-

Posts

110 -

Joined

-

Last visited

-

Days Won

1

Content Type

Profiles

Forums

Blogs

Events

Gallery

Downloads

Store

Posts posted by Atozone Tonine

-

-

thanks for the tips everyone. I will take a look at the bushings...

Not really interested in gong too fast.. its just a daily driver, but i might look into stiffening it a bit.

-

-

Here is one of the circuit breakers I was planning to use:

http://www.optifuse.com/circuit-breaker-thermal-cbw57.php

The one I bought, says it is 12A 12V DC

Will this work? has anyone else done this?

-

n

Ok I lied, here is one more. I did my best to photoshop the cube tail light into the 240z:

this looks great. I wonder if the dimensions would actually work...

-

How much do other 240z's creak and groan when you turn up or down a driveway or incline into a parking lot?

I feel like the chassis is twisting a lot, and it seems to be worse when the gas tank is full.

I can't tell if its the gas tank, springs, or body... but It sounds like an old battleship.

-

My car seems like it flexes A LOT when I turn up onto driveways. Is there any danger of making the car too stiff in one area? Can it have a negative effect (i.e. something might bend or snap) in another area?

-

thanks for the advice.

Do you recommend TXL or GXL wires?

I want to keep it simple, so instead of a bunch of different gauges, i want to stick to 2 gauges (plus battery cable of course)... like a 12ga for most things and 16ga for the small stuff like turn signal switches, etc..

Do you think that should be able to cover everything?

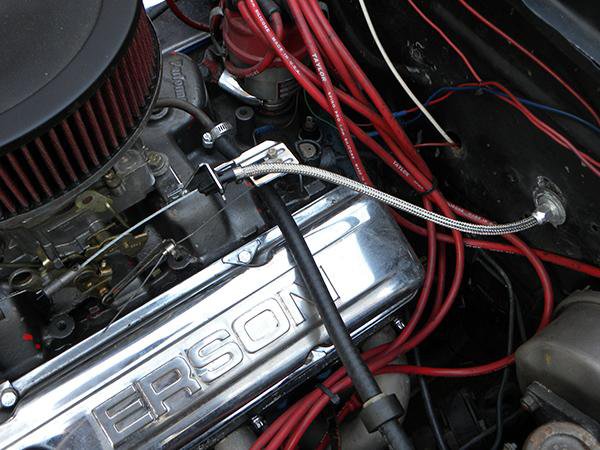

FYI - 72 240z , 350 chevy engine, carb, no AC, no wipers, no heater, no blower motor, no stereo.

-

Its not my daily-driver - Its my ONLY-driver. I average about 8-10 mpg - thank god for the company gas card!

Its a 72 240z with a Chevy 350 from a 72 Camaro.

-

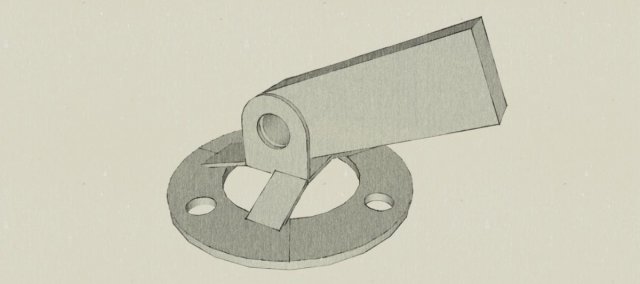

If you wanted to fabricate your own tow hook, where is the best place to attach it? (front and rear)

Where and how does the zccjdm attach?

-

Before rewiring basically everything, I am making a switch panel to control all of my circuits.

I am also making a panel of circuit breakers in the glove box with maybe a battery shut off switch also.

Here is the plan so far:

Top buttons - Headlights, tail lights, Interior lights (if I ever get one)

Middle area - push button start, ignition power

Lower area - Fuel pump, Radiator fan, not sure what else

I will post the final results soon.

Any suggestions on how to divide my lighting circuits? or for the panel?

I was going to do the left separate from the right side, same as the stock fusebox.

FYI - Its for a 71 240z with a 350 chevy. I have no wipers, heater, or AC

-

-

I also traced my doorpanels and will will use a large format scanner to import them into AutoCAD .. then I will clean up the lines and post the results in case anyone wants them.

-

great link - thanks!

-

Thanks everyone for the help - and wow - nice engine bay SpeedRacer!

I routed the throttle cable way - and just took some length off the spring and it seems to be ok now.

-

My throttle had been sticking at about 1500 rpm until i press the gas pedal sharply, then it goes back down to normal idle rpms. I recently replaced the throttle cable and made it run directly from the firewall to the carb, instead of in a loop as it was before, and the problem was much worse, until I adjusted the part where the cable cover mounts on the carb in order to make the curves less drastic. It seems to be a bit better now, but still sticks sometimes until I blip the throttle.

If I open the throttle manually on the carb, it goes back to idle no problem.. so its not the springs, or the carb in any way.

The spring on the gas pedal feels a bit weak, but I'm not sure if that could make this happen.

I am thinking that the cable must be sticking inside the cable cover somehow, but I have lubricated it with LDL dry lube spray very well. Should I use a different lube?

Has anyone else had this problem?

PS. I have an auto trans, and the cable from the trans to the carb is engaged anytime the throttle is opened. I know it should slide and only engage when the throttle is wide open, but I did not have a problem with it before. Could the tension from this cable help the throttle close?

-

Just, fyi. The car is a 71 240z w/ sbc 305. The carb is a 4 barrel holley, not sure how many cfm. How would I find out?¿

I also have a 71 240z with a SMC and Holley 4 barrel card... and also a NOOB! lol. Mine has a wire that ties the choke [open?] permanently. I will get a pic of it asap to show you. Seems to work for me. I have to give it a little gas to start sometimes.

-

I am planning on connecting the rear strut towers in my 71 240z. Is it better to bolt it to the top of the struts? or can I just weld bars between the diagonal braces between the towers?

If a bolt connection is better, I will place one bar between the tops of the towers, and build a simple truss in between the towers.

One issue is - If I use the bolt connection at the top, is there any use of it being removable, since the rest would be welded?

FYI,I would use 1/2" x 1" steel bars. Im not overly concerned about weight.

-

I will check if mine is 2 or 3 row... but it has worked very well so far. The only time the temp has gone past the half way mark is when i drove for 3 hours straight in stop and go traffic in warm weather .. and it was still touching the half way mark. FYI, I have a Chevy small block, use a 50/50 mix of cool and and water, and there is some kind of sand or "leak stop" in the system since I bought it 3 months ago. I need to flush the system to find out what the situation is.

-

Does anyone know if Champion radiator caps come in different sizes? The seal on my cap is broken, so I want to get a replacement, but I can't find an OEM replacement.

I have seen caps on Ebay that say they fit Champion rads, but don't specify a size or PSI.

-

Thanks everyone. Very helpful.

-

Does anyone know the difference between Back Hatch Seal and Deck Lid Seal?

They look the same to me, but one is $6 per foot, and the other is $12 per foot.

http://www.metrommp.com/ > Online Catalogue > 1971 > Nissan > 240z

(I cannot copy the address)Thanks.

-

Awesome Video.

-

I know this topic has already been covered... but i didnt see anything that answered my question:

I want to change my brake, turn signal and rear running lights to LEDs ... can these lights be wired directly into the existing system as is? or do they need a low voltage transformer?

I wont be doing the work myself, but I want to buy all the parts.

FYI - the reason im thinking about switching to LEDs is that Im rewiring the car anyways, and also missing some of the bullb sockets/harnesses... and not concerned with keeping the car original.

-

i will try that. thanks.

Custom Switch Panel

in Fabrication / Welding

Posted

The reason that I want to do all this work is that the wires around the steering column and also in the engine bay are a mess of spliced, and bare wires.

Some of the insulation has actually melted off, so something is not right.

The ignition switch gets so hot that you cannot touch it after about 30 minutes.

Also, since I removed the wipers, blower motor, and a bunch of other useless things, I would just like to simplify everything. .. oh.. .and my turn signals and brake lights don't work, so it would make driving a lot easier... haha.