-

Posts

195 -

Joined

-

Last visited

Content Type

Profiles

Forums

Blogs

Events

Gallery

Downloads

Store

Posts posted by wrcbonk

-

-

Tyler,

I have an RB25. One time we were messing around with my engine and unplugged the vacuum line from the FPR and then like idiots forgot to plug it back in before running the car. With that vacuum leak, the car idled at 1000 and there was distinct sucking sound under throttle. If the IAC turns out to be fine you might want to start looking around for an unplugged or damaged vacuum line.

Bill

-

JCan,

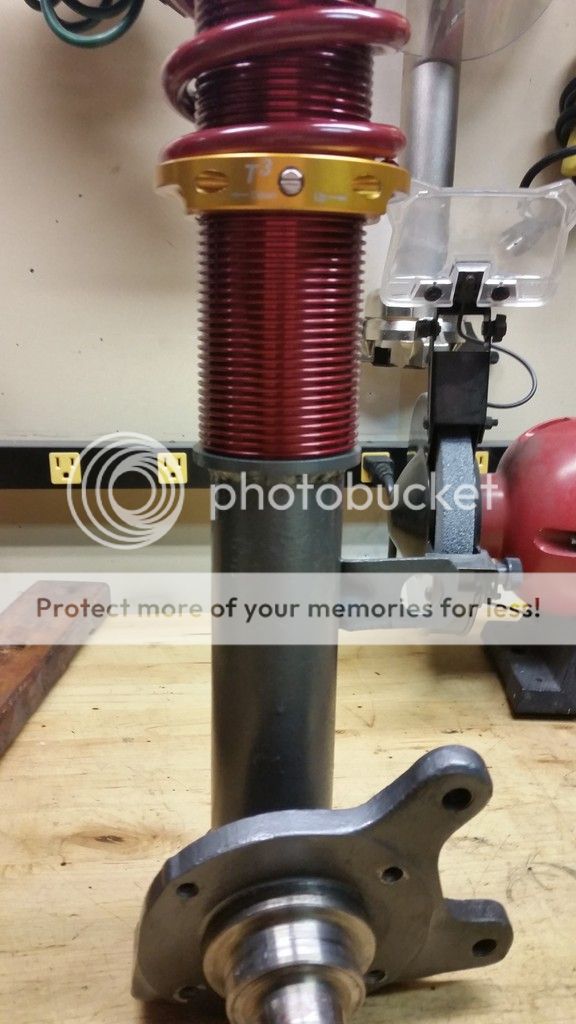

I am using the Techno Toy Tuning (T3) DIY coilover kit for my suspension. The top hat included in the kit rides on the stock strut bearing recessed up and under the insulator. If you want to go with any kind of adjustable camber setup the bearing and insulator would be replaced.

https://technotoytuning.com/nissan/240z/four-corner-weld-coilover-kit-datsun-240z

Bill

-

Leon,

Don't worry, my pace this summer is slow too between work and family vacation. The heat settled, the z went up onto its usual place (jackstands), and onto my summer list. coilovers, zxt stub axles, pinion angles, rebuilt steering rack, maybe rear disc brakes (so $$$$$$).

Got one corner of my coilover project done, will see how long it takes to do the others.

Have a good summer!

Bill

-

Great move replacing the control arm bushings. The stockers in my z had a lot a play when I bought the car. Replacing those bushings made a big difference under hard braking and steering.

Looking forward to seeing your BC coilover install. I am doing the T3 coilover conversion this summer.

Awesome job on the front cowl, looks great.

Bill

-

One of my favorite Z's ever...

-

Ran across this link on SAU. The table will tell you the year your donor chassis was born. Not ground breaking stuff, but nice to know.

http://www.japanesesportcars.com/skyline/history/years_serial.php

-

I bought and installed the Innovate MTX-L wideband. I have a series 1 r33 rb25det in my s30. The wideband was easy to install, calibrate and use. The logging software is adequate. I plan on going Haltech as well to control my rb when funds allow. My understanding is the Innovate wideband will communicate with Haltech.

Notes - way to deep into the instructions they tell you not to run around with the sensor in place, but not powered. It is hard on the sensor not to be heated properly when seated in the exhaust stream. And don't weld in a generic bung. The supplied Innovate bung is longer than ones I see online.

Hope that helps.

Bill

-

You only need a handful of circuits from the old stock engine harness. I would turn the fact that you scrapped the existing stock engine harness as a positive, it will help clean up your enigne bay. I left the stock engine harness in place and most of it is dead weight and looks crappy. Another member found this website http://vintageconnections.com/ These guys should hopefully have everything you need to make a paired down stock-like engine harness that you can reconnect to the interior harness behind the fire wall. There are several circuits from the stock 240z enigne harness you will want to have in your paired down harness. Zster mentioned lights and signals. Hopefully you have converted to a newer headlight harness that only uses the stock harness to "switch" not "drive" the circuits. As you indicated yo ualso need wipers and washer pump curcuits. I used the oil pressure sensor wire, the temp gage wire, and the coil "hot when on" wire to control the thermostatic switch for my fans. You don't need the starter solenoid that comes in the RB harness. You can use the red/white wire off the RB harness for the alternator charge light. You may want the horn circuit, I use it. I will try to check and see if I am using anything else. I managed to navigate around the whole voltage regulator/shunt thing because I am using an after market harness. Its cheating, I know.

I made a fuse block using a blue-sea. Its fine when centralizing minor circuits like stereos, the interior harness, sensor wires (wide-band), or any other accessories, BUT I would not recommend using it for major circuits like electrical fans, I melted a terminal on the blue-sea early on with the fans. If I had to do it all over I would buy another high amperage capacity fuse block and wire essentials like lights and fans to that seperately. Also, I've been meaning to replace my atc blade fuses with blade circuit breakers for a while now.

I hope my ideas are focussed on where you are trying to get help.

Bill

-

Leon,

Those top hats look very cool. Please let us know how they work out for you.

Bill

-

-

Thanks, guys for getting back to me. I agree about Windows 8. I was able to find a nice deal on an Acer 13.3 laptop, with good battery life, and loaded with Windows 7.

-

Lazlo,

I used to live in Bozeman. I wouldn't want to be driving a backroad there without a full sized spare, cell coverage can be limited. For fuel delivery, I did a small surge tank, external low pressure pump feed, and external high pressure pump to the rail.

Bill

-

This is an excerpt from page 5 of Chris Rummel's wiring write up

Speedo - use Navara D21 Ute mechanical gearbox Pinion Assembley Part No 3270202G17

It's what I used and it works, bearing in mind that my diff ratio matched the stock r33 donor.

Hope this is helpful.

Bill

-

Guys,

Wanted to ask real quick if anyone has tried installing and running nissan consult from Windows 8. I have run it on Vista and Windows 7 with no problem. I did Google the topic, but haven't found any discussion. None of my friends have bought a new machine with Windows 8 yet.

Thanks

Bill

ps - I know the real answer to my question is to buy a modern programmable ecu.

-

ZT-R,

The "grande finale" is pure porn, thanks for the update.

Bonk

-

I anticipate having to swap them out for something more generic like the puck style isolators you see in the McKinney kits, maybe something made by Energy Suspension.

-

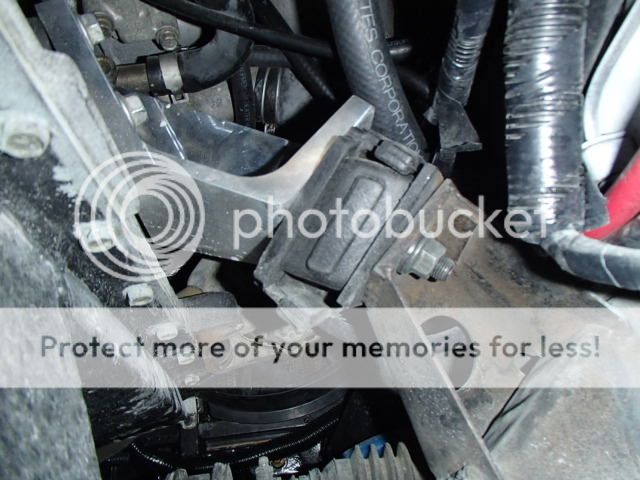

I growned down the set pins on the factory cross member to allow me to rotate the supra isolators positioning the engine at the right orientation.

-

I will try to remember to take pics when I get home and post them.

-

I was never able to figure out the wiring solution to use the factoy tach. I have a 71 s30. How did you get it working? Thanks

-

I bought a prepaid harness for two reasons 1) the harness I got with the car was in bad shape 2) I made it 10 times worse by my own hand:( If you have a good harness to start with, it is simply a handfull of connections to mate the rb to s30.

-

Leon, thanks, hoping I can make the next meet up in the bay.

Mincho, they are Weds, Autobahn 15 x 8.

-

Here is my z back from paint...had to give up my place in the White Z thread.

-

Note: I love my rb 240z and I am not saying engine swaps aren't rewarding and the results aren't amazing, BUT...

I started my RB25DET swap several years ago. Its been driving for a while, but there have been many issues. The motor started right up and yes I documented that on YouTube. But after that, getting road worthy, to be a reliable car thats a whole other matter. Fuel delivery was a major issue for a while, still have a venting problem. Right now I am dealing with radiator fan switch. Its an example of what happens when you do a swap. The 240z came with a fan clutch. The RB came with a fan clutch, but the 240z shroud didn't line up with the RB fan. So now you have to figure out how to I mate them together or do I just go with electric fans. Electric fans require a sensor/switch to turn them on and the electrical circuits to control them. There's nothing off the shelf that works well. You will have many of the same issues if you do a V8 swap as well.

One pretty cool idea as long as you can handle tuning carbs is to have an L-series built by Robello. A stroker 3.2 or more will deliver seriously awesome power and it all bolts up together just like it was from the factory.

my 2 cents

-

I have one of Pat's fully built pans and it works great.

making engine mounts/ pinion angle ?

in Nissan RB Forum

Posted

All-