kijana

Members-

Posts

28 -

Joined

-

Last visited

Content Type

Profiles

Forums

Blogs

Events

Gallery

Downloads

Store

Everything posted by kijana

-

Zentech...........I tried to PM you but "you are not receiving new messages"! ....so I emailed you. Trying PM me again if you didn't receive the email. Thanks.

-

Hello, I broke one of my Hydraulic lifters while clearing them so im searching for one. I can buy one, a pair or the whole set. Please feel free to send me a PM or post here. Thanks.

-

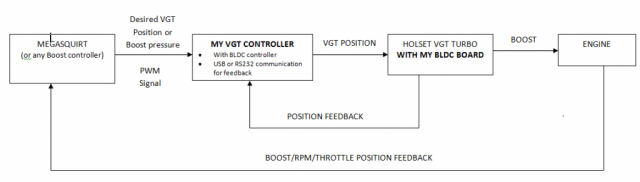

Below is a schematic of how the system works: Please refer to the video link in post 1. I built the electronics myself. The holsets VGT's utilize a BLDC to turn the vanes (through a gear box). My electronics comprise of two boards. 1. My main control board that houses all the electronics needed to control the BLDC motor (both drive it and monitor its position), communicate to a PC, convert PWM signals from megasquirt or any other boost controller to VGT position, monitor temperatures, motor speed, it can also be controlled with a simple potentiometer (voltage control) 2. A board that attaches to the Turbo itself. It contains hall sensors for motor position. To summarize, Im using megasquirt to set the desired VGT position based on RPM using the inbuilt Solenoid control in megasquirt. eg. at 2000RPM open the VGT 30%. My electronics then use the signal from megasquirt and ensure the VGT opens to 30% and stays there unit commanded to change. Please note that I haven't driven the car yet so things might change once I get up and running...but from what I can tell right now just idling, the system seems to be working quite well...very fast and responsive.

-

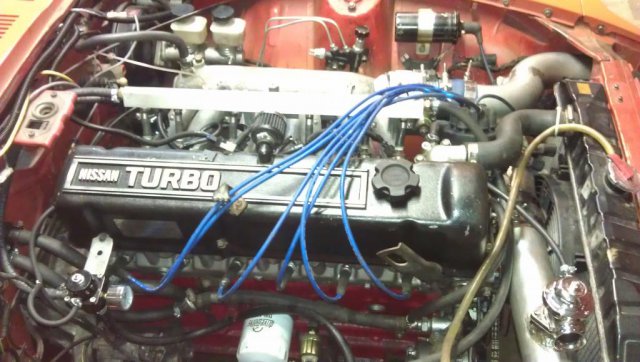

Sorry guys for the silence. Its getting harder to find time for the car now that the weather has finally broken and the family wants to spend time outside riding bikes or camping on weekends. Letitsnow: I just moved from Binghamton and forgot to update my location...im now located in MD (silver spring). let it snow....perfect name for upstate NY. Anyway, I just wanted to let you all know that I have the car idling and successfully integrated my holster VGT electronics with megasquirt. There are a few things I still have to iron out before I can drive the car. 1. Despite having a new oil pump, my pressure starts off at 60 psi when the car is cold but it drops down to nearly 5 psi when the car is fully warmed up (someone please let me know if this is normal) 2. My temps are rising quite quickly when idling. I can get up to 180C (fan set to start running when car reaches 170C) In roughly 10 minutes and stays there...fan is always on (im guessing I will need a new radiator) 3. I might have to relocate my Blowoff valve because it is hitting the hood (slightly) which causes the IC piping to touch the water pump pulley ( I check to ensure this is not the cause of my heating issues by opening the hood and letting the car idle) 4. Get the factory Tach working (right now im depending on Megasquirt). Back to the VGT.... Im loving the away I can change the exhaust tone by opening of closing the VGT...fully closed and you could barely hear the car...open it and it tone deepens. Anyway...Here are some more pics. I'll post a video of the car idling or running this weekend.

-

The electronics might be for sale if there is demand for it but for now its just a project. I kinda fear for my L28 since it stock with about 160K miles on it. The project is coming up will. I have finished the suspension and brakes, megasquirt and the rest of the car is all wired up. Im now waiting for my fuel pump to come in so i can get the car running and debugged. I should be up and running by the end of this week.

-

I just wanted to bring you up to speed on a project I have been working on this winter. I came across a holset HE351VGT turbo last fall and decided to use it in my 260z project. The car: 1974 260z that I picked up last summer as a project. I have put a 280zx turbo stock engine (with the exception of the turbo), t6 transmission, R200 rear end, tokiko shocks and springs and a 16 gallon fuel cell...oh not to mention all the body work including fabricating frame rails. Electronics: I'm will run megasquirt for fuel, ignition and to control the VGT controller (through the built in boost controller feature). I built my own BLDC controller to control the vanes of the Holset Turbo. Megasquirt outputs a PWM which is then convert to a vane position using my controller. I built my own controller because the one i had from my turbo was damaged by a coolant leak. For that reason, i decided to split my design into two: 1. A board that sits on the turbo with only hall sensors to detect the brushless motor position as well as the vane position. 2. A main external control board that has all the brains to run the motor based on a PWM signal, analog voltage signal or serial communication. The turbo: Holset HE351VGT turbo from a dodge that I picked up on ebay. 3" Exhaust all the way back to the muffler. E-Motor sport external waste gate. After taking some measurements, i realized the turbo will not fit in the car with an adaptor as it would have hit the steering linkage. With that i mind, i decided to weld on the turbo to the factor manifold ( only time will tell if it holds up). Present state: I'm getting the turbo, exhaust and intercooling into the car... (p.s...if i had the money i would pay someone to do my exhaust... this thing is a pita) The Holset controller is built and bench tested. -Next will be wiring (lights and megasquit) followed by brakes and running the fuel lines. wish me luck!!!!! Enjoy some pictures. for a video of the electronic controller doing its thing (I'm presently waiting for my megasquit simulator to come in so i can test it as a complete system).

-

Im looking a 240z title and tags..let me know if you have one or know someone who does. Thanks.

-

I'm looking for a complete set of engine mounts (the metal section that bolts to the engine). Please let me know if you have a pair as mine (in my 240z) were damaged. I prefer to use paypal... THanks.

-

Im in Binghamton, NY.... I did however find a ZXT that im waiting to arrive. Thank you all for your help. maybe ill get to run it at lime rock on april 7th...

-

Thanks but i cant afford that price...my price is 2000 max(to my garage) for a clean/semi clean car...thanks once more.

-

Hello, I need a clean or semi clean z car. I dont have much to spend...so take it easy on the pricing. The z will be conveted to a track car so it doesnt need to be complete. I would prefer a 5 speed. Im located in NY but im willing to haul it or even have it shipped if its worth it. Feel free to PM me. Thanks.

-

Dan, I think thats exactly what am going to do....I just wanted to see whats out there before i commit to buying.

-

I'm looking to buy brakets to convert my 260 to a V8. The engine i have is a LT1 and the tranny is a 5 speed T5. Please let me know if you have any brakets/mounts your willing to sell...they could be production (JTR) to custom/home made. Thanks...PM or reply here.

-

Let me know if your willing to part with a turbo exhaust manifold. Need it for an upcoming project.

-

I have never seen a whole kit, but i do know you can find the fasteners at MSA or ebay. They are quite pricey for what they are!!!!!

-

exactly...perpendicular and on the run only. I learnt that from the show trucks on spike. Use the blade from a scraper because its firm and has an edge you can hold on to. It works really good...i tried them all and this worked the fastest when combined with some DA wetsanding.

-

Thanks,my local jober incouraged me to go with a solid cheap paint since this was my first paint job. The paint was nason brand so it was cheap too (good thing because i wasted a lot). Anyway, yes DA sanding is the way to go. I bought a hook backing pad from ebay and found a store that carries 2000 grid da paper. The sanding paper comes with its own pad for more cushoning. (ill dig up the store name if you want me to) -Visit autobody101.com for really good tips and help. I am sure your car with turn out great...be prepared for all the honking you will get.

-

nice work...i just finished the my car and what an experience that was. Just remember to keep it simple and safe.

-

very nice work..keep it up. I am no expert in painting but just like you, i repainted my own car this spring and learnt a lot. Dont worry too much about the clear coat runs. The easiest way to remove the runs is with a NEW scrapper blade, then DA buff with 800 followed by DA 1000 (wet sand). I want ahead and DA sanded the whole car with 2000 (wet sanding) and oh my....it was so smooth. Anyway, here are some pics to keep you motivated

-

i am in a good mood..so here as some pics. I took them from an old gas tank i had from my parts car. I was having fuel issues so i took the gas tank to be cleaned and coated by a radiator shop, bought a WB fuel pump, and my issue ended up being my pressure regulator!!!! Anyway, enjoy.

-

Continue checking for voltages down the line...check to see if your reading any voltage at either side of R9. If reading a voltage at R9, then check pin 26 of the MCU. Also check to ensure you have 5V at pin 31 (supplies VREF for internal ADC circuit) If you get voltage there and your not registering it in MS, then either you need to reflush the code or get a new chip. Hope this helps.

-

a quick look at your datalog seems to indicate your running way lean at higher RPMS (O2 is pegging out*)...also, your spark seems to be way off. Not sure if your loosing spark at higher RPMS or your table is set wrong..or your base timing is incorrect....i would suggest you start by verifying that your timing aggress with what MS reads while idling (using a timing light), then your spark table, then your VE table.... (increase the values at higher KPa and RPMS)...hope this helps. * i am assuming that a higher value on your O2 indicates lean and a lower value indicates rich. * Lean out your settings when idling. It appears your running rich...shoot for a lamda of 14 to begin with (whatever that is on your O2 sensor) Thats my 2 cents.

-

I cant promise to help much but ill give it a try ( am also new to MS and tuning ). I'm at work right now so i can look at your log. If you dont mind, let me know which version of code your running and perhaps post your .msq file and ill take a look later on this evening.

-

Thanks, I measured the resistance on my sensor and your averaged values are almost spot on. Anyway, i guess i didnt understand how hot the Z actually runs. On an upside, i did get the car to run and run great, pulls hard...AFR at 14 while crusing and 12.5 while boosting. The only thing that i cant seem to get right is how to get my car to lean out while decelarating (engine braking)... my AFR bounces around from rich to lean while engine braking and not a contant lean like the stock system did.... Ill try leaning out the VE table futher at those points...