calpoly-z

-

Posts

161 -

Joined

-

Last visited

Content Type

Profiles

Forums

Blogs

Events

Gallery

Downloads

Store

Posts posted by calpoly-z

-

-

I've got a griffen aluminum radiator that has been on my 77 for the last 3-4 yrs. Has some custome mounts welded on and bolts to the stock holes. Radiator is in good shape and I will include the hoses I put together that fit an L28. Worked great when I had a front mounted pusher fan but clearance was a little tight for a puller fan and intercooler pipes. $85 + shipping . Send me your email adress and ill send pics if interested.

-

I will be watching this post closely.

Moved down to Laredo, TX for work after finishing up school and it is HOT down here. The car is all but undrivable for most of the year without A/C. So I guess that means I need to get something installed, and it needs be a very good system to deal with 110+ degrees PLUS humidity from time to time.

I've got a few other things that need done on the car before I worry too much about this, but it would be real nice to have a solid, functioning HVAC system when I finally do get her back on the road.

-

I've got a stock exhaust manifold off a 77 with smog hookups that should work for you. $25 if you're interested.

-

I've got one in pretty good shape out of my 77 parts car that you can have for free if you come pick it up from San luis Obispo. Let me know if you're interested.

As far as buying new I found a local company up here that I bought a new windshield from for around $150 installed in my DD. If you call around you shouldn't have much trouble finding someone to sell and install one for less than $200.

-

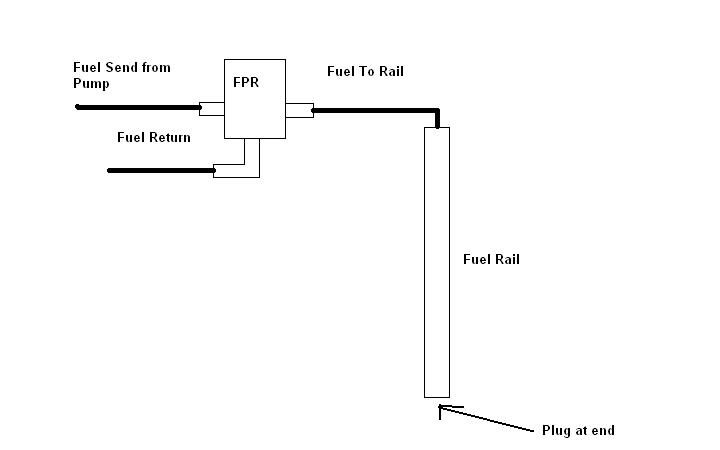

I am using this on my L28. I'm not sure exactly what vehicle the FPR I currently have is from, but it definitely has 2 inlets each 180 degrees apart and the one return outlet on the bottom.

-

I'm in the process of building an O-Ring fuel rail to replace my barbed one, and I was thinking about ways to route the fuel lines that would look a little better. I was thinking about mounting the FPR to the firewall and routing both send and return around the back of the engine. I drew up a little schematic to show how I was planning on routing things, but before I went ahead and did this I wanted to verify that this would not cause any problems.

As you can see, I want to mount the FPR inline before the rail and then have one end of the rail plugged. Does anyone see any issues arising from this?

-

Looks like I have a similar setup as you. If you want to ship it my way I would be willing to help out. As long as all you want me to do is plug your MS into my harness and burn my maps in to see if she runs my car then I've got no problem with that. Hell your even running the same code version I am. Shoot me a PM and we can probably work something out.

-

I've got a set of rear suspension parts from a 77. I'm pretty sure at least the LCA's are the same if not the strut housings as well. LCA's I'll sell for $60 shipped. If you determine the strut housing will work as well then I'll sell everything for $110 shipped.

-

I've got complete bottom end out of a 77, but it's definitely going to need a rebuild. it's been sitting outside for the last couple months and some rust has formed in a couple cylinders, but nothing a slight overbore won't take care of. $100 and it's yours.

I'm in San Luis Obispo so not too far depending on where in SoCal you are. PM if you're interested.

-

shoot me a PM if you can't find someone a little more local to do the work for you and we can work out some details.

-

Depending on your level of expertise in building engines you may want to swap in the turbo motor with the stock ecu in order to work out all the kinks before attempting to throw MS on the engine. This way you know the motor is running good and you are able to break it in without worrying if your tune is decent. It can be a pain in the butt to troubleshoot problems when you don't know if that problem is with your engine management or a mechanical issue. Just a thought from someone who has been there.

-

No kits that I've ever seen. Most people just fab up a plate of steel or aluminum to cover the top hole and throw a cap or plug into the bottom hole on the intake manifolds. For the exhaust I've seen people put a bolt in there and then weld it up. You might be able to find a plug that will screw in, but I'm not sure what the thread size would be.

-

I'd love to help you guys out, but I'm a couple hours south in San Luis Obispo. If you can get the car down here I have tons of space and all the tools necessary to do the job. Hell I even have plenty of time this summer due to the economy postponing my start date at work.

-

You should just be able to get those from your local auto parts store. you may have to got to a couple stores to get all six, but I've found that NAPA or autozone usually have a couple in stock. Plus I think they come in a set with the small and large orings for about $2. Just a thought.

-

Even if the waste gate is stuck open the car should just behave as if its N/A. It won't have a lot of power, but it should still run and drive fine. Right now I'm leaning towards a messed up compressor wheel that is choking the engine under heavy load or something like that. I remember checking out the turbo and noticing it had a bit of shaft play, but I don't recall either wheel looking messed up. We'll check that next though.

If I feather the throttle I can get the car to rev past 4k so the problem seems to be load related. I don't know if it matters, but there is no exhaust on the car yet. Just an MSA downpipe. Thanks for the ideas and please keep them coming.

-

I've been helping a buddy of mine put a 83 turbo motor into his 74 and after facing innumerable little issues we finally have her running great at idle and cruise. The engine is pulling close 20" at idle and it will rev fine under low load. As soon as you try to get on the throttle though the car just falls flat at around 3500 or so. today we drove around with a boost guage and despite all our attempts we were unable to reach positive pressure either. I've set the TPS to spec and timing is at 20 BTDC. Injectors have been cleaned and flow tested and fuel pressure is good. The motor is fresh from the machine shop and most everything is either new or rebuilt, except for the turbo which may be suspect. We are using the factory ECU and harness for now, but the plan is the go MS in the future. Any help would be greatly appreciated. Thanks guys

-

yeah here are a couple.

Here is the little rust spot I was talking about.

PM me if you're interested.

-

I've got one down in San Luis Obispo if your willing to make the drive and pick it up. The hood is in great shape with just a few small surface rust spots. nothing that compromises the steel. The vents are in great shape too. $125

-

I've got one in San luis obispo, but that's probably a bit out of your way.

-

Do they make more power? I thought the typical reason to increase number of cylinders, especially for relatively small displacements i.e. car engines, was to increase the smoothness of power delivery by shortening the duration between power strokes in the engine.

If they do make more power, then maybe the smaller cylinders allow higher compression ratios. With larger bores knock become more of an issue because the flame front has more distance to cover. By decreasing piston bore diameter this become less of an issue (to an extent). We happened to be talking about this concept in my combustion engine design class this week as it pertains to aircraft piston engines and why they needed 100LL with relatively low CR (8:1). Apparently the large bores of these engines (~5-6") means they are very detonation prone. They also have 2 spark plugs to help with this issue as well.

Just an idea.

-

I think that would be awesome and should be a lot of fun. I live real close to the Grover Beach Dunes. I have been out riding in them on dirtbikes, but I always envied the guys in sand rails. Those things looked like sooooo much fun. You would definitely have your work cut out for you, but it should make a great project. Keep up us updated if you start this.

-

The vent from the block goes to your PCV (Positive Crankcase Ventilation) valve that screws into the underside of the intake manifold. If you switch to an N42 manifold this will need to be relocated due to interference with the turbo. From what I've read you should keep this and not vent it to the atmosphere. Do a little research on this and you should come across some good reading.

-

I got one you can have for $30 shipped. I'll be pulling the engine and trans tomorrow or Sat. So I can send you a pic then. I have another one, but it's at my folks place in Houston. I try to get my brother to locate it for me.

-

I've got a full set (2 actually) from a 77 if these are the same as the one's you need. PM me if you're interested.

WTB: Evaporator coil and box '78Z

in Parts Wanted

Posted

I've got the full inside ac setup out of a late 77. This includes evap and heater cores, the housing around both and the control levers. I'm pretty sure late 77 and 78 model years are pretty much the same in this area but not positive. Let me know if you're interested.