scott

Members-

Posts

37 -

Joined

-

Last visited

-

Days Won

1

scott last won the day on January 17 2014

scott had the most liked content!

About scott

- Birthday 10/27/1950

Profile Information

-

Gender

Male

-

Location

Beaverton, Oregon

Recent Profile Visitors

The recent visitors block is disabled and is not being shown to other users.

scott's Achievements

Newbie (1/14)

12

Reputation

-

TimZ, thanks for the link to axles unlimited. I'll check them out. LLave, l saw the ads on eBay. They looked like they were original 280zxt axles and might need rebuilding ( this may be the better option). I saw a lot of " new or remanufactured" axles for less $$. But I've heard that these cheaper axles may not fit 280zxt (may be too long). Also I wonder about the quality and durability of these axles.

-

Is there any place that sells or rebuilds 280zx turbo CV axles that actually fit and are decent quality?

-

I had a similar problem with my dual electric fan set-up driving at lower speed around town. The fans were rated at a good airflow, but it turns out this was at free flow (no back pressure). The fan curve for these low cost fans showed that the flow rate dropped off dramatically with just a little back pressure. My 240z has a lot of back pressure in the engine compartment (poor airflow out). I replaced electric fan with a more powerful Spal fan that has a better fan curve. It solved my problem.

-

I have that air dam on my 73 and I used a large metal file and easily removed material. I was also able to bevel the edge of air dam inward for more clearance. The file was easy to control the amount taken off. I did this with tires mounted and car sitting on ground and the air dam was already painted...no problem

-

-

-

I would like to attach my stainless flex front brake lines directly to my calipers. Both the calipers and the flex line have M10 x 1.0 female threads. Normally there is a small section of hard line that connects to the caliper then to the flex line. The joint between the flex line and the hard line is held in place with a bracket on the strut. On my coil overs I do not have the bracket and so would like to attach the flex line directly to the caliper. Ideally, I would like to find a M10 x1.0 male to M10 x 1.0 male adapter to directly connect the flex line. Does anyone know where to find one? What have you done to connect flex line directly to the caliper?

-

Because there are several factors beside the brake components themselves that affect braking distance, setting up a test with one car and running tests with various brake configurations could separate out some of the variables. The test car could have a base configuration (weight and weight distribution) and set up with wheels (that can fit various brake components) and good tires (so that limits of some brake configurations can be evaluated). Similar brake pads could be used, but there are trade-offs (initial braking distance, fade, rotor wear. Some are better for track use and others for the street) This could be done like component evaluations done in some of the performance car magazines, like intake manifold evaluations or carburetor comparisons done on a base engine. Other factors should be evaluated like brake fade, reliability (this could be harder to evaluate), weight and cost (most are looking for a good balance of features for their braking system). I'd be interested in seeing this. I would like to see how Toyota SW12 calipers with 300ZX vented rotors compare with the stock brakes and with a Wilwood set up, etc.

-

One of the challenges with cooling in a 240Z or 260Z is getting rid of the heat and air trapped inside the engine compartment (hood louvers or 280Z vented hoods can help). The airflow into the engine compartment creates backpressure on the fan. A fan with a 2500cfm rating is moving that air at zero back pressure. As back pressure builds, the fan airflow drops off dramatically (check out some fan curves). It takes a fan with a strong motor to keep good airflow (cfm) with backpressure created in the engine compartment, usually a fan with 20+ amps. The Taurus fans can pull around 35 amps. I am experiencing a similar problem on my two fan set-up. The fans aren't very strong and don't move enough air on hot days in stop and go traffic (they look good though). I don't have a vented hood, so the engine compartment builds some backpressure and traps heat. It is in traffic, traveling at low speed that the fans get the most workout. At highway speeds, the air is being rammed through the radiator, so cooling system capacity is now the important factor. My little fans were rated at around 8 amps, so they are not strong enough. I am now looking for more powerful fans.

-

Checkered Flag Racing has adapters for the 280ZXT axles and also for the Z31 axles http://www.chequeredflagracing.net/Datsun.html

-

Who is running 16x8's with no flares

scott replied to 415DZ's topic in Brakes, Wheels, Suspension and Chassis

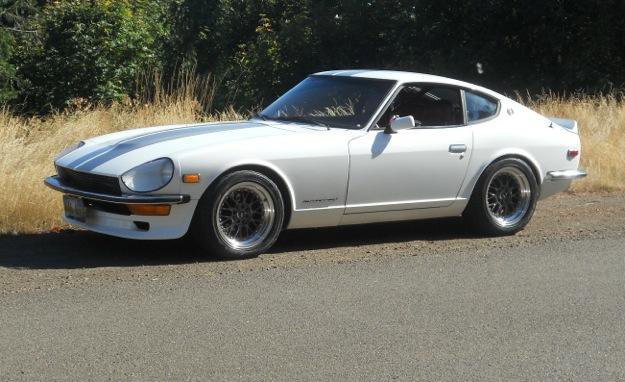

I had to trim mine after it was painted, but by using a file on the urethane and chamfering it inward, it did not show or chip the paint. I am running some XXR521 which are +20 offset, but I use some spacers (19mm in front and 11mm in rear) to space wheels and tires (225 50 16 yokohama) for best clearance. -

Who is running 16x8's with no flares

scott replied to 415DZ's topic in Brakes, Wheels, Suspension and Chassis

415DZ, I have a Xenon front spoiler on my 240Z with 225 50 16 tires and 16 x 8 wheels with a +1mm offset. The car is lowered about 1.5". I had to trim the inner flange where the air dam bolts to the fender. I had to grind back the edge on the air dam and flange about 45 degrees from the wheel opening. I did this while the air dam was installed. I also used a file to grind away a small amount of the air dam bottom edge at the wheel opening for more clearance (Chamfering the edge inward). This is easy to do even after the air dam and wheels and tires are installed. -

Any of you run front strut tower bars?

scott replied to Robftw's topic in Gen I & II Chevy V8 Tech Board

I made my own strut bar and braces. They can be made to fit around single or dual carburetor configurations. I had to also clear the distributor because I have a ford engine. The bars are made removable for access to engine if it ever becomes necessary to remove the engine. -

Who is running 16x8's with no flares

scott replied to 415DZ's topic in Brakes, Wheels, Suspension and Chassis

I have XXR 521 wheels that are 16 x 8 and have a +20mm offset. I am using 225-50-16 Yokohama tires. I had some billet wheel spacers made that are 19mm thick on the front and 11mm thick on the back. This gives an effective +1 offset on the front and a +9mm offset on the back. I also used longer ARP wheel studs. I am running stock struts with Eibach progressive springs. Everything just fits and does not rub. I had to take a file and remove about 1/16"-1/8" of the inner rear wheel arch flange (only on top section). It was very easy to do.