-

Posts

270 -

Joined

-

Last visited

-

Days Won

2

Content Type

Profiles

Forums

Blogs

Events

Gallery

Downloads

Store

Everything posted by wfritts911

-

I deleted the spreadsheet from the 2nd post to avoid confusion, I am trying to finish up some HW tonight and I want to comb through my spreadsheet to ensure everything is 100% accurate before I post it up again. The correct part number for the rotor hat is: Wilwood 170-10040 This hat has an offset of 0.79 inches vs the previously listed hat having an offset of 0.73 inches. Both hats will probably work, but the new one is closer to perfect. I know Pete280Z is planning on going 4 lug instead of 5 lug, which is how this error was found, but is anyone else planning on trying to stay 4 lug? I drilled my hubs for 4 lug when I first did the swap, but it ended up being a PITA to drill the hubs accurately with the equipment I was using. With this in mind, at the current time I don't plan on drilling any hubs, so a local machine shop will need to be used who can tackle the job. This might change if I can come up with a good plan. Once again sorry for the troubles, I should have checked the spreadsheet before I told y'all to order parts from it. Please hold off on ordering anything else until I post an update spreadsheet later tonight or tomorrow. Thanks guys, -Will

-

Well guys, It has come to my attention that the spreadsheet posted in the very beginning has the wrong part number for the rotor hat...the hat listed has an offset of .73 where as the final one I ended up using has an offset of .79. The ideal offset of the hat is .771, but the closest one to that is the .79 hat I chose. I thought I had posted an updated version of the spreadsheet later on but I just looked for it and it appears I didn't. I greatly apologize for any troubles this has caused for the couple people who have ordered hats already. I am about to delete the spreadsheet posted and upload a new updated spreadsheet with the correct info in it. -Will

-

I'm not following what you are talking about? Are you talking about the threaded sleeve that the "JDM" coilovers use to weld onto the cut off stub of the stock strut tube? I like the threaded sleeves to adjust ride height independent of preload/shock travel, but I couldn't find anywhere to buy them. One of the major points I was aiming for was 100% bolt in with no welding. Also from what I have seen(Granted I haven't looked to hard at shock options), most of the s13/14 stuff they are modifying to weld on datsun struts are subpar as far as the shock goes. The Koni was the best shock within budget so thats what I built my setup around. The McKinney, BC, etc stuff doesn't compare as far as quality goes from what I have read, but I could be mistaken. I have a couple people interested in trying to use BC coil-overs with my setup, and I told them I could do it, I would just need the struts to fab up a bracket for. It just complicates the process. -Will

-

Does anyone see a problem with leaving the bottom of all the strut tubes open? Only downside I could see is you can't fill the tube up with some oil, which I'm not 100% what everyones opinions on that practice is. -Will

-

I recruited a guy I go to school with to CAM and machine the axle flange adapters so hopefully we can get all of those cut this week. I was worried I wouldn't have time to get it done, and he needed the money, so I'll let him burn my end mills up for me hehe. I cut Mikellys axle stubs up yesterday so when I get everyones in and get the flanges machined I'm going to try and knock them all out at the same time. Pretty much everything is cutout aside from the mustache bars and a couple of uprights. Hopefully going to start get uprights welded up this week along with the diff mounts. Trying to get this thing going as soon as possible. The only other thing I will need the first 5 to send me is the wilwood rotor hats, but those can wait a bit since all I do is turn the inside out it doesn't take very long to do. But y'all are more than welcome to start sending me those as well. The part number is detailed previously in this thread. Thanks for all the support with this project guys and for sticking with me through the long drawn out process. The light at the end of the tunnel is pretty bright now. -Will

-

I'll just leave this here... There is 5 sets of front diff mounts, rear LCA dropdown, and some upright pieces. There are also some top secret BMW E30 LS1 motor mounts and trans mounts hidden in there(Hint hint for anyone interesed in doing an E30 swap hehe). -Will

-

Alright guys, It appears that the first 5 sets have been claimed unless some people fall through. As previously stated I will give the first 5 buyers a discount rate as long as they stay "in" when I get the kits ready to ship. Judging by the interest now that it is finally going, I will probably try to make 10 sets after I finish these first 5, depends on what my budget looks like. I would like to keep a list going of who is seriously interested for the next batch of sets though, so don't hesitate to send me a PM and get your name on the list. -Will

-

I've got yours Mike, thanks for cleaning them out for me! Also, is anyone planning on running the double adjustable Koni? To where you would need a hole in the bottom of the strut to adjust it? -Will

-

Alright, got killed with school this past week so I just now got the mustache bar and front diff mount mocked up again. Everything looks like it fits good, so I will start cutting out mustache bars and front diff mounts and such on Monday depending on what our Waterjet schedule looks like. With any luck I can recruit some welders for the uprights on Monday as well. All this leaves is the stub axle flange adapters which I will hopefully get on the CNC this week as well. Also have to cut the strut tubes and thread the end of them. Getting pretty close to having this stuff ready though. Those of you seriously interested will need to get some explorer axle stubs to send to me so I can weld the flanges on. You can pick them up for $100 bucks from ebay. http://www.ebay.com/itm/Rear-Driver-and-Passenger-CV-Drive-Train-Axle-Joint-Shafts-Made-in-the-USA-/170985601064?pt=Motors_Car_Truck_Parts_Accessories&hash=item27cf893828&vxp=mtr You can drop ship them to me to save from shipping twice. I will be making 5 sets initially, and I know Mikelly will be getting one of them, those of you seriously interested should send me a PM. I won't be taking any money until parts are ready to ship, but I'd like to know who all wants a set. If I can get 5 buyers before I get everything ready, I will give those 5 a discounted price from the one listed previously in this thread. -Will

-

Got the LCA to Backing Plate pieces cut out today, will get them broke on monday and start getting the uprights welded up. More pictures for proof hehe. -Will

-

I believe you need: http://www.dennysdriveshaft.com/p524_dana_spicer_2_2_1379_large_bolt_pattern_1310_series_flange_y.html This is the link for all of them, I am about 95% sure you need the LARGE bolt pattern yoke, but I will confirm when I get home today. http://www.dennysdriveshaft.com/c161_flange_yokes.html You can get 1310,1330, or 1350 yokes depending on what size ujoints you want to use.

-

As far as the explorer housing goes: - It is easier to find/cheaper - It already comes with the stronger/better cover - I believe the housing is actually stronger than the cobra one - The mustache bar handles the forces that try to roll the diff over, the front diff mount only keeps it from pitching up or down. I think having two mounts in the front could be a bad thing especially if the rear diff mount became loose or something, the front mounts would try to take loads they were never designed for Those are just some thoughts, none of them really matter other than the easier to find/cheaper. Strength is not an issue with either differential. On another note, I'll just leave this here: Production has officially began! This is 7 of 10 "backing plates", will be getting the other 3 cut tomorrow and cutting all the 3/8s plate for the broke brackets to finish up the uprights. Will be mocking everything up this weekend so I can cut the front differential mounts, mustache bars, and everything else on Monday. I plan on getting everything powder coated black unless anyone objects. Will keep y'all posted as things progress, hopefully will start having uprights welded up monday as well. P.S. Sean, when are you going to pay me enough to quit my day job so I can just build cars/cool shit all week for you? -Will

-

Finally got the mustache bar mounts made. Planning on trying to mock everything up tonight or tomorrow, to ensure everything is good. Then I can cut out pretty much everything. Hopefully will be cutting out the uprights this week as well and start getting them welded up since I know they are good to go. See attached pictures. These were the last piece I needed to re-mockup everything after some very minor changes to improve constructability. We are getting closer -Will

-

Hopefully sooner rather than later. Planning on learning to run the waterjet this week so I can cut at night, since getting the current operator to cut stuff for me is like pulling hairs. Hopefully can start cutting out 5 sets this weekend if I'm lucky. -Will

-

This setup uses Dodge intrepid hubs from the early 2000s, not outdated by any means. The reason for that is the F150 outer CV's and the Dodge Intrepid hub are both 33 spline and mate together. I put my kit together trying to use the most OEM parts I could. These hubs are regularly used by sand rail guys doing a setup similar to this. They are plentiful, cheap, stocked at Autozone, and beefy. Plus a mustang hub would make too much sense, its better when an axle swap meant for +500hp uses a hub from a beater sedan like the intrepid lol. Shooting you an email now. -Will

-

Well thats unfortunate. Fortunately I don't think anything to significant had been posted. Will hopefully start cutting out some stuff on monday to try and get this rolling. Aluminum showed up to make mustache bar mounts out of, so hopefully I can get those made ASAP and re-mockup everything to ensure 100% its good. -Will

-

Pfft...that Wake boarding boat you just bought would have bought a lot of Wilwood stuff!

-

The intrepid rotors are pretty deep, they would interfere with the flat plate that the hub bolts to. I looked at a lot of stock rotors trying to find a cheaper option, and found some that would maybe work, but haven't had time to go back and pursue a budget brake setup. -Will

-

I will bet they are lighter than the stock pieces, but I definitely went towards the strong side vs the lighter side. To much liability to risk failure. I will get the weight when I get a chance though. -Will

-

-

I know I've been off the map lately, but its still slowly making its way to production. Sent Texis300 the rest of the parts and updated uprights. He just got everything put on last week and everything appears to fit. All I've got to do is machine some new mustache bar mounts and fit everything up to my car again to make 100% sure a few minor changes are good, then I will roll out 5 sets. I have attached pictures of the new uprights which I think everyone will agree is a much better design. Don't lose hope in me yet, this kit is coming to life slowly. -Will

-

Im not sure why the rotor adapter doesn't come up on wilwood's website. You can search for it on Autoplicity or summit and it comes up though. Wilwood only has a couple of rotor adapters for these style hubs, this one is an 8 bolt flange, the other is some other bolt pattern. Here is a picture with a tape measure of the clearance between the rotor and the ball joint. This is with the ball joint as close to the rotor as it can get, I don't think it ever sees this angle on the car. -Will

-

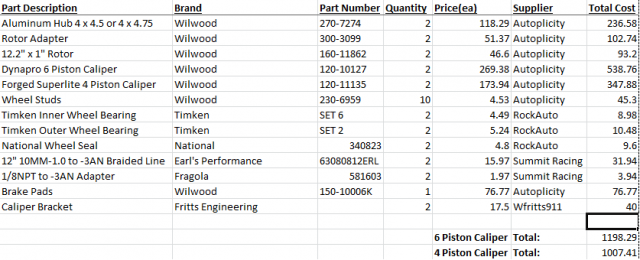

So I've been working on a 5 lug and big brake setup for the front of the Z cars and this is what I've came up with. Everything is an off the shelf component other than the brake caliper bracket that I make. I currently have brackets for the 6 Piston calipers ready to go, haven't made any for the 4 Piston caliper yet. It uses a Wilwood Dynapro 6 Piston caliper, 12.2" x 1.1" rotor, Wilwood aluminum hub drilled for 5x4.5 or 5x4.75. Since everything is off the shelf it makes it a fairly budget friendly swap for people trying to get big brakes and 5 lug. This hub does space the wheel OUT 1/2" from factory. So its not as bad as the 300ZX hub, but it does still space it out farther from factory, which is usually a good thing when trying to find newer/wider wheels. The caliper bracket is made out of 1/2" Thick 6061 Aluminum. It is flat which makes it very budget friendly. Anyways, onto some pictures: Please excuse my extremely rusty parts car strut. You can see this Wilwood hub uses a behind the hub rotor adapter compared to the common hat mount rotors. This adapter is about 100 dollars cheaper than most hat mount adapters. It is currently sitting on the outside of the rotor, but can be flipped around to sit on the inside face instead. I was using some bolts that were too long for mock up so I had to put it on the front face of the rotor. Not pictured is an aluminum center cap for the hub that screws into the hub. These wilwood hubs are drilled for 5 x 4.5(Mustang/Nissan/etc) and 5 x 4.75(Chevy/BMW/etc) bolt pattern. They use thread in studs. They fit the Datsun spindle perfect, no modification to hub needed. The dust shield will need modified or removed to fit these brakes though. I think this is a good budget friendly setup for people looking to go 5 lug and get some big brakes at the same time. These hubs are cheaper than the other aluminum options out there. And I'm not into reselling parts, so you can pick those up from wherever you see fit, Autoplicity tends to be the cheapest place I can find them. Here is the parts list for the setup: Hope I'm not out of line posting this setup here since I'm selling caliper brackets for it. The caliper brackets will run $40 SHIPPED for a pair of them if anyone is interested. I've got a few sets ready to ship now. This includes new bolts for the calipers and brackets. -Will

-

Still looking?

-

About to get the ball rolling on this kit finally. Been pricing materials and coming up with pricing. Right now we are looking at roughly: Aluminum Mustache Bar with bushings and bolts: $200 Uprights (New and improved design from the pictures I have posted): $400 Strut Tubes to go with the uprights, ready to put on aftermarket coil over pieces( Can be setup for Koni's, Bilsteins, or any other strut ): $120 Front Diff Mount: $125 Dog Bone(Rear LCA Mounting point drop down): $75 Axle Adapters(I make flanges and weld them on, Explorer rear axles can be sourced from Ebay for $100 a pair, this price does not include the price of the axles): $250, $350ish by the time you buy the axles Rotor Hat(The center bore needs opened up for the Intrepid Hubs): $25 + Cost of rotor hat Total Cost for custom parts to do the swap: $1195 Now none of these prices are final, and hopefully I don't regret posting these, but I know many of you are interested in what this setup will cost, and this is a rought estimate. The odds are this is pretty close to right, but I won't know for sure until I begin to build them. Some parts may get cheaper, some may get more expensive. Now as far as the front diff mount goes, we will see how this one does, if it ends up being an issue then we will go from there. There isn't really a good way to package a diff mount for these short nose diff, everything ends up acting as a lever. My diff mount that I've been running for the last year only bolts to one side of the tunnel, and I welded it on. If it were me, I would put a couple of stich welds on the front side of this diff mount. The welds would be easy to cut off if for some reason the mount ever needed to come out. But the mount is setup like the RT mount, it isn't in the way of anything, it should never need to come out again. If this mount was welded in, I don't see any issues with it. Even though I'm out of school it seems like I'm still crazy busy, but I am hoping to start making some pieces next week to get this thing rolling. -Will