-

Posts

129 -

Joined

-

Last visited

-

Days Won

2

Content Type

Profiles

Forums

Blogs

Events

Gallery

Downloads

Store

Posts posted by egzlilgituarboy9

-

-

Sounds like the pivot ball for the pressure plate disengage lever broke off. Seems all it needs is a replacement pivot ball/shaft. No need to get rid of the fidanza flywheel. The centerforce clutch should also work with the replaced pivot ball/shaft. Just need to remove the transmission from the bell-housing, then bolt it up to the block with the clutch and pressure plate installed, install the disengage arm, adjusting the pivot ball/shaft, for a very small amount of free play between the throw-out bearing and disengage arm. I will be installing this same setup with a Gen 1 engine with a 1 piece rear main bearing. Already have the external hydraulic slave cylinder from McCleod. Going to order a Quicktime 9023 scatter-shield bell-housing and check it for dimensions against the GM cast aluminum bell-housing.

Just gonna get the McLeod twin disc already sent back the centerforce.

-

I don't have any solutions on this issue, just some questions. I am in the process of getting parts to mate my T56 to my Gen 1 SBC, Are you using a mechanical or hydraulic clutch? Have you found the source of the problem? Which bell housing are you using?

Bell housing is stock. Hydraulic clutch. I believe the problem is in my clutch fork.

-

Pulled it apart to find my pivot balls on the clutch came out of place and were just rolling around inside the pressure plate. The centerforce clutch will not be going back in and fidanza flywheel will be going up for sale. PM me if your interested has 4 miles on it.

-

What kind of help are you looking for?

You put everything together and the parts worked correctly, as implied by the fact that you started the engine, shifted in to gear and drove. Then something changed and now you have a problem. So you could assume that you had a part failure or something came loose. Or that you're beating yourself up with the wrong set of parts, that are breaking because they're not designed to work togther. Since it's broken three times before this seems highly possible.

And what do you mean by "pivot ring was out"? And how do you know?

I know the pivot ring was out because the pressure plate did not bolt to the flywheel correctly. And you could physically see the ring was not seated into the proper place.

-

What kind of help are you looking for?

You put everything together and the parts worked correctly, as implied by the fact that you started the engine, shifted in to gear and drove. Then something changed and now you have a problem. So you could assume that you had a part failure or something came loose. Or that you're beating yourself up with the wrong set of parts, that are breaking because they're not designed to work togther. Since it's broken three times before this seems highly possible.

And what do you mean by "pivot ring was out"? And how do you know?

Well the three times I had problems with the clutch they were not in the car they shipped a defective part to me. Just trying to figure out what is actually wrong with this because if I pull my motor again this clutch is not going back in I will be buying a McLeod twin disc. Should Have worded it better. First clutch cracked from being defective. And the pivot ring is the part where the actual "spring" pivots to open the pressure plate.

-

It's bee a while since i been on the sight , but I have a couple of questions? when you say you have a stock slave cylinder, what year and car is it out of? What is the clearance between your throwout bearing and the clutch fingers? If your clearance is too tight the clutch and flywheel assembly will heat up and expand, taking up that clearance. If my memory serves me right there should be about 0.100 to 0.300 clearance. But don't take my word for it, refer to the clutch manufactures specs.

^^

-

Clearance is good and trans is from a 1994 trans am

-

Bellhousing is stock.

-

Sorry typed it up on my phone really quick. Transmission is a lt1 t56 with centerforce dfx clutch and conversion fidanza aluminum flywheel. Already posted the slave its a stock replacement.

-

So after going through 3 clutches in 4 miles after full rebuild of literally everything on the car first one cracked, bought a new one pivot ring was out didn't work had centerforce build a new one and same thing happened again pivot ring was out, finally went through jegs and got a good one (never will I ever buy another centerforce clutch). So finally after getting everything back together (have to pull the motor to pull trans) went for a shakedown run made it about a mile, went to Rev match down shift to second at about 30 just to go through the gears with the trans being fresh. Then came the issues, after the Rev match clutch would not fully disengage managed to get home without using the clutch and just shifting at right rpms I have a 3/4 wilwood master and brand new stock slave cylinder. I have .975 inches of travel with the slave and from what I can see if pulls open on the throw outbearing and looks like the clutch should disengage. When started with the brakes applied the clutch grabs does disengage but still enough grab to kill the motor when pedal if fully depressed. Didn't hear any pops bangs or vibrations when this happened witch is really weird. And help would be appreciated thanks a lot in advance!

-

Just wondering if you have the proper pressure and clutch plate. The T56 behind the SBC Gen 1 engine must have the specific LT-1 pressure and clutch plate that is a pull type pressure plate. Additionally, the flywheel is also specific to the T56 application. What year SBC engine is installed? Which flywheel is being used? Which pressure and clutch plate are being used? Need more data to advise.

I am using the fidanza 198661 conversion flywheel and centerforce dfx clutch that is a pull type and pre 86 2 piece rms.

-

Thinking I might need a bellhousing to transmission spacer?? Anyone else got any thoughts?

-

OK So here is my issue guys. Finally got my car started after 3 years of intense work motor is a Gen 1 SBC 383 Trans is out of a 1994 Trans am and had been upgraded to stage 2. At First Start herd a clunking noise thought it was motor at first found out the be the clutch hitting something inside the bell housing pulled the slave cylinder to see if i was able to see if i was able to see what it was hitting, couldn't see much besides that the paint on the outer edge of the pressure plate was scratched off and a small groove in it. So I drove it around the block to see how it felt. By the time I got home when I press the clutch in it would not disengage the clutch. When car is off goes into all the gears fine but when started does not go into gear now. The slave cylinder is still opening the clutch I am sure of that, pedal still has pressure and i can watch it open it from the underside of the car. Going to end up pulling the trans in the next few days but just want to see if any of you guys have any idea whats going on. Hopefully that is enough info for you guys please ask me any questions that might help you better diagnose this. Thanks a lot, David

-

I didn't really look at it that much I actually not making them myself. But there tucked up as close as they can be. I will post more pictures once I get them back from final weld and coated.

-

-

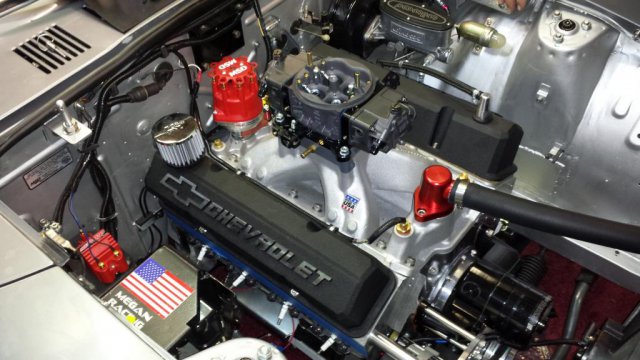

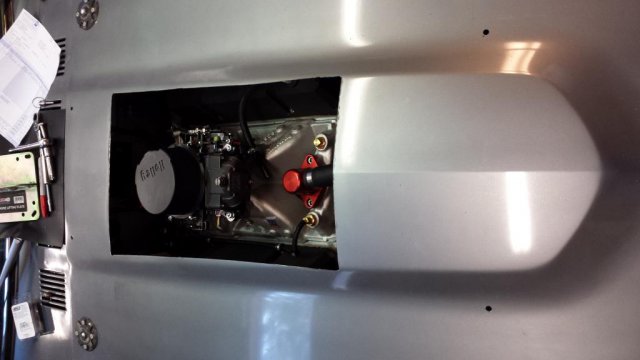

So now that the motor is in I pretty much got everything wrapped up. Finishing up with some odds and end. Heres a list of some parts that got put on since last update. Custom chromoly driveshaft, the driveshaft shop shortened axles, meziere 55gpm water pump, MSD Dynaforce alternator, AFCO radiator, Derale radiator fan, Holley ultra hp 750 cfm, competition hood scoop, Hotchkis hood pins, SSBC vacuum pump. Also currently in the process of making custom headers. Thats all i can think of for now heres a few pictures.

-

Only pictures I've actually found. Haven't seen any other.

-

Been looking through a bunch of threads and can't find any pictures of custom headers made on a sbc Z. Anyone out there have pictures?

-

Finally got the motor in! Fits nice went with a road race pan and going to get custom headers made. Installed carbon fiber braille race battery. Got my MSD digital 6 ignition hooked up. Just about wrapped up the interior besides harnesses. Just waiting on a few things and she should be running in no time! Here are some pictures of the motor being built and the other things I stated before.

-

-

Although you do need to bring it to a machine shop to press off/on the 1/2 3/4 syncro assembly it cost me $100.

-

I bought a manual on ebay helps a lot but I thought it was pretty easy. My trans wasn't to bad I didn't replace any bearings so I didn't have to shim anything either.

-

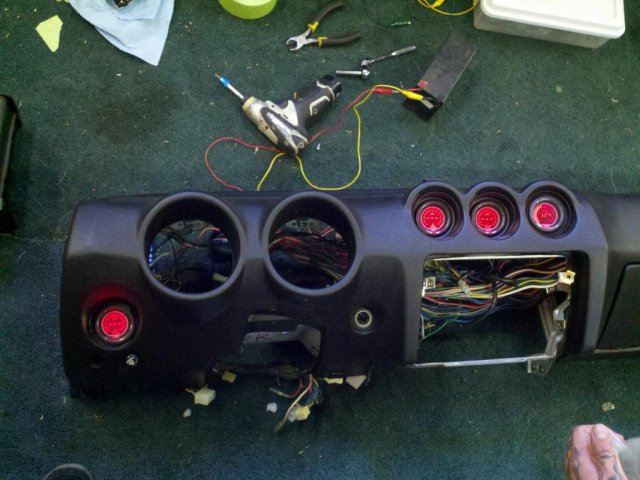

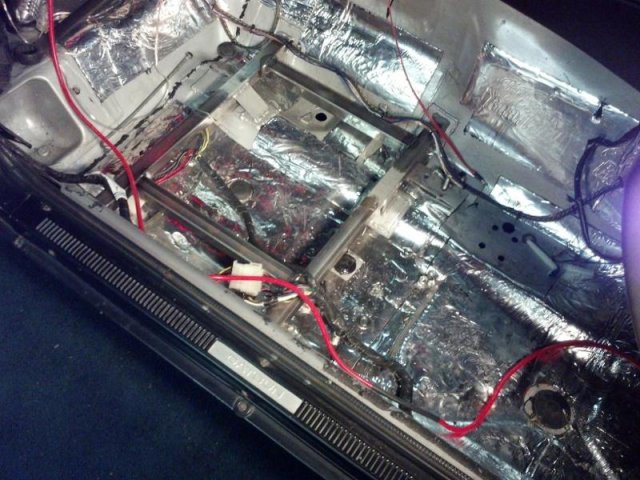

Almost forgot about this thread .... heres an update, rear end is finished after waiting months for my adapters 300zx cv axles are now in. Brakes are finished custom brake lines by Pirtek hoses also threw in a Wilwood master cyl along with a clutch master cyl as well. Finished my gauge setup with speedhut tach and speedo, then prosport gauges for everything else also install a dash cover that turned out pretty good. Got myself a momo steering wheel and a ultrasheild aluminum seat actually is really comfy atleast to me it is! Finished all sound deadning on both driver and passenger side. By now pretty much every bolt has been replaced with stainless or grade 8. Rebuilt my t56 transmission with stage 2 upgrade kit from thegearbox.com very happy with there kit. Now waiting on motor to get assembled almost done and clutch is ordered. Here is some pictures.

-

So I recently got in my stub axles and cv adapters from modern motorsports (after waiting 3 months) decided to replace wheels bearing while im there. So i go ahead and install them and find that when tightend down they are stiff and do not spin well and effort is actually needed to spin them. Also tried taking out the inner seal because I thought that the cv adapter was rubbing on that and still no luck. Could there be a problem with these axles? I even tried the old bearing and same issue, triple checked that all of the bearings were seated fully. Im out of ideas.

V8 Z Heat/Sound Insulation

in Gen I & II Chevy V8 Tech Board

Posted

I Used roadkill.