-

Posts

6 -

Joined

-

Last visited

About Kires

- Birthday 04/07/1975

Profile Information

-

Gender

Male

-

Location

Melbourne, FL

Contact Methods

-

Skype

kires.mccollam

Kires's Achievements

Newbie (1/14)

0

Reputation

-

Back when I was a kid, I worked at a place in Ft Lauderdale called the Z car Center. (3 guesses what they specialized in) I was driving a '79 280ZX at the time. I had just picked up my son from daycare and dropped him off at home, and was on my way back to the shop to finish up a few more hours of work. It was raining cats and dogs, and there was plenty of water in the road. I came to a flooded section, and the water came up to the bottom of the doors, but I was young and fearless so I decided that I could make it through. (I was like 21 or 22, so still 'technically' retarded) I was ... not correct. The water got up to the hood, there was a hell of a bang, and the engine stopped dead. I slogged the rest of the way to the shop, Jeff got the truck, and we dragged her into the shop, where we pulled the plugs out and turned the engine over. Water shot across the shop from all 6 cylinders, and Jeff told me that I'd probably need to rebuild it. I was sad. The next morning I got a ride in to the shop, put the plugs back in, and tried to start her up. I remember that she sounded like a steam engine, and flames were shooting out the side of the block from Numbers 5 and six, where 2 chunks of head gasket had been blown out the side of the block... but she ran. At the time,. it was the most badass thing I'd ever seen. For the next few days, until we replaced the head gasket (which was all the repair she needed) she was driven in and out of the shop daily. That's when I fell in love, and decided it was the only kind of car I wanted to own. ... So the short version is that yeah, I'd say the L28 is absolutely one of the toughest engine ever made.

-

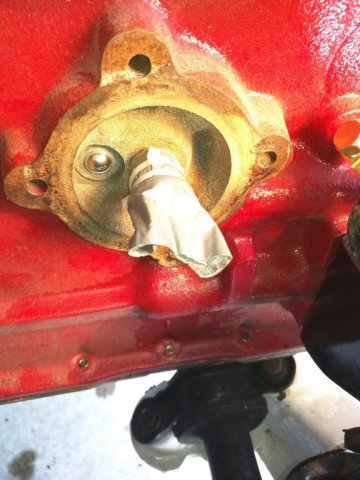

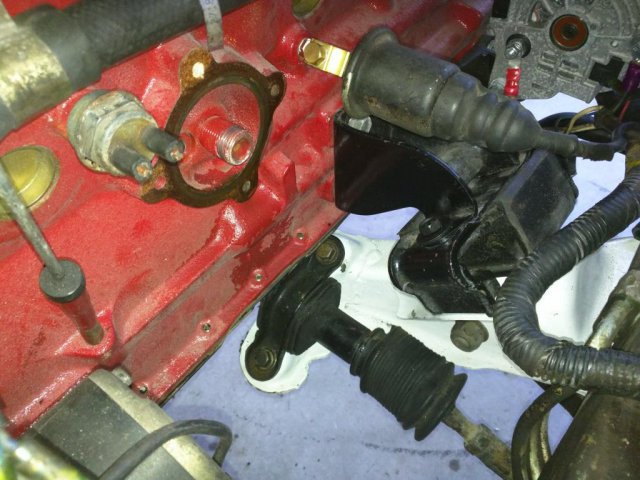

I'll be using the oil cooler assembly from an 83 turbo. It's being connected to a rebuilt engine that was based on a non-turbo block. Both the cooler hookup and the block have bypass valves. I see no reason for there to be two bypass valves and I'm worried that they'll just make it so that less oil gets cooled and filtered, so I'd like to block one of them off. My question is this. Can I simply pack JB Weld over the block's bypass valve, then sand it smooth once it cures? Or should I pull the valve out and use something like a smaller freeze plug or something? I'm assuming I don't want two bypass valves because in the turbo block, the bypass is filled and covered by a slug. I'm pretty sure covering it with jb weld would be fine, but I'd like to be a more than 'pretty sure' before I start doing permanent-type things to the lubrication system. Thanks!

-

Thanks, Bob. I was actually wondering if I could get away with no oil cooler at all during the break-in period, but being able to use the old one will definitely be better. Thank you, sir. I was planning to take a wire wheel to it, but thinner or some other chemical would likely make less dust to drift off into an oil channel or something. I don't think they painted it intentionally; my guess is that it's just overspray, but still. I don't like the idea of having paint sitting there to potentially flake loose and lodge itself in a channel somewhere. (like the Turbo's oil inlet, for example). One guy I asked said it would be fine, that the paint was meant to handle oil or they wouldn't use it on an engine (okay, that makes sense), but my gut disagrees so I'll be removing it before I get the cooler connection on there. Also, I notice that both the oil cooler connection assembly and the block have bypass valves which will end up facing each-other when it's installed. The original block had its bypass valve blocked off. Is there any danger to leaving both valves in place and functional? If so, what would be the best way to go about disabling or removing one of them? Should I knock it out and tap the hole for a plug, JB Weld it, or for-real weld one of them so it couldn't open?

- 3 replies

-

- oil filter

- oil cooler

-

(and 1 more)

Tagged with:

-

Hi, all. I'm (hopefully) almost done installing the rebuilt engine and I've got a question about connecting the oil cooler to the block. As you can see, the block is set up to have an oil filter screwed into it, and I do have an aluminum oil cooler adapter that can be sandwiched in between the block and the filter to hook up the oil cooler. So there is an all-important plan B on deck. However, I also have the original oil cooler setup that came stock on the car, an '83 280ZX Turbo 2+2 and I'd rather use the original connector and hardware if possible, at least for now. Thing is, the block has a male connection for an oil filer to screw on, and the connector assembly I pulled off the stock engine has a male connection that's meant to screw into the block. I'm about 90% sure that the block's connection is just a threaded pipe, and so can be unscrewed with the aid of a pipe wrench and maybe a bit of foul language. However, I'd like to have someone who knows more than me check my math before I do anything that would require a machine shop to set right. So, is the oil filter connector a thing I can just unscrew from the block, or did some overly enthusiastic engineer decide it would be better to press fit the damned thing, and I'm going to have to go with the aluminum sandwich adapter?

- 3 replies

-

- oil filter

- oil cooler

-

(and 1 more)

Tagged with:

-

Paypal sent for barbed rail with pressure gauge. Thanks!

-

I neglected to mention a few things, my bad. The incoming engine management system doesn't use an airflow meter, so that should simplify the plumbing a bit (hopefully enough to make a straight-ish shot down from the naca duct feasible). The turbo itself is water-cooled, and the exhaust side of the turbo and the exhaust manifold are coated with this silver ceramic stuff that should help keep their exterior temp down. I'm definitely getting rid of the stock fan, and I've got a couple of electric ones to take over its job. I've seen setups where the intake is behind the radiator, but it just doesn't seem right to use pre-heated air like that for a turbo intake, which is my main reason for wanting to have the intake coming from outside the engine compartment and have the path to the turbo be as short and direct as possible. (And maybe a bit of positive pressure there won't hurt, either) The power bulge is the raised portion of the hood that runs down the middle, and the front of it is a trapezoid that looks like it could be opened up to serve as the air intake. A raised bit of the hood, right out in front like that, I don't see why it hasn't been used as the intake all along- it just looks like it ought to be, IMHO. If I were to do this, I'd probably see about using the bulge itself as the air duct to get the air back to the turbo, but that would mean going around the intake manifold on the way down, which might be too complicated to be practical. Of course, I don't really know what I'm talking about here, so my reasoning may well be flawed, which is why I'm wanting to run this by some people who actually know about this stuff.

-

The hood of my '83 turbo has a NACA style scoop, which I _think_ is there to bring in air to keep the brake master cylinder cool. I'm replacing the engine in the next few months, and I'm going to have to re-route the intake to accommodate the intercooler and larger turbo. While I'm at it, I'm planning to seal up gaps around the radiator and intercooler, and doing a bit of tweaking of the airflow into and out of the engine compartment for better cooling and less lift. Anyway, I'm wondering if I can use that naca scoop for the air intake (I'd need to fabricate a filter box), since it's directly above the turbo, and I'm thinking that all the air coming into the engine compartment really should be doing so from the front. Using that naca scoop as the air intake seems like an obvious improvement to me, but the fact that I haven't seen it done this way before by people who actually know what they're doing makes me wonder what I'm missing. Is this a laughably awful idea for some obvious reason that I'm not seeing? Along the same lines, would it be possible to open up the front of the power bulge and use that for the intake? The plumbing would be more complicated for that route, maybe using the hood itself for most of the ducting, but it just looks like that would be the obvious place to put the intake. Or would that also be unworkable? Thanks.