-

Posts

632 -

Joined

-

Last visited

Content Type

Profiles

Forums

Blogs

Events

Gallery

Downloads

Store

Posts posted by Danno74Z

-

-

I'm getting ready to purchase a clutch flywheel package for my LT1 T56 project and would like some recommendations. I have a custom bellhouse and HTB that can accommodate either the 153T/12.75" flywheel or the larger 168T/14" flywheel. GM Performance has three flywheels that will work in my setup. They are: 14088646/153T/16LBS/$262, 14088650/153T/~25LBS/$239 and 14088648/168T/30LBS/$172.

Would anybody go with the 168T 30LBS unit? If you want to add some clutch suggestions throw them in too!

Thanks,

Danno74Z

-

All,

Has anyone used TTS Datamaster to log there LT1 engine?

Thanks,

Danno74Z

-

gvincent,

I'm still working on my LT1 project too. I know you mentioned the "Bible Paper" from 73LT1Z back last December. (I have a hard copy of it too) Do you know if 73LT1Z is still around? Just wondering if he has an updated/final paper on the LT1 wiring?

Danno74Z

-

Hi Bart,

I went to the shop and measured the OD of my rear strut tube and they are a few thousands over 2". I have an early 260Z so it should be the same as your 240. Here is a suggestion. Why not go to a muffler shop and pick-up some 2" ID exhaust pipe and have them slightly expand it for you and cut to any length you need. Should be good to go and cost you very little. You might purchase several different lengths to find the sweet spot on the coilover adjustment collar.

Danno74Z

-

Bart,

I might be missing something here but why not buy 1 aluminum sleeve and cut it in half and use it as a spacer to rest your new/old sleeves on. This way you don't have to remove the old weld ring, which I’m sure, is welded on to the strut tube extremely well.

Danno74Z

-

Bart,

I HOPE it works out for you with your rim and tire combination - you are breaking new ground - Cool. Never say never - right.

I have always wondered if one could cut the top strut houses off of the strut tower and graft in about 2" of steel all the way around (an extension) then weld the top piece back on. Then you could move your collar and lower spring perch up the 2" to clear everything and you would not have to use such a small spring. Just a thought.

Danno74Z

-

Hi Bart,

From all accounts I thought 10.5" tire width on a 9" rim was the largest tire one could stuff in the rear even going with the short springs to clear the tire -275mm is 10.826". (no flairs) What spring rate are you considering using in the rear?

Thanks,

Danno74Z

-

Cool - Thanks for the info.

Danno74z

-

Speeder,

Just curious, why are you going through all this work to put a degree damper on a LT1 engine? Are you no longer using the Optispark ignition? One would have to go through this exercise if they were putting in a new cam in the LT1.

Danno74Z

-

Jim,

Yes, I'm still counting everything BUT the items I listed - Drive train only removed. Does anybody have a SWAG #.

Thanks

Danno74z

-

Does anybody know what an early 260Z would weigh WITHOUT the engine, transmission (manual), drive shaft and complete rear end? My estimate without this running gear is the remaining chassis would weigh about 1,800lbs. Any other estimates?

Thanks

Danno74z

-

NICE!!!!!!!!

Danno74Z

-

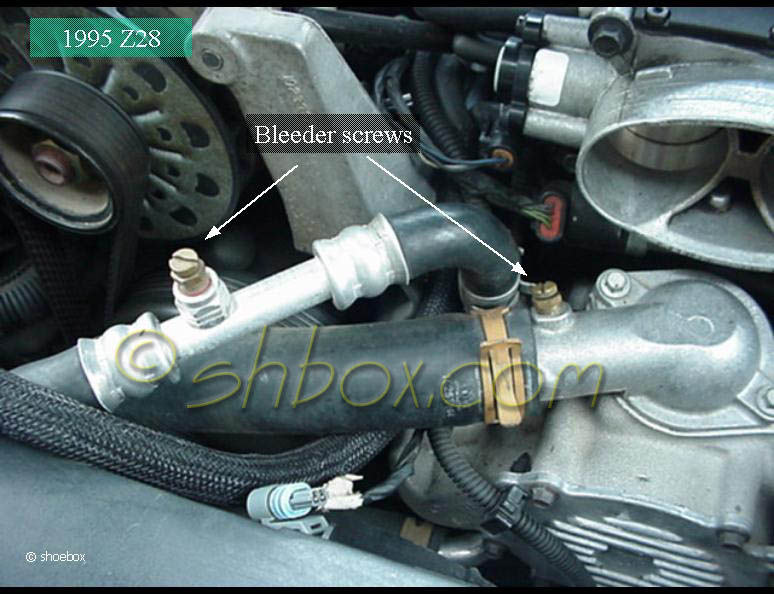

On the LT1 engine there is no coolant running in the intake manifold. There is a steam pipe that connects the left head to the right head on the backside of the engine. From this picture you can see the bleeder screws.

Danno74Z

-

Hi Guy,

Thanks for posting information on Tuner Cat. That Camaro site has a ton of great info on the LT1. I found this site which helps explain the basics of PCM tuning - http://www.lt1howto.com/articles/pcmtuning.htm

Have you downloaded Tuner Cat yet? I thing you can use it for 30 days free and then have to pay the $90 to register and the definition file.

Danno74z

-

shadowbane,

When you say you have the appropriate bellhousing which one are you using? The original one that came with the T56 or an aftermarket unit? Are you sure the fork you quoted for $104 will work with the LT1 AND T56. Ford did use the T56 tranny on their cars but not in the same way GM did on the Camaro. Some members here used the method suggested by JTR to hook up everything and I would suggest you read that section of the book if you haven't already. I would use the GM slave cylinder and use an aftermarket master cylinder as the GM unit would be real hard to retro-fit in a Datsun. GM sells the slave and master cylinder as one unit and to my knowledge you can't buy separately. You might be able to buy the parts separately at NAPA.

Danno74Z

-

shadowbane

Just remember the T56 out of a Camaro (1993-1997) is a pull type clutch assembly with a fork and integrated throwout bearing. It also has a special flywheel for this engine. This is a completely different setup then the push type clutch you are probably familiar with - Caution. 1998 and on went to a hydraulic throwout bearing setup which did away with the fork setup. To make your setup work (your current transmission) as a push type clutch you need a special bellhousing. The T56 transmission offered by GM as an aftermarket replacement for a T5 one could use a stock bellhousing but something about the T5 has a 22 degree angle to it or something. All I can tell you is be very careful so you don't purchase parts that won't work.

Danno74Z

-

Ramsey,

To my knowledge the T56 from 1994 - 1997 years were the same and are the one you want to use if you can. The 1999 is for the LS1 engine and will not bolt up to the LT1 engine. GM does produce an aftermarket T56 but you will have to purchase a bell housing to make it work. I think you will be fine with either the 1993 or 1994-1997 but most people use the 1994-1997.

1994-1997 T56

First 2.66:1, Second 1.78:1, Third 1.30:1, Forth 1.00:1, Fifth 0.74:1,

Sixth .50:1, Reverse 3.28:1

Design Torque Rating: 450 lb-ft

Approximate Dry Weight: 125 lbs.

1993 T56:

First 2.97:1, Second 2.07:1, Third 1.43:1, Forth 1.00:1, Fifth 0.80:1,

Sixth 0.62:1, Reverse 3.28:1

Design Torque Rating: 400 lb-ft

Approximate Dry Weight: 125 lbs.

-

Matt,

Have you or someone else figured out why Dave's ECM had corrupted code or became corrupted over time?

"Code corruption seems to be a common problem with the MS-II CPU...Wonder why that is...?" is this true statement or a very rare instance?

Thanks,

Dan

-

cygnusx1,

I’m just learning about MSII and I have a question for you or really anybody who is in the know. Lets say you had a power surge and your voltage spiked to 15V or more how is the MSII protected? Is it internally protected or is it up to the installer to provide protection to the box. This is for down the road.

Thanks,

Danno74Z

-

Randy,

Try this site.

"Here you will find the most common files that may be missing or corrupted on your computer. Feel free to download at no cost!"

Should be an easy fix but computer issues can be worse then fixing an electrical problem - good luck!

Danno74Z

-

HizAndHerz

Thanks for the fast reply on pin 7. I am not going to use the stock Tach but probably an Autometer unit. I think it should work off of pin 2 but not sure at all - more study is needed

Danno74Z

-

HizAndHerz

Below is the pin-out for the eight cyl EDIS. Can you tell me what pin is used for the signal return ground? I assume it is pin #7 (does not say it) but when you assume something it can bite you! Also, can I use Pin #2 for a tachometer even though it says diagnostic signal to ECU?

Thanks

Danno74Z

8 Cylinder EDIS module pinout Signal EDIS Module Terminal

PIP (EDIS output signal) 1

IDM (diagnostic signal to ECU) 2

SAW (ECU spark control signal) 3

VRS - (crank sensor negative) 4

VRS +(crank sensor positive) 5

VPWR (ignition switched 12 volts) 6

IGN GND 7

COIL 1 (coil drive) 8

COIL 2 (coil drive) 9

PWR GND 10

COIL 3 (coil drive) 11

COIL 4 (coil drive) 12

-

I'm just in the planning stages of my MegasquirtII system. I have an EDIS8 from a Lincoln and VR sensor has the following number F3DE6C315AB stamped on it. There are a blue and grey wires coming from the plug. Is the blue - and the grey +? Thanks in advance!

Danno74Z

-

The answer to the Optispark elimination is yes and no. There are two systems out there that eliminate the high voltage from the Optispark leaving the optical sensor to due its thing and this does seem to help in most cases. Each system will run you about $600 depending on the configuration. IF you have a bad Opti to start out with you will have to repair or replace it as both systems require a healthy Opti. The new Opti will cost about $250. Repairing a bad Opti is more trouble then it's worth and I'm not sure how you could bench test it. Removing and replacing an Opti is a PITA. The water pump and balancer both have to go to get that sucker out. I personally have never done it but others on this board have and I'm sure they can help you out if you need advice. LOT'S of people over the years have tried to eliminate the Opti and it is VERY hard to due as it provides both cam and crank signals to the PCM. It is an integral component to the LT1 engine and I think GM designed the engine around it. In my opinion it is the Achilles heel to an otherwise very good engine.

This is what I'm going to do and I have been thinking about this for some time. I am dumping the entire OEM computer and Optispark system and I'm going to use a MegasquirtII Computer and a FORD EDIS8 module which has 4 coils and a 36-1 crank wheel - very robust and very reliable. All the existing FI sensors and wiring on the engine can be used with the new MSII computer. I give up sequential FI and the MAF meter and use bank injection and a MAP sensor. Pros and Cons to both systems and I won't get into that. I'm building the computer myself and learning one heck of a lot about FI in the process. I figure about $500 (if you build it yourself) for the entire MSII system or about 2 Opti replacements. This is a true HybridZ project!

Danno74Z

153T or 168T Flywheel Recommendation

in Drivetrain

Posted

Can Anybody Help?

Danno74Z