusion. I haven't looked too in depth, but I don't recall ever seeing a broken 31 spline 8.8 stub, maybe SunnyZ can chime in on that? -Will

-

Not sure where I said "strut top" at, but I believe Jon has it correct. When I refer to strut tower, I am talking about the whole assembly that the hub and strut will bolt to. The LCA will bolt to the strut tower. The dodge intrepid hub, which is a standard bolt on hub like many newer cars, will bolt to the strut tower. A bolt on strut tube which houses the insert will bolt to the strut tower/backing plate. I have attached a picture of the fabricated strut tower with the strut tube bolted to it. Please excuse the awful picture and rusty metal. The large hole in the middle is where the intrepid hub sits. The to bolt holes on the left side hold the Wilwood 4 piston caliper. The strut tube is bolted on in this photo. For future discussions, I will refer to this whole assembly as the strut tower. This assembly without the strut tube bolted to it I will call the backing plate. And the strut tube houses the strut insert(Koni single adjustables in this case). These parts along with the stub axles that spline into the diff will be getting welded up tomorrow, the rear mustache bar will be on the CNC tomorrow as well, along with hopefully finishing up the strut tubes. Hopefully I will be able to cut a final front diff mount on the water jet Friday and get it finish welded as well. Then I will bolt everything up and take pictures of the final products on and off the car, this set will be getting power coated by the owner so it will all be bare metal, but future pieces will all be coated. I will be gone from tuesday til monday of next week for an SAE Mini Baja race in El Paso, so no work will get done during that time. But hopefully by the time I come back Texis300 will have recieved the parts and had time to put them on his car and post up on here about how nothing fits and its the worst setup around hehehe. But seriously, once I get the ok from him that everything works on his car as well, then I will begin ordering material and start building 10 sets. The only tricky part to this setup is the F150 CV Axles you get from the parts store, the axle shaft is attached to the outer CV joint by a circlip, which is on the end of the axle. This clip compresses through the splined "star" and uncompresses on the other side. My sources said that you can just pound the axle out and the clip will pop through. I spent quite some time trying that before cutting the axle bar off right outside the cv joint, so the cv could be rotated far enough so the balls would fall out. Once I got the star and small axle piece out, I hammered on the axle from the back side and managed to get it through, but it took a BFH. I've got another set of axles sitting on the floor that I will be assembling for Texis, and maybe these will work easier, but mine would not pop out to save my life. I will be assembling Texis's axles for him, and may or may not do that for other setups. More photos will be coming this weekend. -Will

-

^ Dat260, that was the only requirement for this setup. Strong as hell, and not expensive. SeatleJester, The custom strut tower is similar to the TechnoToyTuning strut tower they sell for the R230 swap. Its is a completely fabricated strut that the Intrepid hub bolts too. The strut tube is fabricated as well and then bolts on and houses a stock style strut insert. If by driveline angles you mean the cv axles, they are good. Then again the 930 CV's have no problem running at 20+ degrees and the F150 outer can do 40+. School, work, this project, and life have me crazy busy lately. I got the thread mill to thread the end of the strut tubes in yesterday, so will hopefully get the complete strut tower coil overs and all assembled tomorrow probably, and will post pictures. Won't get the aluminum in for the rear mustache bar til thursday or so probably, so I will try and post pictures of the diff mounted in the car this weekend. Sean, I will hopefully be mailing stuff off monday if everything goes swell, its so close. By the way, I'm extremely jealous of these Wilwoods and Koni's, stuff is nice! -Will

-

Here is a parts list, for some reason it wouldn't let me upload an excel file so yal get a screenshot instead. This is pretty accurate, but a couple part numbers have changed I think -Will

-

Alright I'll come clean. I have been working on what I will call the best IRS swap for S30s. I have been running my setup for ~9 months now without a single issue. This eliminates every weak link that I know of, gives plenty of differential/gear options, uses minimal custom parts, and will hold a LOT of power. So on to the details, starting from the inside going out towards the wheel: 8.8 IRS differential from 02-05 Explorer/Mountaineer. Woooo! Gear and differential options! 8.8 parts are plentiful and cheap. Custom stub shaft I produce that allows a porsche 930 CV Joint to bolt on. Driveshaft Shop also sells the same shaft at ~250 a piece. 31 Spline. Porsche 930 CV Joint Porsche 930 Axle. Chromoly off the shelf axles run 220 a pair! 97-03ish F150 Front CV axle OUTER CV Joint. Heres the secret, this CV joint uses the same splines as the porsche 930 axle. It splines into the hub with a 33 spline shaft. This thing is beefy. Definitely no stub shaft failures happening here. Parts stores stock the axles. 2000ish Dodge Intrepid Front Hub. Here is the even bigger secret. This hub uses the same 33 splines as the F150 front CV axle. Has a 5x4.5 bolt pattern(Easily redrilled to 4x4.5 for those looking to stay with stock 4 lug). Parts stores stock these for cheap Custom Strut tower that the Intrepid hub bolts to Wilwood 4 piston calipers, 2 piece rotors. More budget friendly brake setup is in the works, but this is the current setup Now let me go ahead and address the "Man this guy is crazy, that is the most frankenstein setup ever." thought that is in your head. I won't lie, reading of the list sounds frankenstein. Dodge Hubs, F150 outer CV, explorer diff, (My setup uses Honda S2000 rear brakes and makes it worse), etc etc. Yes there are a lot of different parts going on, but they are stocked at parts stores, they are cheap, and they are strong. The only driveline part that is breakable is the 31 spline to 930 CV adapter. I take the stock stub axle and weld on a flange that the 930 CV bolts to. I don't foresee these being an issue, but if they are, the DSS ones are an option, they are just expensive. If the porsche 930 stuff becomes a weak link, they sell 300M CV Joints and axle bars that will definitely not be the weak link. Every other part that is in harms way is an off the shelf part, 930 stuff is very common in the buggy world. Kits will be available soon(Hope its ok to say that here). I will post in the vendor section with prices hopefully within a couple weeks. The custom parts include: Front Differential Mount. Rear Differential Mount. Billet aluminum, similar to what AZC sells. Upright/Dogbone piece(One piece unit connecting the 2 dropdowns to the rear LCA mount). Needed to clear differential mounting points 8.8 to 930 CV Adapter(Requires sourcing explorer rear CV Axles and sending me the stubs, or I can source them for you) Custom strut tower with bolt on strut tube. Similar to the TTT setup they sell for the R230 swap. Small axle spacer(Splines on F150 axle are longer than the Intrepid Hubs) The wilwood rotor hat needs the inside bore turned slightly larger to fit the intrepid hub. Currently working on a better solution for this, but its an easy fix. Driveshaft(Not provided by me) Those are the only custom parts you need. All the coil over parts are off the shelf, off the shelf brakes, off the shelf axle parts, etc. You would need to source an IRS differential from an explorer and the rear cv axles from the same vehicle. I will try to get some pictures posted later, sitting in class right now. Texis300 will be recieving the first set hopefully within a week(Sorry its taking so long bud). He will be making close to 700 wheel I believe and will be putting this setup through some stress for sure. I only make a wee little 350rwhp, so I'm not a good test of this setups capabilities. I don't see Texis300 breaking anything, but thats not say he wont. I will make modification to the setup if he finds a weak link Also, for those thinking they don't need the extra strength of the 8.8 differential. This setup will work the same way with the R200 and a bolt on 930 adapter. That will make the kit cheaper(No differential mounts). It will eliminate every weak link from the axles out, making the new weak link the differential or the differential stub shaft. I know SunnyZ was breaking the Z31 axle stubs, but maybe the stock R200 pieces are stronger? I can't remember if I've ever seen anyone break the stock differential stub shaft. Going with this setup will make the kit very affordable(Not that it isn't with the 8.8, but less custom parts makes it cheaper obviously) Now I will open the floor to questions, comments, etc. Hope I didn't bore anyone with the book I just wrote -Will

-

SunnyZ, That setup Texis posted doesn't have that 29 spline weak link. The stub going through the hub is 33 splines, and its stocked at autozone. Keep your eyes open in the drivetrain section this weekend, and I will unveil the swap, with kits available soon. -Will

-

Oh...i just assumed you were calling an volt meter and ammeter, guess the jokes on me. Never seen a car with an ammeter, but then again I don't own an early S30 which is what they apparently came in. From a brief read, it looks like wiring it like factory makes the main power source from the alternator run through the dash harness and to the gauge. Not a good idea IMHO. Upgrading the wiring never hurt considering its 40 years old. -Will

-

The main power wire for the alternator should just go straight to the battery/starter post. The volt meter can be hooked up to any power source. The LS1 alternator plug is a 1 wire plug that goes to the ECM on 99+ LS1's, or goes to an ignition power with an inline resistor on 98 models. I don't have the stock Datsun voltmeter anymore, but when I did, the alternator wiring never even got close to it. -Will

-

Just for anyone else looking to know, that diff has had about 10k miles behind an LS1/T56 car with a overly strong clutch. Its lasted through 5 broken halfshafts(1 at ~100mph). It also went about 1500 miles in a L28ET car before I got it. I knew the diff leaked, and checked it every once in a while, but it must have got low or it might have spilled some when I pulled it out of the car. It was starting to make some funky, not so good sounding noises. Marbles in a jar, grinding-ish sounds, etc. It got the upgraded washers/bolts when it was new from FlatBlack on this forum who had it behind the L28ET car. It was however a great diff, always spun two as far as I know. It lasted a good amount of dragstrip passes(Always on 275/40R17 street tires though), ~8 autoX events, and ~10k street miles. -Will

-

Damn I don't know what it is with some of Monster's stage 3s. Had a buddy with one that broke the springs as well, he was missing the dowels for the transmission and thought that might have caused it. My stage 3 has over 30k on it, with LOTS of slipping at the track to get good sixty foots, and lots of beating up other drivetrain parts. Granted its all been with 300-350 wheel, not the high numbers like SOME people( Read: SunnyZ) are putting out. Last time I had my transmission apart everything still looked brand new, disc looked great, flywheel and pressure plate looked perfect. -Will

-

Keep in mind the 98 gas tanks are metal, the fuel filler neck is metal as well and not removable, so unless you hack it off and clamp on rubber hose it is definitely not going to work. I'm running a stock 280Z tank with an external walbro 255 and a corvette filter/regulator. Never had any starvation issues that I know of. -Will

-

Drive line clunk caused by T56

wfritts911 replied to matt_w's topic in Gen I & II Chevy V8 Tech Board

My car does the exact same thing. My T56 has a bunch of slop in it as well. Its had the same clunk when going from decel to accel(And vice-versa) ever since the LS1/T56 was in my firebird. Same clunk on 3 different rear end setups, its still there on my 8.8 swap. Most definitely in the tranny. More noticeable in higher gears at low rpm. One of these days I will finally tear down my transmission to rebuild it and hopefully figure out what the issue is and fix it, but that day is a long ways away. Only real downside is shocking the drivetrain on shifts. I think the slop has helped kill a few ujoints. And obviously being extremely annoying and making the car sound like its about to fall apart to other people. -Will -

I think making the stock Bilstein gland nuts work is as easy as any other strut. It just requires welding one more thing. The Bilsteins come with the female and male nut. You just weld the female part to the top of the strut and you're good to go. If you cut the threaded portion off, but don't cut all the way down to the thick portion of the tube, the female nut actually has to be slightly press fit in, helping keep it aligned right. Grind out a little lip in the female nut to let the body fit through. Then the male nut threads into the female nut like a normal setup. Piece of cake if you are competent enough to do your own sectioning. That's on 280Z strut tubes -Will

-

Texas Turbo Tom 240 to LS2/T56/Magnacharger build

wfritts911 replied to texis30O's topic in S30 Series - 240z, 260z, 280z

Didn't realize you had a thread hiding over here in the S30 section, I rarely come over here, too busy hiding in the LSx section. That super charger looks like its ready to kill my axle setup You really should have decided to go auto, then it would have been more than strong enough lol. I'll hopefully be racing next weekend. Once my coil over parts come in Friday, take a short trip up to school, machine some things, and hopefully have it on the ground this weekend if everything goes as planned. Have you decided if you're going to flare the car yet? 315s sure look good! -Will -

Assuming the car is more than a simple bolt on car(i.e. cam, heads, etc), a mail order tune doesn't quite cut it. When it comes to more serious mods like a cam, hoping some guy halfway across the country can get a solid tune without logging or anything is kind of sketchy. I always rag on a lot of my non-LS buddies for doing E-tunes, although theirs at least involves logging and sending that to the tuner, then him changing the tune, and the owner reflashing, then rinse, wash and repeat. Unless I'm mistaken Frost just has the ECU mailed to him, puts a "Hope I got it right the first time" tune on it, and mails it back. As good as he might be, I'm doubting he gets a cammed car anywhere near good the first time around. Just my take on mail order tunes. Good luck finding a proper shop, LS1tech and other LSx forums are definitely the place to ask. -Will