-

Posts

37 -

Joined

-

Last visited

Content Type

Profiles

Forums

Blogs

Events

Gallery

Downloads

Store

Everything posted by Datsun Deron

-

Tuning turbo and flat top pistons for 10 psi results

Datsun Deron replied to Datsun Deron's topic in Nissan L6 Forum

I haven't dyno'd my car but in my opinion 250 to 300 hp should be very attainable. I'd say anything more would be pushing it and need the addition of meth injection. If you havent purchased a turbo already I suggest going right to the t3/t4 turbo right away, I wish I would have... If you have it built I'd say run the setup and see what happens (but then again im cheap). The reason I went with flat tops and p90 was because I couldn't get anymore power out of my f54 (flat tops) and n47 head combo. I didn't want to pay another $1000 to rebuild a bottom end again with only 15,000 miles on it. I've been very pleased with the setup I've got, great power for daily driving. -

Tuning turbo and flat top pistons for 10 psi results

Datsun Deron replied to Datsun Deron's topic in Nissan L6 Forum

arrang - I am running a 180 degree thermostat at the moment, good to know about the 160 degree thermostat. I just picked up a 3 row aluminum radiator a couple weeks ago but haven't installed it yet. It's on my todo list. Excellent suggestions. I'll add a lower thermostat to my shopping list. six shooter - The sensor is the open GM sensor pyro - thanks , Im hoping next year for some meth injection maybe. What are your thoughts on a 90 PSI pump? Or do I have to get the expensive 200 psi ones? Ryaapp2 - great read thanks for all the info. -

Tuning turbo and flat top pistons for 10 psi results

Datsun Deron replied to Datsun Deron's topic in Nissan L6 Forum

@ letitsnow - Thanks for the info thats very interesting and a relief. I'd be curious to see now what happens on a 1st to 4th run. @ dexter72 - Good to know I will install an NA cam as soon as I can. I can really feel the power start to drop off around the 5000-5500 mark so that should help. I'll get to a larger turbo one of these days . @ six_ shooter - I'm am using the typical GM sensor. Great info on your setup and regarding not running an intercooler. 180 and 190 is getting up there wow. -

Tuning turbo and flat top pistons for 10 psi results

Datsun Deron replied to Datsun Deron's topic in Nissan L6 Forum

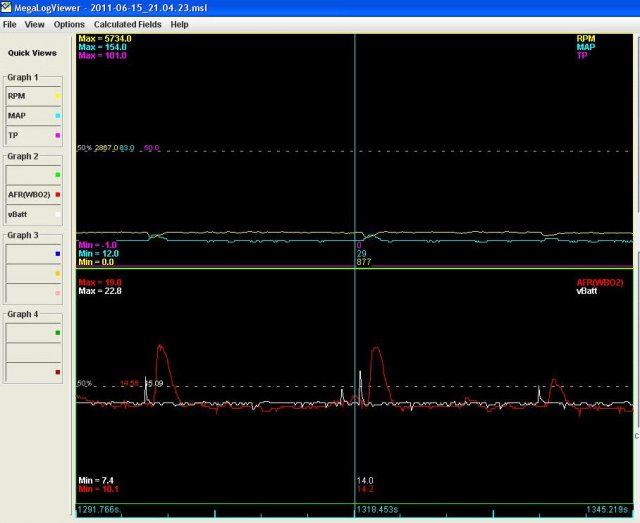

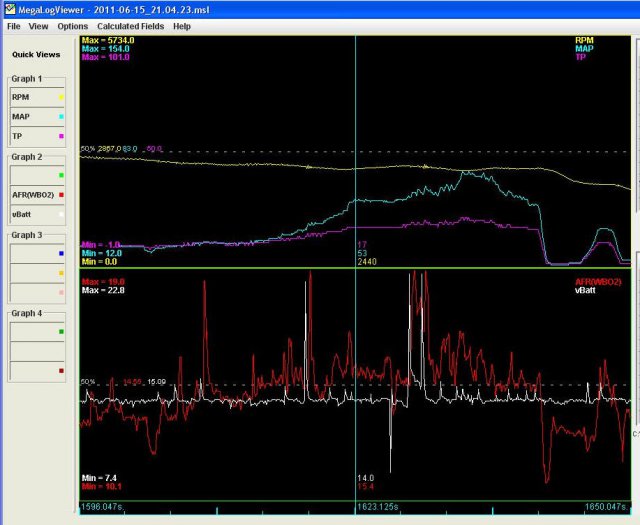

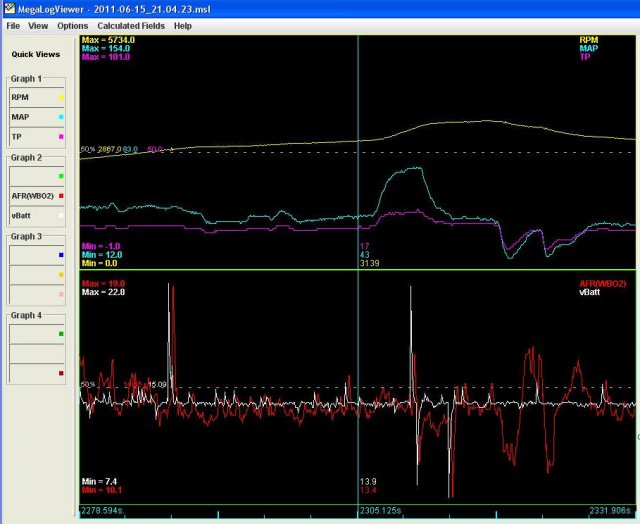

Well I managed to get out and do some data logging yesterday morning and had some interesting results. I'll have to retract my previous statement about this being an FYI post as I've now got technical questions... I did a 3rd and 4th gear pull to around the 5300-5500 mark. -The lowest IAT that MS saw during the drive was 58 which is consistent with the weather network. -At the beginning of the pull @1800 rpm my IAT's were 64.5 (first screen shot) -At the end of the 3rd gear pull my IATS were at 87 degrees (second screen shot) -From here on out the IATS just keep climbing and climbing -At the end of my 4th gear pull my IATS were at 102 (last screen shot) -I wasn't able to get into 5th since the speeds were getting up there. I was very surprised to see the IAT's continue to climb until I let off the throttle. In my mind I thought it would level off somewhere but there was no sign of that. I'm just wondering if the readings from this sensor are actually accurate. The sensor has a potential of getting heat soaked from external sources, radiator etc. That being said I can't see it getting heat soaked that fast when the car is moving I've just seen heat soaking at idle. My turbo has a heat blanket and my manifold is wrapped as well. The only potential candidate I could see would be the radiator. Also when I let off the throttle between gear changes the IAT temps did level off. So that must be an indication that it is accurate? Have others seen similar results where the IATs continue to climb on runs with multiple gear changes? As far as I can tell there are two major issues that need to be addressed. The air filter is pulling in hot air behind the radiator. (im not running a shroud anymore like the picture below since I'm running a pusher style fan now). And the poor placement of the intercooler with no ducting. I also need to change the bins in my timing and VE table as im getting into the 180s for MAP at times. The picture below shows where my IAT sensor is (it's on the bottom of the pipe) right before the throttle body. It looks like I've got some changes to make and more data logging to do. -

Tuning turbo and flat top pistons for 10 psi results

Datsun Deron replied to Datsun Deron's topic in Nissan L6 Forum

@ roger280zx - My apologies if you or anyone thought this was a thread about problems with my tuning or timing, that was not my intention. I made this post entirely just for the record incase anyone else was dreaming of running flat tops and a turbo, perhaps I wasn't clear. From what I've seen there isn't a whole lot of information out there regarding this setup so I thought I'd add my experiences. Most forum threads say to avoid this configuration all together and I'd like to prove that it can be done with decent results. Also with what I've read regarding my combo these results are fairly typical (low boost and retarded timing) so I really wasn't surprised with my findings. That being said I absolutely appreciate everyone's input and will definitely make use of the suggestions that were said. I agree if I can squeeze some more timing out of the thing I'll have even more fun. With the suggestions you've made regarding the intercooler location etc it could save me the hassle and cost of buying a meth kit in the future. @ letitsnow - I'll try to do some logging next time I'm out and let you know the outcome. I'll see if I can take off a little early for work tomorrow . -

Tuning turbo and flat top pistons for 10 psi results

Datsun Deron replied to Datsun Deron's topic in Nissan L6 Forum

@ arrang - Thats a great point, I'm running the stock 280zx turbo camshaft I can't confirm the stamp on it. I've got quite a few spare non turbo cam's laying around. I'll take a look to see if I can find an A cam. I do have an aggressive non turbo reground cam but I dont think that will help me much since the turbo is sized so small. @ letitsnow - Good to know about the other plugs, next time im due for a replacement I'll be sure to look into those. The car feels great, pulls very nicely with the current setup. Plenty of power through the full RPM range. Unfortunately I've never been in a low CR 280zx yet to compare the difference. @ roger280zx - I'm thinking I'll try to calculate the intercooler efficiency with the setup as is. Then later I'll add some ducting and compare the differences. I don't think I'll change the angle of the intercooler this summer, if I do it might be more of a fall/winter project. (summer is a busy time for me). The current setup in the car feels great so I'm not in too much of a panic to change anything. @ dexter - I'll also close the gap to 25 and see how that helps. Thanks again all for the input, I'll try to provide some updates to this thread when I can. -

Tuning turbo and flat top pistons for 10 psi results

Datsun Deron replied to Datsun Deron's topic in Nissan L6 Forum

@ Gollum - You didn't come across rude at all. I'd be very curious to see what would happen with 110 octane as well. @ Dexter - Thanks for the heads up on the lower bins. I noticed the stock turbo guys were running in the 40's and made it a little conservative just incase. I'll be sure to adjust those next time im tuning. As for weather here we do get some pretty hot days through July to September ranging anywhere from 86 to 104 degrees (when we get the real heat waves). I haven't tried closing the spark plug gaps yet, and I am currently running NGK plugs (two steps colder). We had some detonation issues when I first did the swap. Would two steps colder be too cold? I could possibly run 1-2 degrees more timing but pulled it back for the added insurance. @ roger280zx - I had originally tilted the intercooler so more of it was being hit by the opening in the air dam. Ideally though straight up and down, further back with some ducting would be the ideal way to go. I've actually been very curious to calculate the efficiency of the intercooler with the way its currently laid out. I should get on that. I might also look at ducting in the near future. @ pyro - Thanks for confirming the 8.8:1. My very scientific calculations came from information from this forum or zar.com. -

Tuning turbo and flat top pistons for 10 psi results

Datsun Deron replied to Datsun Deron's topic in Nissan L6 Forum

@ BluDestiny - The engine pulls great with flat tops and turbo. I've been really happy with my setup. I originally did a non turbo build, then converted to MS, then wanted to turbo but was too cheap to pay and have another bottom end rebuilt. I figured I'd run her and see what happens, so far so good. If I did another turbo L28 build I'd still likely shoot for either a stock compression ratio or closer to 8:1 maybe. Good luck with the build! If you need to steal any timing or fuel maps just let me know and I can send it your way. @ letitsnow - That sounds about right from what I saw on the tuning/map sharing post on hybridz. The stock turbo motor is a completely different animal from this configuration. -

Tuning turbo and flat top pistons for 10 psi results

Datsun Deron replied to Datsun Deron's topic in Nissan L6 Forum

Randy - my air fuel ratios are 11.5-11.7. The injectors have not been flow tested. Gollum - ill check the plugs when I get a chance Letitsnow - I could hear the ping by ear driving the car. Then we pulled the timing back 2-3 degrees for a safety margin I'm honestly surprised to see much concern regarding my results. From what I've read regarding my configuration I thought my results are pretty standard. Keep in mind I'm running non turbo flat tops and a p90 head. This setup brings my compression ratio way up around the 9:1 mark instead of the low factory compression at 7.4:1. Should I be able to pull more timing? I thought most people shy'd away from this setup for that very problem. -

Tuning turbo and flat top pistons for 10 psi results

Datsun Deron replied to Datsun Deron's topic in Nissan L6 Forum

Sorry I should have mentioned in the post incase it got missed in my signature. I'm currently running a Spearco intercooler with MS-2 and EDIS Ignition. -

Hi all, I thought I'd post my findings on tuning my car for the archives. I've been running flat top pistons, a stock turbo from an 84 300zx (same size as a 280zx turbo), 7 psi and a P90 head for a couple years now and decided it was time to start turning up the boost. I purchased a manual boost controller from ebay and installed it last weekend. I think it cost around $20 dollars. The hardest part of the tuning was getting the boost set properly on the manual boost controller. Mine was pretty sensitive. 1/2 a turn made a difference of 3-4 psi. For the first few full turns until you find the sweet spot it made no difference at all. After some very brief 15 PSI spikes I was able to get the thing set to 10 PSI (where i wanted it). Once we started tuning with higher boost the flat top and p90 combo becomes a detonation machine. The most timing I could run at 10 PSI (165 KPA) was 14 degrees. The one other restriction that might affect my tuning is the fact that my air filter is located behind my radiator. I'm hoping to relocate this in the near future and will post again later if this allows me to advance the timing any further. As for a power difference it was hard to tell on the butt dyno since we were tuning while driving uphill (where I drive its primarily flat) but I do believe that the car is faster despite having to pull so much timing out. I think I will likely leave the car at 10 psi for now until I can get my hands on a meth injection kit. But then again that little knob is just waiting to be turned . Edit - I should note I'm also running 94 octane fuel Here's my ignition table to date:

-

Well I wrapped my manifold last night and so far so good. I actually wrapped the manifold in the car with some old 2 inch header wrap that my father had kicking around. Unfortunately I don't know the length but I used the entire roll. It was a bit of a pain to get installed and took about 2 hours. It would have been a breeze had the manifold not been in the car...The header wrap roll was already cut into two very long pieces so that helped make it a little easier to fish in there. I would just wrap the pipe and fish the rest of the wrap out the other side then repeat until completely done. I was able to wrap cylinders 1 and 2 in one piece, 3,4 and 5 in one piece and 6 in one piece. I wore gloves, long sleeves, a dust mask and eye protection. Even with the long sleeves I still managed to get some of the fibers on my arm. I took a shower and tried to wash my arms best I could but it was still itchy going to bed. My advice would be to wear long sleeves and tape your sleeves to the gloves. I also had some scrap 1 inch wrap sitting around and I used that for the downpipe. As for the turbo blanket I purchased that off ebay from a seller called "speedmotoring" for $43.95. It was incredibly easy to install. I had to add a little slit for the wastegate arm but that was all. Its held on with two metal springs. For the metal zip ties those were also purchased off ebay from a seller called "l88_tools" it was 9.99 for 12 ties and I purchased two packs just incase. I didn't want to pay the local price which was over triple the cost. I ended up using 4 ties for the down pipe and around 10 for the manifold. For cylinders 3 and 4 I had to connect two of them together to make it fit. After the install the underhood temps are MUCH cooler, I also found that the turbo spools up sooner and faster. I wish I had done some datalogging of the before and after but unfortunately don't have much for before datalogging since I've switched computers. Here are some pictures:

-

Rain would be free water injection

-

I purchased a CX Racing intercooler pipe kit from ebay for mine from a seller called "Just-Intercoolers" he had an auction where you could pick 8 or so pipes for a set price (whatever bends you wanted). Once I got them it took a few hours of cutting and aligning but im happy with the result. The only downside is I'd prefer my air filter to be in front of the radiator or pull in cooler air somehow. Since all the pipes are on one side of the car it makes it tough to fit another one through there. I might look at building a box around the air filter to pull in air from under the car. My intercooler is a spearco same side unit as well.

-

F54 Block Flat top Piston work with P90?

Datsun Deron replied to MadMaxDallas's topic in Nissan L6 Forum

Thanks for the info Gollum you make some very good points, especially regarding timing. I suppose comparing flat tops to dished pistons is indeed apples and oranges. The million dollar question for me is if I keep turning the boost up and retarding the timing at what point does it become worthless. The only real solution is to spend some serious time and money playing on dyno to find the answer. As a side note I also ran an MN47 head with flat tops for a few years. The flat tops with p90 head and turbo has been far more fun . -

F54 Block Flat top Piston work with P90?

Datsun Deron replied to MadMaxDallas's topic in Nissan L6 Forum

I've been running flat tops with a p90 head for the last two years without any problems what so ever. I was too cheap to rebuild the bottom end so I just swapped the top end. Currently I'm running 7 lbs of boost using a stock 300zx turbo (same size as the factory 280zx turbo) with a Spearco intercooler. I'm also running Megasquirt II with EDIS. For timing I'm running 19 degrees at full throttle and the car pulls very nicely. I run the car slightly rich at full throttle 11.2:1 ish AFR just for the extra insurance. I also run 94 octane in the car. I tried running 21 or 22 degrees but I started getting some pinging. I'm hoping to turn up the boost to 10 psi later this summer and see what happens... My advice would be to go for it and run flat tops with the p90 head but get the THICKEST head gasket you can to bring the compression down. I really wish I would have done this. If you can I might also suggest getting a larger turbo charger then factory which should run more efficient at higher RPMs and might bring your intake temperatures down somewhat and give you more power. Another option if you want to run more boost would be meth injection as well but that could always be added later. Overall ive been very happy with my setup, the car has great power on and off boost. I hope that helps, if you have any other questions just let me know. -

Major voltage spikes and sags with Megasquirt II 3.0

Datsun Deron replied to Datsun Deron's topic in MegaSquirt

My apologies, I never got an email saying I got a reply. Looks like my notification settings were outa wack... Anyways yes the problem was solved!, I found this thread http://msextra.com/forums/viewtopic.php?f=101&t=28178&start=20 Long story short I did what the first post says (220nf cap on the H1 position) and problem solved. Car runs solid as a rock ever since last year. -

Major voltage spikes and sags with Megasquirt II 3.0

Datsun Deron replied to Datsun Deron's topic in MegaSquirt

Thanks tennesseejed, (I'm assuming the voltage regulator your talking about is in the alternator?) We were suspecting a bad diode in the alternator too however we still saw the same voltage spikes with the alternator completely disconnected from the battery. In the datalog the voltage ran consistently lower since it wasn't being charged off the alternator but we still saw some major sags and spikes and felt the car surge. -

Hi Guys, I posted at MSEFI about a week ago regarding this problem and haven't gotten anything back yet. Hopefully someone here might have a hunch as to whats going on. Heres the original post with the additional troubleshooting we tried. I'm having some major voltage spike and sag issues with MSII V3.0. I originally thought the issue was my tune until I started data logging. Upon closer inspection when the voltage spikes the car leans out immediately after, when the voltage sags the car goes rich. You feel the car shutter for a brief moment as well when this happens. This happens during all driving conditions as well as when im crusing at a steady rpm with constant light throttle. I was wondering if anyone has had any similar issues or if theres something else I can try for a fix then what I've tried below. For info on my car its a 1982 280zx Datsun and for Megasquirt im running MSII V3.0 with a relay board that a friend and I put together. also I'm running EDIS with a dodge caravan coil pack. The alternator is a 105 amp alt that was purchased online as well. (I think zman of washington?) I am also running version 2.889 of the firmware on Megasquirt. (we just upgraded from 2.6 last week to see if that helped) The battery has been mounted in the trunk of my car and I've got a thick (2-4 gauge) power wire running from the battery to the starter. The ground wire (2-4 gauge) for the battery is grounded to the trunk of the car. To try and remedy the problem of the voltage sags and spikes we re wired the relay board's power and ground wires with 12 gauge wire. The relay board now pulls power directly from the starter where the battery and alternator connect. The relay board also has one 12 gauge ground now that grounds on the starter where there is a thick (4-6 gauge) factory wire that grounds to the frame. The switched power (16-18 gauge) wire from the factory ecu is still in place. After re wiring the issue doesn't seem to have improved at all unfortunately. We then connected a wire directly from the alternator to the starter with an 80 amp fuse and bypassed the fusible link. This also unfortunately didn't seem to make a difference. After we did that we ran a power wire and ground all the way back to the battery in the trunk and still got the same voltage sags and spikes. Then the last thing we tried was pulling the fuse from the alternator to the starter all together and we still got voltage spikes and sags. So we're really not too sure what to try next. Here's whats floating around in my head for possible scenarios... Could something be acting up on my megasquirt or relay board that would be causing this? We double checked and made sure the power,ground and switched 12 connections are nice and tight on the relay board and that nothing is loose. If something on the board could be causing the issue where might I start looking? I have a large capacitor for a car stereo and was thinking of running that inline with the 12 volt wire to see if it'll smooth anything out. Could the EDIS coilpack be injecting some voltage into MS? I've included some screen shots of the voltage sags and spikes. You'll notice my AFR's follow the trend of the voltage spikes and sags when throttle is constant as is RPM. (im running an AEM wideband sensor as well). The pulse width not shown here echo's the AFR's and I can get screen shots of that if it helps at all. Thanks!

-

Im running the MSD 2225 fuel pump at the moment and it flows 225 l/h as well I believe. If you do go this route however be advised that the MSD fuel pumps are VERY noisy. I've heard the same complaint from many others as well. Here are my install pics if that helps at all: http://www.zcar.com/forums/888793/my-msd-2225-fuel-pump-install-pictures

-

I was able to build, install and have my car running on Megasquirt in about a month over the winter. Just do your home work and you'll be fine. I also used the relay board and it made wiring extremely easy. I started with fuel first and ran the factory distributor for the year, the following winter I switched the spark system to EDIS. I had that on the car for two years and then this winter I took the plunge and swapped my head for a P90 and a z31 turbocharger. Megasquirt has been the BEST thing that has happened to my car and has been an awesome experience to install. This year we will be fuel injecting my brothers 1952 chevy car he's restoring and my father is now wanting to do it on his 1969 Camaro when its ready to be road worthy again. So I would say do it because you won't regret it once its all said and done. I'd say its also nice (but not necessary) to learn how to tune Megasquirt on a non turbo car first, less chance of things going boom that way.

-

Hi all, Well now that my car is finally back on the road and turbo charged I can start putting some of my documentation on here. I just wanted to say thank you to everyone on this forum for contributing and helping out. With out you guys there's no way I would have been able to undertake such a project. I'll try to make this as detailed as I can: Materials used: 10 feet of straight 3 inch aluminized exhaust pipe (dynomax) $50 2 - 180 degree aluminized exhaust bends (dynomax) $30 + $30 = $60 6 Muffler flanges and 3 gaskets - $40 Flex pipe (installed later) - $30 I also used 4 hangers and an exhaust reducer for my muffler but I had these laying around the garage Total cost for the project $180 Time spent 10-12 hours Materials left over - approximately 5 feet of straight pipe thanks to the extra length on the bends. Here is what I started with: Tools used (and a welder of course forgot to snap a picture of it): How I went about it: I removed my old exhaust and using the yellow angle tool I measured the approximate angles and lengths that I'd need. Based on that I knew what I had to order for pipe. I didn't actually have the down pipe installed (as it was being built) when I began this project so instead of working from the turbo back I actually started in the trickiest part first. I started working from where the exhaust goes over the cross member. I don't really know what the correct method is but it worked quite well for me. I assembled and tacked my pipes together as I went and once the cross member bends were done I worked my way back towards the muffler. Once I was able to line up with the muffler I tacked it and assembled the rest of the exhaust towards the front of the car and got it close to where I thought it would be. After I got the down pipe installed I was then able to complete the rest of the exhaust. I left most of the exhaust tacked and then welded it all up after I was happy with the fitment on everything. I built the exhaust pipe in three parts so everything is removable. It was VERY tight to get a 3 inch flange through the crossmember but with a little grinding its able to go out and in as needed. After everything was done and the gaskets were installed the fitment through the cross member was a little tight for my liking. In order to have some give I added a flex pipe which you will see on the "installed" pictures. Here is what I ended up with before the install, I have labeled the lengths and angles as well. (NOTE: These are all approximate and are by no means exact). (I "stitched" the side angle and top angle photo's together in photoshop if you are wondering why they look a little "odd" as well) Here is the exhaust installed: All in all it wasn't too bad of an install. I'm not too happy about having to reduce from 3 inch to 2.5 for my muffler but I'm just too cheap to get rid of my Magnaflow muffler and buy a new one. I might change that sometime down the road though. Hope that helps!

-

Wheel Show! Post your pics of you wheels

Datsun Deron replied to k3werra's topic in Brakes, Wheels, Suspension and Chassis

I thought I should add to this post. Im running 17 inch eagle alloy rims with approximately two inch wheel adapters. -

EDIS 6 won't adjust timing with megasquirt II

Datsun Deron replied to Datsun Deron's topic in MegaSquirt

Well just wanted to give an update that it was infact the jumper. Lazyness on my part it appears from not reading ALL of the EDIS instructions... sorry about that... Thanks again Matt for pointing out the missing jumper . Once we changed it we were able to adjust everything perfectly not to mention it runs fantastic! Very responsive. -

EDIS 6 won't adjust timing with megasquirt II

Datsun Deron replied to Datsun Deron's topic in MegaSquirt

Hey Matt, Thank you very much for the confirmation I'm going to check that jumper tonight.