-

Posts

247 -

Joined

-

Last visited

-

Days Won

14

Invincibleextremes last won the day on December 25 2022

Invincibleextremes had the most liked content!

Contact Methods

-

Website URL

http://Www.youtube.com/invincibleextremes

Profile Information

-

Location

Usa

Invincibleextremes's Achievements

-

Ford Super 8.8 irs swap thread. Rear brakes too

Invincibleextremes replied to Invincibleextremes's topic in Drivetrain

- 277 replies

-

- disc brakes

- suspension

-

(and 7 more)

Tagged with:

-

Weld in plate to get the max caster and bring strength back to the shock tower. The reason for the needed caster mod, is the mustang spindles have an offset bearing, and were designed for 8 degrees of caster in general. Proper wheel placement in a Datsun s30 requires the offset balljoint and shock top. David in the dark blue car just cut his front fenders instead, and kept his ball joint in the normal location.

- 90 replies

-

- 1

-

-

- suspension

- 240z

- (and 5 more)

-

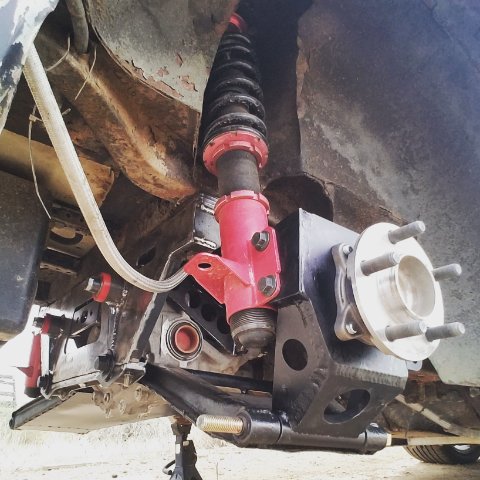

new front bolt on control arms available that make the 2014 mustang spindle swap a bolt on deal. green car also has baer brakes and he really likes them. the suspension picture isn't of the new arms, but is of the spindle swap in general. This particular car has modded stock arms. faded red car has the front spindle swap and the rear 2015 mustang hub and diff swap too.

- 90 replies

-

- suspension

- 240z

- (and 5 more)

-

Ford Super 8.8 irs swap thread. Rear brakes too

Invincibleextremes replied to Invincibleextremes's topic in Drivetrain

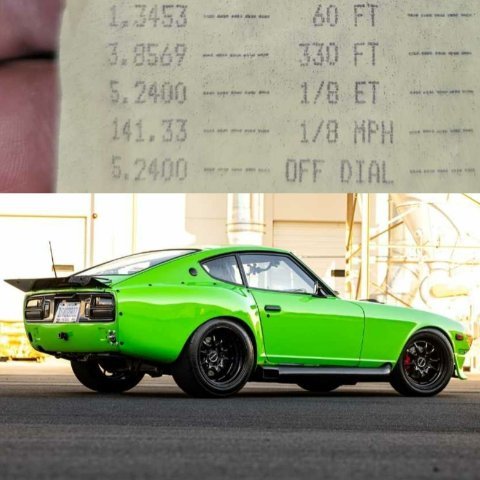

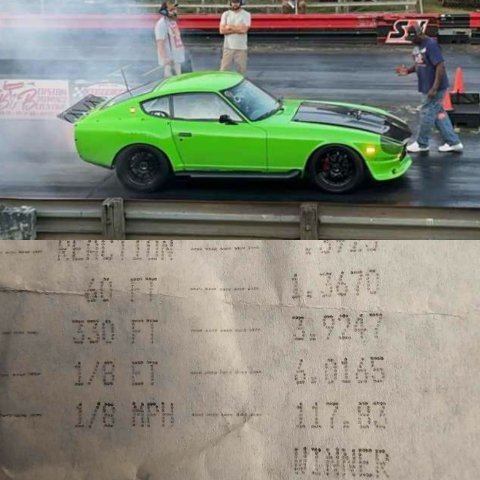

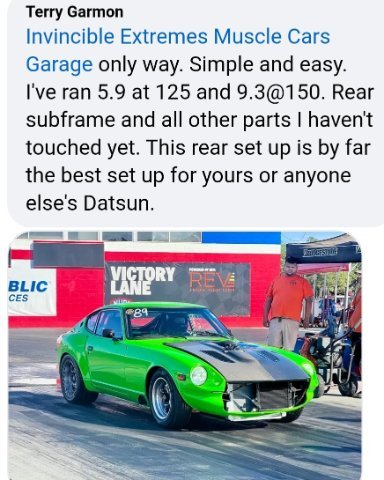

175 mph back to back Class wins for Davids Blue 260z with a 434ci LSX running a half mile event. Terry's green car has over 1,000whp but turned down for pump gas it pulled a 1.3 60ft on a 6.0 @ 118 run for the 1/8 mile. his best so far has been 9.3 @ 150 mph in the 1/4 mile and 5.9 @ 126 in the 1/8.- 277 replies

-

- disc brakes

- suspension

-

(and 7 more)

Tagged with:

-

Ford Super 8.8 irs swap thread. Rear brakes too

Invincibleextremes replied to Invincibleextremes's topic in Drivetrain

There's an optional piece now that replaces the mustache bar and rear drop downs and drastically strengthens the rear of the car and completely illuminates the toe issues these cars sometimes come with from the factory. The newest version of the mustache replacement is lighter and has more provisions for fuel line routing. It ties in the mustache bar anchor points with the 4 drop down bolts, making the entire back of the car incredibly strong, while still having proper isolation in the rear differential mount for the cradle via common aftermarket mustang bushings.- 277 replies

-

- disc brakes

- suspension

-

(and 7 more)

Tagged with:

-

Ford Super 8.8 irs swap thread. Rear brakes too

Invincibleextremes replied to Invincibleextremes's topic in Drivetrain

- 277 replies

-

- disc brakes

- suspension

-

(and 7 more)

Tagged with:

-

Ford Super 8.8 irs swap thread. Rear brakes too

Invincibleextremes replied to Invincibleextremes's topic in Drivetrain

David hit 171 mph repeatedly in the half mile event recently and looked darn good doing it. He also spent the weekend kicking butt at ls fest proving once again the absolute reliability of the super 8.8 setup. His lsx 434 hit a best of 10.3 @ 141 mph with a DA of over 4000 and him using a 100 shot.- 277 replies

-

- disc brakes

- suspension

-

(and 7 more)

Tagged with:

-

This is the sister thread to the rear diff swap thread. More people do the diff swap than the front actually, and many do all 4 corners. Thread for the rear is in the drivetrain forum.

- 90 replies

-

- suspension

- 240z

- (and 5 more)

-

Good news is by the time you decide, you will hopefully have seen my own rusty pile on the road, or at least more and more super 8.8 swapped projects out and about this coming show season.

- 90 replies

-

- suspension

- 240z

- (and 5 more)

-

Stock smallest is the v6 2005 brakes, they are 11.5 and comfortably fit 16 inch wheels, and struggle with 15s. There are aftermarket 2005 to 2014 front brakes by wilwood and others that are 4 piston calipers and are specifically designed for 15 inch wheels. At that point, you still benefit from the taller balljoint, the Ackerman, and camber at the hub adjustment, but aren't saving much money, because s197 aftermarket brakes aren't 200 dollars like the factory refurbished ones are.

- 90 replies

-

- suspension

- 240z

- (and 5 more)

-

Definitely agree with using the biscuit style and then squeezing some caster out of it as well. You won't need much camber on the street, and that's where the caster really helps you out. Maybe a hassle to adjust, but you won't have to cut, so thats your only option unless you want to change your track width on those kinds of adjustments.

-

Ford Super 8.8 irs swap thread. Rear brakes too

Invincibleextremes replied to Invincibleextremes's topic in Drivetrain

As time goes on, more and more of the kits get installed on various project cars, mild to wild, including my own rusty widebody car.- 277 replies

-

- 1

-

-

- disc brakes

- suspension

-

(and 7 more)

Tagged with:

-

Explorer 8.8 and apex aren't going to hold your hp. Guys with far less hp have issues with both the diff and the flex in the apex parts. I was referring to the super 8.8, which is a 34 spline monster that costs peanuts and comes out of the 2015 mustang. That gold car is andrews, and is a 6 speed car that puts down procharged 6.0 ls power effortlessly with the super 8.8 and mustang hubs. Also, the 8 ball cv axles with 300m shafts cost HALF of what dss would charge you, and that's not even talking about the cost savings involved in not having to upgrade the 280z outer stubs etc. Gold car is andrew waldony, not hard to find on Instagram, or just look me up, same name on Instagram as on here, i tag all my high hp customers in pictures of their cars. You can waste your money, or you can get what actually works.

-

Ford Super 8.8 irs swap thread. Rear brakes too

Invincibleextremes replied to Invincibleextremes's topic in Drivetrain

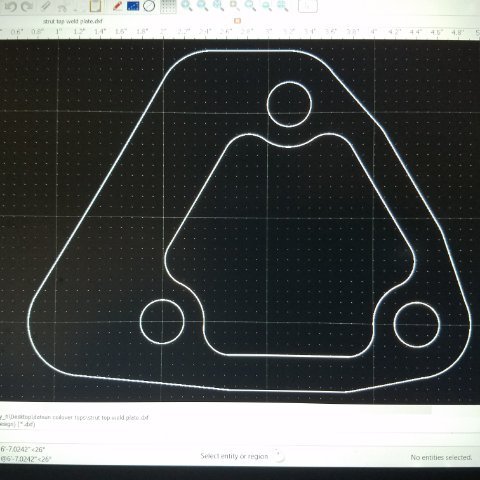

Designed a replacement for the r200 mustache bar that ties in the suspension mounts too, but still has bushings for the rear of the diff cradle.- 277 replies

-

- disc brakes

- suspension

-

(and 7 more)

Tagged with:

-

Ford Super 8.8 irs swap thread. Rear brakes too

Invincibleextremes replied to Invincibleextremes's topic in Drivetrain

Nick shredded his r200 turbo axles, and his r200 whined, so he swapped to the super 8.8 and did the front mustang spindle swap with boss 302 brembos too. Motor is turbo 1jz making around 600 with an e85 tune.- 277 replies

-

- disc brakes

- suspension

-

(and 7 more)

Tagged with: