-

Posts

2943 -

Joined

-

Last visited

-

Days Won

23

Content Type

Profiles

Forums

Blogs

Events

Gallery

Downloads

Store

Posts posted by RTz

-

-

It is common for someone to lower their car 1" and still use the stock SHOCK and strut tube

J,

Its probably VERY common... however, In my experience, its not the best move.

IMO, if a Z is lowered ANY, shorter dampers should be a consideration.

-

I agree that the bump stop is now closer to the strut tube, but without a lot of experience here, I must ask, does it even matter.

Jolane,

Yet another way to say all this... If you lower a stock car with springs only, you will use up some of the quoted 3" of travel. If you lower the car 2" then you would have only 1" leftover before the top of the strut tube hits the bumpstop. You can put any damper in the world inside that tube and it will never change that. The most direct way to add more bump travel is to install a shorter damper and shorten the tube accordingly. If you shorten it 1" then, practically speaking, you'll gain 1" of bump travel (setting aside motion ratios for the moment). So now, in this scenario, you have two inches. The T3 gland nut does not address this in ANY way. I don't even see the point of it. If you lower a Z and you expect good handling the strut needs to be shortened. There are a couple of other ways to increase bump travel but they are a bit of a tangent.

-

it it because you realized the entire shock/strut assembly would have to rotate for it to change the angle?!

Actually, I just imagined a one piece A-arm with its inner mounts parallel with the longitudinal axis of the car. Pivot the A-arm up and down... no need for its 'leg' angles to change right? Now, spin the whole A-arm assembly in a horizontal plane (so its rear mount is far outboard). Pivot the arm again... stilll no bind. It now just travels an arc that would promote caster change... BUT the angles between the legs don't change.

-

I think were talking about the same thing... we just have different opinions.

Jon,

I'm beginning to think I am wrong about the angle change during travel. I believe you are correct.

Forgive?

-

True, but IME having the TC on a clevis like that and being able to run a larger amount of caster was a big improvement over stock, poly, or GMachine setups I ran previously.

I couldn't agree more... Brian's are also adjustable so I'm not seeing your point.

When you're talking about 1" difference in the length of the arm (guessing since the tie rod end end also moves the pivot forward from stock probably an inch) I don't know that the difference in the caster sweep is going to be that huge an issue.

Agreed' date=' probably not a huge issue. But I don't want any more caster change than necessary. I fail to see the advantage of the heim and combined with it being farther forward just doesn't excite me.

I don't like the way you worded this part. I know what you mean, but I don't think the argument you make is really true here. The bolt through the clevis gets locked down once the caster is adjusted, so there is no pivoting of the clevis "as the caster changes with movement". The impression I get from reading your post is that the clevis can change its angle because it is left loose at all times.

I think were talking about the same thing... we just have different opinions. No matter how tight the clevis bolt is, there is no way for me to imagine that it wouldn't rotate with even a small load. I'm not implying "leave it loose". However, I think torquing it to oblivion won't do anything either. *IF* there is caster change during travel (from a non-ideal location of the rear pivot point) then I don't see how it could NOT rotate. The angles must change. So something either has to flex, pivot, or break. Its possible I'm looking at this all wrong... If you type REAL slowly, maybe it will sink in

-

because in all honesty' date=' i'd rather buy something that has had input from a board such as this, than the ones from T3...[/quote']

If my opinion matters... Those don't really do anything for me. The heim bracket pushes the pivot point farther forward than Brian's. The farther forward the pivot is, the more caster change you'll have as the suspension reciprocates. Also, becuase of the caster change with movement, the angle between the LCA and the TC rod MUST change. With tech-toys design, the TC is clamped solidly... that means things must bend to accommodate the caster change. Brian's design has a pivot for this reason.

HTH.

-

Unless you don't have a rev limiter

...Point taken

rt

-

It's not the Caddy motor that will break things - it's the tires you run.

Phantom nailed it... If you can't hook up, you can't break anything.

-

If this is so - these engines are very lightweight or am I not understanding something here. Look at the weight of the M70 12 cylinder engine:

M70

V12 SOHC 24V. 1988-1994. 155kg 341lbs

Used in E32 750il' date=' 850i

5.0 (300bhp)

[/quote']

Hi,

The info I have agrees with the 341lbs BUT... thats bare longblock only... no manifolds, starter, etc, etc.

John's 522lbs would give it about 180 lbs of 'stuff'... probably not far off on a V12.

-

I like the look of the LEDs but to me there was something very harsh about the light that they put out.

Sparky,

Curious, did you play with the dimmer at all? Did it reduce the harshness any?

TIA

-

Hi all' date='

I've been looking in to this idea of pointing the T/C rod at the ball joint, and I've got a slight concern that it may cause interference with the wheel rim:

[/quote']

Rob,

I went out and took a couple pics. @ full lock... First pic clearly shows enough room for this wheel/tire combo... a 15x7, 4 1/8" backspace, with a 215/50 tire.

Second pic... There is enough room for a 4 1/4" backspace... I'd say, with stock dia. springs, you'd never conceivably hit the TC if aligned with the BJ. However, with coil-overs and proper wheels, it looks like you'd run out of room.

HTH

-

Right. I agree 100%. So what does that have to do with aligning the TC rod to the ball joint?

Brian,

I'll answer Jon, if I may... Trail has nothing, geometrically speaking, to do with with aligning the TC to BJ. The reason for the change is simply one less part to build, marginally less weight, and a slightly improved load path.

-

But the 1mm max. depth of cut sure makes for some boring hours going back and forth!

Damn... hats off to you!

-

Thanks Ron, I've just been going at the slot in one go with a 12mm 4 flute endmill.

Ballsy... especially on a combo machine

-

I'm thinking that maybe the crappy milling was a result of not being able to clamp them very solidly.

Rob,

Nice job.

Regarding your slot finish... are you climb milling or conventional?... Can make a heap of difference in the finish.

-

Pistons struck electrodes at high rpm. DAW

How does that *open* a gap?

-

Look'n good, Brian.

-

PS' date=' as I recall, factory clutch type LSD's had a typical preload of ~35-40 ft-lbs. (with car in the air, and one wheel locked, only takes 35 ft-lbs force to break free your other wheel from the LSD clutch action). Autox's (I know Ron did this at least once right Ron?) may wish to have this tightened up to a higher limit approaching 90 or 100[/quote']

Ross,

Pretty well nailed it. The production car diffs ran, as you say, 35-45 and the last NISMO comp. diff I bought was close to 55. Nissan diffs are pretty easy to adjust and its necessary for a track car. How much depends on car set-up and driver preference... at minimum 55lbs. Go up from there.

Tom,

Very nice car! The fact you car didn't move one on axle isn't cause for alarm... especially if its a production car diff thats never been shimmed. The significant portion of the 'lock-up' comes from the side gears separating, putting pressure on the clutches. In order for the side gears to separate they have to have something to work against. Essentially, that comes from two places... what little grip is left on the inside tire and the pre-load on the clutches. The inside rear, generally speaking, dosent have enough grip to work against, hence the 'help' from the pre-load. However pre-load, on its own, isn't enough either unless its substantial. So the typical LSD, if you raise one wheel off the ground, won't provide much torque at all to the other. In normal conditions, once the reaction has begun, the amount of 'lock-up' can be substantial.

-

I'll second Jon... It would take a preload setting way beyond usable to expect the car to move about on one axle.

-

-

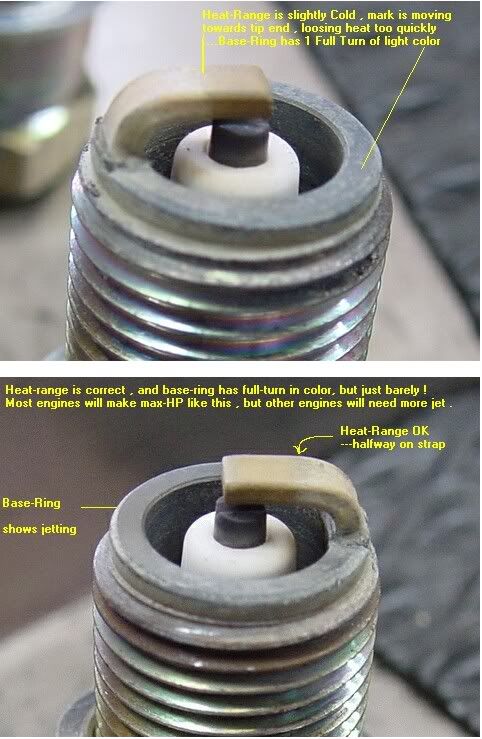

My understanding is that the heat range of a plug only affects the temperature of the center electrode and insulator.

Sam,

I respectfully disagree. The ground strap, if the proper heat range, will indeed run hotter.

Taken from Champion spark plugs....

"If you make modifications such as a turbo, supercharger, increase compression, timing changes, use of alternate racing fuels, or sustained use of nitrous oxide, these can alter the plug tip temperature and may necessitate a colder plug."

Also, the way I understand choosing the right temp range is shown in the below pic...

This clearly illustrates the ground strap running hotter. Twenty bucks says Braap is right

-

How to Tune and Modify Engine Management Systems

That should be the Jeff Hartman book... If so, its a good read.

-

Nobody knows? I'm starting to think the 75's fuel pump didn't have a relay, and maybe just was wired to a 12volt hot.

Hi,

Its located under the dash, nearby the steering column. It looks about the size of two standard relays side-by-side. It has two plugs attached to it (becuase its actually two releys, main and fuel pump) If memory serves, one plug is black and one is clear.

HTH

-

I think your missing the high point of whats being analized in the videos. problems like a vortex or un equil plenum filling can be seen and corrected.

I can only assume you're addressing me. I agree that you have an issue that needs resolution, but I also think its a terribly small representation of the big picture. I don't believe you can say that you have laminar flow or a propensity towards equal cylinder filling when your test's only show the static picture... too many other influences. No doubt, its a starting point and I appluad your efforts. However, once you show static flow to be acceptable... your work has only just begun. Of course, this is just my opinion... I could be wrong

Aftermarket EFI

in Nissan V6 Forum

Posted

Wolf3D.

P.S. I agree with 260DET... If you're unfamiliar, the best choice will likley be to follow your local tuners advice.