alainburon

Members-

Posts

583 -

Joined

-

Last visited

-

Days Won

3

alainburon last won the day on October 11 2021

alainburon had the most liked content!

About alainburon

- Birthday 10/29/1970

Contact Methods

-

MSN

alainburon@hotmail.com

Profile Information

-

Gender

Male

-

Location

Houston, Texas

Recent Profile Visitors

The recent visitors block is disabled and is not being shown to other users.

alainburon's Achievements

-

alainburon started following Heavy Duty frame rails and connectors , HybridZ Apparel Order Thread - 100% of Profits Will Be Donated, round 5 , Hybrid Z at 2021 ZCON and 2 others

-

Unbelievable man, Interesting how all of a sudden you have interest in doing this, I guess it took someone else to ask you. I asked you multiple times to share the digital file in order for me to make some shirts. You blew me off and gave me a bunch of BS excuses. That's great support to fellow S30 and Hybrid Z supporters. No thanks to you I was able to get the file and made my own Under Armour shirts.

-

Saw your Z on

Absolutely beautiful Z. Keep me in mind if you ever feel like selling it. -

Thanks, it was a great turn out.

-

Thank you and you are right I was shocked an LS car was chosen but I agree with you not every Z has to be original. I do appreciate the work it goes into an all original build too though. By the way the NOS is not just decoration....LOL

-

I want to thank all of you here for giving me inspiration for my build. I have adopted the Hybrid Z name for my build years ago since this site provided a lot of information that I consider priceless. I was able to meet some great people at ZCON, some that know my build and others that just wanted to say hello and compliment me on my build. When I built this car I built it as my version of what a Z should be therefore I know a lot of people were not going to like it since it was my vision and nothing else. Taking my car to ZCON for the 1st time and walking out of there with these awards it’s just incredible, especially with all the awesome cars I was competing against. It’s great to see the judges appreciate all the hard work and effort that has gone into it. These are the awards I received. 1st Place in Ultra Modified Best Engine Gold Cup- This was totally unexpected and shocking it was given to a Z with and LS3 since most of these guys are Nissan purists. Again, thank you all for your support and keeping this site alive.

-

Something else I noticed as I started driving the car is that I could barely hear the 6x9 speakers I installed behind the seats. It seems like the sound was muffled due to the seats being in front of the speakers. The other issue is that the motor in this car is fairly loud and the stereo needs to compensate for that sound so I had to turn it up and at some level the speakers would get a bit distorted due to all the bass they needed to put out. My system is a JL Audio 6 channel 600 watt amp which runs four 6x9 JL Audio 3 way speakers, two are mounted on a panel by the taillights and the other 2 behind the seats. I also have two 6 ½” JL Audio speakers on the door panels. I spoke with the JL Audio support team and explained what components I was using as well as the car they were in and the locations of the speakers. They mentioned that I should replace the two 6x9’s behind the seats with a subwoofer and that would help tremendously since I would be able to run the Low Pass signals through the subwoofer and the High Pass signals through the remaining 4 speakers instead of high and low pass signals through all the speakers which is what’s happening now. That would give crisper highs, deeper bass without distorting the speakers. Since I did not want to build a subwoofer box due to the limited space I have in this car they suggested running two 6 ½” subwoofers in place of the 6x9’s behind the seats. So another project begins. I have to say JL Audio customer support is incredible, they calculated how much space I needed for each subwoofers and I built the enclosure to their recommednations. I removed the 6x9’s behind the seat and made wood panels to enclose each area. I put some L brackets on the wood panels and bolted them in place. Then used tons of silicone to ensure it was completely sealed. I had already put Dynomat in those areas so that helps eliminate the tin sound. Then I built a wood face panel to bolt the subwoofers in place since the holes I had for the 6x9’s were too big. I used foam behind the panel in order to eliminate any rattling and bolted the panel in place. Fitted everything and re-carpeted the panel. The sound difference is incredible, it blows me away how much bass comes out of these little subwoofers. I don’t listen to rap all the time so I don’t need a rolling boom box but certain songs require clear bass and these speakers deliver. Below are some before and after pictures as well as part of the process.

-

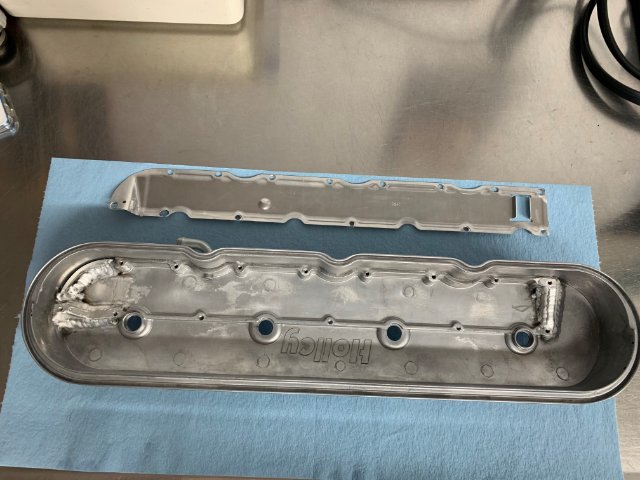

jpndave is correct, the Holley valve covers are a lot cleaner look since the coils mount directly onto the valve cover which gets rid of the coil brackets.

-

Another issue I ran into is oil consumption. I would rive around 20 to 30miles and pull out 16 ounces of oil out of the catch can. After confirming the catch can was plumed properly by reaching out to the manufacturer the hunt for the problem began. Of course I had a lot of suggestions from the 6 AN lines I’m using in the catch can is too small, I have a broken piston ring, etc.. The guys that made the catch can (Elite Engineering) where the ones that told me what the problem was from the begging and they were right. It was the Holley valve covers. The baffles on the Holley valve covers are terrible, so you wind up sucking more oil than you should through them. Unfortunately my ignition coils were mil-spec wired in place and I did not want to have that redone so I tried one last thing with the Holley valve covers. I ordered a new set but their taller version which allows a bit more room between the rockers and the valve cover. I also purchased a driver’s side OEM valve cover and removed the baffle from it and had it fit on the Holley valve cover. Problem solved, drove 150 miles and pulled just a few drops of oil from the catch can. So please be aware of these issue with the Holley valve covers. I have attached some pictures of the differences in the baffles between the Holley and OEM. This is the OEM Valve Cover. This is the Holley Valve cover. Notice the difference in the baffles. Holley has more holes. These 2 pictures are the Holley valve cover modified to use the OEM baffles.

-

Yes, an "H" with AN fittings is exactly what the LOJ unit is, well I added the AN fittings to it. I put it between the water pump and the heater core. The only feature the LOJ unit offers is a port on the side for a Nissan water temperature sending unit which I'm not using anyways, I blocked mine with the plug they provided. Here are some pictures of some others that are available as well. The metal one is a Vintage Air unit and the other looks like something home made but it worked.

-

After researching countless hours and talking to everyone and their sister I decided to follow what LOJ Conversions suggested since it made a lot of sense to me. Not to mention some of the suggestions I was getting were just way out there. Like, remove the heads to check for blown head gasket etc.. According to LOJ the heater circuits on Chevy LS powered vehicles utilize a heater control valve that has an internal bypass. When the heat is off in a Chevy LS powered vehicle, coolant still flows through the heater hoses. You are not supposed to block the heater ports on your LS water pump, they must be looped to always allow flow. If flow is blocked in these ports, you will cause a pressure differential on your water pump impeller creating cavitation, resulting in aeration of your coolant and an overheating condition. The Datsun 280Z system works a lot different than an LS power vehicle, it has 2 heater control valves that block the flow of coolant into the heater core, it has no bypass valve. One valve is operated by the heat/cool level and the other is operated via vacuum. So when you turn the system to heat both valves open and allow coolant to flow through the heater core and back to the water pump. When the heat is off then the path is blocked and creating the exact same problem LOJ is describing. So I did a little test, I ran the car until it got to its operating temperature which was between 215 and 220. Then I turned on the heater at the lowest fan setting this way the fan does not aid much in the cooling process and to my surprise the temperature dropped 10 degrees to 205 to 210. So I decided to purchase their LS Swap Heater Bypass Block since I’m not driving my car with the heat on all the time specially in Texas. I removed the hose barbs it came with, drilled it and tapped it to ½” NPT and fitted AN10 fittings. I installed it on the car and sure enough overheating is now gone completely. Car runs at 195 to 200 steadily. By the way I’m running a factory heater and A/C on this car. The A/C was always super cold before the swap and the heater worked well so I left it stock. No point trying to fix something that works well already.

-

JCI 4l60e driveshaft fitment question

alainburon replied to Spdrcr's topic in Gen III & IV Chevy V8Z Tech Board

I hear you, in my case I had no choice. Mine was leaking from the rear seal. I replaced the seal twice and still leaked. I was also told that not having proper engagement could damage the transmission bearings in time. You can always try it like I did, if you have no leaks or vibrations you may be ok. -

JCI 4l60e driveshaft fitment question

alainburon replied to Spdrcr's topic in Gen III & IV Chevy V8Z Tech Board

I just went through the same issue, my JCI driveshaft was too short. 1 1/2" is too much. I bottomed out my slip yoke and pulled it out 3/4" then had the driveshaft made to fit. I verified this with Modern Driveline and Tick Performance. -

Let's talk lighter weight clutches for LSX motors

alainburon replied to 280Z-LS3's topic in Gen III & IV Chevy V8Z Tech Board

I guess the biggest question is how are you going to use your car? I see you have drivability concerns which leads me to believe you want to drive the car on the street. If that's the case why do you want a race clutch? -

Heavy Duty frame rails and connectors

alainburon replied to toolman's topic in Gen III & IV Chevy V8Z Tech Board

That's a good idea to straighten the tubing. I used a tubing straightener since I had multiple diameters of tubing I was working with including brake lines. It was just much easier to adjust to different sizes, not to mention it came out perfectly straight.