-

Posts

346 -

Joined

-

Last visited

-

Days Won

17

Content Type

Profiles

Forums

Blogs

Events

Gallery

Downloads

Store

Everything posted by markrolston@mac.com

-

Progress on my insane VQ35HR 240Z project

markrolston@mac.com replied to markrolston@mac.com's topic in Nissan V6 Forum

The car is coming back together but not done so I will miss this weekends NISMO Fiesta in San Antonio. Engine is running roughly and we think it's a stuck exhaust side VVT. Going to replace it with a part that fixes cam timing in place on the exhaust side. -

Progress on my insane VQ35HR 240Z project

markrolston@mac.com replied to markrolston@mac.com's topic in Nissan V6 Forum

yes. actually just spent many months doing some reworking of the engine after blowing it up at COTA. I'm hoping to bring both to the show. -

Progress on my insane VQ35HR 240Z project

markrolston@mac.com replied to markrolston@mac.com's topic in Nissan V6 Forum

one more week to go before Nismo Fiesta. There's a lot still to do. I really only expect to get it put back together and running to be able to get it down there. Real test and tune will have to wait. -

Progress on my insane VQ35HR 240Z project

markrolston@mac.com replied to markrolston@mac.com's topic in Nissan V6 Forum

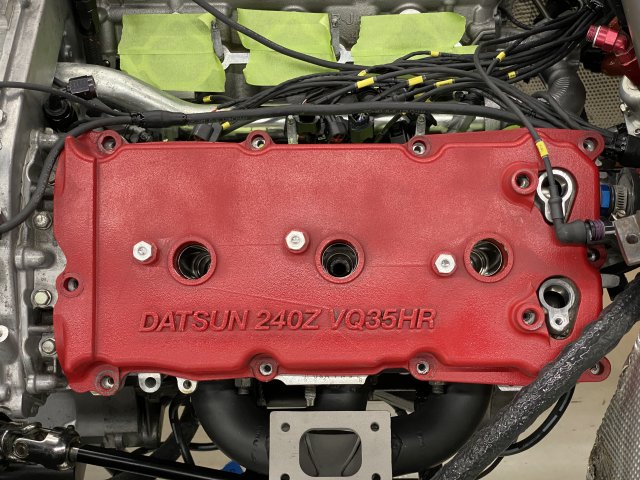

Crunch time! Still planning to test/tune in mid September and drive it to Nismo Fiesta in October. Shift actuator installed the transmission. Driveshaft arrived. Fixing leak on cam covers and while they are off we'll repaint them with a nice speckle red. I always loved the way Ferrari intakes looked with that texture. Lastly I'm converting the 3D printed canards into a mold to make carbon fiber parts. -

Progress on my insane VQ35HR 240Z project

markrolston@mac.com replied to markrolston@mac.com's topic in Nissan V6 Forum

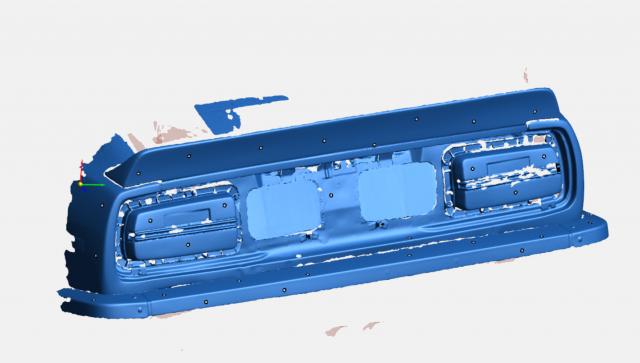

it’s a Peel 3D light scanner. Not as accurate a laser but ok for car scale stuff. -

Progress on my insane VQ35HR 240Z project

markrolston@mac.com replied to markrolston@mac.com's topic in Nissan V6 Forum

headed towards finish. I think I can get it back on the track end of august. That means I can test at Harris Hill in September and get some track events in with rest of 2020. And there's Nismo Fiesta in early October. Pics here show finished canard 3D prints. I'll use those as molds to make carbon fiber parts. Also pic of air tank in back for the paddle shifters (pneumatic). Lastly, buttoning up some rewiring. -

Progress on my insane VQ35HR 240Z project

markrolston@mac.com replied to markrolston@mac.com's topic in Nissan V6 Forum

not the actor. a different Mark Rolston. -

Progress on my insane VQ35HR 240Z project

markrolston@mac.com replied to markrolston@mac.com's topic in Nissan V6 Forum

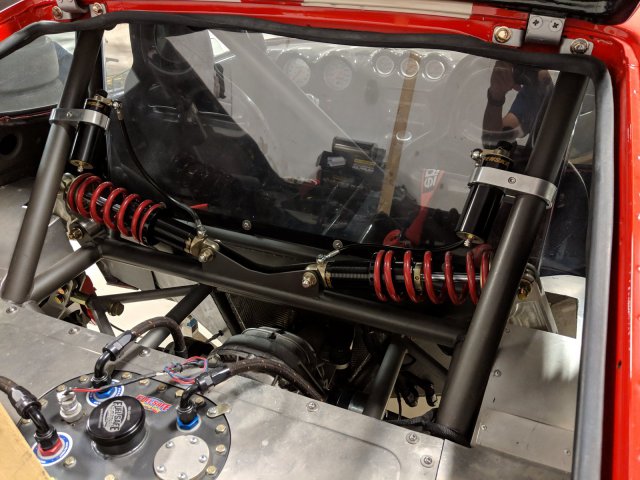

here's a shot of the holes in the back panel and a pic of the hatch area that shows you how open the rear is to the ground. The rear suspension packaging is open. So the idea is to flow air past the diff up over the fuel cell and out the holes. -

Progress on my insane VQ35HR 240Z project

markrolston@mac.com replied to markrolston@mac.com's topic in Nissan V6 Forum

Good idea. I'll take a look. -

Progress on my insane VQ35HR 240Z project

markrolston@mac.com replied to markrolston@mac.com's topic in Nissan V6 Forum

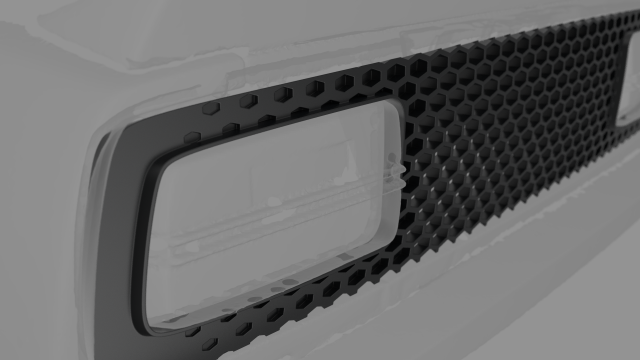

I have something interesting to share. Since waiting on some parts I have time to stare at the car and imagine other things that could be worked on. It's a blessing and a curse. I'm also a product designer by trade and 'making stuff' is a daily thing. On top of this, Andris' shop got a 3D scanner and that immediately starts to beg the question "what else can I scan?". So, we scanned the front to make the canards. That was cool. And just lately we've scanned the rear of the car to create a custom back panel. I love the stock look of the back panel but because the back suspension area is open, I want to move air from under the car to out the back panel. That should break up the stagnant air just below the wing and above the diffuser.... At least it can't hurt... I think. So I decided to design (with help from Hayes Urban, a fantastic Industrial Designer) a mesh panel that would hide these holes. It's done now and we'll do a test print soon. I'm concerned to not jump the shark on custom bits here. The car is already a departure from stock but overall it has to retain that 'first read' of the original design. We'll see when it's on the car. -

Progress on my insane VQ35HR 240Z project

markrolston@mac.com replied to markrolston@mac.com's topic in Nissan V6 Forum

I'm using a Motec M130. The transmission is an HGT 5 speed sequential. It's shifted through an air powered actuator that is trigged via the paddles. What's nice is we can program the ECU to handle the drop throttle and rev match on shifting. We're also wiring up wheel speed sensors since the ECU can handle traction control. -

Progress on my insane VQ35HR 240Z project

markrolston@mac.com replied to markrolston@mac.com's topic in Nissan V6 Forum

I'm using a coiled up cable that can wrap around the column without drooping too much. -

Progress on my insane VQ35HR 240Z project

markrolston@mac.com replied to markrolston@mac.com's topic in Nissan V6 Forum

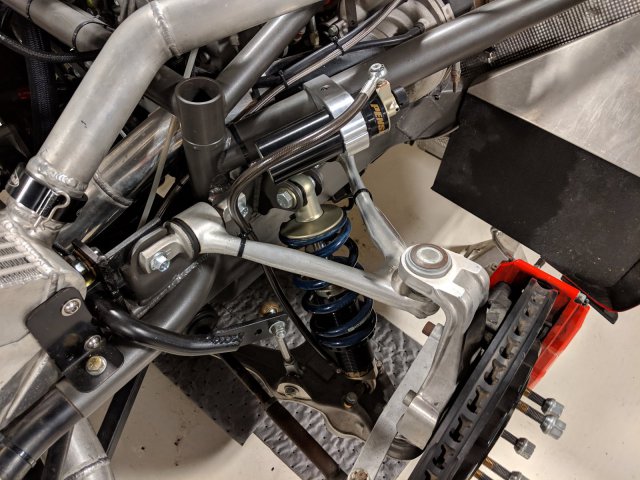

Since the engine was out for wiring (new ECU) and the transmission, we sent some piping to get ceramic coating. Before it was starting to look a bit rusty. The paddles are attached to the steering wheel. But they are pretty small. So I'm going to cut some larger paddles out of rigid carbon fiber sheets (2mil) and attach those. Also took a few pics of the engine and suspension just for fun. -

Progress on my insane VQ35HR 240Z project

markrolston@mac.com replied to markrolston@mac.com's topic in Nissan V6 Forum

Still making progress... just slow. The Sequential Transmission is in place. waiting on a driveshaft. look how much space it frees up! I wish I had done this back when we made the tunnel. It could have been so much slimmer. I also did a scan of the back panel. I'm going to make a mesh screen that's custom designed around the lights so the back can vent. It's a particular oddity of the way I built the car. Since behind the driver's seat is a plexiglass panel, the back is open to the ground. The opening in the back panel will allow air to flow up from under the car and over the diff and ideally break up some of the cowl effect of air at the back. At least that's what I hope. -

Progress on my insane VQ35HR 240Z project

markrolston@mac.com replied to markrolston@mac.com's topic in Nissan V6 Forum

Thanks. a Motec M150 -

Progress on my insane VQ35HR 240Z project

markrolston@mac.com replied to markrolston@mac.com's topic in Nissan V6 Forum

hi again everyone. I took the car to COTA for a March 15 track day and had intended to get some much needed video of the car on the track. Unfortunately, while I had a good amount of track time at the smaller Harris Hill track, nothing is like COTA. The new brakes worked great. The car is fast. However, the tune ran lean and nearly cooked the back panel of the car. The heat meant the fuel started cutting out and so I took it home. COTA tests everything about a car. So for the last few months the car is back apart for a few fixes. But one thing leads to another. Tune problems means a new ECU. I had been using the factory ECU and it was always going to be a problem. Yet it was a surprise to see it fail so soon. So a new ECU means new wiring. Out goes the engine. and hey while we're at it let's do a few other things. Andris's shop got a new 3D scanner so we scanned the front-end and we designed a form-fit fit set of canards. I'll 3D print the design and then use that as a mold for a carbon part. I had been trying to mold them with foam but they never quite fit right and looked lumpy. Lastly, in the middle of last year I ordered a sequential gearbox. Some things take forever to build. It finally arrived 2 weeks ago. So here we go. We'll get it back on the track by July and hopefully be able to shoot video then...and just drive the thing for a while. -

Progress on my insane VQ35HR 240Z project

markrolston@mac.com replied to markrolston@mac.com's topic in Nissan V6 Forum

front Wilwoods have been replaced with Stoptechs. It feels better already. I'll find out for real at COTA next weekend. Working on a set of canards to try and balance front-to-back. Otherwise I think this thing is finally ready to go beat up on the track. -

Progress on my insane VQ35HR 240Z project

markrolston@mac.com replied to markrolston@mac.com's topic in Nissan V6 Forum

btw- useful info for some. we've been chasing down a soft pedal feel with the brakes. They work but given the disc size (14") they should work a lot better. It turns out these wilwood calipers actually flex under braking so they apparently give up some of the critical braking pressure. That is super lame for what should be solid equipment from them. I'm now looking for another caliper that fits and is built better. -

Progress on my insane VQ35HR 240Z project

markrolston@mac.com replied to markrolston@mac.com's topic in Nissan V6 Forum

The car is essentially finished (lol, really when is it ever really finished?) and ready to race this fall and spring. I still haven't anodized the wing mounts. I'll find some time in the winter to do it. It's been 11 years building this (slowly) so it's time to drive it. I do plan on doing some photography and video asap to get ahead of eventual track wear and tear. -

Progress on my insane VQ35HR 240Z project

markrolston@mac.com replied to markrolston@mac.com's topic in Nissan V6 Forum

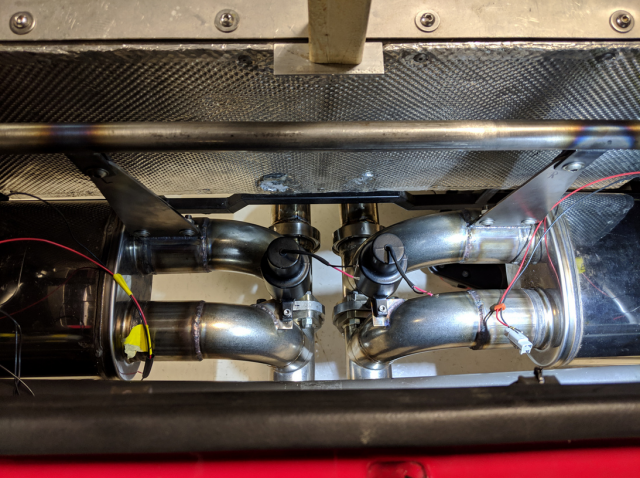

yes– It's a straight exhaust path without obstruction with the valves open. When closed the air is routed through the mufflers. -

Progress on my insane VQ35HR 240Z project

markrolston@mac.com replied to markrolston@mac.com's topic in Nissan V6 Forum

I'm just finishing replacing the mufflers as well. The original ones were too heavy and didn't do much sound attenuation. These sound much quieter when the valve is shut. That whole area in the back (between the fuel cell and tail lights) will get insulated to keep wiring and the fuel cell cool. I did a drawing where the back panel of the car is a mesh steel instead of the carbon panel for cooling. The lights and license plate remain as is over the mesh. It might be really cool looking and definitely useful to vent hot air from the diff and exhaust. Right now we're hunting down an oddity about the brakes. The rotors are huge (14") but the car has never had enough bite. They should be a lot better given the hardware. So we're experimenting with pads and talking with WIlwood about the Master Cylinder size versus the calipers to make sure it's set up right. The wing is down and it's right now just polished aluminum. I'll drive it like that for a bit to decide whether or not to paint or anodize it black. -

Progress on my insane VQ35HR 240Z project

markrolston@mac.com replied to markrolston@mac.com's topic in Nissan V6 Forum

small update. cutting down the wing mounting to a minimal form. I need to choose whether to leave it bare aluminum or paint it black. Any opinions? -

Progress on my insane VQ35HR 240Z project

markrolston@mac.com replied to markrolston@mac.com's topic in Nissan V6 Forum

this forum has really slowed down but I thought I'd make a brief update since it's been a while. I've been driving the car, slowly tuning the setup. You can imagine that a completely custom chassis is going to have it's own pros and cons to discover and tune. Right now just finishing up installing a new set of springs and 2-way adjustable shocks. We are adding some rock shielding to the engine back- the open wheel wells are cool looking but invite all kinds of rocks into the engine bay. Also working on adding a wing to the rear for better aero. -

Progress on my insane VQ35HR 240Z project

markrolston@mac.com replied to markrolston@mac.com's topic in Nissan V6 Forum

I'm still working on that question. I spent the last few weeks tamping down a long list of NHV issues- so many panels that were rattling. It meant I haven't driven it enough. But what driving I've done is encouraging. It's frighteningly fast, so much so that I need to put in traction control asap or all that power will be a waste. There's a funny oscillation effect that happens with this P/W ratio- if the car hits a bump, your foot can tip into the throttle a bit, given the throttle responsiveness, the car takes off, so you back off the throttle, and the car slows, causing your foot to tip into the throttle again. back and forth. crazy. I need to create more of a ramping to the throttle input since it's an electronic map. That will dampen the sensitivity at mid-throttle. I've experienced the same with a FF Cobra with a Coyote in it. Afa handling, the springs are too soft so those need to be replaced. Otherwise it feels balanced and controllable. I've yet to see how it handles a hard day at the track. -

Progress on my insane VQ35HR 240Z project

markrolston@mac.com replied to markrolston@mac.com's topic in Nissan V6 Forum

yes. you got it right. adjustability. and behavior under compression.

.png.f91242f58d13fe1f9acfcc05f30ec13d.png)

.png.8e2778b6f12b66c0755b675e42f64d3d.png)