-

Posts

90 -

Joined

-

Last visited

-

Days Won

1

Content Type

Profiles

Forums

Blogs

Events

Gallery

Downloads

Store

Everything posted by alexx933

-

I average about $550 take home per check. Not the greatest lol but I put on my first stripe on the 18th! I'd rather not remove my manifold again haha I had quite a few issues when my exhaust gasket blew. So no paint for me in the near future. and no plugs in our bench stock haha But I am very seriously considering trading my z for a 91 240sx with an rb20 tomorrow. I'm ready to switch gears on my project. I love my z but I lack the skill set/resources required to repair it and finish it how I'd like to. A fair bit of rust and possible bent suspension on my car combined with a very clean install on the 240sx is pushing me to trade. BUT I love my car and would hate to see her go. It's tough to decide. Everybody complains of the regret about getting rid of a z.

-

Holy crap haha that takes some effort! That thread sealant better be worth it's price tag though! $4.25 for 6ml is pretty steep for an E1... I think I will find a silver plug or paint it silver to blend in a little more. My stock intake is pretty cluttered as is. I appreciate the help! I like how you don't always give the answer. You make people think a little bit so they truly understand it better.

-

Tony, the supplement doesn't specify. Nor did the calculator. I'm not even sure what the A and G stand for... So I'm assuming it was talking about plain kPa. 10psi was as high as I wanted to go. She is my only car at the moment so I'd rather not blow the engine! I actually just read another of your posts in which you stated the limitations for the stock maps. I want to say it was one of Ben's z's posts. Needless to say I had myself a laugh after you told him off. As far as brass plugs go, other posts, such as this, say a brass plug will work. I should be able to find one at home depot. This should be exactly what I need right? No special threads needed?

-

I may have misunderstood the pressures required to make the relief valve open when I originally read the manual trying to identify it. I was reading this earlier today at work and was wondering the conversion for kPa to psi. Just looked it up. The turbo supplement says the valve opens between 42.7 and 50.7 kPa. Found a conversion calculator and that equals 6.19 to 7.35 psi. Had I done this sooner I might not need a post haha Sorry for making another pointless thread! Thanks though!

-

I haven't plugged that as I read that the emergency relief valve doesn't activate until extremely high boost pressures upwards of 20+ lbs

-

I have a diagram in the car. I will take a picture of the controller and diagram later tonight. The t-fitting used has been drilled for a vent. I don't think that was/is the issue. I could stop after boost and rebuild it. My car already runs rich so I doubt there is a fuel issue either.

-

Hi guys, I have just been stationed down in Florida at Tyndall AFB and had my car shipped down here. Won't ever do that again. Running a stock 1981 turbo engine. I've been wanting to install a boost controller and run about 10lbs. I have no intercooler, just the stock j-pipe. I have had a boost gauge for a while just to monitor the engine. For the past year and 3-4 months, my engine has only been hitting about 6lbs of boost. I haven't thought too hard on it because it seems to run strong. This past week, I ran around to build my boost controller from hardware stores and finally got it together. After waiting out the rain for the past few days, the controller was installed today. Ran the lines into the cabin so that I could adjust it easier. I left base and set off down the road with the adjusting screw almost all the way out so that I was at base boost. The first pull was at WOT. The z went just like normal until at full boost. Then, it sputtered and stopped accelerating hard. I eased off the gas and it pulled hard in a specific position. After a couple more tries. The same thing kept repeating. I adjust the boost higher without any change at all. The screw was fully in to make the boost as high as possible. I still only could hit about 6lbs. Personally, I'd rather be able to maintain full function of my throttle than have "higher" boost. Even though I never went over stock levels. So I turned around to uninstall the controller. Currently, she is cooling down so I don't burn myself. Any thoughts as to why this is happening? This should be a very simple procedure. Thanks!

-

viable compressor outlet to j-pipe coupler options

alexx933 replied to alexx933's topic in Turbo / Supercharger

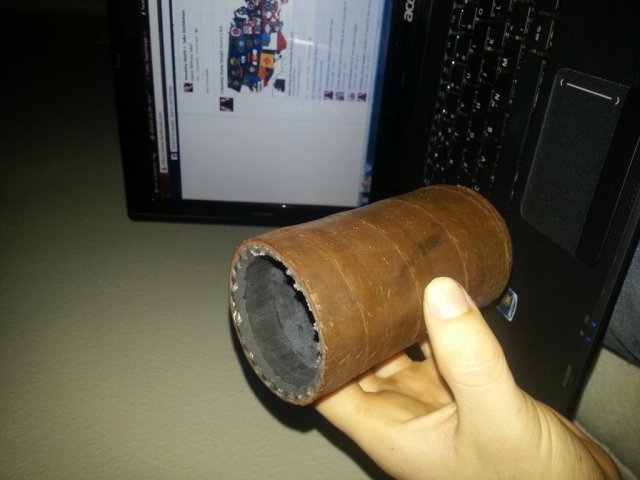

I wish that ugly brown tube would have worked but the ID was slightly too small and wouldn't slip on at all. I ended up ordering a 4 ply woven aramid reinforced turbo hose which has an ID of 2 inches and length of 4 inches. That's fairly long but the turbo and j-pipe should slide right up to each other. I'll just make sure and clamp them down hard. Once again, thanks for the help! Maybe this will resolve some of the issues I've been having! -

viable compressor outlet to j-pipe coupler options

alexx933 replied to alexx933's topic in Turbo / Supercharger

The eBay one is too thick? I didn't think that would be much of an issue. I may end up taking your offer softopz. I'll pm you if I can't find something. -

viable compressor outlet to j-pipe coupler options

alexx933 replied to alexx933's topic in Turbo / Supercharger

The turbo hose isn't your typical silicone coupler. Sorry if the picture is a rediculous size, but hopefully you can get a grasp of what I meant. So you'd trust this kind of coupler right next to your turbo?? -

I have some major boost leak going on due to having a huge tear (about an inch long and then another inch long tear going 90*) in what looks like the original 81 connector from the turbo to the j-pipe. My local auto store had some specifically turbo hose that is seriously thick. It is about the right diameter but slightly too small. Even submerging this turbo hose in boiling water for minutes at a time won't allow the hose to be pliable enough to slip on. That part sucks because this hose is $3 per inch!! So I had to put the torn coupler back on. I have seen a lot of silicone couplers being used in numerous threads and was wondering if they hold up to the heat. My main concern isn't intercooler piping as much as it is proximity to the turbo. I'm sure my hands are not the only ones to have been burnt while working close to the turbo. I don't want to buy a silicone coupler and have it go out on me while I'm driving down the road. Any feedback, links to threads, or suggestions to finding my answer would be appreciated! Alex

-

At rockauto.com Nissan 1986 300zx 3.0L V6 Electrical- connector Crankshaft position sensor connector After clicking on all those, you get one option for about $50. Not exactly in the price range I wanted, but it will be brand new. I plan on cutting the harness side off and attaching the MS wires.

-

Nevermind about rockauto. Found what I need. Thanks for the help!

-

Rockauto doesn't have the plug. I'm not really familiar with where to go for z31 parts. Where should I be looking? And I need a boot on mine because I live in Washington. I really can't avoid the rain up here.

-

Rockauto doesn't have the plug. I'm not really familiar with where to go for z31 parts. Where should I be looking? And I need a boot on mine because I live in Washington. I really can't avoid the rain up here.

-

I have the spindle and distributor for my megasquirt venture, but now I want to have the plug for it! I have paypal.

-

Spindle-Pin-Puller Loaner program

alexx933 replied to Dave's topic in Brakes, Wheels, Suspension, and Chassis

Just sent your payment! -

Spindle-Pin-Puller Loaner program

alexx933 replied to Dave's topic in Brakes, Wheels, Suspension, and Chassis

Thanks for doing this once again! -

Drifting handbrake (hydraulic handbrake)

alexx933 replied to RebekahsZ's topic in Brakes, Wheels, Suspension and Chassis

Will you pm me your number? -

Drifting handbrake (hydraulic handbrake)

alexx933 replied to RebekahsZ's topic in Brakes, Wheels, Suspension and Chassis

It's nice to know I can always come here for more information on my new (your old) rear discs! I got the package a few days back and sent a message to you. Tomorrow will be the day to start tearing into everything. The plan is to get everything done in one day as I just sold my other car. -

Spindle-Pin-Puller Loaner program

alexx933 replied to Dave's topic in Brakes, Wheels, Suspension, and Chassis

I'm in as well! -

Spindle-Pin-Puller Loaner program

alexx933 replied to Dave's topic in Brakes, Wheels, Suspension, and Chassis

Have all the pullers been spoken for? -

Hey Phil, do you still have this or have you traded/sold it off already?

-

Ran off the road. Any advice for my next step?

alexx933 replied to alexx933's topic in Non Tech Board

I'm very much looking forward to finally being active after over a year waiting! And those will be some nice perks, but I'm pretty sure that I will try to retrain into a different field after my first contract. I like working too much to sit at a desk for the entirety of my service! -

Ran off the road. Any advice for my next step?

alexx933 replied to alexx933's topic in Non Tech Board

I had intended to have it towed from my uncles to my mechanic/mentor's house to look over everything with his eyes as well. However, before trying, I ran it down the road just to do a small check. The Z started and stopped without any major issues so I decided to drive it the 10ish miles to my destination. Sure enough no major issues. The steering was slightly tweaked enough that the car veered to the right but not very hard. If i wasn't paying attention for 80-100 yards, I'd be in the ditch. I put the car on stands and took my time looking everything over. None of the suspension pieces were bent, cracked, kinked or otherwise visibly damaged. The pickup points also seemed to not have moved at all either (looking from both underneath and in the cabin). My steering rack boots were torn and my bushings seemed to have been original. Aside from that and the frame damage, we found no mechanical damage. So even though I'm greatly upset at myself for my accident, I'm glad to say I can continue to keep it on the road a bit longer until I find another shell! You can be rest assured that my reckless days in this car are done. As another side note, I booked a(n) (ch)Air Force job leaving in March! I got into the administrative aptitude area. Meaning I will become a desk jockey but the specific job is unknown at the moment. This all means I will try to find a shell down in Texas as opposed to Washington for obvious reasons or just wait until I arrive at my first duty station assuming it's not overseas.