Neveragain55

Members-

Posts

105 -

Joined

-

Last visited

-

Days Won

1

Content Type

Profiles

Forums

Blogs

Events

Gallery

Downloads

Store

Everything posted by Neveragain55

-

Really great work guys, I'm super excited now about shaving, cutting, welding, and smoothing her down. I prefer the non webbed intakes myself but a lot of cats tell me that the webbed intakes help to avoid the whole "heat soak" issue. Thanks for all the great advice and pics guys.....

-

Thanks..... So I can eliminate all that stuff and she'll idle just fine and none of it will affect keeping heat in the car..... Excellent......

-

I realize that I’m about to ask some questions that have been discussed (ad-nauseam) but the specific questions I have havn’t been covered, and if they have I haven’t seen any discussion on them in these forums unless I overlooked them, If I did let me preface my inquiry with an apology. What I specifically want to know is if it’s ok to completely blend all of the offending raised sections & weld shut all offending orifices from the L28 turbo intake manifold and still be able to run heat & regulate the air properly. I don’t care about the emission stuff. If one completely gets rid of all offending holes and raised air regulator connections, how will the manifold regulate the incoming air? I’ve seen these “completely stripped†intakes on turbo models so obviously it can be done. I’m just concerned about the “air regulator†and keeping heat in the car. I’ve attached some pictures of my intake manifold after it was blasted, and I also attached a picture of a turbo intake set up without these objects being lopped off. I also just added pictures of my intake manifold with the areas I want to get rid of circled in red. Thoughts and guidance would be most appreciated. Intake Idea.bmp Intake Idea 2.bmp

-

Thanks guys, I'll smooth it out and keep on truckin.....

-

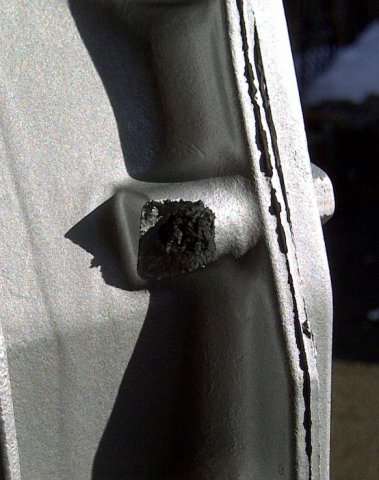

So I blasted my tranny this morning, and then I proceeded to tape it up & paint it. Just as I was feeling really proud of myself, I noticed a slight glitch, a section of material missing on the housing where a pan bolt threads in. I don’t think its cause for major alarm but I took some pictures and posted them for some of you experts to hopefully give me your opinion. What are your thought’s, am I worrying unnecessarily, and if it needs to be fixed, what’s the best way to go about it? As always, thanks in advance.....

-

Modifying a T3 actuator bracket

Neveragain55 replied to Neveragain55's topic in Turbo / Supercharger

Did the actuator bracket have the correct angle or did you have to position the actuator arm directly over the oil inlet of the center section? I guess you could do that, but I wanted to keep all of the original angles of the original set-up the same. I already had a Dremel, so all I had to do was attach one of those "cutting disc's" to it and cut through the tack welds to get the old actuator housing off, and then I smoothed everything down with a cylindrical sanding disc. Took me all of 30 minutes to do and cost me nothing. Good luck with your set-up………… -

Modifying a T3 actuator bracket

Neveragain55 replied to Neveragain55's topic in Turbo / Supercharger

Thanks, and will definitely do............ -

You guys have a lot of great knowledge and I never leave these forums without learning something new. This is the reason why I enjoy these forums so much. Trust me I realize the aggravation and grieve I'm setting myself up for by not simply sending the components out to be balanced just to be safe but it's sort of in my DNA to operate the way I do, and for whatever it's worth - the method to my madness has served me well these 30 years of restoring cars and bikes. Quick story to the point: 16 years ago I bought a 1979 Suzuki GS750E without hearing it run or so much as turn the engine over, but instinctively I knew she wasn't seized or locked up. I Completely tore down the bike (never opened the motor) put everything back together, and after spending roughly $2,000 dollars - 16 years later she's still running like a demon and has almost all the compression she had when she rolled of the line in 79. I sure hope my gut is as equally right about my turbo......

-

So I searched the internet hi & low and made many phone calls looking for the right bracket that would mount an internal wastegate actuator for my T3, but could'nt find the right bracket with the right angle for a new actuator. In the end I decided to just cut the actuator can off of the original bracket and use it instead of beating my head against an unmoving object. Once I get the new can in, I’ll make the measurements for the mounting bolts, drill the holes, and mount everything. I’ve attached pictures of the old actuator before and after the mod, including the new actuator I plan on purchasing for others going through this. Hopefully it will give some of you some ideas............ Ciao…….

-

I can't or won't argue sound logic or known equations & numbers because I'd lose that argument all day long and I know it. Sometimes in any rebuild of any component we all just have to trust our gut in addition to the experience we've all gained over the many years of turning wrenches, and my gut is telling me she'll be ok. I understand what you’re saying and respect the fact that you have much more knowledge in this area than I do. But in case things do go awry, I promise to report any and all anomalies so that others can benefit from my mistakes. Thanks for the reply Tony...........

-

Well my turbo is back together sans the wastegate actuator. I’m going to put a 10psi unit on and I’m going to modify the original bracket by taking off the tack welded can and drilling the holes for the mounting bolts of the new actuator. Why somebody didn’t make a bracket that angles correctly for the T3/T4 models is beyond me. There are several that will fit those particular turbo’s but none of them have the right angle in order for the oil inlet to be properly un-obstructed. I went back and forth and did a ton of research on the “balancing†thing and settled on trying a little experiment first. I fired up my air compressor, cranked the air pressure up well over 100psi, pointed my conned air nozzle at the hot end turbine and spun the hell out of her. She whipped around at lightning speed and didn’t so much as shake, vibrate, or anything. She was as steady as a rock, so needless to say I didn’t feel the need to send those components out to be balanced. Now before I get the avalanche of scolding for my back yard under the shade tree method with the airline. I can’t imagine a bench getting the turbine to spin much faster, and if it were out of balance I would have seen and/or felt it. I felt comfortable enough that I reassembled the whole thing and I’m positive she’ll perform just fine under power. If not – lesson learned and I'll have it professionally balanced. I also have to agree that $500.00 seems like a bit much to rebuild a turbo, especially given the prices of new and good used turbo’s on the market……..

-

I was thinking about powder coating them and I happen to know someone locally that could do it for me but I think they'll be fine with just painting the outer halves. The more I thought about it the more I realize that billseph is right. The insides of the pulleys are going to constantly be getting cleaned because of the belt. Your suggestion is a good one however if I were building a show car and I needed all the parts and surfaces to look sharp, and it's much appreciated. Thanks Dude.........

-

Thanks, Sound logic, so I'll only paint the outer sides and leave the insides alone, thanks.....

-

Please forgive this question but I have zero experience painting pulleys. I blasted all of the external parts of my engine and I plan on painting all of the parts before I put them back on. My question pertains to pulleys (specifically the inside “V†of the pulley where the belt resides) like the water pump pulley, power steering pulley, etc. etc. The question is: do I paint the inside of the pulley or leave it bare? My thought process is that if I leave the "V" section of the pulley unpainted rust will eventfully form and prematurely eat away at the metal. If I paint the inside of the pulley, the paint will surely come completely off after the first few hundred miles and I’ll be left with bare metal again anyway. If I paint or coat the inside of the pulley, which material and/or paint would stand up to the belt running around it. I know, I know, but when you’ve all stopped laughing, let me know what you think or which direction I should go. I have this aggravating way of over-thinking every little detail but it's just part of my OCD Thanks in advance gang…….

-

I found the actuator from this web site for $39.00 bucks: http://www00.mailcar.net/catalog/index.php?seller=mpgstore&main_page=product_info&mode=s&schm=1&cLink=c&products_id=380303320381&psemtrk=google&utm_campaign=EcommerceStoreMarketing&utm_source=GoogleBase&utm_medium=GoogleBase&utm_term=GoogleBase I found the bracket from this web site for $29.00 bucks: http://www.atpturbo.com/mm5/merchant.mvc?Screen=PROD&Store_Code=tp&Product_Code=ATP-WGT-011&Category_Code=WGT The actuator I found is also the same one on eBay, I attached some pictures.

-

Deaner, No worries on the double post (we’ve all done it) I’m definitely going with the high temp sealant. Permatex actually makes a whole range of high temp sealants that surpass the “Orange†high temp sealant. So I’m going to do a little research and try to get the sealant with the highest temp rating as these turbo’s get pretty hot. Thanks for your input, much appreciated…..

-

Deaner, I was actually thinking the same thing because I’ve searched the internet, turbo parts suppliers, & eBay high & low and I’m not seeing a gasket (made from any material) that will fit that 7 bolt configuration which seriously leads me to believe there never was one. And if there were gaskets used (back in 1982) there sure as heck aren’t any available now. I’ve mated them in a test fit and the surfaces mate up perfectly with no gaps so I think the high temp orange sealant is a viable option. The biggest take-away I’ve learned from all of this is how important it is to visibly look and check everything before it’s pulled apart. Something I already know, so shame on me. Thanks everybody……….

-

Thanks Dexter, That actually makes sense because I can't seem to find a gasket anywhere (internet or otherwise) that would fit between the two housings perfectly, and like I said in my original post, I couldn't remember seeing one when I ripped it all apart. When you say (You will need a gasket on the back of that wastegate flapper housing though) you’re talking about the four bolt pattern where the exhaust bolts on right? Serves me right for not paying closer attention…… Thanks for all the help gang...........

-

Kaito, It is an original T3 turbo that came with the car and I looked at the metal gasket on eBay from the link you sent me...... But there is a large area of material that would cover the actual internal wastegate if I used this gasket. Would that be correct? Wouldn't the wastegate be blocked if I used this gasket, or I am completely off here? If the one you sent is the one that should be used then I'll definitely get it. I just want to be sure. Thanks for your help.......

-

Ok Gang, All of the parts for my turbo rebuild have been procured and even painted with POR 20. I’m at the stage where everything is ready to be bolted back together but I have a dilemma. I don’t remember there being a metal gasket between the "7 bolt" turbo housing and the "7 bolt†internal wastegate exhaust section. I’ve looked all over the internet and all I see are “5 bolt†metal gaskets but not 7 bolt metal gaskets. Were their no gaskets that went between these two sections or am I just not looking in the right places? I’ve attached pictures so you all can see exactly which two parts I’m talking about including a picture of a 5 bolt gasket. As Always, Thanks…………

-

Appreciate the reply,s guys and the logic sounds solid.

-

So I’ve seen this topic beaten to death in many forums and I definitely don’t want to rekindle any former disagreements over the topics validity, but what are your collective thoughts on balancing the shaft & blades of a turbo once it’s been rebuilt? The populist seem to agree that if there are no discernable grooves, marks, or shaved areas on the nut or base of the blades – balancing is not needed because the components were all balanced from the factory. Apparently (from what I’ve read) the Garrett T3/T4 turbo’s came with balanced components from the factory. My particular turbo shows no signs of any metal being removed for the sake of balancing and the nut holding everything together is whole and unmolested. Add to which, every “Turbo Rebuild†video I’ve watched never ended with the turbo being balanced. (for whatever that’s worth) I realize all the turbo rebuild shops say that this is sacrilege and won’t hear of any turbo not being rebuilt without a proper balance job at the end, but I think it’s also safe to say that they’re all a little bias given the loss of revenue (for them) skipping this process. Please do share as I am now inches away from rebuilding my T3

-

Thanks, I was able to get everything I needed from the web site you provided and a couple of others.

-

So I saw all the Garrett T3 turbo wastegate actuators on eBay and I’ve been all over the various turbo rebuild web sites and I haven’t seen anything that resembles or comes close to the stock wastegate actuator that came off of my original turbo set up. I’ve combed over the posts in here and haven’t seen anything on where one would go to source one. Do any of you know where I could source an actuator that will bolt right onto the turbo or are there any other aftermarket ones that will work with the original set up? I've attached pictures of mine for reference. Thanks in advance gang……..

-

I saw a couple of YouTube clips on the Freeze-Off stuff and I’m sure in certain applications it works but I didn’t think of trying it only because I had the penetrant available. I’ve talked to a lot of people on this subject and I’ve seen many YouTube clips on various methods to get seized/frozen/rusted studs & bolts out, and my take away from all of it is that studs and bolts become stuck for dozens of different reasons. So there’s no magic bullet in getting any of them out, it’s all about trial & error until you mistakenly trip over that one method that’s going to work for your particular situation………….