-

Posts

265 -

Joined

-

Last visited

-

Days Won

1

Content Type

Profiles

Forums

Blogs

Events

Gallery

Downloads

Store

Everything posted by ukcats07

-

Throwing these in here because I know I had them on the site at one time. Google Sketchup drawings of the mount I made for this car. Thanks to Brian Lane for the inspiration.

-

I'll throw My hat in to the ring!

ukcats07 replied to leopard_125's topic in Gen I & II Chevy V8 Tech Board

Nice! Love the rims...that motor is not too bad either -

I used WD-40 and had no increase or change in idle. I might try again with the *unlit* propane torch. Any guesses on the drip of oil at the bottom of the bellhousing? Could it be because this motor has not really been broken in (driven on the road)?

-

Connected the electric choke today and the motor settled down considerably. Seemed to idle around 850-900. I didn't have the aftermarket tach hooked up (my tach setup is unreliable at the moment), but it was definitely below 1000. The only thing is, my vacuum dropped from around 18" at idle to about 13". It was steady and behaved the same way as you see in the video, it was just below 15". Could this be an indication that my timing is a little retarded? I know it could potentially be a vacuum leak, but everything I've read on vacuum gauges shows that I would see a clear indication on the gauge if I had a significant vacuum leak. I also have no idea what type of cam is in this motor as it had absolutely no markings on it when I got the whole setup. I also noticed that I keep getting a small drop of oil at the very bottom of the transmission bellhousing. I had this same issue when I broke the motor in, however when I took it all out I put teflon tape on the flywheel bolts and the rear main seal area was PRISTINE. Could I have filled the oil pan with too much oil? I really hope it's not a rear main seal... I'll up the timing and see how it runs tomorrow.

-

Awesome. Thanks for the good info, I'll take the air cleaner off and give it a look-see tomorrow. I might take another video and post it for scrutinizing if I can't get it to come down.

-

This is one thing I need to figure out. I don't have the electric choke connected and I'm not sure if this is the issue. I just started it up a few minutes ago and it was idling pretty high again. I've got the slow idle screw completely backed out. Does the fast idle screw do anything if I have the choke disconnected? I also have the timing set to 12* initial with vacuum advance disconnected.

-

I posted a while back when I started the motor for the first time and broke the cam in. I had an exhaust leak where I forgot to put thermactor plugs in the heads. My motor sits too close to the firewall to install them with the motor in the car, so around thanksgiving the motor came back out of the car. The Air Force has been kicking my ass for the last six months and I finally got some time to put the motor back in and fire it back up. She fired up on the first half crank! Unfortunately the motor was overheating and starting to really tick me off. After running through all the normal (read: cheap) steps for overheating I happened to stumble upon someones suggestion that the intake manifold bolts might not be completely torqued. Sure as **** my intake manifold bolts were about a full turn loose! I torqued and re-torqued them about five times and fired the motor back up...no more overheating!! Now this is all at idle in my driveway, as I don't feel comfortable with the brakes to take it down the street. I'm guessing though that if it stopped overheating in the driveway then it's most likely not going to overheat on the road. Took a small video today...don't mind the rat's nest around the battery, that will be taken care of pretty soon, also the tach is temporary. Just need to get new brakes, re-bleed the system and then I'm taking it around the block. Any comments on the vacuum I'm getting? Looks about right according to the research I've done.

-

Brake Nightmare (No fluid to rear brakes)

ukcats07 replied to Gilli's topic in Brakes, Wheels, Suspension and Chassis

Looks like this might be the problem. I disconnected the the rubber hose at the drum and had no fluid while under pressure. I then unhooked the hard line from the rubber hose at the top side and the fluid started flowing from the hard line. Now if only the local places had this line in stock... -

Brake Nightmare (No fluid to rear brakes)

ukcats07 replied to Gilli's topic in Brakes, Wheels, Suspension and Chassis

dragging this one from the depths I'm having the same issue as the OP. When I bleed the front brakes with my pressure bleeder I get great flow, no air etc. Put the pressure bleeder on the rear and I get nothing, not even a drip, out of the rear drums. I pulled the dual circuit pressure differential switch off and moved the pin to the middle and re-checked the system. With about 15 psi on the power bleeder I get flow on both sides of the differential switch and both sides of the pressure regulating valve. So I know that fluid is flowing past the valve and down the line to the rear of the car, however I still get nada out of the bleeders! What else am I missing here? I even put about 10-15psi on the bleeder and kept it at that pressure for about 10 minutes and I still got nothing out of the rear bleeders. Potential line blockage somewhere? -

Here's a video of my second start. Any experts out there here anything that doesn't sound right?

-

I might throw a different fuel pump on this week to see if that helps. I'm also hoping that the noises I was hearing are gone now that I've installed the rocker arms the correct way. I'm gonna start it up again this weekend if you want to pop by for a little bit. I'm thinking Saturday around nap time for my kids. 1230-1300ish. I'll PM you my address if you can make it. What kind of beer you like? It'll be cold

-

Just finished adjusting the rocker arms the correct way and #6 intake was WAY loose. I'm talking 2 to 3 revolutions loose. That may have been what I was hearing, as it was definitely on the driver's side during break-in. FWIW

-

With my coolant leak problems fixed, I attempted to start my 302 this past Sunday. Here's the rundown of how it went: Stabbed the distributor on the exhaust stroke instead of the compression stroke. A couple backfires through the carb, and a few small flames, convinced me of this. Found true TDC and installed the distributor at 10* BTDC with rotor pointing at #1. Pumped the gas a couple of times and she started right up. 15-30 seconds into startup, the paint on my headers was up in smoke. Between this and worrying about not getting oil pressure, etc, I didn't get to put the timing light on it. I also had the radiator cap off and totally forgot to put it back on...3 or so minutes into startup I had coolant basically spraying out of the radiator fill neck. It's at this time I look at the water temp gauge (did I mention I was way behind the engine on my cross-checks) and it was at about 215-220. So, between the radiator spilling coolant and the temps kind of getting up there, I went ahead and shut it off. I immediately noticed that the #7 cylinder did not fire at all. It was the only cylinder that still had paint on the header tubing. Went to pull the plug on that cylinder and the wire came off pretty easily. I'm pretty sure it just didn't seat on the spark plug (confirmed, I believe, on my second start attempt). Just to clarify, my headers didn't glow red or anything, the paint just blistered and smoked right off. It's probably because I used BBQ high heat paint, and not VHT or header paint. Stupid decision. My oil pressure was stable around 55-60 psi at 2500 rpm and my fuel pressure varied between 3.5-5 psi (@ 2500 rpm). Brand new Holley 4160 carb. Is this pressure too low for this carb? Manual says 4 psi min and I'm concerned that I might be lean because of the pressure. Any merit to that thought? I'll try to post my video to youtube here shortly. My Canon SD1400 used a nice 1GB of space for about 7min of video. Need to cut that down for youtube, I believe. After doing some research as to why the water temps got a little hot (220 isn't really that hot actually), and why the header paint went up in smoke, I think my timing was most likely off. On my second start, however, I barely touched the distributor from the first start and it timed at around 32 BTDC at 2500 rpm. Is this too advanced for an early model 302 during cam and engine break-in? Started it again yesterday and it ran pretty good for about five minutes, temp didn't really creep much higher than 190 (180 thermostat), oil pressure was stable around 60 psi and fuel pressure was again varied between 3.5 and 5 psi. At around the 5 minute mark it started to sound a little different and between my inexperienced ears and nerves from firing this up I went ahead and shut it down again. It dieseled for about a half second and then died. After researching again, I found out the correct way to install my rocker arms for the heads that I have. I have the positive stop studs which require the nut to be torqued down after putting the respective cylinder to TDC. I was installing mine as if they were adjustable rocker arms, doing the whole zero-lash 1/2 turn routine. Could this have been what I was hearing. I suspected knock, but after listening to some knock examples on youtube and comparing to my video, it definitely sounded more like valvetrain noise. I'll try to cut the videos into segments and post to youtube for your viewing pleasure. Thanks Doug

-

First start tomorrow! Any last-second advice?

ukcats07 replied to ukcats07's topic in Ford V8Z Tech Board

Geez. What a comedy of errors. So I took the manifold off and successfully put a helicoil in it...no problems there. Bought a new thermostat housing and it bolted up nice and flush. Put everything back together Monday night (after scraping gaskets for what seemed like days---scraping gaskets sucks) and roll it into the driveway tuesday afternoon for attempt #2 at starting this motor. Fill it with water and no leak at the thermostat housing..yay. However, I noticed a puddle of water in both valleys of the water pump to timing chain cover interface, right above the water inlet/outlet respectively. I thought it was water that was leaked from the hose etc. when filling it up. Grab a paper towel and dab it up so I can have a good baseline in case anything leaks during startup. Well, of course, as quickly as I'm dabbing it up it's filling the valley right back up through a threaded hole in the timing chain cover. Of course I can't start it with it leaking coolant this badly so I have my friend help me push back into the garage so I can go research WTF is going on. Turns out that most people have this problem when their water pump gasket is shot. Easy fix. Take the water pump off and find that I didn't install the water pump backing plate to timing chain cover gasket. Jesus. No wonder why it leaked so bad. I put a new gasket with some Permatex Right Stuff around the coolant passages as suggested on another forum. I'm going to push the car into the driveway again on Saturday morning and hopefully the third time will be a charm and I'll have a V8 Z that can move on its own. On a side note--I'm using an oil pan with the screw-in dipstick tube as my block was meant for a front sump pan. I am having a pretty good leak at the dipstick and I can see that it is leaking between the nut and the dipstick tube. It is most definitely not leaking between the pan and the threads of the nut as I can see oil leaking between the nut and tube when I tighten the nut down. I also notice that the dipstick tube is quite loose when it goes into the pan before I start screwing the nut down. Is it supposed to fit pretty snug before being tightened down with the nut? Also, am I supposed to be using an O-ring with this setup? If so, where is it supposed to be installed? I've tried searching for this issue with google and have had very little luck finding an answer. I suspect my dipstick tube not being tight in the pan is probably the culprit. The bottom portion of my dipstick tube looks similar to the one above, it just looks like a standard tube and not braided steel. Thanks for any help -

First start tomorrow! Any last-second advice?

ukcats07 replied to ukcats07's topic in Ford V8Z Tech Board

Wow. I had a mental list of things that had the potential to go wrong. This one was nowhere near that list. Let's start with the first error that was kind of funny once I realized what was going on. Started filling the block through the heater hose bypass (with a flush-tee) and noticed I had a slow steady drip on the passenger side of the block down near the oil pan. My immediate thought it WTF is this and why is it leaking. Turns out the coolant drain plug for the block was not installed. Quick trip to Ace and I figure I'm on my way. Continue to fill the block and all of a sudden I get a pretty good leak at the thermostat housing. Take a look and realize I didn't RTV it and the bottom bolt looks like it's not pulled all the way. Pull it off, RTV it and start tightening. On the last turn of the bolt, wham it gets really loose, really quick. I proceed to cuss very loud and try my hardest to throw my 1/2" wrench through the earth and out the other side. Pull the housing off and of course the first few threads are trash. F'n brand new Weiand intake and I get to take it off and drill/tap for a bigger bolt. I'm definitely going to go get a new housing as well, as I think the one I have wasn't completely flat. At least that's my theory. So should I drill/tap or get a heli-coil set and go that route? Damn, this was not how I envisioned this day going. Oh well, could have been worse. -

First start tomorrow! Any last-second advice?

ukcats07 replied to ukcats07's topic in Ford V8Z Tech Board

Roger that on the fire extinguisher. I bought one the other day in anticipation of starting yesterday. I had an RX7 catch fire on me when I was 16 and luckily I had one in the car. Minimal damage. However, two weeks later when the repairs were done, said fire extinguisher was nowhere to be found when it caught fire a second time!! I had to watch it burn while the fire department completely doused it. Total loss. Not a cool way to start my senior year. Both times it caught fire about an 1/8 mile from my high school parking lot and both times a good portion of the school got to watch my car roast. I think the angle of the pictures make it seem like it's way above the radiator cap. It does sit higher, however I can push it down with minimal force and it goes below the radiator cap. If I can push it below the cap, the air should work it's way out right? Also, I'm assuming you're talking about something similar to a heater hose splice in contraption that has the garden hose attachment on it? I looked for one today at the parts store and the biggest they had was 3/4". Nothing on the order of 1.5" Also, glad I looked it back over as I had the water temperature gauge installed incorrectly. I'll post videos and pictures if/when it starts today. -

Well, tomorrow is the big day. Was gonna be today, but ran out of sunlight and didn't want to chance starting this car up in the dark. Any last-second advice? I've checked the: Drive shaft bolts transmission fluid engine oil--5qts adjusted the rocker arms a bunch of other small things as well Dropped the HEI dizzy in at TDC with the rotor pointing at #1. Put the cap on and lined a post up with the rotor mark--that was my number one in the firing order. Worked counter-clockwise in the firing order for the other spark plugs. That was the correct way to do that right? Engine has been primed, and I have good oil pressure. Water temperature sensor (mechanical) is hooked up and in the engine bay for easy access. (Oil pressure gauge is as well) I have a one-wire alternator (100A) and I wasn't for sure if I needed to hook the WR (white/red) wire from the Datsun harness to the output of the alternator. I don't believe this wire is to be hooked up. Any thoughts? I really don't want to fry anything in the harness if the alternator spikes. Anything outside the obvious I should focus on tomorrow before I turn the key? This is a carb'd 302 BTW. Thanks

-

Which adapter cap are you using? I made my own pressure bleeder, however I didn't have a spare 240 cap to work with and the cap I do have is not sealing on the reservoir. I would definitely just like to buy the Motive adapter and make it work with my bleeder if you know which one will fit the 240 reservoir. Any luck picking up a cap at one of the local auto stores? I have a 73 BTW. I tried O'reillys and NAPA today and they are not able to order me only the cap..has to be an entire master cylinder. Any other car's reservoir caps compatible with the 240's that I might be able to pick up?

-

Filled my 302 tonight with 30W Castrol and primed it to check and make sure I'm getting good oil pressure for the first time. I was given this motor over a year ago as a fresh (5 years ago, but never ran) rebuild. I took it apart and inspected every piece about a year ago and put it all back together. My first time doing that BTW. Definitely a good feeling to see oil coming out of the lifters and 40-50 psi on the gauge. It only took seconds to happen, contrary to some posts I've read where people have spun the drill for upwards of 10-20 min. Might have been cause I filled the oil filter before priming. Thoughts? Man I am so close to firing this thing up. I only need my radiator hose to come in, exhaust made and to reconnect the Datsun wiring harness (all easy). Thanks to my 15 hr/day work schedule I probably won't get this fired up for another month, even with so little to do. Oh well, no need to rush I guess...

-

For anyone else who's doing a Ford swap---talked with JCI conversions and they will make a driveshaft to fit the ford trans for the same price as their GM version. $235 shipped is a pretty good deal IMO. Especially coming from a company that knows Datsun V8 swaps. I most likely would have bought from them had they sent me a response email yesterday morning instead of this morning. I guess I'm impatient and PST had a good price and a good day for delivering the Drivehaft.

-

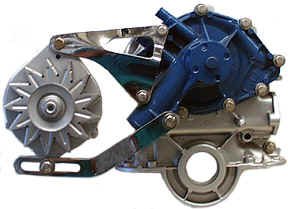

So I stopped being cheap and decided that $90 was worth not thinking about this problem. I ordered this alternator mounting kit from Summit and I'm going to mount it low like this guy did I have an idler pulley bracket that I made that puts an idler pulley right above the water pump--similar to 74_5.0L_Z. Don't know why the pictures are rotated 90 out. Oh well, head-tilt chin lift method works. Dont forget to treat for shock. Always...treat...for...shock. Wait, that's self-aid buddy care...nevermind.

-

Okay, so this is really frustrating me. My 302 was given to me over a year ago as a longblock with nothing on the frontside. No brackets, no accessories, etc. Block is mid 70's (from a Falcon I believe) with a timing cover that fits a reverse rotation water pump (driver's side inlet). Now the alternator brackets that I have are the triangular piece that bolts to the water pump and the curved slotted piece that's used for tightening the belt. These won't work with my water pump. I have been searching and searching to find out how to mount an alternator to a 5.0L with the driver's side inlet water pump. From what I can tell, I'm going to have to find a JY with a 5.0L and grab the aluminum bracket that a stock tensioner mounts to. It's either that or use spacers to make the current mounts work. I'll try to post pics here in a little bit. Can a stock alternator mount (for say an 89 mustang) be bought at a parts store? edit: This is the bracket I am in need of This is the bracket I have This is the water pump and timing cover that I have FWIW I have serpentine pulleys (probably matters for spacing)

-

Just got off the phone with Performance Shafts. $250 shipped to my door. The guy I spoke with was super nice and said I should have the drive shaft by Friday. Radiator, carb and a few other small things left and I might be able to start this car soon!

-

Any shop names? Like sticky280zx said, $20-40 for shipping is not a whole lot.

-

Damn, thought I had this topic watched. Sorry for the no response. I definitely walked away as I thought it was too high myself. I also heard some not so great things about the place in question from a speed shop here in town. They did not recommend using this place due to quality issues, not necessarily price. Yeah, they wanted $70 or $80 (if I can remember correctly) for the slip yoke and like $50 for the NEAPCO adapter, about $120 in labor and some more for the weld yokes and u-joints. I'm probably just going to give Denny's or Precision Shaft Technologies a call on Monday and see what they look like price-wise. Yeah, sorry about that. They didn't say anything about it standing up to 300whp etc. I just threw that out there when I was talking to them to give them an idea of the power-level of my motor. I was basically stressing to them that this driveshaft does not need to be anything crazy.