-

Posts

409 -

Joined

-

Last visited

-

Days Won

1

Content Type

Profiles

Forums

Blogs

Events

Gallery

Downloads

Store

Posts posted by datman

-

-

certainly looks like it did, doesn't take long for a car to rot with all the salt they put on the roads in the winter.

-

-

If you have a really rusty Z lets see it, I just bought a Z for spares and it has so much rust its scary. I'll take some pictures in a minute.

-

verocious motorsport sells them, very good service from those guys.

-

Yep just rebuilt my l28..tested compression before fitting plugs and got 160 160 160 160 120 100 !!! adjusted all the valves to correct gap and got 170 on all of them, had me a little worried though.

-

Ok I disconnected the alternator and the spikes in the temperature dial stopped. Does anyone know the best way to fix this? I have the old style alternator with the voltage regulator fixed on the inner fender.

-

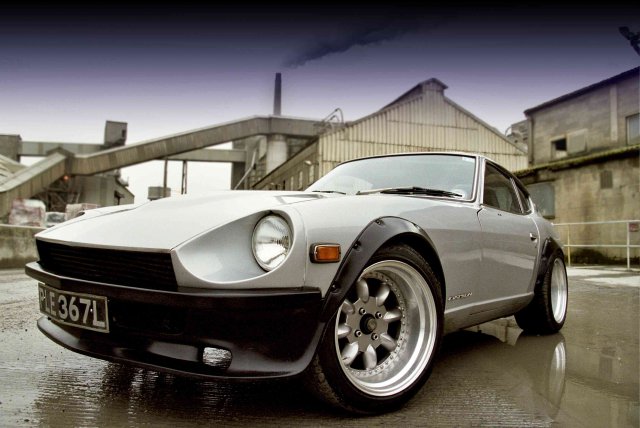

Tony, I'm running P zero rosso's 235/45/17 front and 255/40/17 rear ... I think I will use 255's on the front and 285's on the rear once I've worn these out. The 235's are a bit stretched on the 9j rims

-

Thanks Braap, that's what I thought but my MS dial for Dwell shows it is doing something even though I set the ignition settings in MS for EDIS. Is that normal?

-

-

Can anyone tell me what setting the dwell should be set for on MSII using EDIS? I would have thought it should be set to zero as the EDIS handles dwell. I have my ignition setting set up as per the manual but I see movment on the dwell dial.

Thanks

-

What about the fact I'm using EDIS? doesn't the edis module handle dwell? if so then should i set dwell to zero?

-

Ok I will check the voltage levels and dwell settings.....note my temps are in C not F ! 144 is 44 degrees over boiling!!! this is the problem....Ive checked the water temperature with a thermometer and its around 85, its the high revs that causes it to go to 144, when I drop to idle it corrects itself.

I will try with the alternator disconnected

-

ooops

-

Ok I have the car driving now,it pulls hard but the mixture is allover the place. I tried using megalogviewer but the files are always huge even if I just drive for 5 mins...is there something i'm missing? Also my temperature seems to go upwith the revs,, like to 144 then as I lower the revs it drops back down to 90. I thought it was noise from the injectors so I ran a screened cable but its still the same. Any ideas? maybe the edis needs a supressor. Here my file from a 5 min drive,maybe someone here can explain why it is so long.

Thanks

-

yep same kit.....well so I've been told by the company I bought my kit from.

-

Here si my recent experience.

F54 N/A P90 head/ 2mm head gasket. CR 8.35:1. MegasquirtII.EDIS. Holset HE351(HY35).

Like you I had never tried anything like this before. After fitting the engine back in the car and connecting the fuel system I connected the pump to 12v to set the base fuel pressure and check for any leaks.

I then connected all my ignition side of things and then played around with connections and VR sensor wiring until I had a solid spark when cranking.

At this point I wired the megasquirt and connected the injectors and fuel pump to a separate fuse block removed the fuses and loaded an msq filefrom the upload msq file thread. The 2 things that I was most concerened about were ignition settings and injector settings as I ad read stories about burnt out injectors and ignition drivers.

All the info is in the MS manual and hybridz has some great threads also.

I was lucky as my car started pretty much first time and only needed a small adjustment to the throtlle plate to idle.

Once the engine had warmed up enough for warm up enrichment to turn off and acceleration enrichment was set off I adjusted the required fuel setting until my AFR was near 14:1.

I should be able to start driving the car and logging runs this weekend with anyluck.

Good luck with your car!

-

Still not driven it yet buts its running better now.

-

I've just fitted the same flywheel, It was a very tight fit on the end of the crank. I can't imagine the bolts wouldl come loose, especially if red loctite was used. Let us know what you find. What type of clutch kit did you fit?

-

Thnaks Dave, I tried loading your msq but my MS gave me a few warnings and for some strange reason shut down !! I did copy your ve and ignition tables though, thanks for that.

-

Well my car finally started after being in bits for months, I had problems with the EDIS at first, I had the 4 pin plug wired upside down! not good when all the plugs fire at once!

After sorting the edis problem and using a bit of ptfe tape to stop the fuel rail leaks I tried it again. It fired straight up...it's a lot quieter than my old L28 NA. Oil pressure at 50psi just above idle. Timing was a little out but the trigger wizard soon sorted that out.

One problem I do have is a hissing noise from around #1 injector, it only happens when I close the throttle, I guess it must be a bad seal where the injector meets the manifold.

A few questions for you guys:

What sort of temperature do you have your coolant fan come on?

Is it normal for fuel pressure to drop from 40psi down to 20psi as soon as you switch the ignition off? I thought it would lower slowly.

Specs fo the engine as follows:

NA F54/90 .5mm oversize flat top pistons. 2mm steel head gasket

New bearings all over

ARP bolts crank/rod and head

Nismo oil pump

Holset HE351cw

Walboro 255 fuel pump

Delphi 650cc low imp injectors

Sard fuel regulator

Collins dump valve

MSII fuel and spark

EDIS

Megaview

60mm throttle body.

76mm IC pipework

600x300x76 Intercooler

76mm stainless steel exhaust with 1 straight thru rear oval silencer

Innovative LM1+LC1 wideband (not hooked up yet)

Will be happy with 300HP

Thanks for looking

-

Just had the same issue, check you have the correct links jumpered on the back of your MS PCB and if you're using a relay board check you have a connection from the screw terminal all the way to the 37pin connector at the MS.

Then you have to figure out the MS ignition settings for the setup you're running, little confusing at first but the MS site has some good reading material on the subject. Good luck.

-

Just divide KPA value by 6.89.....

101.325kpa (atm pressure) / 6.89 = 14.7psi

-

Here is a reply from a well respected Turbo dealer.

OK here's the deal: Turbochargers come with 2 different designs of seals on the compressor side, "dynamic seal" and "carbon seal". Dynamic seal is nothing more than a piston ring style labyrinth type seal machined into the thrust collar on the compressor side of the turbo, where the O.D. of the ring seals against the I.D. of the compressor backplate. This is not designed to seal the oil in the bearing housing under negative pressure (vacuum in the compressor due to throttle being upstream of the turbo in a draw through system) and also doesn't seal well in systems with marginal oil drainage. A carbon seal is an actual lip seal which uses a spring backed ring of carbon in the compressor backplate which seals against the outboard side of the thrust collar, and will rarely allow any oil at all into the compressor under any conditions. Of course, for a draw-through system you need a turbo with a carbon seal. The problem is, 90 percent of OE turbo applications use the dynamic seal, so you will have a hard time finding one. You can, however, convert any Garrett T3 or T4 series turbo to carbon seal by changing these parts, but it needs to be done by an experienced turbo reman shop. Also be aware that ALL Rajay turbos have carbon sealed compressors, but you will not find one in a junkyard (except on a Corvair haha) because they are usually found in aircraft and aftermarket applications. Carbon sealed Garrett T-3s can be found on some Volvos, SVO Mustangs and Thunderbird turbo coupes, Buick Regal T-types

-

No i realise a BOV wouldn't be needed if a pre turbo throttle was used, actually my brother tried it on his race car at the weekend, unfortunately his garrett BB turbo didn't have a carbon seal...lots of oil in the IC..not good.

Show off your rust pictures

in Fabrication / Welding

Posted

well more than 100 bucks but it has a lot of good parts that fetch pretty good money over here. Rear lights are good, interior panels are good, all the glass is good, gearbox, engine was running when parked up, dashboard is unmarked, all in all it will fetch a lot more than I paid for it, not that I bought it to make money.

Being a 72 it is classified as classic car over here and road tax is free......if it was ever to be restored, cough....re shelled or maybe used to convert a rust free left hooker to R hand drive.

or maybe used to convert a rust free left hooker to R hand drive.