-

Posts

76 -

Joined

-

Last visited

Content Type

Profiles

Forums

Blogs

Events

Gallery

Downloads

Store

Everything posted by strokerzedd

-

The deed is done. If I got paid by the hour I'd be one broke mechanic! The right spring clip stays in the diff. It's a tight fit but it does fit. I hope that these photos help anyone else that's as inept as I am. Now on to the wiring!

-

Thanks for the photos J. When I received my VLSD the right spring clip was already in the diff and the vendor reminded me to take it out before assembly. A friend of mine just emailed me and told me that his VLSD right spring clip is in the diff as well. Your photo of the right halfshaft doesn't have the clip on it. Should the clip stay in the diff and we simply insert the halfshaft through it? That would explain the shallow groove for the spring clip on that side. If this is the case how come it isn't common knowledge or did I just miss the memo? J. does the VLSD work well for you in your application? Can it handle your horsepower?

-

Both types of halfshafts I have in the photos have 29 splines. But I do have a favor to ask of you since you have a VLSD and halfshafts. My longer halfshaft, the right side, had a much shallower groove for the spring clip than the shorter left side (I cut it deeper in an attempt to get it to fit, hope I didn't screw it up). Is yours the same and is the spring clip on the longer shaft thinner than the shorter shaft? The spline ends are different on my longer and shorter halfshafts, one is blunt and the other tapered. Are yours the same? I asked this question on another thread as well, probably not supposed to but I wasn't sure where to get the best responses, http://forums.hybridz.org/showthread.php?p=1002630#post1002630 and Z240 confirmed that mine were the right halfshafts and J. Soileau RB26zcar said that he has had the same diff in his car for awhile. If you can post some close up photos that would be great, especially of the spring clips and grooves and the ends of the halfshaft spline.

-

RB26 240z with 300ZX 88SS Shiro VLSD Diff CV joints

strokerzedd replied to strokerzedd's topic in Nissan RB Forum

I bought the 27 spline 280Z stub axle Billet adapter companion flanges from Ross at Modern MotorSports, although mine were machined from the stock units not custom that he sells now. http://www.modern-motorsports.com/catalog/product_info.php?cPath=&products_id=46 He also supplied the pdf instructions that describe how to shorten the Z31T half shaft for proper geometry. I tried downloading it but it's too big, if anyone wants it contact me and I'll email it to them. I'm sure that you've read this thread that gave me a lot of the info I needed. http://forums.hybridz.org/showthread.php?t=114798 The length of the halfshafts seems to be okay. I've looked at your build photos many times during my build process. How's the VLSD standing up? What are the pros and cons? To paraphrase Ross at Modern Motorsports regarding his companion flanges and the Shiro 88SS VLSD: Will these billet adapters work with a 1988 Viscous (VLSD) Differntial taken from a 1988 SS Shiro Edition 300zx (Z31) turbo car and halfshafts? This won't increase the track? Ross: Yes, they work very well with the viscous axle/diff setup.♥ You HAVE to have the shiro CV's to go with the diff.♥ Any other CV's will not work.♥ CV's etc don't change your track, your control arms and top strut mounting location control your rear bearing housing location ie. track width. -

RB26 240z with 300ZX 88SS Shiro VLSD Diff CV joints

strokerzedd replied to strokerzedd's topic in Nissan RB Forum

To tell you the truth, when I bought the VLSD I wasn't really up to speed about the differences between the R200 diffs. Thanks for the info, my diff does have the washer with the 3/4" hole, so it is the VLSD and they are the proper halfshafts. Now if I could only get the damn things in. -

I apologize if this is the wrong venue but I'm hoping one of you has also put a VLSD in your RB26 powered 240z. I purchased a 300ZX 88SS Shiro Viscous LSD Differential with CV joints several years ago from a wreckers way down south and only now am attempting to install the CV joints. My 1972 240z has undergone a complete rebuild once again: suspension/coilovers/fuel cell and surge tank, a seriously tweaked RB26. I cannot get these halfshafts in and I wonder if I was sent the wrong ones, perhaps for the 1988 300zx turbo? I can't find photos of the 300ZX 88SS Shiro VLSD CV joints anywhere on the net and I know that they're specific to this model only. Does anyone have photos? In the enclosed photos are the two silver CV joints that were sent to me with the 300ZX 88SS Shiro VLSD as well as the left side 1988 300zx Turbo CV joint. The longer silver CV joint halfshaft is the right side, but the groove for the spring clip was very shallow and wouldn't allow the spring clip to sit flush with the spline surface so I ground the groove deeper, to no avail. Any ideas, anyone?

-

I purchased a 300ZX 88SS Shiro Viscous LSD Differential with CV joints several years ago from a wreckers way down south and only now am attempting to install the CV joints. My 1972 240z has undergone a complete rebuild once again: suspension/coilovers/fuel cell and surge tank, a seriously tweaked RB26. I cannot get these halfshafts in and I wonder if I was sent the wrong ones, perhaps for the 1988 300zx turbo? I can't find photos of the 300ZX 88SS Shiro VLSD CV joints anywhere on the net and I know that they're specific to this model only. Does anyone have photos? In the enclosed photos are the two silver CV joints that were sent to me with the 300ZX 88SS Shiro VLSD as well as the left side 1988 300zx Turbo CV joint. The longer silver CV joint halfshaft is the right side, but the groove for the spring clip was very shallow and wouldn't allow the spring clip to sit flush with the spline surface so I ground the groove deeper, to no avail. Any ideas, anyone?

-

Anyone using the AEM Water/Methanol Injection Kit?

strokerzedd replied to strokerzedd's topic in Nissan RB Forum

I'm running an AEM 1621U ECU, or will be as soon as I finish the wiring mess I'm in the middle of. Talked with a guy in town that has methanol on his Skyline and his brother is putting in a 6 nozzle system in his very modified RB26. He tells me that the single nozzle systems aren't equal across all cylinders and he's looking for 900hp. Apparently increasing the fuel to cylinder #6 to stop it from leaning out due to intake manifold deficiencies sets up harmonics in the crank in high power motors. As an aside, anyone with an RB26 240z using the Skyline clutch booster with a twin disc clutch? Some say that the twin disc can be too heavy without boost. -

Anyone using the AEM 30-3001 - HD Water/Methanol Injection Kit?AEM 30-3001 - HD Water/Methanol Injection Kit on an RB26? Is it the best way to protect the 6th cylinder from leaning out or better to put the money into a tuned intake manifold? If so, which tuned intake manifolds is everyone happiest with?

-

I asked my mechanic about our experience with the CP pistons: Different numbers are due to factory tolerances. A bit more variation than I expected but still livable. If they were RB25 pistons, they would have stuck out .060 more. That is way more than can be compensated for with head gasket thickness. Stock pistons were close to the same protrusion. Remember the block was surfaced because the top was badly etched so we gained a bit of protrusion that way. The other guys should have measured the piston protrusion before final assembly. Have to allow enough squish for clearance. .035" is minimum recommended piston to head clearance to allow for stretch. 1.1 head gasket is .044 thick, leaves maximum protrusion of .009" Not very much. Hope this helps.

-

I put 86mm CP pistons in my RB26 and ran into the same problem. The pistons stood a couple of thou proud of the block but weren't identical across the board. The pistons and rods were all identical. I called CP as well and they were perplexed. Meanwhile my mechanic moved the pistons around and kept getting the same measurements. He measured the connecting rods in the bores and got the same weird measurements. His explanation was that the crank journals were not identical. I had already purchased a Cosworth 1.2 mm head gasket but had to buy another one, 1.8mm thick this time. That solved the problem and I'm not sure that the small decrease in compression is really going to make that much difference in my tweaked motor. When I'm finished my build I'll have a garage sale with all of the extra parts I picked up!

-

Just finishing my project and discovered that I'm missing parts. I need the two relays that attach to the green plugs shown below. I also need to replace the power transistor plug that's broken on my harness.

-

Chris Rummel's easy follow RB into Z wireing guide

strokerzedd replied to Rumnhammer's topic in Nissan RB Forum

My R32 RB26 engine harness is quite different looking than Chris's RB25, I don't have the same 2 relays or large white connectors next to the Blue ECU plug. I'm just a little apprehensive cutting the harness up without a clear roadmap. I'm curious where the description "AF09" or "AF04" comes from, can't find them on the wiring diagram or R32 pinout diagram and it would help in following Chris's excellent thread. I don't have a main white connector upon which all of the work is being done. So am I instead cutting all of the wires down(only ten are used) not required from the blue ECU connector on the R32 RB26 engine harness? I've pulled the whole old wiring harness out of my 240z engine bay and I'm hoping to use the RB26 harness in it's entirety since it's almost 20 years newer. The definitive answer to using an Autometer tach is to use the Summit Racing MSD tach translator #8918 for an RB26 transplant into a 1972 240Z? -

-

What don't you have to put back on an RB26?

strokerzedd replied to strokerzedd's topic in Nissan RB Forum

Mike, I see that you found the thread with the photos of the custom machined front turbo inlet, I wasn't sure where I found it but here it is for anyone else: http://forums.hybridz.org/showthread.php?t=127109&page=8 I like stony's idea, using the stock rear turbo inlet on the front, just have to find one now. Totally off topic but a friend just sent me this link for an electronic gauge cluster that he's ordered, might be an interesting add on for performance capture.http://www.dashdaq.com/ -

RB26DETT into 240Z Beginner Progress

strokerzedd replied to getoffmyinternet's topic in Nissan RB Forum

I just figured out the answer to a problem that's been plaguing me for the last year. I put in an LSD and CV joint half shafts with the 280z stub axles and Modern Motorsport adapters and everything was measured within spec, but everytime I torqued the stub axles the rotors were 12 thou out. Tried turning everything 180 degrees countless times, had the rotors and stub axles extra machined by my machinist to no avail. Admittedly I was doing a lot of other work on the car, but a year!!!!! We finally determined that the inner stub axle curved race that rests against the outer bearing curved race wasn't machined correctly at the factory, you could see a difference in coloration where the two surfaces weren't touching. Everything measured 100% out of the car but when it was torqued 220 foot lbs it was being twisted out of balance. The poor bastard that owned the original 280Z must have been really frustrated by the rear end vibration that the dealer was never able to find! Just wanted to say that it's been fun following this build and this thread. It's been two years since I pulled my 3.1 litre stroker and took the RB plunge and I'm still months away from starting the car. I'll post a thread when I'm finished, I've been taking photos throughout. -

Here are more photos from the same car, it's from your hemisphere if that helps. I also found a flange that someone fabricated.

-

-

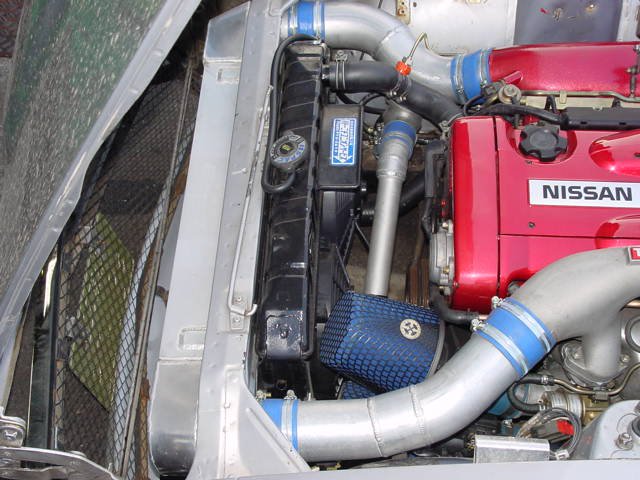

Mike, I've only briefly looked at it. I broke my leg and ankle a month ago and it's slowed all aspects of my life down considerably! I contemplated cutting the stock base plate and fabricating a straight tube forward but the allen screw that holds the plate on the engine side is recessed and won't be accessible. I'm not sure what others do. Perhaps fabricating a short 2" long pipe that allows access to both allen bolts and then using a silicone adapter to the join another pipe to the air cleaner is the answer. I found the photo below that shows a straight pipe, so it's possible. I've collected a library of photos off the net showing every aspect of other peoples builds but it's funny the close up details you need you never find, that's why I've tried to post detailed photos of my build as it progresses.

-

Referring to your initial query, I've installed an external oil cooler in my '72 240z in addition to the stock water cooled oil cooler with oil filter adapter. The dealer accidently ordered a 19" wide 3 row rad instead of a 21" and I couldn't return it so I built a rubber mounted oil cooler bracket into the rubber mounted rad mount. I built a rad shroud for the electric rad fan so I think that I'll have adequate cooling.

-

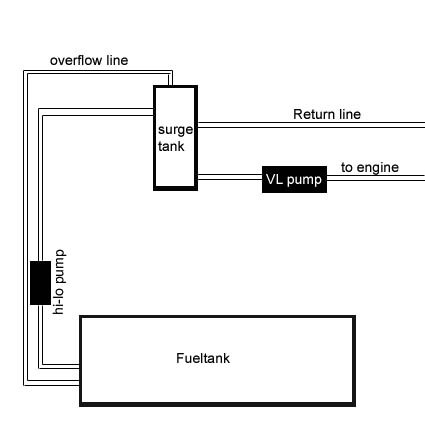

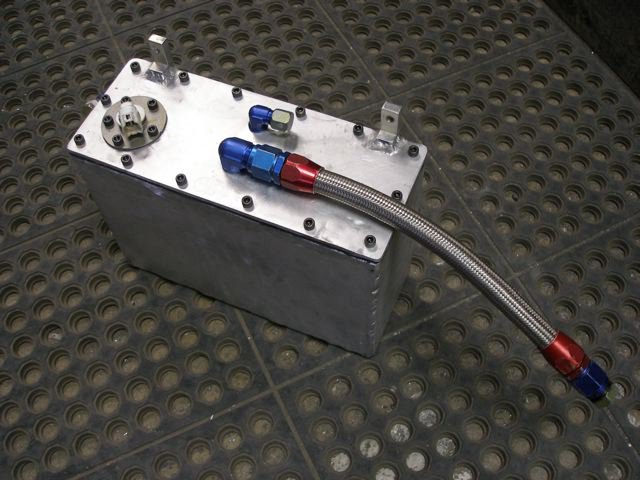

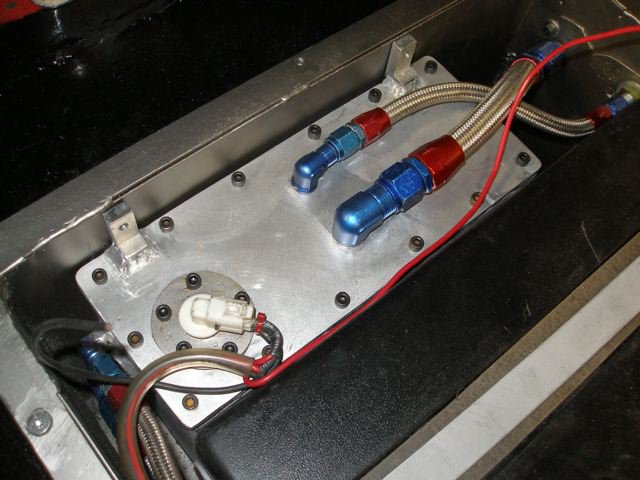

The surge tank/swirl pot is always kept full to the brim by the low pressure pump from the fuel cell and the return line from the fuel regulator returns back to the surge tank/swirl pot as well insuring it's always full. The high pressure pump insures that the fuel injectors always receive high pressure fuel but the regulator controls the whole systems pressure, effectively applying "brakes" to the whole system. The high pressure fuel pump can't override the fuel regulator so the high pressure fuel pump just doesn't work as hard. Installing two high pressure pumps in series won't increase the pressure, just give you added insurance should one fail. I should have put a low pressure pump in the fuel cell but just installed two of the same since the fuel regulator will determine how hard it works after it's filled the surge tank/swirl pot. As long as your surge tank/swirl pot is big enough, once it's filled you won't ever use enough fuel to empty or even partially empty it since it's constantly resupplied by both the fuel cell and the return line from the fuel regulator. More info cut and pasted from the net: Fuel Surge Tank Vehicles fitted with EFI from the factory have a surge tank in the fuel tank - so when you’re accelerating or cornering, fuel can’t rush away from the fuel pickup, causing the engine to stall or surge. Surge tanks for high hp applications (700+WHP) need about 3.5 - 4.5 litres. • EFI uses an electronic fuel pump, and the supply lines after the pump are pressurized to around 40-60psi. That’s a LOT! In most cars, the electric pump is mounted INSIDE the fuel tank and pumps fuel up the length of the car to the engine's fuel rail. So this means that you have 40-60psi pressure on the fuel supply line from the pump, right up to and inside the fuel rail. The fuel rail holds your fuel injectors onto the intake side of the engine and houses a volume of fuel under pressure, which flows through the injectors and into the engine when the ECU tells the injectors to open. Pressure is maintained in the fuel rail by the fuel pressure regulator, which has a mechanically controlled diaphragm that allows excess pressure (fuel) to escape, and in doing so maintaining the correct pressure within the fuel rail. So the unused fuel flows out of the fuel rail through the fuel pressure regulator, and back into the fuel tank.... and the cycle continues. In a carbureted fuel tank, when you have a light fuel load (less than a 1/3 of a tank) the pick up line will frequently suck a pocket of air. With a carburetor this is no problem because the float bowel holds a fuel reserve, but with EFI there is no factory fuel reserve and a moment of reduced fuel supply with cause the engine to fuel starve, run lean and possibly break. Now a little about EFI fuel pumps.... There is a reason they are usually mounted inside the fuel tank - THEY DONT SUCK GOOD. Unlike a mechanical carburetor pump, they aren’t very good at drawing fuel out of the tank... they are useless at it. Fuel almost literally has to be poured into the inlet of the pump - you'll hear the term "gravity fed" used to explain this. By having the pump inside the tank, the inlet is submerged in the petrol right at the bottom of the tank and thus gravity is forcing the petrol into the pump. So THAT'S why you need a surge tank! Basically they are a secondary fuel tank you can place somewhere suitable to gravity feed the EFI pump. Of course somehow fuel needs to get from the fuel tank to the surge tank - this is where an electronic carburetor pump, or "lift pump" is used. These are a low pressure, high volume pump that CAN suck. MAKE SURE to use EFI fuel hose for any rubber lines after the EFI pump. Carburetor fuel lines can’t handle the high pressure. Some places also have "EFI" hose clamps... these are just normal hose clamps with beveled edges and solid clamping face that doesn’t bite into the rubber hose at all. You MUST use a carburetor fuel filter before the lift pump (an EFI filter provides too much restriction), and an EFI fuel filter after the EFI pump (a carb style paper element filter is of no use against the higher feed rate of an EFI pump). As such dedicated Pre Filters are available to screen out foreign matter without restricting flow. For ease of installation, a 300zx style EFI fuel filter works well, having barb fittings at either end. Simply chucking an in-tank EFI pump into your carburetor fuel tank won’t always work.... in most EFI tanks there are baffles that keep the fuel around the pickup of the pump to avoid starvation when the fuel is low and you are cornering. Most people put baffles in themselves or make a "swirl pot" - a small lowered pool at the lowest point of the tank where the inlet of the pump is then put. Doing this yourself is EASY. Just be careful, and make TRIPLE SURE you know which line is which when you are attaching hoses!! Pump selection, When choosing your lift and main pumps its a good idea to ensure your Lift pump will slightly outflow your main pump, keep in mind this is flow not pressure. Your lift pump needs to be able to supply enough fuel all the time. I don't think a weld in sump and fuel tank baffling is the best idea, I still don't like the idea of a ton of fuel pumps. I think that one pickup pump from the gas tank feeding one decent sized surge tank (doesn't need to be huge) and one single high-flow pump from there to the engine. As for a lot of ss hose...there really isn't any other option if you want the best fuel system setup. Although I have seen one fuel surge tank setup that used mandrel bent tubing with compression fittings rather than hose, this would be lighter than all SS lines, but much more custom work would be involved. http://www.sdsefi.com/techsurge.htm Step away from the Walbro. Get a NISMO pump. You will probably not be running your 720cc injectors at 100% for any duration of time, so the NISMO will do just fine. FYI for my use we used two NISMO spec. pumps but that was for the greater headroom that two provided- two pumps run in parallel. Ended up with a 40% over capacity, but under boost pressure you'll be glad to have the NISMO pump in there. The Walbros and the Bosch both have lower flow ratings at higher boost pressure, the NISMO does not drop off as dramatically. Don't bother with the Bosch pump either. Been there, done that mistake. Definitely do not install a fuel pump "inline" aka in series with the stock one in tank. At least, don't do that without a collector tank for the secondary pump and a return line to the primary tank. That kind of system ends up being more complicated than just running twin NISMOs in tank. We always use the Apexi intank of SARD units. Apexi = best. SARD = better price wise Apex and Nismo are the same pump. A single Nismo/Apex has been tested as the highest flowing intank pump you can buy up to about 80 psi. A single Nismo will do 600 whp with enough injector. http://www.stealth316.com/2-fuelpumpguide.htm 1. Do not use 1/4" - 3/8" o.d. lines on a racing fuel system between the fuel cell and the pump. Racers often joke about their first racecar and how the fuel line was so small it functioned as the main jet. Ensure the fuel is supplied through lines that are of the correct size for the application. Push-Lok, stainless steel braided hoses, and aluminum tubing are the most common fuel lines used on race cars. 2. Avoid right-angle hose-end fittings from the pump to carburetor as much as possible. Although they are inexpensive and readily available, they're restrictive and frequently cause fuel flow troubles. Hose ends with angles of 90˚ & 45˚ should also be avoided if possible. Nonetheless, should it become necessary to use one, use radiused hose ends (90* bends) as they have much better rates of flow. They're manufactured from aluminum, equipped with swivel ends for a positive seal and are easy to install 3. Use a relay to ensure the electric fuel pumps are provided with the proper voltage in order to maintain proper fuel flow.

-

The fuel pump from the fuel cell to the surge tank is low pressure so it doesn't matter what you use. I'd stay away from the Walbro though. The following info is taken from various threads: • Yeah everybody's got different experiences. Here's mine: Bosch pumps are great, until they decide to fail. When they fail, you will not know until a piston is melted. They will only reduce volume at max line pressure. • Walbro pumps are great too until you run out of fuel. Believe it or not, the commutator of the Walbro runs on bronze BUSHINGS. Yes, BUSHINGS, not bearings. So if you run out of fuel once, there's a good chance you already hurt the bushing. No fuel = no lubricity. The Walbro engineers know about the problem already. I've had a discussion with them about it. So I am always hesitant to use Walbros on street cars where running out of fuel is a reality. • A1000: I've only used them on race cars so I can't give you any feedback on these. I ran 900whp with a -8AN feed and a -6 AN return. That could be why I didn't have pressure problems. The pump is great for race cars though. Weldons: Forget about it. Don't even think about using these. Reliability is non existent.

-

Great test thread. Surge tank, fuel injected motors need one and it needs a low pressure pump to feed it from the fuel tank and then a high pressure pump to feed from the surge tank to the motor. The surge tank is simply there to insure that the motor never suffers a fuel pressure drop, especially in the corners, otherwise pistons start to melt. The fuel is fed to the surge tank and filled to capacity, the high pressure pump feeds fuel down a large fuel line to the motor fuel rail. The excess fuel if fed back to the fuel regulator from the fuel rail middle fitting. The fuel regulator limits the fuel back pressure, approx 15psi, and feeds the excess fuel back to the surge tank through the return line. The PDF diagram enclosed shows the lines and fuel direction required. Mine might be unduly complicated but I'm overbuilding the whole car. Z Fuel System & Oil Cooler.pdf (DR).pdf

-

The fuel rail needs to be fed from both ends to insure an adequate supply of fuel under acceleration. The hole in the middle top is the line that runs to the fuel regulator and then the fuel goes into the return line back to the fuel tank. Fuel injected cars need a surge tank to insure an uninterrupted source of fuel to the injectors. Stock fuel injected cars have a small tank within the main tank, but if you're running the power you want you'll need a separate surge tank. I installed the pumps inside both tanks to cool them and keep them quiet, but it's a lot easier to mount them outside of the tank. Make sure that they get adequate ventilation, some pumps overheat easily.

-

I'm still building mine and I opted for an RCI fuel cell with 2 x Denso Fuel Pumps (part #195130-1020) Supra Turbo, one mounted within the fuel cell and the other inside the surge tank that I built. I've got AN stainless steel fuel hise purchased used from one of the nascar teams carrying fuel to the engine compartment and an Aeromotive 13109 fuel regulator under the hood with an HKS fuel rail and RCI 1000cc injectors. I collected all of the info below while researching my build, it might help you make a decision. Hope no one gets upset that I cut and pasted. Fuel Pumps http://www.stealth316.com/2-fuelpumpguide.htm Great info & links The A'PEXi BNR32 fuel pump 404-A011 (an upgrade pump for the Nissan Skyline GT-R) is the highest flowing in-tank fuel pump at line pressures up to 75 psi and at 13.5 volts. It is installed in some Mazda cars that use a factory Denso fuel pump nearly identical in size and design to the 3S factory Denso fuel pump. The relief valve opens at about 75 psi, limiting use to boost pressures up to 30 psi if base fuel pressure is set at 45 psi. With available flow measurements at only 13.2 volts, we do not know yet how this pump performs at lower or higher voltage. Nevertheless, if this pump is installed with a re-wired electrical circuit (providing at least 13.2 volts during WOT operation), six injectors up to 720 cc/min can be supported. The factory R33 Skyline GT-R and HKS Skyline upgrade 1407-RN019 fuel pumps are the second highest flowing in-tank fuel pumps at line pressures up to 75 psi and at 13.5 volts. These fuel pumps may flow a little less than the other pumps below 65 psi, but this is not important when using large injectors. It is the flow at the high boost ranges when large injectors would be required that is important. These pumps can support six injectors up to 640 cc/min with 13.5 supplied volts. The Denso fuel pump 195130-1020 (the Supra Turbo MKIV pump $170 at http://cgi.ebay.com/ebaymotors/195130-1020-Denso-Fuel-Pump-Supra-Turbo-Stealth-3000GT_W0QQitemZ250215237239QQcmdZViewItem is one of the best in-tank upgrade choices if you are using injectors up to 550 cc/min and are providing at least 13 volts to the pump. When 18 volts are supplied, the Supra pump is good for injectors up to 880 cc/min. At 13.5 supplied volts no other in-tank pump, except for the R33 Skyline GT-R and A'PEXi BNR32 fuel pumps, flows significantly more fuel up to 70 psi line pressure or 27 psi boost. It is a direct drop-in replacement; all other non-Denso choices require some modification to the fuel pump assembly. It is as quiet as the stock pump. One disadvantage of the Supra pump is its relatively heavy current draw (at 13.5 V, 16A @ 43 psi, 19A @ 70 psi) and large decrease in flow as supplied voltage lowers. Good, heavy-gauge wiring (meaning re-wiring the fuel pump electrical circuit) is a requirement to get the most out of this pump. The Walbro GSS341 model (also called the 255 lph HP) flows a little less than the Supra Turbo pump up to about 67 psi line pressure (24 psi boost), when 13.5 volts are supplied to both pumps. However, at 12 supplied volts, the Walbro GSS341 outflows the Denso 195130-1020 above 55 psi line pressure. Like the Supra fuel pump, the Walbro GSS341 is an excellent choice for 450 cc/min injectors, especially if the fuel pump has not been re-wired (12 supplied volts). Also like the Supra pump, it can be used with up to 610 cc/min injectors if 13.5 volts are supplied, and up to 720 cc/min injectors if at least 16 volts are supplied. The Walbro GSS341 draws about half as much current (at 13.5 V, 8A @ 43 psi, 10A @ 70 psi) as the Supra fuel pump. Some slight modification to the fuel pump assembly is required and it may not be as quiet as the Denso pumps. The price is even less than the Supra pump at $100 to $150. Bosch 044 Fuel Pump Quite possibly the most popular aftermarket fuel pump, capable of providing 300lph free flow and 200lph at 5 bar (72.5psi). We recommend these inline fuel pumps be installed between the in-tank fuel pump and the fuel rail. They require extensive fabrication to mount in tank. Feeding these pumps with another pump in series will boost the pressure at the fuel rail. I wouldn't skimp on your fuel pump as lack of fuel pressure/flow will melt pistons or hole them. I would recommend the Bosch 044 with a surge tank. I would also look on the forum about the wiring to the fuel pump mod for z's as they can suffer from voltage drop which can really mess with advertised flow rates the Bosch 044 is used by many racers and maintains flow rates across all the pressure range (not many pumps mention this fact). Finally the 044 has screw in fittings that allow you to secure the high pressure side better than just clamping it. Handy to know when you could have fuel pouring into your engine bay. It is also worth noting that these pumps can suffer premature failure if the have to suck fuel up to them....e.g. if the pump is located a long way from the tank or mounted higher than the tank, it fights gravity. There were lots of Japanese complaining about failure, but they were all mounting them in the trunk and pulling fuel up to them. One guy even had the stock 8mm line feeding the -10 inlet with the pump in the trunk... I've used quite a few of them over the years from Aeromotive, Paxton, etc, and have had zero failures when the pump is mounted around the level of the bottom of the tank. • One Nismo or Apex in tank fuel pump on 91 octane with 720 cc injectors is done at 500 whp. After that you need more fuel. A single 044 will do 580 whp on good fuel . A single Nismo/Apex/HKS/etc will do 580 whp on good fuel. Dual Bosch 044’s with 800cc injectors will do 600hp. • I wouldn't run two fuel pumps because if one dies then you are screwed. For big HP, I would say go with one big pump that is sucking fuel from a surge tank. Then "Y" it at the engine to go into both ends of the fuel rail with a single return from the regulator. • Most people who do it right the FIRST time, use the stock fuel pump to supply fuel to the surge tank. A lot of guys use aftermarket pumps to supply the fuel, because they initially bought a smaller pump and then wanting more power, they just kept the one they had in there from the previous upgrade. • Use -10 AN (5/8â€) from the tank to the pump, -10 AN from the pump to an inline -10 filter and -8 AN (1/2â€) from the filter to a bulkhead "T" under the hood. Two -6 AN 's from the "T" to each side of the fuel rail. A single -6 AN from the center of the rail to a regulator #13109 (6AN) or #13101 (10AN), and -6 AN from the regulator back to the tank. If you don’t have a tank with a drag-sump style outlet, you will need a surge tank.