h4nsm0l3m4n

-

Posts

271 -

Joined

-

Last visited

-

Days Won

1

Content Type

Profiles

Forums

Blogs

Events

Gallery

Downloads

Store

Posts posted by h4nsm0l3m4n

-

-

I went from this:

To this:

I used the cheapest HVLP gun I could find at Harbor Freight, think the whole setup cost like 20 bucks. Here is my gun setup:

I used single stage urethane paint and spent a lot of time thoroughly prepping and cleaning the metal... I'm no painting master but i think it turned out really well for my first time ever painting anything. I believe if youve got the space and the compressor there's really no reason not to use a gun to paint. Its actually really easy once you get the technique down, and it seemed to go fast. Even though with all the knooks and crannies make it difficult to work with the paint gun I had the engine bay painted in a few hours. Something like a body or a fender, would be so much easier and quicker.

I would reserve paint cans for small parts you end up painting separately. For example, I painted my battery tray well after I was done painting everything else. I did not want to mess around with the overspray and cleanup of the paint gun so I bought some PreVal and rattle can primer and had it done in no time. Since PreVal takes automotive paint I didnt even have to buy more paint. Well see how well it ages...

-

Just got home from the shop and thought I'd throw up a quick update. During the last few days I finally wired up the standalone harness to the stock wiring and ran wires of the new high pressure pump. Yesterday was spent sorting through the fuel system and fixing a few leaks that cropped up. Today I filled the car with oil and water (appropriately). With not much left to do I sat down, put the key in the ignition, turned to "start".... and was rewarded with a blast of angry V8 music through open headers! I was so amazed.. It barely cranks over before it roars to life like its a brand new car!

Tomorrow I'm calling up the exhaust shop and scheduling an appointment for early next week. In the mean time I still have a few things to do mainly, mount the electric fan on the radiator, mount the ECU, relays, and fuse box, and wire up the Autometer tach, and speedo. I also need to insulate all the wires from the headers and do some general fit and finish type stuff to get the car driveable.

Its getting close!

drvrswntd: never got a PM from you, just FYI

-

Realize its been a while but I'm still looking for this...

-

Hoov is totally right. If youre not looking to spend "gobs of money" build up a stock VG twin turbo motor. You should be able to learn to drift with it and you can build them up to the power levels youre looking for if decide you are ready for more power.

-

I dont know maybe I'm just too picky but if the car was anything but pure stock I would seriously hesitate before buying it if I intended to use it regularly. I dont think a new (to you) motor is really a selling point. You can get L28s dirt cheap, who knows where it came from. If it was rebuilt (which you say its not), who was it rebuilt by? If its anyone other than a well known shop its subject to a lot of scrutiny. A non-rebuilt motor's service history is a huge question. Rebuilt turbo? Again if it was anyone but a qualified shop (with reciept proof) its not really worth much more than a used turbo. The rest of the parts can be nit picked the same way. In this old of a car if its not new, I would question its longevity. If its rebuilt or replaced, I would question the level of workmanship.

Since our cars are actually pretty cheap and easily attainable I dont feel that any mods really add a lot to the value of the car. The body and "completeness" of the build are what ultimately will add value. The cars obviously repainted, how good of a job did you do with the paint/body work? To be a restoration candidate the car will have to be repainted. If it has to be redone then that subtracts a lot of potential value rather than adds it. Also how good of a job did you do with the swap? Is it hacked together in a rush, or did you take your time and iron out the details? Everyone I've talked to scrutinizes any swapped car MORE than a regular car. This is on average swapped cars are a little more "unstable" than factory cars. Theyre also typically driven in a very different manner. Even my co-worker's beautifully over-restored SR20 swapped 510 wagon (which he drives every day and to which I compare all motor swapped cars) still occasionally refuses to start.

To your credit, you could have done an awesome job with the car and I think a few potential questions would be answered simply by driving and looking at the car and not looking at the spec sheet. You can tell a lot of things just by how the car drives and you can usually spot a hack job a mile away. I feel that our cars are too personalized and unique to have an inherent "worth." You cant look up a KBB value, this isnt a Camry. The price is really up to what value each individual person applies to the car and it will vary greatly between each person who looks at it. If you sell I would list it early and, if you can afford it, do not be in a rush. Eventually you will find someone who values the car at a price you can be happy with.

-

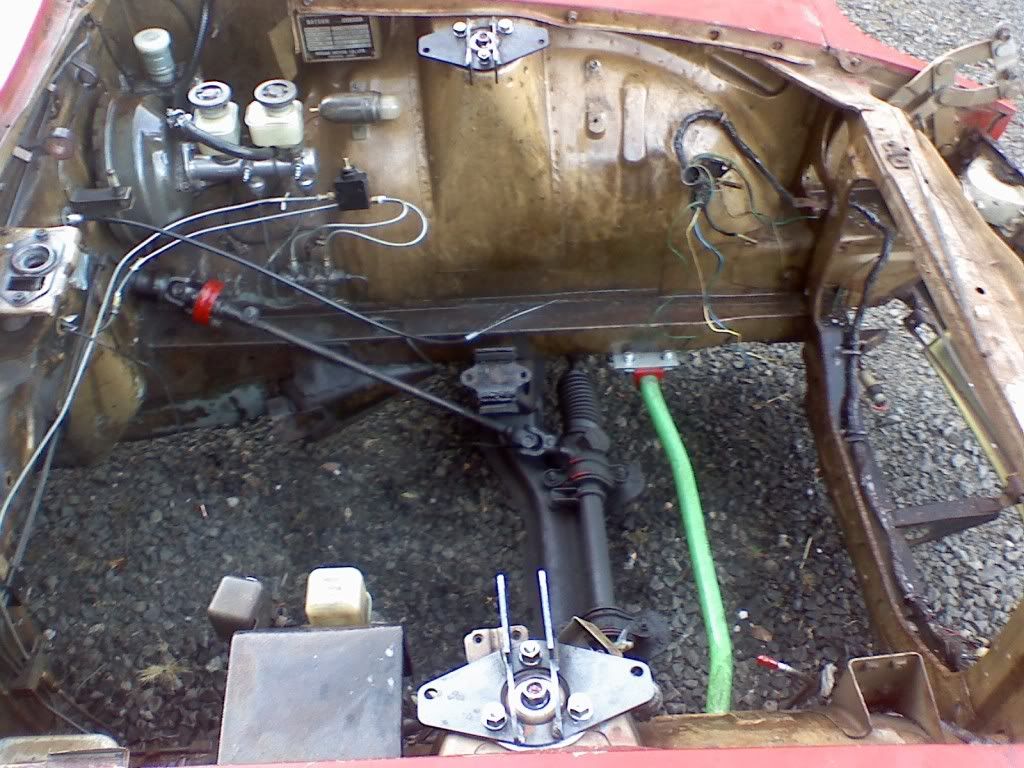

Hey guys, I've been working on swapping an LS1 into my Z for a few months now and I figured I'd post something up sooner or later before I was done. Yesterday it finally struck me that... theres not much left to do, so I just wanted to share my progess

Here are some pics (you can find more if you click in my sig), a brief descriptions follows:

Here are some pics (you can find more if you click in my sig), a brief descriptions follows:

Before I installed the LS1 I decided to sandblast, fix all the rust and paint the engine bay. I painted it "Championship White" from the Acura Inegra Type R, which is the color I plan for the rest of the car. I think it turned out great (for my fist attempt at painting ever) now I just wished I had painted it all at once! I also put in toyota 4x4 calipers and ran all installed all new brake lines for the car.

The engine swap itself is nothing crazy, just a stock LS1/T56 from a 2000 firebird (77k miles),no turbos or anything. Since this car will see a lot of track time and I've read the F-body stock pan baffling is relatively poor I dropped the oilpan and put in a new baffle from Improved Racing. For fuel I'm using a Walbro 255 lph pump, corvette FPR, new 3/8" hard lines and the stock 260z tank. I'm also running a surge tank from BC Broncos fed by a second, low pressure pump. To clean up the fuel lines in the engine bay I flipped the LS1 fuel rail. For wiring I got a standalone harness and flashed ecu from chevythunder.com and am in the process of finishing up the wiring inside the car. Chevythunder provided me with appropriate fan relays and fuses for the Ford Taurus fan I'll be running

Whats left? Not much! For wiring I need to hook up the standalone harness to the ignition and run wires for the Walbro pump. For mechanical parts, I'm going to design and order sheet metal mounts for my Taurus fan. I also need to hard mount the new ecu, relays and fuse box. Lastly I'm waiting on driveshaft from JCI and its off to the exhaust shop to weld up exhaust and fire the beast up!

-

I may be the odd man out here but I've worked with a lot of mills, lathes and CNCs during school and I dont really see the need to have one. I've known several guys who graduate and spend some money on a used mill for their shop. What theyve told me every time is that they spend almost the same amount of money on all the extra stuff (good vises, good collets, good end mills, setup/fixturing tools, I consider a digital readout a requirement, etc). And thats to go with just one form of fabrication (milling, turning, sheet metal work, etc) if you buy a lathe thats another set of stuff. Plus the darn things are HUGE. Getting in place just seems like a huge enterprise, and if you ever move youd pretty much be forced to sell it and buy everything over again.

If it were up to me I'd invest in a set of good basic set of shop equipment (good welder, compressor with various air tools, band saw, drill press, maybe a sander/grinder). Then procure a reasonable CAD package and learn to use it well. With this setup you can make very basic parts and brackets for whatever you are working on. If youre wanting to make more fanciful parts break out the CAD program and make friends with the local machine shop. They will make anything you throw at them for actually very reasonable prices. Theyll setup the machine, run your parts, and do an awesome job (I've never met a machinist that wouldnt bend themselves backwards to help me get the parts I want) all without moving 2 tons of equipment into your garage and forcing you to clean/service/stock it. You can spend your time doing what you love - working on the 1000 other things your car needs finished before its "done". An additional bonus is if they make 1 they can do more parts for not much more money, so youre building something cool you can get extras and sell/give them away and make other people very happy.

I know some of you are excellent machinists and fabricators (I'm no slouch either) and you want to make your own parts.. Thats cool, if thats what you want to do just for principle, I do not want to split hairs with you. However I do feel that unless ALL you do is build custom parts you dont need to turn your garage into a machine shop. Save some time and support the local professionals, they need it now more than ever...

-

Having just recently graduated with an ME degree and gotten out into the "real" world I'll put my 2 cents in...

I think Challenger is absolutely correct. When I was going to school it was more than a full time job (I'm really enjoying working ONLY 40-50 hours a week

). I too was in class typically 8 or 9 every morning and though I didnt stay till midnight (I went home) I still was busy studying or working on other school related projects until about the same time. I did not have time to do anything else. During my senior year I only had classes 3 days a week and in addition to studying and doing homework all the rest of my spare time was spent either doing design for my senior project or in the shop fabricating parts for it.

). I too was in class typically 8 or 9 every morning and though I didnt stay till midnight (I went home) I still was busy studying or working on other school related projects until about the same time. I did not have time to do anything else. During my senior year I only had classes 3 days a week and in addition to studying and doing homework all the rest of my spare time was spent either doing design for my senior project or in the shop fabricating parts for it. As far as difficulty with classes and professors I feel thats a necessary evil. I've had many classes where the tests that have an average score of 50 or below, these are just hard tests... What I saw was that there are people that STILL get 100s on tests even when the rest of the class gets 30s and 40s. If SOME people are doing ok it certainly means you can too, theyre not super-human. I have found that in engineering classes it is extremely important to understand the concepts you are learning first. If you can understand the basic concept you should be able to find an equation that will lead to the correct answer. I found this particularly true for classes like Thermo and Heat Transfer.

Your Calc class story doesnt sound very surprising, though I do think that 90% seems a little high. 50% is something I've seen routinely. With 200+ students TAs have a hard enough task wading through the drivel thats typical of most people's homework assignments. If someone is given clear instructions on how to setup the problem for the TAs to grade and they cannot follow simple directions thats their own fault. If one cant follow simple instructions how can they be expected to solve complicated problems in a real situation.

Finally about choosing a major. The average college student changes their major several times during their academic career. It is perfectly normal to want a change and there is nothing wrong with making it. I think your family will be much happier to see you graduate with a degree that you are genuinely interested rather than struggle through a degree that gives you nothing but pain. Also (and this is me being an idealist) I would not choose a major simply because of money, or how "stable" a job seems to be. Ive worked at several engineering companies and let me assure you MANY engineering jobs were lost when the economy tanked. Many of those guys are still not back in work. I also know quite a few engineering graduates who have not been able to find work. Another thing to consider is that many technical jobs are going overseas. My point is there never is a "stable" job, everyone is always playing the game trying to stay afloat. Secondly, I feel money should not be a factor in your decision. If you are smart about what you do you can turn any degree into something you can make money with. Focus on doing what you want and what interests you. Being interested in you studies makes you that much more devoted to them and later will make you that much more passionate about the work you do.

One last bit of advice: Get involved with the professors. They are always thinking/working on some kind of new, cool, research. Put yourself out there as a volunteer and get involved with what they are doing. It will give you a better sense of what exactly youre working toward and really give you a good idea if you like what you are learning. Plus its an awesome way to do some really interesting things and get a good reference for when you apply somewhere else to work!

-

I would recommend just taking them to a good local machine shop and asking them to press them out. I dropped it off in the morning and got them back by closing time, $25 for everything. Saved me hours of headache and uncertainty. Replace the pin with a 5/8 grade 8 bolt and never have the problem again.

-

I would be interested as well. In what kind of time frame do you see this happening?

-

When I switched to rear disc brakes I didnt feel a huge difference in terms of braking power. However, consistency and ease of maintenance are much improved. Also with the 240sx caliper setup you have a huge selection for brake pads (including R compounds) for further tuning in your application.

Though stock brakes and good pads work great for autox and street driving I suspect if frequent track days are in your future vented rotors are going to be highly desired. I also feel that if youre doing a V8 swap with high hp some front brake upgrades are good insurance. I'm upgrading to toyota calipers and vented rotors alongside my LS1 swap. I figured with 400+ hp you can get going very quickly very easily. A couple hundred bucks is not much compared to the net cost of swapping the LS1. For me I saw little reason not to go through with it.

-

I dont want to seem rude but how much track driving experience do you have? Unless youre a very hardcore and very picky or particular driver I think you can have a lot of fun driving your car on the track regardless of what the car actually is. I've seen all kinds of cars at the race tracks and autocross events from the most boring honda accords to fully prepped race cars and from what I've seen everyone has an awesome time. If youre a beginner (which you may not be, I dont know) I'd hazard to say you want to drive as much of a stock performing car as you can get so you can learn gradually rather than jumping in head first.

On another point if youve only really driven your Z car 4 miles in the last 5 years how can you honestly say that youd like a BMW more? My car's been down for only 2 months due to my LS1 swap and I already feel a little detached from it, I cant imagine a few years. I'd recommend keeping the car but dont sink any more money into it. Drive it as it is and have fun with it. Remember, you dont HAVE to constantly be upgrading the car. You can be very fast with just a few key mods and a lot of driving experience and really knowing the limit of whatever car you have. Do some track days and autocross events. If you learn to like it and see its potential invest further, if not sell it and buy what you really want.

One last thing (sorry to drag on) I just recently graduated with a mechanical engineering degree myself and if your program is in any way similar to mine the last 2 or 3 semesters are really the most important since it was the time when we did our Senior Engineering Design Project. I think focusing on that and finishing strong should be a priority, since you have the rest of your life to play with cars after you're done

-

Dont know if S12+8 use the same pads as the S12Ws but in case they do I used Hawk brake pads from a 300zx (Z32) in my S12W calipers. This setup gives lots of options for brake pads. Mine fit great, I didnt have to modify a thing. I cant wait to mount them on the car!

I believe you can also send them your brake pads as a sample and they will make a set for you to fit with the brake compound of your choice.

-

1/4" line seems small. My Z has 5/16" from the factory....

The stock pickup on your Camaro tank should have 3 nipples. Output (3/8"), return (3/8"), and vapor (5/16"). I used most of Z's original fuel line. I bought some quick connect fittings from Napa that adapt from the stock 3/8" (outlet and return) on the pickup to allow use of a 5/16" barb. I used two small lengths of 5/16" Goodyear fuel injection rubber fuel to bridge the gap between the pickup and the stock Z hard lines using 5/16" fuel injection clamps.

Up front I am running a stock LS1 intake/fuel rail and flipped the fuel rail so the input is on the passenger side to avoid having to plumb everything to the drivers side.

Cable, I haven't read much about flipping the fuel rail but it seems like a very clean solution to avoid having to run fuel lines to the driver's side. This might be a dumb question but was it fairly easy to flip the rail around? Anything I should watch out for if I were to do this? My plan is to run a corvette FPR by the fuel tank and run one fuel line coming all the way up to the engine bay. If I can avoid having more hoses snaking around in there that'd make for a really nice looking install.

-

I'd like to buy a 240z urethane air dam. This is the one I'm looking for:

I have a 280z style one in exchange if anyone is interested.

Please let me know what you have, thanks.

-

I have heard good things about TTT parts. Looking at the design I particularly like their version of the Z car front LCA using the boxed design over say the billet aluminum LCAs from Arizona Z car. Their rear LCAs are H arms which I believe are fairly common and effective, though inferior to A arm type designs if I remember correctly.

As part of my suspension overhaul I will be buying their full setup (front LCAs, TC rods, bumpsteer spacers, rear LCAs) probably tomorrow. Once they come in I can put together a quick write up of my impressions.

-

This is a pretty neat idea. If these cars are used on the TR6 I would think they should be a good match to the L28 after some tuning.

Is this the kit you were reffering to: http://www.amazon.com/Genuine-Weber-45-MCHH-Carburetor/dp/B0036Z10FU

If those adapters match our twin SU manifold it should be ridiculously easy to bolt this up. I guess linkage would be the only issue but it shouldnt be too hard to figure something out. If that kit works that is one heck of a deal for upgrading our fuel system...

Post more pics of video if you get a chance

I'm seriously considering switching my 4 barrel to this setup, I still have my SU manifold and everything...

-

If your pulley is cracked I'd invest in a new pulley. As far as the crank keyway being worn if youre looking for quick fix for the problem you might try this: http://www.miata.net/garage/hsue/LoctiteCrank1.html

I actually just had the same problem a couple weeks ago and used the same procedure as outlined in the above link. It seems to have worked very well and should hold until I have time and money to properly rebuilt the motor with a new pulley and crankshaft.

-

I saw this on GRM forums a couple of days ago. Definitely turned out great and makes me consider doing this to my car. I'm sure its fairly involved but probably not much more than painting a car. I dont know much about body work but the best part in my mind is that you can tear a panel off and start over if you mess it up the first time.

What I'm curious about is what brand/compound vinyl wrap he used for his process. There are many different manufacturers out there and their prices vary a LOT. For $120 the wrap he used cant be high quality so I question the longevity of the material, additionally more expensive materials are easier to apply (I think) making the job that much easier. Anyone know more about different vinyl materials? I might like to try something like this on my Z but would like to find a nice compromise between good material and cost, so I'm not getting the cheapest crap I can find and still going to have an excellent finished product.

-

New old stock motorsports sells CNC bent brake and fuel lines for our cars: http://www.newoldstockmotorsports.com/index.php?cPath=1_19

-

Mine doesnt look anything like that. I have a feeling i have a little fabbing to do, one way or another. I can either do what arizona z car shows, or i can notch the mount the stock firewall-mounted lever is attached to. That way the gas pedal just has a little more travel. All i need on the Holley side is about 3/8" of more cable travel for wide open throttle. But as you can see, its a bit janky right now.

By the way, do i have the linkage mounted to the correct hole on the throttle on the carb? Once again, kinda how it was when i got it, but if i should move it let me know.

I could be wrong but with your setup, if you try mounting the linkage to a lower hole on the throttle lever the medal should give you more opening. I dont think it matters what hole you use really...

-

I assume you are using cable linkage as recommended by Dave. I had this exact problem when I did my conversion as well, the stock pedal doesnt have enough travel. I used a spacer to space out the accelerator pedal so it has more travel before bottoming out. As long as you dont make the spacer too thick it shouldnt drastically change your pedal layout. In fact, if you look closely on their on the installation instructions page (http://www.arizonazcar.com/cableinstall.html) it looks like AZC had the same issue during their install but did not mention the problem. It looks like they used a similar spacer to correct this issue as well.

The other option you have is changing where the throttle cable is mounted to linkage on the carb. If you mount the little pivot lower on the linkage arm pressing accelerator pedal would open the carb more and should allow 100% throttle position.

-

Not mentioned in your OP, nor are they sold on tirerack, but Falken rt-615s are a great tire. I autocrossed in them all summer long and also drove it a bit on the side, and theyre still in great shape for this year! Many of the guys running street tires also run these and give them much praise. I think theyre a great value for your money as well since they offer similar performance to some of the other big name tires you mentioned at a lower price. I bought mine new at less than $100 a tire (15" wheels) here: http://www.vulcantire.com/azenis_rt615_t.htm

Just a side note from the reviews I've read people say theyre fine for autocross but dont do as well for open track events as they get very greasy and slide when hot...

-

If you get away with something, is it then ok?

That's sort of the principle I'm going by. Most tech people here probably wouldn't realize or care that the p79, etc, heads came out of a later car. I don't plan on competing on a national level either, where inspectors might be more interested in whats inside the car. Heck, most of the time I don't even specify a particular class when I run, so really I can do pretty much whatever I want...

I'm trying to build the car per SCCA rules mostly because I thought it would be fun and more interesting to build the car to a particular ruleset.

Wiring all components for the LSX Swap

in Gen III & IV Chevy V8Z Tech Board

Posted

Thanks so much for finding this! I'm having as hard time dealing with this issue myself. I looked up the same part at RockAuto.com and found a little more reasonable price. $26 for the same part.