Neveragain55

Members-

Posts

105 -

Joined

-

Last visited

-

Days Won

1

Content Type

Profiles

Forums

Blogs

Events

Gallery

Downloads

Store

Everything posted by Neveragain55

-

Liquid Penetrant is basically a petroleum based oil with a fluorescent dye that is used to check materials for cracks and discontinuities. It’s been around for dozens and dozens of years and there isn’t really anything out there better at getting into crevices, nooks, crannies, and tight fittings. See some attached literature on the stuff. http://valleyinspection.net/pen.html http://en.wikipedia.org/wiki/Dye_penetrant_inspection

-

Well I managed to get two more bolts out of the turbo housing tonight with little to no effort. I drenched all the seized bolts in Liquid Penetrant last night and when I made another attempt today to unscrew them, two of them came out like butter with no resistance what-so-ever. I guess it needed to just sit a little longer. All of the other seized bolts are flush with the housing so the only way to get them out is the drill & easy-out or the drill & tap method. The reason why penetrant works so well is it’s natural ability to seep deep into alloys through capillary action (sorry, I’m a certified level II PT inspector) Hopefully sitting another night will coax even more bolts to leave their rusty homes. Hope this follow up helps others going through this or a similar situation. Liquid Penetrant can be purchased on the internet in aerosol form very easily and you don’t need any special certifications to buy the stuff.

-

Thanks for the reply Billseph, Looks like you went through the exact same problem I’m going through now minus the crack in the housing. I definitely agree with your premise about welding a nut or bolt onto the broken bolt because it’s just going to re-shear again in a different spot. I also agree about staying away from the Chinese knock-offs on eBay even though I want to be careful not to offend anyone who chooses to go this route. I’m going to basically attempt a similar approach to what you did on one bolt to see if I have any success, if so I’ll attempt to get all the others out the same way. If I’m unsuccessful at getting any of them out – on to the machine shop it goes regardless of how much they charge me. One of these turbo’s complete and new would still cost waaaaaaay more than whatever a machine shop is going to charge me to get these seized bolts out. Thanks for the help……

-

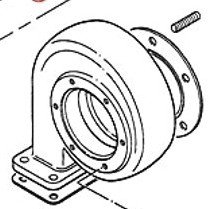

Hi Gang, So in the process of ripping my turbo apart, most of the bolts that screw into the housing (that bolts to the exhaust) snapped (see attached picture) My efforts to heat up the bolts failed, as well as my attempt at using PB-Blaster and liquid penetrant to loosen them up. I’m going to take it to a machine shop to see if they can salvage it by getting the bolts out (any good machine shop should be able to accomplish this) Just in case the housing can’t be saved, do any of you tech savvy folks know where I can source just that section of the turbo (without bolts seized in it) for less than a king’s ransom???? Thanks in advance…

-

Is this a Garrett Airesearch Turbo

Neveragain55 replied to Neveragain55's topic in Turbo / Supercharger

Thanks Tony............. I'm still learning all of this stuff so as small or trivial as you may think things like this is - they help me to better understand all things L28ET. -

Is this a Garrett Airesearch Turbo

Neveragain55 replied to Neveragain55's topic in Turbo / Supercharger

Thanks Tony...........that makes sense, but what was throwing me was the fact that I've seen a lot of these turbo's (on 280ZX cars) that actually say "Garrett" or "Garrett AiResearch" stamped on the scroll. -

Is this a Garrett Airesearch Turbo

Neveragain55 replied to Neveragain55's topic in Turbo / Supercharger

Scratch the previous post bro, Just found the info I needed. Turns out it "is" a Garrett TB03 turbo. Turns out that Nissan "did" in fact put their name on a lot of components manufactured by other folks. The reason why the guts in mine look completely different is because the guts were mostly gone. Thanks for the reply Cygnusx1 -

Is this a Garrett Airesearch Turbo

Neveragain55 replied to Neveragain55's topic in Turbo / Supercharger

That's just it........... There's no discernable markings anywhere on this thing that remotely resembles a typical T3. I’ve looked at typical T3 rebuild kits online and the parts in the kit, and the guts of this turbo are different. At the risk of sounding incredibly ignorant, I have no freaking idea what kind or type of turbo it is. -

Hi Gang, Finished ripping apart a 29 year old turbo tonight (happy happy joy joy) and once I cleaned it all off I was quite surprised with what I saw All the literature on my donor 1982 L28ET says that they came equipped with Garrett AiResearch TB03 turbo’s. I’m wondering if this is in fact a Garrett turbo with Nissan stampings on it. Before anybody asks, I believe this is the original turbo on the car by the similar amount of rust all around it and exhibited everywhere else in the vicinity. Is this a Garrett or some red-headed step child on my engine? I'm asking because I want to buy a rebuild kit for it and now that I see it says "Nissan Motor" on it I'm stumped as to where to get a rebuild kit (if one exists for this turbo) As always, thanks in advance.......

-

Thanks guy......... Will do

-

Thanks………….. I’m going to follow all of your advice to the letter. I’ve read many books on how important it is to make sure all the internals of the L28 engine are balanced before it’s re-assembled. Because of the lack of specialized tools and experience, I’m having the machine shop clean, mill and rebuild the head. I also believe that the hydraulic pivots can be re-used but I want new valves, valve guides, springs, and sintered inserts put into the head when it's rebuilt. I don’t need the port/polish deal because I’m not trying to squeeze major horsepower out of her. The lobes on the cam aren’t visibly worn, but there is some slight surface rust that I believe they’ll be able to clean off without taking too much material off. Spot on with all the tips on the bottom half. I’m going to instruct the machine shop to perform all the usual clean up treatments to the block as well as bead blast every inch of it. I plan on bringing the new pistons, rods, pins, and rings to the shop to be balanced & assembled. I also plan on having them clean and balance the crank along with the rods & pistons. Once all of this is done, I’ll take over and re-assemble the lower half myself after I paint the block, and paint the interior with the Glyptal paint. Still not sure which head gasket to use though because of all the different materials and suppliers to choose from? I’ve noticed that everybody seems to have a difference of opinion when it comes to this. Thanks for everything guys…………really

-

Thanks Clive, I may be asking you some questions regarding vendors and suppliers for parts as I get further along in this project. There are lots of folks out there selling engine rebuild kits and external parts but I’d like to get some references on the better vendors.

-

Hey Clive…………… This is the motor you just sold me bro…….. The pistons didn’t have any rust on them but the rods had some slight surface rust. I had to knock them out with a baby sledgehammer and I’m definitely not re-using any of those parts because they were destroyed in the process. I plan on buying a complete stock engine rebuild kit but I want to use the total seal Moly rings opposed to stock rings. The crank can definitely be cleaned up and re-used and I believe the block is going to survive also after a thorough cleaning. If for any reason the machine shop tells me that the block sustained too much damage from rust (which I doubt) then I’ll have to source another F54 turbo block. I plan on using Seifert Automotive Machine Shop in Torrington for the work based on all the praise from the folks in the CT Z-Car club. I’m going to let them rebuild the head and if they feel the hydraulic lifters can be re-used then so-be-it. If not I’ll have them converted to mechanical. Small world isn’t it??????

-

Thanks Dan, The rust seems mostly concentrated on some exterior surfaces, and a little in the areas on the bottom of the block where you would normally put the glyptal paint. I won't be getting the block into the machine shop for another month or so but once it's in & surveyed, if it's too far gone and I need another block I'll definitely contact you. I don't think it's that far gone and I'd really like to keep everything together as a whole unit but if I have to piece-meal it together, then so-be-it. I understand you may have sold your block by then, but I appreciate the reply just the same, and I will definitely be checking back with you if in fact I will be needing another block. Thanks......

-

Thanks Let-it-snow...... That's what I was pretty much concluded after all of my research. I did find a couple of Nissan dealerships on the web that claim to have new crankshafts, but for $800.00 dollars. Thanks Leon, If the machinist tells me the hydraulic lifters are gone or will be gone soon when he does the rebuild, I'll just convert to mechanical lifters via the inserts as shown by Big Phil on You-Tube.......... I'm sure you've all seen the video and/or know of the conversion or Big Phil. Thanks guys..........

-

Thanks for the advice Fric Frac, I apologize if I gave you guys the impression that the donor motor is a complete waste, it’s not that bad it’s just the crankshaft and cam that I’m unsure about. I looked at the crank even closer after making my post and I really think the machine shop can clean it up enough to be used again. The cam isn’t hard to source (if I have to replace it) and the reason why I'd really like to keep it stock is because of all the stern warnings all the other members have given about changing cams in the turbo engines. I still haven’t been told by anybody why mechanical lifters or (pivots) would be better than hydraulic other than the fact that Nissan doesn’t make them anymore if you need to replace them. For example: will the timing remain within tolerance any longer or will the engine be able to withstand increased horsepower upgrades better then hydraulic lifters? Or is there some other benefit that I’m unaware of? I think I should note here that none of these parts have been to the machine shop yet so all of them could be good, I’m just speculating in case I need to purchase new parts or go a different route all-together. BluDestiny, Are you also saying that Clevite sells stock crankshafts between $50.00 to $100.00 (if I needed one)? Thanks guys, all this really helps….

-

Ok Gang, Finished ripping apart the entire engine and I have a better idea of what I’m dealing with. This particular L28ET Turbo “donor†motor that’s going into my 77 sat in mud & muck for roughly ten years and she definitely shows it The head (P90a with hydraulic lifters) is in pretty good condition, except for some mild surface rust on the lobes of the cam. The machine shop I’ve chosen to rebuild the head should be able to source the parts including a stock Nissan “M†camshaft because it specializes in Z-Cars. The bottom half suffered severely from condensation so the internals of the block exhibits a good amount of rust. The pistons, rings, and rods are all completely gone and need to be replaced. The crank has some mild surface rust on the throws, webs, and counterweights but the journals look like they can be brought back to life with a good polishing. I was worried about extremely deep grooves in the cylider walls left by frozen rings stuck in one spot over nine years but their not that bad and should clean up nicely with just a simple honing. I’m hoping the machine shop can just sand and/or bead blast the surface rust, polish the journals, and salvage the crank and camshaft which leads me to my inquiry……… I’ve looked at a lot of the parts suppliers listed here in Hybrid and yes I’ve read a lot of engine rebuild post’s but I can’t seem to find a solid supplier for the OEM crank, cam or hydraulic lifters if in fact I have to replace them. I’m fully aware of all the aftermarket suppliers that exist but I’m really trying to keep all the internals stock because of the durability and reliability of these engines. If any of you have experienced some really good results using certain aftermarket suppliers over others or know where I can purchase OEM parts - I’d really appreciate it. The other dilemma I’m wrestling with is what to do about the hydraulic lifters, a lot of folks have written posts explaining that they are no longer available; others say they are but their expensive (which I really don’t care about) and yes I’ve seen all the videos on converting from hydraulic to mechanical. Are there any particular advantages over converting from hydraulic to mechanical? Or is it all the same under 300 horses which is where this engine is going to wind up when it’s all said and done. I’ve attached some pictures to give you all some idea of what I’m dealing with. Thanks gang….

-

No worries mate.......... And thanks for all your help and advice, it helped a lot.

-

I think you might be a little confused Fric Frac, I don’t have a S130 ZX, I have an older S30 Z that I’m putting a ZX Turbo motor into. Hence, I don’t have the ZX hood with the air duct; I have the older hood without the turbo air duct. To your point however, extra insulation would help with a stock set up.

-

Fric Frac, I agree with everything your saying. I spend a lot of time at Lime Rock Race Park in Connecticut in the summer’s and I’ve seen many race cars with heat resistant flexible tubing that runs from the front lower valance area, snaking its way up to various parts of the engine that the drivers are trying to keep cool. The NACA style duct on the Turbo ZX cars works brilliantly and I love the mod Nelsonian did to his hood, but I don’t have the resources or welding capabilities to pull that off so I’m going to try to route cool air to the turbo via the tubing. I’m also going to warp the turbo, exhaust manifold, and hope for the best. I’ve seen lots of intercooler set ups and honestly, some of them look a bit overblown and overdone. I think some guys do it more for the "wow" factor or the look than the functionality. HowlerMonkey, My donor engine came out of an 82 ZX Turbo car and the turbo itself is your basic garden variety stock unit without water coolant lines. I believe the balance I’m striking by wrapping the exhaust & turbo along with funneling cool air to the turbo via flexible tubing will keep things cool enough for the average Sunday driving I plan on doing with the car. My day's of romping on the gas, burning through tires, and coming home with 5 speeding tickets in one day are waaaaaaaay behind me (yes, 5 in one day)

-

260DET, Thanks for the info and the link, I looked through most of it and saw a picture of someone who simply installed what looked like a large diameter flexi-hose that is positioned in the lower valance area and snakes up to the turbo. I think this would be just as, if not more-so effective than cutting a hole in the roof and installing an air duct. You’re directly funneling cool air straight to the turbo by using this method………… Kinda reminds me of the direct funneling method GM used in their early firebirds to get more air to the air cleaner. (a poor man's forced air induction system) As far as the heat in the turbo impacting the oil once the car has been shut off – I don’t see any guaranteed way of assuring that all of the oil won’t be affected. I think there has to be a balance of keeping the turbo cool without causing the turbo to self implode by containing said heat. Nelsonian, Without sounding like a hypocrite, I love what you did with your hood and the vent looks great, but I think I’m going to try to funnel cool air to the turbo via some type of metal flexible hose. If there are too many other components blocking the way or it just doesn't work, I'll look into doing exactly what you did. It looks great. Thanks guys.........

-

Excellent reply and write up Tony D, very informative and filled with great ideas about how to best go about keeping things cool under the hood. I’m probably going to go the route you outlined, Jet-Hotting the exhaust manifold and have it properly, professionally wrapped in a good quality thermal material and I’ll wrap the section of the turbo that you described. MonkeyHowler makes a good point with keeping air flowing through and under the hood which is why Nissan went with the MSA style air dam on the hood of the turbo cars that funneled cool air to the turbo area. Question: A. Is there a similar style MSA air duct that can be put on the existing hood of a 1977 280Z? Thanks for all the input guys; it’s all very appreciated…..

-

I have nowhere near the knowledge you have in this field Nelsonian. The only experience I have regarding heat and turbo’s stems from my brief ownership of my first Z car which was an 83 280ZX Turbo when I lived in Florida some years ago. On the more excruciatingly hot days (which were many) the car would run poorly. The Z-Car gurus that I met down there all told me that turbo’s don’t like heat, and as such don’t perform very well unless the heat is contained some way. I’ve seen many posts here in Hybrid and other Z-Car forums where owners went with wrapping, jet coating, and other means of containing the heat that emits from the turbo. Connecticut doesn’t suffer from the same intense heat as Florida obviously and as I stated in my initial post, I don’t plan on increasing the horsepower much more than stock or modifying anything that would increase heat or pressure regarding the engine. At minimum, I plan on making some type of heat shield to protect the master bake cylinder and beefing up the intake manifold heat shield with an added layer of protection the way Fric Frac did. I’m a little undecided on wrapping the turbo in some type of thermal wrap but I’m at the infancy stages of this build so anything can change over time. I’d love to hear from other’s regarding the “too much heat containment might be a bad thing†argument that HowlerMonkey raised because I think it’s worth exploring, especially if certain components will prematurely wear out if they can’t release the heat they create. Everyone seems so intent on containing heat with little thought of what that containment might mean to the turbo over time.

-

Wow you guys are good, Thanks for the encouraging words Fric Frac, I'll definitely be posting my progress with this. Nelsonian, It looks like you've gone through this ritual as well with very good results, but let me as both you and Fric Frac something. What do you guys think about HowlerMonkeys comment about not allowing certain components to shed heat? Seems like one of those dammed if you do, damned if you don't scenarios to me. Howler Monkey, Are talking about not allowing the turbo itself to shed heat or other components? Seems like a good topic to explore.............. Thanks guys...............

-

Fric Frac, The work you did is absolutely beautiful and it looks very professional. I appreciate the advice and I’ve seen other posts in other forums where others have done something similar to what you did but your's looks far superior. I’ve seen a lot of post's with people saying that the biggest restriction is the restrictive size of the runners on the intake. Also, thanks for the info on "northern auto parts." I completely understand where you’re coming from regarding the research deal and you’re absolutely right. I made the mistake of not reading the forum rules regarding the word "best" and I apologized and still do apologize for that. The problem is that when any of us see a post asking for help on a particular subject, none of us have the ability to know if the person asking for help hasn’t scoured the web already. So to “assume†that they haven’t is in my humble opinion a bit short-sighted. I spend many hours on car forums and Google researching car related subjects, so I don’t think it’s fair for any of us to “assume†that people on forums haven’t taken the time to look or research things. I actually spent three weeks trying to find something on this subject before I wrote my post, and a lot of that time was spent in Hybrid Z. Cygnusx1, Thanks for your help, and thanks for being directly responsible in me getting this neat project. I’ll research the web site you gave me and keep you in the loop with my progress.