-

Posts

405 -

Joined

-

Last visited

-

Days Won

1

cheftrd last won the day on July 18 2009

cheftrd had the most liked content!

Contact Methods

-

Website URL

http://www.mjrperformance.com

Profile Information

-

Gender

Not Telling

-

Location

Okinawa

Recent Profile Visitors

The recent visitors block is disabled and is not being shown to other users.

cheftrd's Achievements

Newbie (1/14)

12

Reputation

-

Re-connecting the orange/brown wires restores it to whatever cylinder operation. Green goes to green. GMR pu must be bolted down, and clamps around one of the coil power supply wires (at the coil so it doesn't register current from more than one coil). http://documents.msdperformance.com/8918.pdf

-

There are a lot more than that. The six or seven that I've personally seen all start with the front clip from the BNR. Uses the frame members, cross member, front support, etc. Aprons and suspension are all custom, with pipe uppers. Old post, but to the OP, It's a ridiculous amount of work for not much gain, as the car already has fantastic traction from the get-go. I'm guessing that with the way the engine sits forward in "Skyline" position, it actually handles worse.

-

Sort of, but not really...LOL. It's only at idle, and because there was so much fuel going in dirty, it took a lot more fuel to get it to burn correctly. At 7k rpm, there's 17ms to get all the fuel in, so pretty much once you're past the mid range, there's no real benefit to be gained from tweaking injection timing, other than keeping fuel stand-off to a minimum, if it's even a problem.

-

I saw that, and asked him about it. His timing is start of injection, and he found it best starting about 350°, which is 10°BTDC, or just when the valve is opening, so it's IVO injection. All I did above was changed it to somewhere I knew was going to be IVO, and its far from optimized. Once I play with it some more, I'm guessing that I will find the same results Andy did. The injectors on in the TWM DCOE throttles are also a little further away. It runs good now, but I'm also wondering how much better it might run with some Denso UC injectors with a 50μm SMD atomization vs. dirty DW modified 440 EV14's...LOL

-

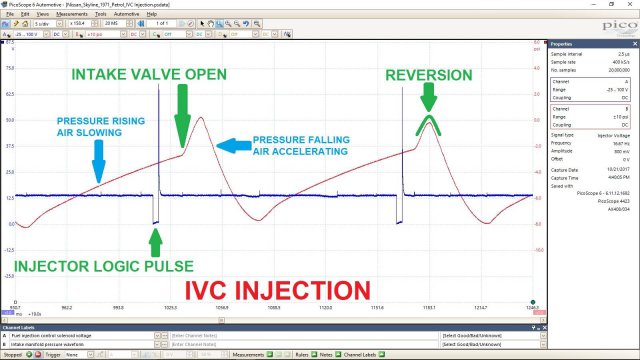

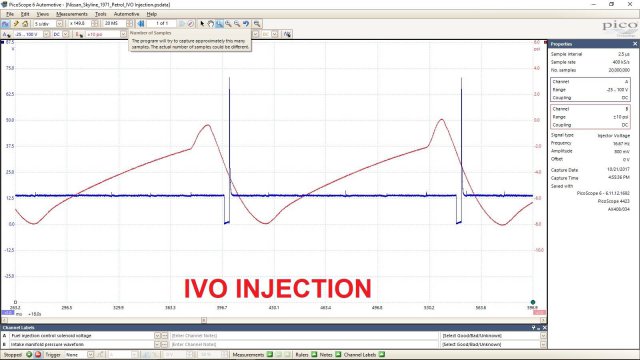

I recently had a real fight with a set of TWM DCOE ITB's on an L, that had me going in circles for months. Car ran fantastic. Turn-key start and idle from dead cold with only ignition timing manipulation (No idle air control), awesome transient response, good power, and excellent drivability... But it would foul plugs at idle, no matter what I did. Tuned loads of engines with ITB's, but always with the injector at the port. Finally got it figured out as an injection timing issue. I'm posting the write up here in case someone else ever comes across it, and hopefully won't have to struggle with it like this dummy did You can also find it on my Facebook blog. Motorworx Warning: This is going to be long, and go to nerd level-7. Eject before it’s too late. I’ve been having a problem with a high compression, long duration cam engine running ITB’s that is fouling plugs on idle. Each fuel injector is placed just behind each throttle plate, and a significant distance from the intake port and valve. There are also two slight turns in the manifold before the fuel gets to the port. I was told the engine would idle without fouling the plugs on the Mikuni DCOE carburetors, and that left me with the question: "What's the difference between carburetor idle fueling and port injection (PI) idle fueling?" The most significant thing I came up with was the timing of the fueling. I didn’t have the car, so I decided to dig a little. I bounced the problem off the good people on the FB group “Guild of EFI Tuners,” and some of the people with experience with this kind of set-up said “injection timing,” and “higher fuel pressure,” for better atomization. I also bought SAE Technical Paper 2000-01-2834 “The Effects of Port Fuel Injection Timing and Targeting on Fuel Preparation Relative to a Pre-Vaporized System.” I have quite a bit of experience calibrating ITB engines in pure alpha-n, alpha-n in VE, etc., but it’s always been in PI engines with the injector at the port. In that case, injection timing has always been best with intake-valve-closed (IVC) injection, end of injection in the 400° to 450° BTDCC (before top dead center compression) range. The above SAE paper, as well as SAE Technical Paper 2003-32-0023 “The Effect of Fuel Manifold Injection and Injection Timing on Performance and Emissions for a Spark Ignited Engine” both back this up. So does every stock engine I’ve logged this on. This is because injecting fuel IVC, onto the back of the hot intake valve and port floor just before the valve, gives the fuel time to vaporize, for better fuel preparation before the valve opens. Injecting IVO gives poorer fuel preparation, and a decrease in port fuel film (lower X-Tau). The better fuel preparation of IVC injection is what gives sequential injection its low-speed advantage over batch-fired injection. Vaporized fuel burns more efficiently, and cleaner than atomized fuel. It’s also why DI engines get choked with carbon; they inject directly into the combustion chamber, preparation is poor, and particulates abound. So a carburetor in an isolated runner circuit will obviously deliver the highest idle fuel when the port flow is highest. Flow and vacuum are not necessarily exactly linked in time, but for the sake of what I’m doing here, they happen close enough together. This should be when the intake valve has opened, port pressure is dropping, and peaks when the intake valve closes, but air is still flowing to fill the port. Fuel should flow the least when the pressure is highest, which is just before the intake valve opens (unless you have a lot of valve overlap and reversion). This is the time when fuel is being injected in the standard PI model, when intake port pressure is climbing, and will peak just before the valve opens. With the injector at the port, aiming at the valve, it sprays onto the hot valve, so port flow is irrelevant to the fuel injection. Turns out that injecting fuel into an air stream that’s slowing down, possibly reversing, far from the valve, puts a lot of it on the port wall, meaning a lot of it that’s getting to the cylinder is probably doing so in liquid form from the port wall. The first picture just shows the two laptops on the car; one running the Haltech ECU Manager software, the other running the Pico DSO. On the scope, I’m capturing #1 injector voltage signal on channel 1, and pressure in the #1 intake port with WPS500 pressure transducer on channel 2. This way I can see where the injector is opening vs. pressure in the intake runner. The second picture is a marked-up scope capture of the injection happening at 440° BTDCC. Port pressure at the time of injection is about -20kPa and climbing. As the pressure climbs, the intake valve opens and a reversion spike from cylinder pressure (big cam, big valve overlap) drive the port pressure to zero, and over zero, very quickly. Then the vacuum very quickly increases, and I assume the port flow with it. The third picture is a scope capture of the injection timing changed to 270° BTDCC. Port pressure at the time of injection is about -27kPa and falling quickly. At this time, I hadn’t changed anything but the injection timing, so it ran kind of rough, which was one of the hang-ups I had earlier... Everything in the book was tried, including changing injection timing, batch-firing the injectors, etc. When these changes were made, it ran worse, so in the spirit of "That didn't work" and "It's not the way we've always done it," it was abandoned quickly...dummy. What I hadn't keyed in on, and what one of the technical papers turned the lights on to, was the effect on AFR. Not the real AFR, as that doesn't change with injection timing, but as it's read by a sensor. The same amount of fuel is being injected for the same amount of air that's entering, but suddenly we're showing really rich because we're burning more of the O2. That's obviously a step in the right direction, but the excess fuel needed to be taken away to make it happy again. The effect of changing the injection to mid IVO was a 7% decrease in the VE table (a lot less fuel) to achieve the engine’s “happy point.” The idle screw had to be reduced, as the engine was much “lighter,” (more torque) and sounded much smoother. Timing is zero-throttle-table @ 20° BTDC in both captures. 30 minutes of idling did not foul the plugs, where 10 minutes would do it before. A very interesting thing that happened was the effect on the fuel film. Where the engine had a crisp transient response on a snap throttle from idle at approximately 1.8ms of fuel in the zero-1000 transient fuel cell, it now required 7.2ms for the same crisp response. I assume this is because there is much less fuel on the manifold and port wall when the throttle is closed, and it has a lot of dry area to condense on when the throttle is snapped open. This is in line with the findings in the SAE paper on IVO vs. IVC injection timing. It also means it’ll go rich on closed throttle, and need some transient disenrichment tuning. Next round I will also bump the fuel pressure, and see how that affects it. Feel free to comment. Matt

-

Shifter should stay in the same spot, as you're using the Z32 rear housing and mount. Clutch will be RB26. Spline is the same, so there are no mods required if you are using RB26 front case. Questions about RB25 are both yes. I still have one aluminum rear sump pan for dropping 26 into S30. Will part with it for $200 plus freight. You must fab pick up, and desired sump baffling. Probably need modding to go into Z32, as well.

-

Link to my page which has some of the stuff on it: https://www.facebook.com/mjrperformance/ I mostly just dabble in high performance these days. Nothing very serious. Build and tune engines for a couple of teams. Sell, install, and tune Haltech when time permits. Don't know if you can view without being friends, but this is his Hakoska album: https://www.facebook.com/kazuma.okuhama/media_set?set=a.489249354470777.1073741825.100001571511640&type=3 ...and Z album: https://www.facebook.com/kazuma.okuhama/media_set?set=a.109482819114101.12869.100001571511640&type=3 ...and Z restore album: https://www.facebook.com/kazuma.okuhama/media_set?set=a.1162347173827655.1073741829.100001571511640&type=3 If you send me a friend request, you also might get in that way... https://www.facebook.com/matt.hutchens.7

-

For some reason, the Platinum systems don't like using rising edge on Nissan Optical. No idea why, but I tried that early on with this car, with bad results. That's probably why I didn't consider it rotating backwards...LOL. 24-1 to me means twenty four dash one, as in twenty four on the trigger, and one on the home I'm really hard to understand sometimes... I almost never use missing tooth triggers, so it never crosses my mind that I might be confusing the hell out of people LOL. Sorry. Anyway, these CAS adapters from Dookies have a less-that-desirable shaft quality. If I'm ordering the parts, I'll use a Scorcher unit from Performance Ignition in the future. Thanks for your replies. Matt

-

Got it fired up today. Runs like a champ. I've done 6 Elite systems so far. The Elite system is much, much more sophisticated. Even though the tuning software seems kind of the same, it's not. There's a lot more stuff to monkey with, and not a lot of definitions or explanations. It's a very advanced level system that requires advanced level knowledge. I really struggled with it at first, it was a steep learning curve. The online support is pretty good though. Using the ESP software with a wireless internet connection, the guys at Haltech can help with troubleshooting remotely if you need it. They've also been really helpful at answering questions and explaining things in depth.

-

That's what I did. When I talked to Matt at Haltech, he thought flipping it was a better option, too. There's something in the way the trigger is set up when Nissan optical is selected, that doesn't like rising edge. Conversely, when using an Elite system, it wants to see riding edge. Anyway, flipped it over, and only had to slightly elongate the two holes for the screws. Going to try to get over and give it a crank today. Fingers crossed, but 99% sure this will work.

-

Thanks for the replies. Got it worked out yesterday... Was able to spin the CAS 180° and use the 24 tooth window as Home...same problem. Next step: Even though the signal at the ECU is clean on the o-scope, I couldn't get away from it being an engine problem. So I figured we'd spin it without using the engine. I pulled the CAS again, didn't have drill, as I was at the owners house, so I wrapped a string around the CAS shaft, turned off the injectors, and gave at a whirl. Datalog showed a CLEAN ramp with no drop-out's. That turned on a bunch of lights for me. So with the CAS out, cranked the engine... ...and the L distributor spins the opposite way... Wrapped the string again, only to spin it backwards, gave it a whirl, and the drop-out's were back. Pulled up a known-good waveform I have for Nissan 6 cylinder CAS and started counting teeth. When spun in the correct direction, there are 60 falling edges on the Trigger signal between each falling edge of the 6X windows used for Home signal. The 6X windows are all uniquely sized 4-8-12-16-20-24 teeth. When the CAS is spun backwards, there are 56 falling edges on the Trigger signal for 5 of the Home falling edges, and then one 80 falling edge signal. If I counted right, if using the rising edge on the Home signal, that should give you 60 teeth on the Trigger signal. Going to try this today, and if there's still something goofy, I'll put a 24-1 AEM disk in it. Interesting that this is a kit that's sold here in Japan, but no mention of trigger problems, that I can find. With the uneven count running backwards, there's no way it would run any EFI without the ability to change edges, or a custom disk, etc...

-

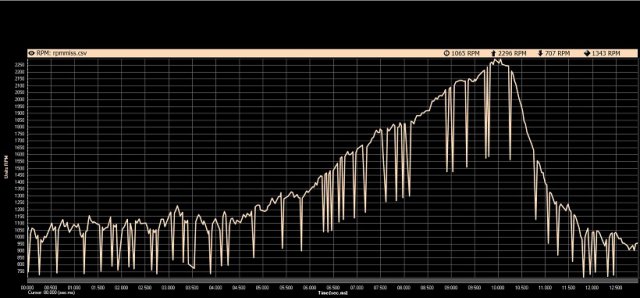

Wondering if there are any members here running Haltech and an RBXX CAS for signal, and if so, what are your trigger settings? ECU is PS2000. Having a problem with "rpm drop-out's" where the ECU "thinks" the rpm has fallen, but hasn't... Starts and idles clean (296° cam), but the drop-out's, as viewed in the data-log picture, are playing havoc with ignition timing, target lambda, etc. Battery voltage to the CAS is good, no voltage drop present on the CAS ground, and the 6X/360X CAS signal is clean when scoped at the ECU. For giggles, tried another CAS, and another new PS2000 ECU, with the same outcome. Ignition timing is dead on, using the 12 tooth window for Home, the Tooth Offset has no affect (so it's zero), and the trigger angle is 100°. The ECU gets engine RPM from the 6X trigger signal (per Haltech). I can't count the number of Nissan's I've tuned using the optical CAS, and this is the first time I've had a problem like this. Although the Home window is selectable, all of the RB's use the 24 tooth window by default, and the PRO systems for the GT-R's it's not even selectable. This is the first engine I've used the optical CAS on, that didn't come with it. This has me wondering if the ECU doesn't like anything but the 24 window for Home? That's all I have left to check, but it requires pulling the pump to change the shaft location. With the above taken into account, it "feels" like a sensor/ECU compatibility issue. No problem with the CAS. No problem with the ECU. No problem with the actual signal. ECU just doesn't like the signal...but it works fine if on the engine it came with. Some ECU manufacturers have trouble with the optical CAS resolution, so they have aftermarket disks; Haltech isn't one of them. So before sticking a 60-2 wheel on the crank, and a modified distributor for the Home signal, I thought I'd run it by the biggest L forum in the world Got another one in the wings, with the same set up , waiting to be finished, so I have to get this worked out... Thanks for any input.

-

Pix working again... I let my hosting package lapse, and always forget that the pictures are hosted there...

-

Standard polyurethane car paint works, as well. A bit more involved,as you have to mix it and should use some flex to keep it less brittle, but it's pretty impervious to solvents, gasoline, oil, and what not. Anything in a spray can will work, but my be more suseptible to chemicals, rust, etc.

-

Great numbers. That's a lot of squeeze on stock pistons.