-

Posts

76 -

Joined

-

Last visited

Content Type

Profiles

Forums

Blogs

Events

Gallery

Downloads

Store

Everything posted by strokerzedd

-

I haven’t checked this site in years and just thought I’d update this build initiated over 10 years ago!

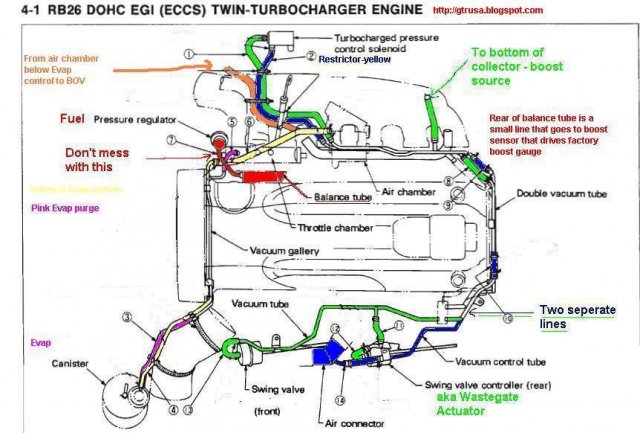

I’ve owned the car since 1975, and continually updated it culminating in an amazing 3.1 litre L28 conversion that was the best sounding motor I’ve ever heard. I started this RB26 conversion ten years ago, had to build so may pieces and convert everything, business and life got in the way but it will hit the road this spring. Ironically, 3 years ago tuning it on a Dyno and on one run while decelerating from an 8500rpm run it spun a bearing and I had to rebuild it after 100 miles! Turns out that having a very difficult time getting the car running due to wiring, change to throttle body intake and other issues, the oil pan had accumulated a lot of unburnt gasoline that doesn’t lubricate bearings very well! Damn. Surprised the — out of me!

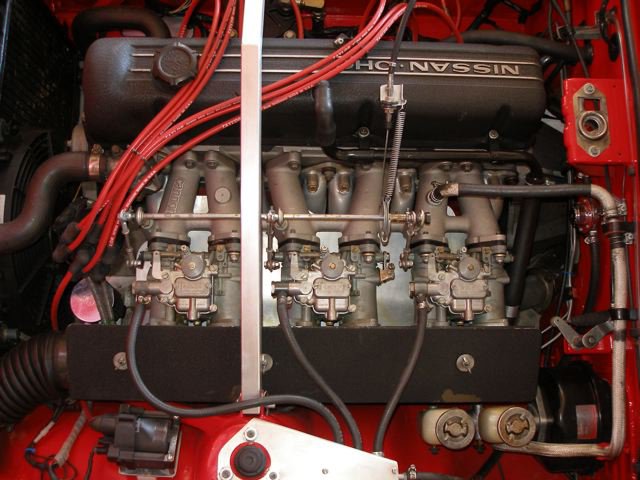

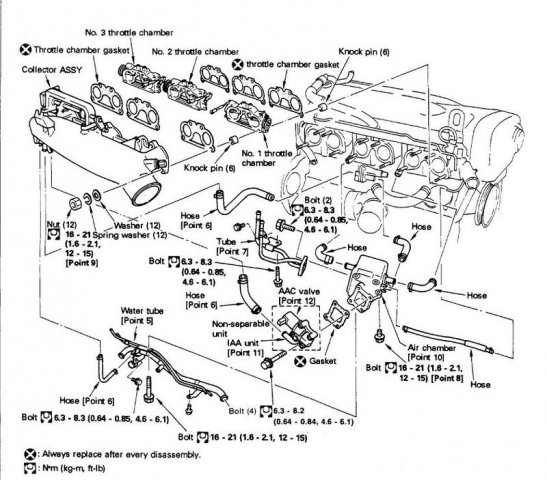

While rebuilding the motor I decided to address several issues. Firstly I’ve cut out most of the radiator support to give me more room for the rad-intercooler and turbo intakes. Next, I re-installed the original 6 individual stock intake system, Nissan built a great system and the throttle body conversion I installed didn’t function well and didn’t give me enough tuning latitude.

Benn building my dream car condo near Calgary for the last year, I’m really close to finishing it and then I can tackle finishing the Z and the other cars I’ve been collecting. Having tow car lifts now is going to make working on the cars so much easier!

Next I’m going to install the BCE Racing Coilovers that are replacing the simple Cosmo Coilovers conversion that didn’t cut it. Looking forward to driving the car after so long!

-

the TV business is a cruel and shallow money trench where pimps and thieves run free and good men die like dogs. There's also a negative side......