-

Posts

1985 -

Joined

-

Last visited

-

Days Won

9

Content Type

Profiles

Forums

Blogs

Events

Gallery

Downloads

Store

Posts posted by Xnke

-

-

Reading plugs doesn't even tell you lean or rich, really. All it tells you is how hot or cold the combustion chamber is, and those plugs look "ok" for a factory tune.

If the engine is running hot, your timing is not correct. Check your damper, make sure it isn't spun. Make sure you have both the Z31 MAF, ECU, and trigger wheel in the distributor. I've never done that particular swap but I would imagine you need to know what the stock timing is for the Z31 ecu in it's home configuration.

-

Bore the oil galley larger diameter to the front sump pickup, drive plug into old galley.

Bonus, new pick up galley is larger diameter.

-

While I don't think driving it without a helmet is safe, I have to say that is about as low as an S30 should ever go...it looks great at that height.

Is that X-brace behind the roll bar required?

-

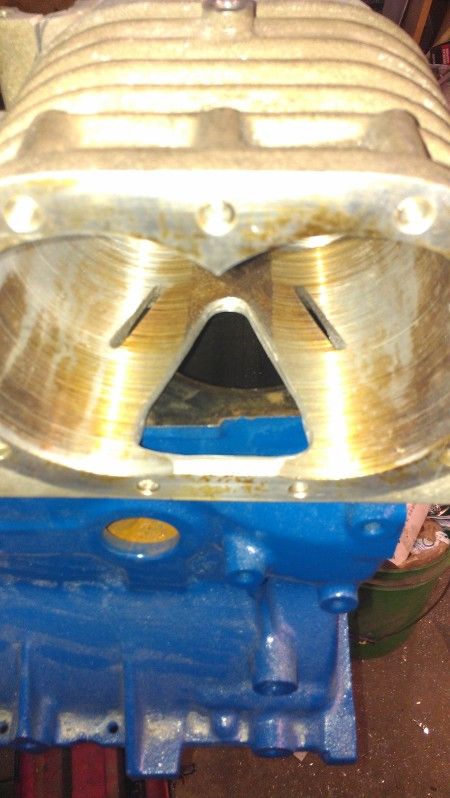

Started with a standard GM Series II 3800 M90 supercharger, gutted the case and started chopping. Got it cut down, then went to the stock shelf and started fitting stuff up.

All cut down on the back end, anyway. Getting things cleaned up and this made it VERY easy to do the intake side porting.

Now you can see how we're going to work this. Raising the inlet up and opening the bore from 65mm to 83mm.

Getting things sealed back up on the inlet side, all the intake porting is done, just need to run over things with a cartridge roll or two and clean up the burrs and divots from the carbides.

Much more direct path into the rotors, will be noisier but that's easily dealt with for 99c at the shooting store.

A few good shots of the porting, both inlet and outlet ports. It doesn't take much to push an M90 up to 600CFM inlet flow, but it does take some work to get one higher than about 650CFM...Stock this housing pushes 520-540CFM.

Not much to it, a little cleaning in the case and all those "score marks" wipe right out. they're not even deep enough to catch a fingernail, but the carbon and oil deposits make them look like someone went at the case with 36 grit paper!

Might try to find another rotor pack, as this one has some miles on it. They're not terribly hard to find and this one will work for a while yet. It's not leaking nose drive oil, so the front bearings are still tight enough to keep the seals from going to shit. I've rebuilt the rotor pack in my M62...it's a shit job unless you've got the special jigs to do it. I probably would be money ahead to pay the 500$ to have a rotor pack re-coated and rebuilt. However, good condition M90 rotor packs are all over and are far less money than a newly rebuilt one.

I still need to cut down the nose drive to the proper length, then it's two ball bearings, one snout seal, and two case bearings to replace. A new baseplate will have to be cut and I will be refining the method used to make the charge pipe, hopefully making it flow better than the current charge pipe and also lower profile...that way I can get it up off the lower radiator hose and alternator. -

Stock for stock, there is no difference in flow. The turbo cars got squareport heads because the additional heat will burn the liners out over time.

The K stamp cam specs have been posted here, the cam is short on duration and a little short on lift compared to some of the others. 222* seat to seat, 219* at 0.050", and 0.300" valve lift were what I measured last time I had one installed in a head.

-

Call delta camshaft and ask for the Racer Brown 325R profile on a 110 degreen lobe seperation angle.

That would be 275* seat-to-seat, and 250* at 0.050" lift, with 0.475" valve lift on 110* lobe seperation, so something similar to 35/65 65/35 valve events.

Sound similar to what you have now?

The standard schneider grinds are all on too narrow a lobe seperation for good idle vaccum. the stock lobes were on a 108 lsa, but when adding duration the LSA has to get wider to maintain that vaccum. Less material removal needed to just keep the LSA the same or close, plus you get the rowdy idle everyone thinks of with a "cammed" engine.

-

Funny, I called Nissan Comp down in Smyrna and while many sizes are out of stock, there are plenty of stock in selected, thick, sizes.

I am considering just buying a few dozen....they're not too expensive compared to getting them from Isky or MSA.

-

Isky has them.

Leave out any idea of adding more parts to fly out into everything when you start thinking about the valvetrain. With that much retainer holding it in place, it *might* all stay together, but with the revs you'll be running with that cam profile, I'd want to be *sure*. If you do use shims, they need to be hard...the lash pads are HRC52-55, last batch I checked, which is very hard but can be machined with carbide tooling.

Make sure your retainers can handle a 300thou lash pad, there are two heights that isky sells/sold and three heights that Nissan Comp sold (they sold stock, isky shallow, and isky deep, IIRC.)

-

What grind number was your Racer Brown cam? I know where some of the older datsun profiles went to, and JWT didn't have them...they only have the old stock cams, to my knowledge.

-

Just buy a 350Z. The panels aren't even close...

-

They probably are listing the P90 hydraulic lifter assembly, not the rocker post.

-

Yes, that's what he is saying.

The air temp a foot or two over the asphalt is much hotter than 85F when you get out in the desert...

-

Started work on the M90 case this weekend...I would say it will be simpler by far to work with a supercoupe M90 than any of the GM blowers.

GM blowers are FAR cheaper, though....

-

Shifting up at 7200-7300.

-

I too, had to machine a little off the washer I had. Even with the modified stock damper and it's line-fit (not even a true press fit) I have no scuffing and no marks to the nose of the crank, even driving the supercharger.

-

The space is normally used to allow the crank bolt washer to be thick enough for a centering register while still not contacting the nose of the crankshaft...that gap is there to make sure that you don't clamp the crank bolt up on the crank, instead you should be clamping the crank damper.

-

Things are good. New cam makes more power overall than the wide-lobe-seperation cam, but it breaths too good for the supercharger...Making 140kpA at 3800RPM but it falls off slowly to about 135KPA at 7300RPM. I'm moving as much air as the little M62 can move...and then a tiny bit more.

Also noticed that doing back-to-back-to-back-to-back, i.e., just drive back to the starting line and stage up again, 1/4 mile drags, the IAT's and coolant temps get lower each pass...started at 122* IAT and 181* coolant temps...8 full-throttle passes later IAT was 109* and coolant temp was 166*. No time slips, we were running untimed tonight. Was crossing the markers at 5200RPM in 4th gear, so that's just about right.

Found out what happens if you overfill the gearcase on the super though...the slightly higher hot pressure will force out the excess all over the engine bay.Don't worry about blocking the silencer holes...at WOT it'll still drown out the exhaust.

-

They should take the full compression. The bolt should not torque up against the crank snout, the pulley should hold it off a 0.020" or so.

-

If you need it to space the crank damper off the front of the crank, make it from steel. Aluminum will embed and you'll loose the torque on the snout bolt, and the damper will likely come off.

Hardened steel would be safer still, but you could probably get away with unhardened or prehardened-machinable.

-

The line with the bolt in it ISN"T the overflow line...it's ported vacuum. Usually used for distributor vacuum advance, but only if the distributor is set up for it! some distributors use it, others do not.

-

Narrow up that rear end, or get different wheels. Trying to stretch tires and stuff those up in there is going to look awful, and after the really really good body work you've done don't let something as simple as wheel fitment screw it up.

-

Where is the intake air temp sensor?

-

If you can't find the info, buy the books.

-

I have an oil cooler from a ford truck that I have mocked up under the air dam in front of the passenger wheel. The ducting goes from the brake-duct hole in the air dam to the cooler, then exits into the wheel well through a mesh screen.

I haven't installed it yet, other things have taken priority.

Can't get a smooth idle with homemade ITBs

in Fuel Delivery

Posted

I had exactly the same results, Metro, when I converted from MS1Extra to MS2Extra. Every single MS forum post I made, I was the one to blame, it was grounding, can't be the MS2, Can't be this, can't be that.

Pull the MS2 chip out and reload my old MS1 tune...smooth as anything. Plug in the MS2....back to the rough idle.

I never figured it out, I just tuned around it and went on.