-

Posts

2366 -

Joined

-

Last visited

-

Days Won

27

madkaw last won the day on December 1 2025

madkaw had the most liked content!

About madkaw

- Birthday 08/25/1962

Profile Information

-

Gender

Male

-

Location

Bloomington, Indiana

Contact Methods

-

Yahoo

S_finnerty1018@comcast.net

Recent Profile Visitors

The recent visitors block is disabled and is not being shown to other users.

madkaw's Achievements

-

The vacuum log from has reappeared ! I added back the lines I took off before ZCON. 2 x .250 lines merging into a 3/8 line to a remote stepper valve . Kind of got it working today . The biggest must is to have it close all the way . You can’t afford to loose any vacuum with the ITBS .

-

So after doing a valve adjustment my ITBS did sync up better . I guess I will have to keep an eye on that. I took out most of the injector trims and my afrs between the banks paired up better -especially at light cruise . I also worked out linkage issues I was having. You get no instructions with this kit and there was adjustments that I could have done better like the main rod-the only rod-to bellcrank. I didnt have it pulling the linkage in a straight line. Also found the linkage on the side of the ITB loose . This caused the linkage to rub against the body of the ITB. I got all this sorted right before ZCON . It was 4.5 hours to Nashville on smooth highway. 80 mph is where she likes to cruise . AFR's were around 15 on flat ground. No issues on the round trip. Got some great compliments from Peter Brock on my airbox . Cold idle is still 650rpm and about 800rpm when hot . AFRs at idle are normally around 13.1 Now to move on to IAC . I gave up on it right before I left .

-

I will do this -eventually. I did pull the center ITB and tested the flow past the butterfly using a vacuum cleaner . Not sure thats an appropriate testing method but the sync tool showed same flow between the two ports. So maybe my issue with 4 is a porting of that intake runner at low flow. At this point I did another valve adjustment -cold- and I did end up finding small adjustments needed, so we will see if that changes anything. Meanwhile I am going to use injector trim to even things up the best I can before Zcon.

-

I’m using cable control on the linkage. So the issue with them is the cascading effect of using cable on one ITB that has direct linkage to the other two . It causes #1 ITB to open up sooner no matter how I try to adjust . I also have #4 port that doesn’t flow as much air as the rest . Maybe a butterfly issue - slightly off. I would go with rod linkage but I’m pushing it for time to make it to ZCON . I’ve tried syncing the best I can at lower TPS by just holding throttle open with cable adjustment and calibrating 3-6 . Once I’m around 12+ TPS - AFRS blend much better . As far as #4 - I will address this with injection trim . It’s just light cruise where I have to pull some fuel . I’d love to try the rod linkage but I’ll have to see how much time I have . It won’t help with the center ITB . I’ll have to take it off and see about doing something with the throttle plate . Again - it much time for that right now

-

So I took my Z to C&C -150 mile round trip. Engine ran strong but not right. Afrs were off between the banks. Thought I had a sync issue but I believe I have an injector issue. One plug looked rich and that was the bank running rich. #4 valve clearance checked and compression test is good. I've swapped injectors around to see if it follows. Weird thing is the AFR,s smooth out under more load-its worse under light throttle. It seems more than what a small butterfly sync issue , but maybe not . Used my new airbox also. It does quiet down the stacks. Speaking of stacks can someone buy me some TTT horns ? lol My 50's look to small in the box

-

Back to synchronizing itbs . #4 reads less than #3 port . Bleeder screws do nothing on any ITB - are they just there for looks ? No blockage I can see anywhere . I can pull the needle completely out and it does nothing to change air flow . I thought previously it was #3 was hanging on the linkage but that turned out to not be the issue . If I got any adjustment out of the bleeder screws I think I could get it dead nuts . I’m at a loss . Been searching on line but with no luck . Maybe cheap Chinese stuff .

-

So after much searching and an upgrade to 1.6 firmware I was able to control these fans very well . They must have some built in controller that can decipher the low PW signal from MS . Testing at 87hz -which is what MS3 offers - they worked smoothly with no humming or any strange behavior . My GOD they move some air . Still wish I knew how much CFM they really are . The 1.6 firmware allows for a low/partial speed and full speed . Haven’t tried any AC controls since I don’t have AC yet .

-

These are pullers and I will have them set up to come on with AC . Megasquirt 3X just came out with firmware to control with PW . I think the only option is fans at full speed with AC . I have a buddy that said he can make a controller that will do a better job . I have no idea what CFM these fans are except they are 300 watts and they are SPAL fans OEM

-

While waiting for my stacks to get printed I jumped on this other project . I ordered AC but my cooling system wasn’t up for the task. My 15” Mishimoto with no should struggles to keep up in traffic . Watched a couple of YouTube videos and decided to step up to some brushless fans from a Chevy Volt . I went with them because they look like they would fit the radiator . It’s TIGHT -even after carving on it for a day . It’s been a learning curve on how I was going to power and control them . Hope this works !

-

Well while the z was in the back garage I pulled the exhaust off . I had tried something that I won’t do again but I used a square port gasket ( Nissan ) on my mn47 head with my square port header . I was getting some small leaks when I pressurized the exhaust during leak checks . I went back with the gasket to match the head which worked fine before . Also stared at the ITBS for a long time trying to figure out why #3 was sucking more air . As you can see in the pics the linkage was digging into the side of the ITB . Shining a light into the ports before hand did seem to show 3 open a hair more . It was such a small difference I can’t swear I did anything , but I’m betting it’s enough . I ended up just filing the tab on the linkage down . I also figured a way to run my coolant bypass on #6 . I’ll run it under my ITBS on top of the heat shield . Might also try again to run air for a remote IAC . It’s actually getting too busy under the ITBS . Also on the to do list is to find some different cooling fans . I want to run brushless for the versatility and power since I want to install AC . AC is ordered from AC solutions but that’s a month out at least . Cold air box got glued tonight . 75mm Stacks are getting printed out and I’m getting close to finalizing this long project !

-

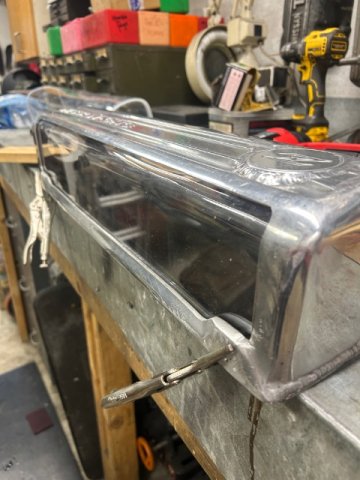

Well much rain is forecasted so I’m taking her off the road to attend to issues as in exhaust leak somewhere and # 3 port pulling more air than the others . Of course the only way to see the butterfly in the ITB is to remove it . I think the exhaust leak is at the header flange so that’s a remove project - ugh . I also think I might have pulled off my air box scheme . Taking me a while to get better at forming the plexiglass but the new buck is spot on for the most part . Hopefully I get all these issues resolved during the downtime . The engine is really running good but I’m hoping longer stacks will bring me into the sweet spot . A friend is printing out the 75mm stacks and I’ll probably also do a set of 90’mm . I think I have plenty of room to fit 90’s without impeding flow around them .

-

Okay so the two tables for VE has given my some more fidelity with the tune . Can’t seem to pull off the two timing tables with AlphaN. Cant figure a way to include or delete a MAP sensor that doesn’t screw with the tune badly. I think with MS you have to use ITB mode which I thought took more expertise and data logs than I have . Runs good with SD running the timing , but I’d like more refinement. Still working on my air box and a buddy is printing me Velocity stacks to try . Also trying to put AC in the car ! I think the IAC idea might be scrapped for timing correction IAC .

-

Twin cam head for the L6 from Derek at Datsunworks

madkaw replied to Derek's topic in Nissan L6 Forum

I would be completely satisfied with an NA with those CFM numbers !! -

Latest updates are more tuning . I’ve now figured out have to get 2 x16 tables for VE and timing . I’ve also converted AFR so now I’m total Alpha male - lol. I haven’t driven since converting timing to Alpha N so that will take some time and knock ears . Weather has been so hot I haven’t driven the car in days . I also still have an issue with one bank O2 sensor . I must have a small leak somewhere that hard to find - maybe underside the header flange . I’ll have to try a smoke test to try and find it . Spark plugs all looked the same though my reading is wacky on 4-6 cylinders . So far mpg has been decent though that isn’t much of a consideration right now .

-

The thing runs so good I can’t believe they aren’t very closely synced . First time doing ITBS so don’t know what to expect . I think they have been very good . Alpha N is a bit of a learning curve . I think I figured out I how to get 32 table for VE - but it runs well with 16 . I have a good MAP signal and I can see why some would use or try MAP density . I have a 3/4” log and soon it will be 1” . I will try it sometime just to prove to me - ha .