-

Posts

247 -

Joined

-

Last visited

-

Days Won

14

Content Type

Profiles

Forums

Blogs

Events

Gallery

Downloads

Store

Posts posted by Invincibleextremes

-

-

-

-

-

-

You would need a hybrid axle... 240sx on one end and 2015 mustang on the other end... the weak link being the 240sx parts. Or just drill the mustang hubs for 4 lug... that would be strongest.

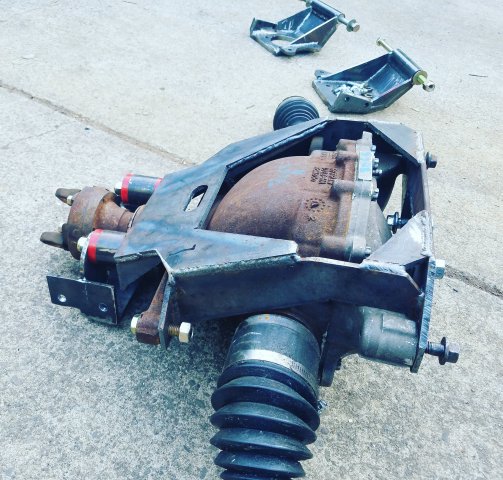

Here's another customer setup I tacked together. He'll need to notch his crossmember and tie in with the two halves up front... or I can provide a laser cut crossmember already tied in... working on getting a batch of those in once I design that.

I changed the angle of the diff which works better with an rb25 or an LS. Carbed motors sit at an angle and it worked with the older version but a more inline approach is what most will need.

-

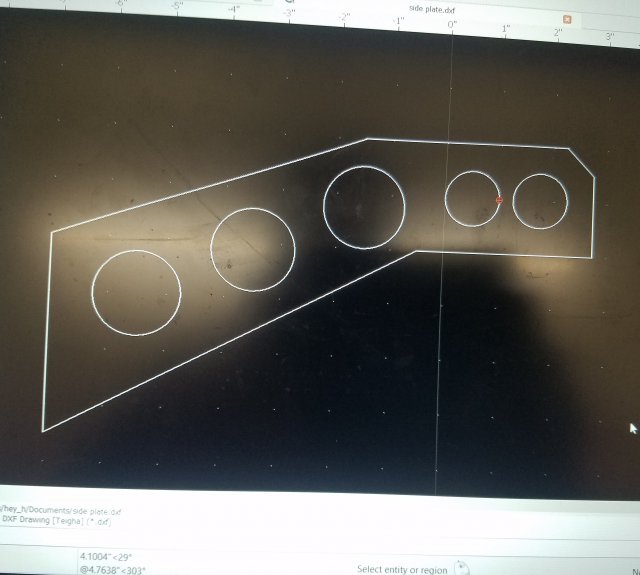

Built a mock up kit in foam board which allowed me to take it with me and draft up a bunch of the parts and I then took out some weight in areas that didn't need the extra material.

Paid for a batch of different parts to get laser cut, which definitely speeds up my efforts vs having to hand cut all the parts.

Working on a few customer orders at the moment and I'll post pictures before I ship them out.

Also having a small batch of 800tq axle shafts made for this conversion. Last batch we got fit perfect so we're getting more.

$65 per decent cv axle plus the $300 each shaft makes for some relay cheap, really strong cv axles.

Maybe one day I'll go with some of the aftermarket 800hp, 1400hp or 2000 hp axle assemblies being offered for the 2015 mustang but in a car as light as a datsun I dont see the need just yet.

And as someone pointed out... LESS has done 8's in the 1/4 mile.

-

11 hours ago, seattlejester said:

Congrats on putting it together!

While I appreciate your efforts and bringing another option to the table, per the forum rules though I will have to suggest any pricing and sale information and such be conducted via PM or better yet setup a post in the vendor section!

Also must warn you on the group buy type situation. You seem a driven individual, but in the past several have ended badly. Building and selling is slow and inefficient, but it does allow you to manage expectations and prevent things from getting out of hand.

thank you, edited best I could and I will stick to the rules and post in the vender forum when i have kits available.

-

On 6/11/2019 at 8:39 PM, fusion said:

Would you mind summarizing your efforts? Like what does the kit come with, what parts are needed, and what power level it can support? Does the Z need to be modded?

I've read the thread but not 100% sure.

Thanks

In short. Kit is bolt in instead of an r200. One bracket on the drivers side in the trans tunnel is in the way but the parking brake cables are left untouched.

Uses 2015 mustang brakes, hubs, cv axle parts and diff.

Requires custom length axle shafts if using factory cv. Or 800hp and 1400hp race axles.

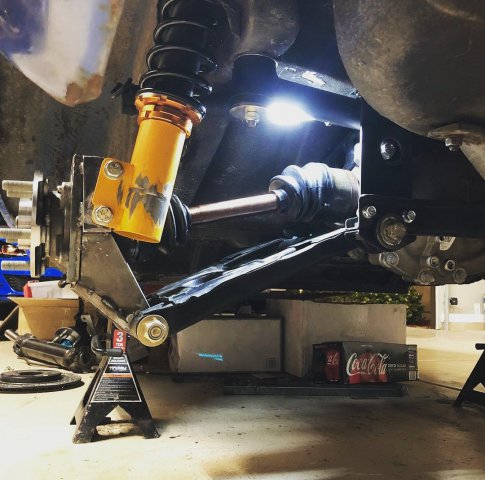

The kit bolts up to 2004 neon coilovers with swapped tops.

Also has the option to run smaller 2014 mustang brakes and use 15 inch wheels as a result.

New 34 spline super 8.8 is 30% stronger than the older 31 spline 8.8 diff and shares NO parts with them. Thats a quote direct from ford.

Some Older 8.8 swaps have easily held 800hp on a datsun and NONE have ever been this strong or used a cradle.

The custom shafts are 800 ft lbs capable but use factory cv so 500hp is what i would trust them at. 800hp has been used on much weaker parts... but I'm not going to make those promises.

The 800hp axles sold by DSS are for a 4,000 lb car so you make you own guesses as to what they're good to on a datsun...

***contact for pricing if interested, on an individual basis***

Today for example i ordered some half inch cut pieces at an amazing deal so price will reflect that in the future.

-

Cutting them by hand takes forever and theres no way i'm working for free.

-

-

-

-

Built jig for the uprights and making progress. Still a few more things to finish and I'm dropping it off for the customer. Both sides will be gusseted btw...

Oh and had a chance to snap a pic of whats needed from a 2015 mustang (brakes can be 2014 for smaller wheels)

Brakes, hubs, cv axles with custom length shaft, and the diff itself comes from one donor car.

-

-

Mismatch would be if i stayed with a small motor and toploader... plans are for insane level hp.

-

Got a 1,000 hp nascar driveshaft... 4.5 inches in diameter.

Compared to the current aluminum corvette driveshaft I've been using so far.

Btw nascar driveshafts are $90 to $150 all over ebay. Too long for this, but cut and balance isn't too bad cost wise, and the driveshafts usually come with billet yokes which are worth the purchase price by themselves.

Spicer 1350 u joint flange and factory five super 8.8 driveshaft adapter for the cast iron diff. Automatic cars that used an aluminum diff get a different adapter because they used a different driveshaft from ford.

Not sure if i mentioned this, but my goals for this car are to use a 532 cubic big block ford stroker with aluminum heads and a toploader 4 speed... and later a nascar trans if the toploader lets go.

-

I'm in portland. You're welcome to stop by at the end of the week and look it all over.

-

Thats close enough i guess. Should i make you a set from this batch? The guy I'm working with who's helping with the axles is in California as well

-

-

Not a problem. I can make as many as there is demand for. And who ever is on the fence can always just wait for results from either my car or another customer before contacting me for anything.

-

1

1

-

-

Currently only planning on making 3 right now. I can make as many as people want really.

-

Back in town and working on a couple cradles for a couple guys who want them here and now. Still waiting on the axle shafts.

$255 per shaft if bought in bulk and they're made from scratch, and heat treated after. Got my hopes up, because these would be just the ticket to assemble on factory 2015 mustang cv axles.

Mind you the factory axles use a hollow shaft on the left side... and these new ones don't.

I'll post some pics soon of the cradles and hopefully have news on the shafts. Fingers crossed I'm dealing with good people... would be nice to have 500hp at 4,000 lbs capable cv axles for under $700 a pair... plan B is the $1,300 ones rated to 800hp at 4,000 lbs but thats a good bit more money.

-

13 minutes ago, wongboh said:

Subscribed. I was tossing around the idea of building a jig to shorten the super 8.8 assembly and mount in my Z but this seems like a much easier option and will let me get my Z back on the road sooner. Thanks for tackling this project on and bringing an affordable option to market. I would be interested in the tack-welded kit.

Just doing what i can. I should be back to work on it on the 25th, and I'm still waiting to see how the new batch of axle shafts turns out.

-

Thats literally what several different people are doing. Just not worth dealing with the factory stubs.

Ford Super 8.8 irs swap thread. Rear brakes too

in Drivetrain

Posted

David refreshed his diff with new bearings and seals.