thetremendoustim

-

Posts

116 -

Joined

-

Last visited

Content Type

Profiles

Forums

Blogs

Events

Gallery

Downloads

Store

Posts posted by thetremendoustim

-

-

Okay so my oil pump shaft is at 11:30 and when Its at a really rough idle It's set at 15* BTDC, however in order to do that I had to fully advance the distributor (dizzy screws fully clockwise position). I advanced it even more after taking off the cap screws and moving it but it didn't seem to change anything. But with the dizzy screws set in the middle position, the crank marking would read about 20* btdc, am I one tooth off on the shaft?

-

DOODT i just figured out what the BCDD is last week

its this son of a bitch

boy is it ugly, i just straight up swapped the TB's out with another one I had. I can even tell you what four screws you need and how much of a pain in the ass they are to change since they have a hexhead

btw, as for your earlier fsm question

carfiche.com my friend

it has helped me with EVERYTHING, you can even run to your local car shop and I got a ohmmeter in the $5 clearance bucket and when I ghettorigged it up to a 9v I am able to test the continuity of any wire in the car and test the resistance of every sensor, in fact tonight I just tested the character curve of my CHTS and the readings from my AFM

:mrgreen:

:mrgreen:

free FSM + $5 ohmmeter = THE BEST DEAL on earth i can go on for ages

-

(Don't know what tank it is. Slightly different tank than stock 240z, with 4 instead of 5 nipples, different locations see pics).

you should uh probably find out what fuel tank that second one is hahahaha

also, I used a simple adapter from Lowe's/HD on my fuel pump, see I have a feed line (from 74' tank) thats i think 3/16 and the electric pump (76' pump) that has a 1/2 inlet so I just got a couple different sized barbs and....well...humans are logical creatures so figure it out

-

So I tested my turbo AFM according to the FSM and I got the following results:

test #1 yielded my AFM resistance is somewhere around 210-230ohms but a good 40-50ohms away from the recommended 280-400ohms.

test #2 sliding the air flap while measuring the resistance yielded a very shaky needle* as i slowly pushed in the flap and slowly let off. Did it do this for anyone else?

*The exact "shaky needle" measurements are as follows:

when the contact touches the carbon strip the resistance immediately jumps to 100ohms

when the contact goes to the first "carbon strip exit" (doesn't it look like a fwy exit?) the resistance rises to 200ohms and falls down to 400 as it progresses to the next exit.

when the contact goes to the second "carbon strip exit" the resistance rises to 200ohms and falls down to 400 as it progresses to the next exit, and so on and so forth until the flap hits halfway and then mildly imitates the stated function pattern with slightly higher and higher resistance measurements.

-

I find an unbelievable amount where somebody adjusted the throttle body open to compensate for low idle and ending up having the idle switch never making contact because of the throttle opening.

This will throw off timing since it is different with the switch in the on position than off for the same throttle opening.

http://atlanticz.ca/zclub/techtips/tps/index.html

this is how my tps is set, once you push it to about the 1500rpm mark it loses contact with the idle and i'd say about 1/2-5/8 throttle it hits the WOT marking (which actually just goes to nothingness)

-

The flap is facing the air cleaner, I would take a picture but its getting dark outside right now. The potentiometer box is on the right (facing engine) with the plug facing down. I promise you its on right.

-

i did the same thing haha, are you are urs is on right?

yes it only makes sense going on the right way, how CAN you put it on backwards?

-

Open the throttle body screw or stop plate a little more, that should increase your idle RPM. Do you have an idle air control hooked up?

Oh, not having the thermotime switch plugged in is a probable cause as well. Mine got unhooked this winter and I almost killed my battery trying to start it.

I dont have a vacuums hooked up and i'm not running any reciculation or emissions.

ALso I might add that I unhooked the CHTS while it was running and there was NO change in how it performed. One question, is the "water temperature sensor" as referred to in the L28/S30 manual's the same as the "Cylinder head temperature sensor" in the S130/L28et manuals and guides?

-

just go to kragen/shucks/autozone w/e and rent one!! i've done it three million times! you buy it and when youre done they buy it back!

-

check ur vacuums for any "sudden high idle" problem

adjust ur IAS?

this should help...

http://atlanticz.ca/zclub/techtips/efisystem/280zfuelinjectionbook.pdf

-

California Law is that in a motor swap the motor has to be the same year of the vehicle or newer. Other than that, I couldn't say.

hey whereabouts are you in minot? just curious...I have my friends relatives that went to Bismark high i think that's what it's called... the one that won state football and they wear purple and black?

-

L28et

N42 non-egr manifold

Okay so if you know anything about my swap its frickin frustrating. I've got it to turn on, idle and that's it. Usually it will turn on and sound beautiful but go to idle like its going to die any second and stays that way probably 300-400 rpm. If i try to give it ANY gas it immediatlely dies. When it dies after idling for a little bit i can hear the AFM flap clacking back to the off position.

My timing is 15* btdc and here's what i've tried:

I've redone all the vacuums from intake to TB and on IM but everything is clean.

I've tested continuity from AFM and TPS to ECU and they both check out good.

All injectors are firing perfect and are turbo.

Fuel pressure is perfect (around 40's) throughout the whole ordeal

ALL relays and electronics are fine but these are my hypothesis' (in order of suspicion)

1. Something to do with the BDCC maybe?

2. Something to do with the AAR?

3. Something funky with my AFM resistance?

4. Something wrong in my wiring?

5. I dont have a thermotime switch or water temp switch wired yet but my CHTS is plugged in and fine, however maybe just maybe that's the problem?

its been like this for a couple weeks and I'm officially F*******-***-**** pissed off.

and uh there's 2 versions of this video...i dunno why hahah

(low quality)

(high quality)

-

-

Check your throttle position sensor to see if the switch is on only when the car is at dead idle and make sure you didn't use any conductive silicone on any of the connector boots whether on the tps or the air flow meter.

Also........are you running the turbo injectors with the turbo ecu?

yeah i'm running the turbo injectors and ECU.

I tested the AFM and TPS continuity to the ECU and they both check out perfect.

With the car in its really rough idle state:

I can unplug the TPS without any change

If i unplug the AFM, it starts to die faster, and when i plug it back in it will rev up and then start to die slowly again.

here's my TPS box

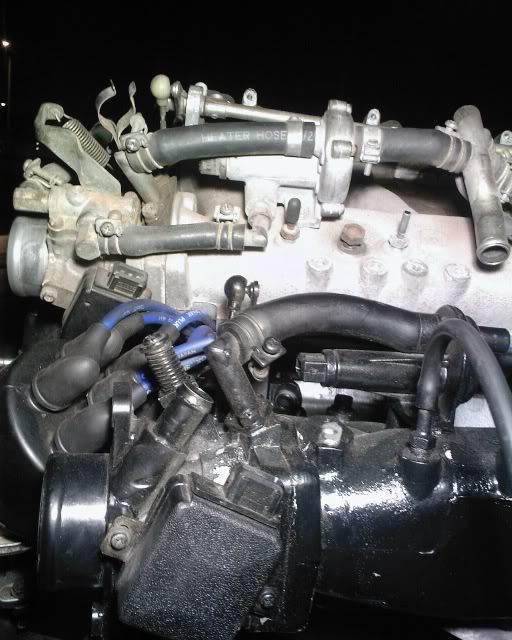

I'm thinking the problem might lie in this large object coming off the TB which I just noticed TODAY.

My intake was from a PO and is a N42 non-egr, and this huge thing coming off the TB right before the plate has a vaccuum line , a weird plug and a flathead screw at the bottom (underneath rubber boot) . I'm thinking IAS? There is a 3/8" hole and a 1/4" hole inside the TB running down into the BBT -> "big black thing." ;P

P.S. if this has anything to do with something I'm idling at 15* btdc

-

i've searched and already read the atlanticz writeup, my questions is much simpler anyways.

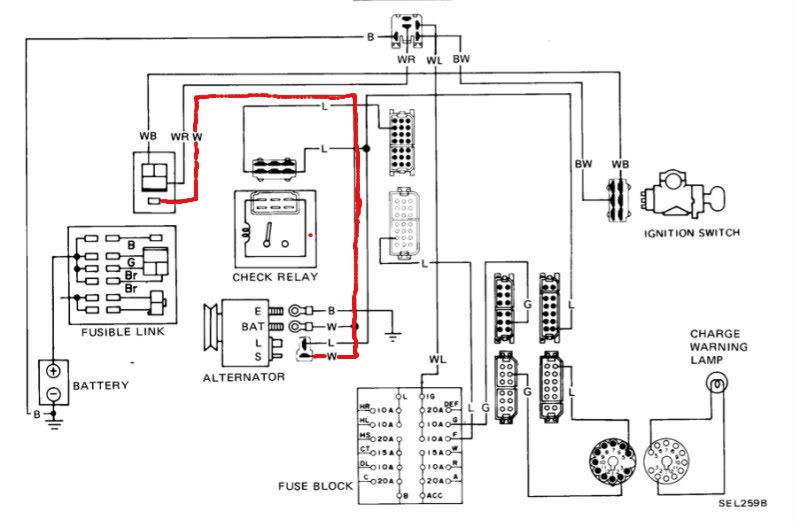

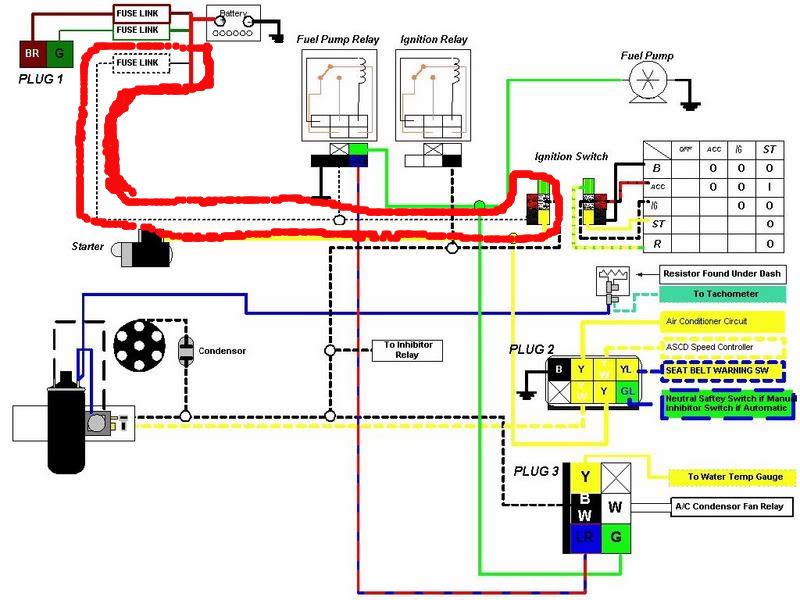

Okay I just want the most basic charging system, no check light no nothing just charge the batt. My super old alternator, i have no idea what year it is (PO) but here's a picture.

question: can i run only this wire

to the fusible link from the ignition

to the fusible link from the ignition  and be okay?

and be okay? -

sister and she's 14. i hope you're proud of yourself michael jackson.

you watch yourself my jokes are killer (check date o.0)

Haha, I can't stop watching your video! Its just too funny for some reason.She doesn't sound 14. Tim, I think you're lying to me.

if you check out my most recent, that's my girlfriend's laugh ahhahah but yeah i kinda sorta got it running, just having some problems cuz everytime i try to give it air it dies. my vacuums are solid, my afms on right, i'm just twiddling my fiddle right now trying to figure out whats going on...

-

sister and she's 14. i hope you're proud of yourself michael jackson.

-

So i figure i'm about two teeth equals off on my oil pump even though I put it on with the notch marking perfectly long story short i somehow come up 1.5-2 teeth off on my L28et. Can i just retard the distributor alot and move each spark plug one clockwise position? I'm prety sure i can like 99% i'm just wondering would I have to worry about the CAS tripping out since its an '83 dizzy...

-

help me please this is probably the worst first start in history

-

"grumpyvette, I've got some really easy questions for you that I cannot find out but still need answered. They're concerning the intake manifold on my L28et, its non-egr N42"

1. This is off the hot side my J-pipe and there's a nub I forgot where it goes to, perhaps number 3?

2. where does the air regulator connect to considering i'm not running ANY emissions?

3. Coming off the TB, what goes to this connection?

4. This is actually on my BOV and there's a nipple, should I connect this to the nipple coming off my wastegate (as seen in this picture)?

-

I figured out my problem and my question was stupid, you can delete this thread

-

Okay wow thanks guys, but out of curiosity why do I have a vacuum leak if I don't use a L28et throttle body?

Hughdogz- first, your ZX-T is to DIE for Its the most B****n ZX i've seen!!! also, yeah the input flange is bolted to the throttle body. But, what do you mean I have a massive leak at my cold start port??

I didn't know I had so many leaks...

I didn't know I had so many leaks...mike- thanks for that guide, and that ebay seller I think i'm going to pick one up from him, they look pretty nice!

Here's another picture of the TB area I took quite a while ago, but I haven't added anything or removed anything since.

-

Okay, I have a stock t3-60 from a '83 turbo and I have a few questions.

I'm going to try to run 12psi (with a BOV and FMIC) But how do I modify the wastegate so that it does this instead of the stock 7-8 psi? I've searched and read the wastegate posts but it seems that everybody already knows how to do this! I also have a non-egr N42 on so I THINK i dont have to worry about any pop-off valve issues.

yeah i'm noob. I do have a "nub" thing on the tube coming out of the compressor side and to be honest I totally forgot what it's for XD but maybe its used in the wastegate process? Help me out here guys...

yeah i'm noob. I do have a "nub" thing on the tube coming out of the compressor side and to be honest I totally forgot what it's for XD but maybe its used in the wastegate process? Help me out here guys...

-

http://zdriver.com/forums/showthread.php?t=24764&highlight=non-egr+n42

THanks nismo I see what you mean with #4 going to the J-pipe I was really confused.

AS for the CAS connector I can't find it on the Harness but i'll keep looking maybe its buried under some electrical tape or on the other side that i spliced off (XD)

and from what I understand #2 and #5 I can just plug off?

to the fusible link from the ignition

to the fusible link from the ignition  and be okay?

and be okay?

am i one tooth off?

in S130 Series - 280ZX

Posted

"help" bump