LT1-280z

Members-

Posts

67 -

Joined

-

Last visited

Content Type

Profiles

Forums

Blogs

Events

Gallery

Downloads

Store

Everything posted by LT1-280z

-

Please help - handling issues

LT1-280z replied to LT1-280z's topic in Brakes, Wheels, Suspension and Chassis

Sorry I was vauge on the lowering. The ride height is 6-1/2" now as measured from next to the pinch weld front and rear. It was quite a bit higher maybe just 3/4" lower than stock. Thanks again to everyone. -

Please help - handling issues

LT1-280z replied to LT1-280z's topic in Brakes, Wheels, Suspension and Chassis

Thanks Cary, Yes lots of good advice here. I really appreciate it. So far disconnecting the rear sway bar and softening the shocks seems to have really tamed things down. Droop limit makes a lot of sense. Seems like a similar affect as sway bars but centered on the inside and only active when enough roll is achieved. For this car I do still want it streetable. I've been giving some serious thought to a dedicated track car. Something like a chump car. So I can beat the snot out of it and not worry. -

Please help - handling issues

LT1-280z replied to LT1-280z's topic in Brakes, Wheels, Suspension and Chassis

Oh yes I did spin. 360's across the grass thank goodness I missed the armco. I was pushing it and the rear let go and just kept on going. Usually I can feel it coming on and "play" with it with the throttle but with the current setup it just let go and went around and around. I tried disconnecting the rear sway bar and setting the shocks to F3 and R2 today and it seems better. I can't really test it fully on the street. I will try swapping the springs next. Maybe work on adding more negitive camber to the rear. Jon, Interesting info, I'll certainly will relax on the LCA angle. What spring rates would be a good match for slicks? Thank you all for your suggestions. I'll post my progress. -

Please help - handling issues

LT1-280z replied to LT1-280z's topic in Brakes, Wheels, Suspension and Chassis

Will try the sway bar disconnect tomorrow. As far as ultimate potential, yes taking away grip in the front won't be as fast as keeping front grip and fixing the rear. But with the imbalance I'm slower now than before adding the front camber. Agree probably going neg in the rear LCA while in corner and will probably get worse with the softer setting on the shocks and disconnected sway bar. How can the rear LCA angle be improved? Front was easy with the spacer. -

Please help - handling issues

LT1-280z replied to LT1-280z's topic in Brakes, Wheels, Suspension and Chassis

Wow, Thanks for replying so quickly. As for the BZ3099 I got mine from http://performance.importrp.com/tokico/tokico_shocks_illumina_series/tobz3099/i-526545.aspx Great price and good folks to deal with. I did try the shock setting in the rear down to 3 but it was no better maybe worse. I'll try your recommendation of F3 R2 - its not a good idea to test these things on the street I can maybe get a little more camber on the front - the camber plates are limited. I would have to do control arms to go any further Rear is not adjustable (yet) I'm sure tires would help, but I was getting passed by cars with street tires. I would like to get it working right with street tires first. rather than cover up the balance issue with slicks (btw the guys with slicks were really fast) Hot tire pressures were at 28 front 30 rear, I upped the rear to 35 and it felt a bit better but no where near what it needs to be. yes the pressure goes up about 6 cold to hot I was carful not to let the LCA to go neg. they are about level in the rear so there will be no camber gain there, the front has the spacers so they are still slightly +. I was thinking improving the rear LCA angle might help but its not at all easy to do. I did have questions on the rear bar easy enough to disconnect and try it. When is it loose? It generally feels like is on a knife edge on initiation, but turns in quickly, then mid corner steady state it feels like the rear wants to let go if you even think of trying to go faster. no where near balanced. I remember diving a 924 turbo many years ago, it felt so balanced, push it in a corner and the front and rear slip pretty much even. that's what I want. That will help confidence and with confidence will come speed (of course more driving lessons wouldn't hurt ether) I could see how a little neg toe on the rear could counter the oversteer a bit. I was also thinking of backing out some of the front camber, split the difference, it was pretty much dead 0 before the camber plates so maybe back to -0.75. (just to try to find ballance) If I can get this sorted I will consider slicks (I have a spare set of 16x7 wheels) Thank you all for your suggestions! -

I’m hoping someone can give me some advice on improving the handling of my Z. Its really not where I want it to be. My car is a V8 conversion with an LT1 and I have upgraded most every area. I have coilovers, Tokico Illumina, sway bars front and rear, AZC wilwoods, VLSD diff with CV’s, 17†wheels with bf goodrich kd 225/45. I take the car to HPDE events and as my skills have improved I have been finding limitations in the handling of the car. At prior events I found the car limited by understeer but generally stable and predictable. In an effort to take it to the next level I added camber plates to the front allowing -1.25 degrees, roll center spacers and lowered the car significantly more. Front struts are BZ3099 and for the rear I replaced the tall 280Z isolator with the shorter front one. At the last HPDE the car’s front turning grip was greatly improved but now the rear is giving up in a bad way the car is somewhat oversteering, feels unstable cornering like the rear is going to go out at any second. Here are the alignment settings Front Camber = -1.25 Caster = 4.6 Toe = 0.21 Rear Camber = -1.15 Toe = -0.01 Scales (with Driver) Left 50.9% Front 47.9% Lf/rr 50.1% Right 49.1% Tokico’s are set at 5 all around Spring rates front = 200 rear = 250 Any advice is greatly appreciated, I really need to get this sorted I can’t have 944’s and Honda’s lapping me!

-

You need a lawyer. Without one, and if the judge is having a bad day the court will mess with you in ways you can't even imagine. All the hair splitting arguments will just make it worse - get a lawyer. AND quit driving like a fool.

-

Here's the parts I use with the stock radiator tanks - re-cored with high efficiency core and extra nipple added to upper tank for oil cooler return then tee the vent tube into that. works great. Part Number-Manufacturer-Description-Original Application 20893-Gates-Lower Radiator Hose-1995 Camaro V6 3.4 (lower) 22011-Gates-Upper Radiator Hose-1995 Monte Carlo, Grand Prix, Lumina, Cutlass V6 3.4L (lower) 18774-Gates-Oil Coolant Hose-1993 Beretta, Cavalier, Cavalier V6 3.1L (Heater To Pipe-1)

-

Cutting off EGR Valve instead of Blocking Off

LT1-280z replied to Challenger's topic in Fuel Delivery

Challenger, When I did mine I cut it off just as you show in red. I didn't weld anything shut. I removed the 6 plugs along the EGR passage then through the opening tapped and installed pipe plugs in the small holes in the intake runners. As far as cutting, its aluminum, a new blade in a hack saw will do just fine - use a sawsall if your really lazy. good luck with it. -

ezzzzzzz, Please pardon my suggestions if you're already considered these. I've been watching this thread with interest and I had an "outside the box" thought. Have you considered flipping the assembly around and have the nut on the outside similar to modern CV axles? With this arrangement the the CV adapter would be part of the stub axle (no nut) and would be installed from the inside. The hub adapter would then be the splined bolt on part. Advantages: more clearance - longer CV axle shafts different lug patterns and offsets on the same stub axle by having a selection of hub adapters. Disadvantages: CV adapter is part of the stub axle so no swapping flanges - see idea below. If the spline snaps the wheel goes flying - making the spline as large as possible (as you have done) should mitigate this risk. I have an idea to deal with the CV adapter being fixed to the stub axle to allow for interchangeable CV adapters, I'll have to draw it up to explain it clearly, but basically it will become a three piece unit with the nut on the outside. Tom

-

Replaced my stock Heater valve with a honda one

LT1-280z replied to wigenOut-S30's topic in Interior

The cable is from the same application as the valve - 70's Mopar. I had to cut it down as it was way too long. I got mine from a JY. The valve is new from Four Seasons. -

Thank you all. I agree with bjhines, I wouldn't mess with the bolts. I never heard of anyone shredding the 10mm bolts. So why tempt fate? I did have a thought while dealing with this; what about re-tapping the ring gear to 12mm? Ultimately I came to the conclusion that if a 10mm bolt isn't a failure point it didn't make sense to mess with it. For me its not like I'm making 500hp and dumping the clutch at full throttle with slicks. (hmm... sounds like fun) There are probably better choices for rear ends if that's your thing. But then again I have heard of the R200 holding up to some serious abuse. (other stuff breaking first) Dave - yes I will definitely be at ZORB meets, zee you there!

-

Older R200's have 10mm ring gear bolts. Newer ones have 12mm (not sure of the cut off year). Most LSD units are 12mm, but the ratios tend to be 3.70:1 and numerically higher. In order to install a LSD unit in an older R200 or if you want the numerically lower ratios common in the older R200 (3.54:1 being most common). You use spacers to make up the difference. Although some have not used spacers and have not reported problems, IMO spacers should be used.

-

Necessity being the mother of invention I wanted to share something I came up with. Since it’s nearly impossible to get small quantities of metric sized tubing in the US and I don’t have access to a lathe. I came up with an idea to make my own by resizing 1/2†OD tubing by forcing it through a die. I started with 1/2" OD x .035†wall DOM tubing I purchased from Fastenal. The OD / ID are too large to start but after shrinking its darn close to 12mm / 10mm. Using a scrap of 1/2" plate I had lying around I drilled a 31/64†hole with a bit from a standard 1/16†to 1/2†drill index set, I then slightly tapered the hole with a hand reamer about 1/4†deep to make the die. I then forced a 10†piece f the tubing though the die with my hydraulic press. The tubing diameter was reduced to very close to 10mm x 12mm. It did come out a little curved but with such short pieces it won’t matter. I cut the now reduced tubing using a tubing cutter to make sure the cuts were square, into 10.5mm pieces. I then used a counter sinking bit to remove the internal ridge left buy the cutter. The OD came out jut a little over 12mm making a nice press fit into the differential housing, with little effort I used a 10mm bolt and nut to draw the spacers into place.

-

Replaced my stock Heater valve with a honda one

LT1-280z replied to wigenOut-S30's topic in Interior

Here's another solution Its a Mopar heater control valve, interfaces nicely with the dash control with just a longer cable, fine adjustment works great when you want just a little warmth or open it up all the way for full heat. I wanted to move all the potential carpet soaking pieces outside Now there's contiguous pieces of hose between the valve and the core. -

LS_1 / 280Z Speedometer Question

LT1-280z replied to rwwisnesky's topic in Gen III & IV Chevy V8Z Tech Board

Good to know, who'd of thought? I built my own and I designed it to work with the PCM. Maybe there is a market for it? -

LS_1 / 280Z Speedometer Question

LT1-280z replied to rwwisnesky's topic in Gen III & IV Chevy V8Z Tech Board

Here's some info. http://www.thirdgen.org/techboard/ltx-lsx/320227-ls1-vss-pulse-92-a.html http://www.skulte.com/T56.html http://www.lt1swap.com/wiringharness.htm Looks like the T56 is 17 Pulse per rev. However if you are using the stock PCM the speed signal from the PCM is already calibrated to 4000 Pulse Per Mile. I highly recommend using this signal and have the PCM programed for you tire size and diff ratio. This makes the speedo calibation simple = locked in at 4000 PPM. The VSS signal is required by the PCM anyway so why not use the calibrated output? -

Alternatives to SBC JTR motor mounts?

LT1-280z replied to gdv350ss's topic in Gen I & II Chevy V8 Tech Board

Thanks gdv350ss. Here's a picture of the steering shaft area in my Z. I have a Mustang power rack. The input shaft is higher and a little to the outside. This puts it right in the way of the stock perch area. With the perch moved rearward you can see the shaft has a clear shot and clears the block hugger header nicely. As far as how low the engine is, I'm using the corvette pan to gain a little more clearance - absolutely nothing is lower than the frame rails. The harmonic damper is about 1/2" above and centered directly over the rack. I would estimate a little more than an inch further back than the picture of the JTR mount gdv350ss posted. -

Alternatives to SBC JTR motor mounts?

LT1-280z replied to gdv350ss's topic in Gen I & II Chevy V8 Tech Board

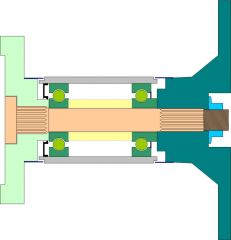

Speedway has good stuff and good prices - super easy to deal with, recommend them. I agree about the JTR mount, bolt in? sure, but not as refined as could be if you like to fabricate. Here's what I did for my LT1. Tied the cross-member to the T/C rod mount with a piece of 1/8" steel bent to form a pie shaped "U" channel and welded it to cross-member (cross-member and new addition are still totally bolt in - 4 more bolts at the T/C mounts). Then used 2" square tubing to make a perch for the engine mounts. I used the same mounts specified by JTR. A long mounting bolt comes up from the bottom. (a breeze to install the engine). This mount did a few things, strengthened the frame by tying the cross-member to the T/C mounts , Mounted the engine lower and further rear than the JTR mount , left room (after slight notching) for the AC compressor using the stock Camaro LT1 location , and whacked out my drive-line angles (see http://forums.hybridz.org/showthread.php?t=127832 for that fix) I don't know if there's enough room for an LSx but there's a pretty wide area on the pie shape to go further back. -

Terry, Yes, the half shaft angles are better, also with the pivot center of the inner CV is raised so when the car is up on jacks the outer CV's have plenty of clearance. Before this mod they were a pain to get the outer CV's off and on the flange. My VLSD R200 has the shorter metal vent tube. I could see how the taller plastic one would contact the frame. Another thing this did was to increase oil capacity by almost 1/2 quart (using finned cover - non finned would be less) and sink the front pilot bearing more deeply in oil.