Roostmonkey

-

Posts

508 -

Joined

-

Last visited

Content Type

Profiles

Forums

Blogs

Events

Gallery

Downloads

Store

Posts posted by Roostmonkey

-

-

I'm hanging on to the L28 for now. Probably wont drop this in until the 07 convention is done. That will give me time to gather everything else needed and build this motor for 450-500 whp. I will be at ZDAYZ again tho.

-

and brought me a ton of work to do.He alsp brought a rb25 rwd tranny and rear sump pan and drive shaft to modify.Thanks to everyone thats posted swap info here, it will make things alot easyer for me.Happy holidays everyone.

and brought me a ton of work to do.He alsp brought a rb25 rwd tranny and rear sump pan and drive shaft to modify.Thanks to everyone thats posted swap info here, it will make things alot easyer for me.Happy holidays everyone. -

All steel 7ga, and up is hotrolled. My plans have changed and I wont be needing any of these now. No more L28 mods, its Rb time for me.

-

Hey Pete, Wolf makes a plug and play for the RB26dett.Do you think I should go that route or stick with the V4 on this next build ?

-

I own a 10 man metal fab job shop. These machines are far from a hobbiest's tool. The units I'm looking at run between 120k and 180k.Ive seen the "hobbiest" units and although they can cut a pretty horsie shape, they use a handheld plasma torch U bolted in place and cant hold a tolerance for dick.Even the highend plasma's dont match the waterjets precision but for my business, plasma does a great job.I'll dig threw my stash a z parts and see if theres anything you might want in trade for the file.

-

Thanks, Ive got a Cnc Plasma table and have been shopping for a new replacement.Its a bout 14 yrs old and is getting tired. The machines Ive been looking at should do a pretty good job on something like this.

-

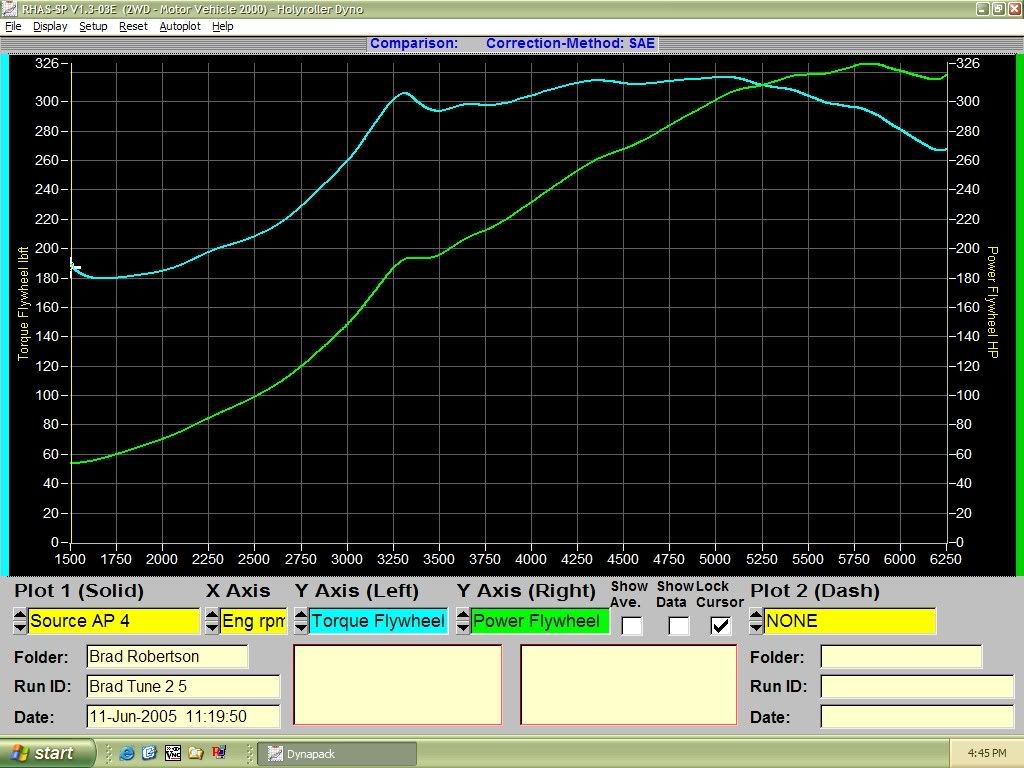

Mine is similar, very smooth delivery. This was on a Dynopac

-

Ive been following this thread and I too would like one of these flanges.Is there an option to have them cut from stainless? If not, would you sell the DXF so I could make my own? I know the layout and testing is the most time consuming aspect of a project like this and you should be compensated for your efforts.

-

Not if its just a T3 type flange.

-

Fax me a sketch and I'll CNC plasma them for you. PM me for details.

-

I was going for the metalic olive when I chose this paint but it changes dramaticlly in the direct sunlight.I like it better when its overcast.

-

-

the wheels are something like BBS ???? I know he had them built for his Z.

-

This was Johns car and is the reason Baddog Parts came about. It seems that a dog was standing in the road around a blind corner and John being the humanitarian that he is, sacrificed his ride for the wellbeing of the baddog in the road. The car that replaced it is way nicer.

-

Hey Greg this is Brad from the ZCCNE. Theres a guy out in Albany with an LS1 swap (as I remember).

-

the stock manifolds weld fine as long as its been cleaned well. Not just with a solvent, you need to remove the outer skin with a grinder/sanding disc.I would use a 5052 h 32 material, Its stronger than 3003 and easyer to form than 6061.I would use a 1/4" thick plate for the connection to the stock runners and 1/8 for the plenum. The thicker stock allows you to open up the hole on the inside and get a decent taper to the runners.Once thats all welded and polished, the plenum can be welded on.

-

26 is a tad thin IMHO. I would use 20 ga for exterior body panels and 18-16 for floor pans.Stock pans are thinner but they have stiffening ribbs pressed into them to add rigidity. If your tranny is out of the car when you do the pans, bolt the tranny carrier back onto the car to hold the tunnel opening at the stock dimension.

-

All better now.Not even gonna say what it was.....It holds strong to my 13 psi setting and when I lift, it lets out a nice deep KSSSHHH. I guess next time I'll look closer at the painfully obvious before whipping out the credit card.

-

thanks Mike...it is stainless and they're mandrel els cut and welded together then polished to appear as one pc.

Took it for a spin tonight and its still bleeding air off at 5-6 psi.Its so loud, I was sure it was BOV.Checked all the hose connections from the turbo to the TB and everythings tight.Its got to be the wastegate dumping air.Guess I should have put my money into a better Boost controller.I'm using a Dawes Devices unit and its been pretty good so far.I'll make some adjustments and see if thats been the problem.

-

Another view

-

Well, I installed it last night but didnt get the chance to try it out. It was dark when I finished and I'm also in the middle of upgradeing the headlights. Heres

a pic to show the install and how sexy it is.

a pic to show the install and how sexy it is. -

Thanks guys.

-

theres no options for spring changes.At least they dont mention any alternates on their website. I'll run it tomorrow and see what I get.

-

I just recieved my tial bov and I dont see any adjustment provisions.Most likely doesnt require any adjustments but the Turbo-X unit I'm replacing, did.Does anyone know if this is the case? Ive searched Garrett's site and theres no info.I'll get the flange welded on tomorrow and try it out after work.Its a beautiful piece of work, almost too pretty to put on a motor.

and brought me a ton of work to do.He alsp brought a rb25 rwd tranny and rear sump pan and drive shaft to modify.Thanks to everyone thats posted swap info here, it will make things alot easyer for me.Happy holidays everyone.

and brought me a ton of work to do.He alsp brought a rb25 rwd tranny and rear sump pan and drive shaft to modify.Thanks to everyone thats posted swap info here, it will make things alot easyer for me.Happy holidays everyone.

a pic to show the install and how sexy it is.

a pic to show the install and how sexy it is.

Zanta came to town...pics

in Nissan RB Forum

Posted

Got the motor with uncut harness,ecu,nismo billet clutch,new drive shaft,five speed tranny and rear sump oilpan. still need motor mounts,oil pickups etc... I met a kid with a GTR and he had this package ready to go into a 240sx and decided not to do the swap. I just met him at the right time and scored.