-

Posts

312 -

Joined

-

Last visited

-

Days Won

4

Content Type

Profiles

Forums

Blogs

Events

Gallery

Downloads

Store

Posts posted by jpndave

-

-

Have they got special pricing for BF?

-

You're headed in the right direction on the engine.

I have enjoyed following your progress on this and just picked up the Hot Rod issue to read that article. Have you been trying to make a trip to the Salt Flats? If you do, I'd be happy to help out any way I can. That's very drivable for me.

-

Nice! I am going to go the same route on the SubtleZ front/YZ rear and like the look you have here.

-

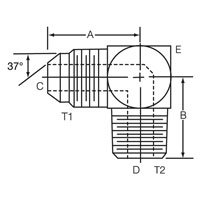

Something like this will be your tightest turn but would require removing what's there, I found 3/8, 1/2 & MIP to -10AN. I looked at a set of heads I have here and I'm sure you can remove the fittings without pulling the heads. The swivel fitting hose ends would be nicer if you can accommodate them and would eliminate two leak points. I have some of the 0-ringed swivel hose ends on my Jeep and they work really well.

What is in there now is likely one of these two varieties. Even if he used the o-ringed ends you can get fittings either to a 90 or as a 90 hose end. It depends on what is threaded into the head. I would pull those fittings or find out what the thread is and I think they could be sourced. I'm happy to look them up for you if you find out what you have.

These appear to be what you are asking for now. One of the photos is the tightest -10 female to -10 male as an adapter, the other a hose end. I don't know if that's close/tight enough to clear.

I found a lot of solutions in my books but most (and the tightest turns) would replace what's there either as a fitting or an end. Once we have an idea, I'll shoot you part numbers for whatever manufacturers make them. These photos are just a taste of what I found. If this isn't helpful, LMK.

-

I have a bunch of different AN catalogs I would be happy to look at. Usually it would be NPT to AN, male both sides. Does it have NPT, o-ring or ???? where he has put the fittings in that are there now? If you have room, you could remove those and replace with a 90 for a much closer fit.

-

Very nice!

-

Yes there are always compromises on any project. I'll just lay out the plan and try to make the best of it.

-

Future content

-

Future content

-

Future content

-

Future content - Interior

-

Future content - Body

-

Future content - Suspension

-

-

Transmission

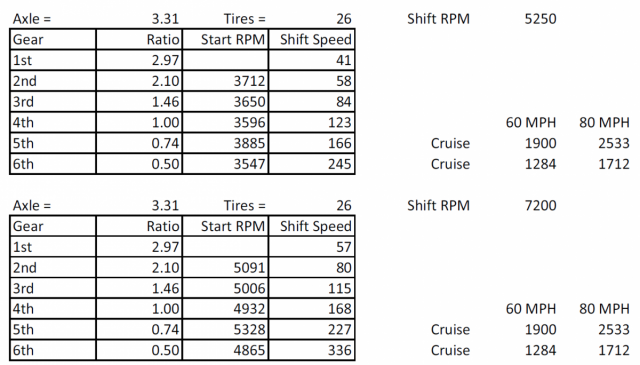

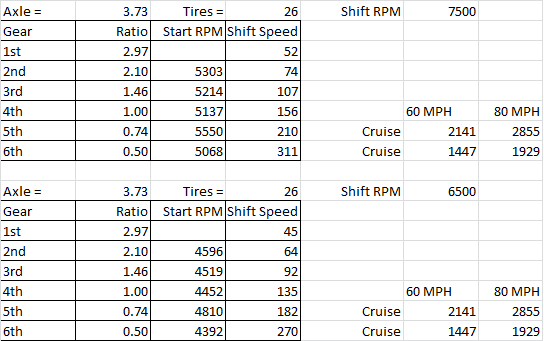

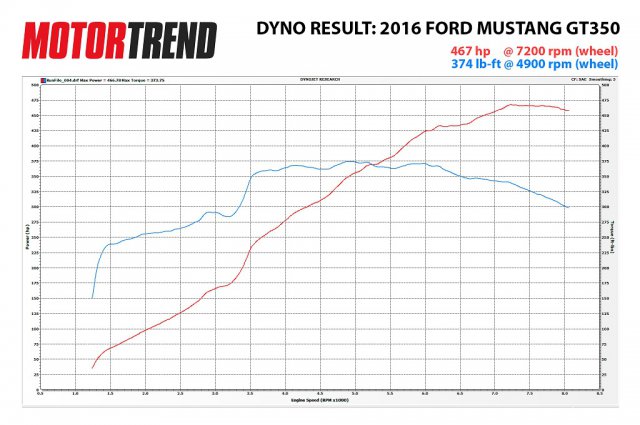

Tremec T56 Magnum wide ratio with Modular Bellhousing. I chose the wide version because all of the ratio spreads are very close to the same and all easily fit in the Voodoo power band which is very wide. The first chart shows short shifting at the crossover for torque/hp which keeps it in the big flat area of the torque curve you can see above and the 2nd shifting at peak HP. 1st gear at redline would be 65 mph with 3.31 gears, 57 mph with 3.73. REM (smoother shifting at high RPM) and Cryo (strength, supposed to make them good for 1,000+ HP) gears. Blueprint trans with bronze shift bushings throughout. The Magnum already has the better syncros and other parts. Lightweight smaller diameter clutch and flywheel for less rotational mass. The Voodoo uses a dual mass flywheel, I'm not sure how much I can mess with that and not cause balance issues. Stock aluminum bellhousing which I have along with the transmission. Scattershield will be integral 4130 in the tunnel when the floors are replaced. The added weight just as well increase body stiffness and it needs replacing anyway.

-

Engine Details

Voodoo Specs:

5.2L DOHC flat plane crank 4 valve heads with VVT 94mm bore x 93mm stroke

SAE Net Horsepower @ RPM 526 @ 7500

SAE Net Torque @ RPM 429 @ 4750

8250rpm redline

Update: These appear to respond REALLY well to long tube headers, open exhaust and a tune. Mustang boys are reporting over 500rwhp with only minor adjustments so far, projecting over 600+ at the flywheel fairly easily.

-

Future content - Summary

-

I decided to start a build thread for my project to document and share the process. I hope to get some valuable insite from forum members and maybe it will help someone else along the way. My car is a 1973 240Z I’ve owned since 1986, my high school car. I recently brought this old girl in to give her a full makeover. The plan is a Pro-Touring/G-machine type build. This will not be a stripped down race car. There are some excellent examples here and I really respect those builds but that is not what I am after. I want something with breath taking performance and extremely light weight. No, I won’t be using full carbon body work and titanium fasters. I’d love to but the project needs somewhat of a budget. I will be using top quality parts and materials. Fiberglass and 4130 aren’t out of the question.

Ok, for the driveline. I’ll get this out of the way and just say to all of those out there that yes, it would be easier to just do an LS. I intimately familiar with the engine, controls, all of it and had originally planned on using a really healthy LS3 based engine. That said, I have always loved the sound and visceral feel of and high revving engine that is in there. I have a 2.6L (280 block, 240 crank) with triple DCOE Webers, Tri-Y exhaust, ported, balanced, cammed, etc. engine. I would like to keep those two traits with 3 times the power in a lightweight excellent handling package. I know there are Nissan purists or other import options out there. I respect those builds too. However, Ford had to go and introduce a new flat plane crank engine “Voodoo” version of the Coyote. So, as much as I have never been a Ford guy, this new engine is just too good to pass on. So, Voodoo it is with a Tremec T56 Magnum 6 speed and a "new version" 8.8 in the rear. I will be doing full upgrades of chassis, suspension, paint, and the works. She needs to be comfortable so power windows and locks and a replacement HVAC including A/C that actually works. Weight will be minimized and safety addressed. Though not a track car, track days are in the vision and I will weigh out each option to best fit the intended vision.

I have the Tremec Magnum in the wide ratio version and Modular bellhousing. A Coyote may have to be used initially until the Voodoo is available at least semi reasonably priced. The Voodoo is based on a Coyote and with the right “buy” on a Coyote, I should be able to make money on the deal rather than lose on that. I would start with a truck Coyote, replace pistons, rods (already have a set of Manley “H” beams) and cams. The wiring and programming I would do myself on both. An aluminum 8.8 will be used with rear CV joints and shafts probably the Porsche 930/935 variety. Hubs will be aluminum or a lightweight unit bearing 5 lug and source will depend on the suspension choices.

Let me just get this out of the way this car is NOT the best starting point for a project. I will be doing complete floors, supports and front frame rails as well as a lot of bodywork. The car has been in at least 3 collisions and the salted roads and years have taken a huge toll. That said, she’s part of the family with a lot of memories attached and that means something to me. I have a rotisserie ready to assemble but will need to get everything at least straight and structurally sound enough to sit in the rotisserie before it goes on there. I will most likely be replacing the parts and tack welding in first then up to fully weld everything in. All the structure will be tied together front to back. I have debated buying the Bad Dog products or just fabricating things, maybe even out of 4130. I'm thinking of using 2x3 tubing up front then split for the supports along with thinner sheet for the floor and integrate that into the roll bar/cage/seat mounts as well as the transmission and differential mounts underneath. I'm thinking of integrating a scattershield into the tunnel rather than the bellhousing.

I will be doing flush glass (possibly MR10), shaved gutters and a lot of other “clean-up” details while I am in there. The bodywork will be a full set from John at ZTrix/Reaction Research consisting of Subtle Z fenders, air dam, hood, solid cowl, early style fiberglass bumpers, YZ rear fenders, doors, hatch, a 2-taillight (Ferrari tailights) rear cap and then a Motorsport Classic rear spoiler like the car has now but in fiberglass that may be built up a bit with a wickerbill. I have quite a few ideas for some clean venting and details formed into these parts. We’ll see where it goes. I’ll play with the aerodynamics as much as possible with the platform to get some solid downforce and clean things up where I can. Wheels and tires will be Michelin Pilot Super Sport 245/35R18 front and 295/35R18 rear on either a 5 or split 5 spoke wheel.

Brakes will be a Tilton/Wilwood style aluminum pedal setup with 3 remote reservoir master cylinders - no power assist. At the wheels will be 6 or 4 piston calipers and the biggest rotor on aluminum hats that I can make work. Possibly a Woodward aluminum column if I can make that do what I want. I will consider electric power steering but will replace the rack with a new aluminum version either way.

Suspension and hubs will be replaced with 5 lug aluminum or unit bearing versions. A double wishbone coilover setup just from the standpoint of I’m already re-doing all the structure anyway and it would be easier to adjust and get proper geometry. With the way all this is packaged I don’t know what the best way to set that part of it up will be yet.

Interior will have a new A/C unit, power windows and locks. Lizard skin soundproofing like I used on my last Jeep project. New gauges, probably Speed Hut, completely new wiring, console, etc. It will still be discernable as a 240Z but pretty much everything will be upgraded. I have 1-1/2” 0.095 wall 4130 for the roll bar/cage. I’m not sure yet how extensive that will get but it will tie everything in the back together and the forward part is not fully decided. I won’t do full door bars because the car will still be a driver but maybe a combination of the two. Sound system will be Polk MM6501 front, MM651 rear (neodymium magnet/composite cones - they weigh just over 1lb and have incredible sound) and a good head unit. Thinking the new Sony high power and do away with the amp and sub to save 20lbs. I have the 10” Alpine SWR-T10 Sub for my Jeep with the neodymium magnets but that with an amp still adds about 20lbs. On this car, that’s 4-5 horsepower, not sure it’s worth it, we’ll see. That engine should be music enough anyway.

This isn’t going to happen overnight but it will be done right. I have a climate conditioned, well-equipped shop/garage including MIG/TIG as well as Ocy/Acetylene, plasma cutter, sheet metal brake, tubing bender, etc. I can fab most stuff on site and have access to CNC machining as necessary. I’ve been at this stuff a long time. I appreciate feedback and suggestions but please don’t muddy up the thread with off topic or tactless comments.

I’m going to try and at least start this out in an orderly fashion. I’ll follow with posts detailing the systems of the car that I just wrote about. I don’t know how long the site will allow editing but I’ll keep these first posts up to date as long as I can.

Thanks for sharing the ride…

Dave

-

Nice Mike!

How are you going to plumb in those head drains? That looks like a really good idea!

How are you going to plumb in those head drains? That looks like a really good idea! -

Sweet! Let me know if you need a hand with the wiring or flash on that engine.

And, I would LOVE to stop by sometime I am that way and see your car! I'm working with John on a full set of 280YZ/SubtleZ fiberglass parts for my car now.

-

Can this still be added to, I am interested in two sets of gauges.

Thank!

-

Yep - Ford did in the new Mustang GT350. I've been seeing quite a few of them at the Dearborn Test Track and they sound pretty friggin' awesome.

http://articles.sae.org/13709/

It looks like there may be a VooDoo crate motor, but I'll bet it will be pricey.

Already planning one. I will start with a Coyote and then change to the Voodoo as soon as I can get my hands on one. Have the Ford Tremec Magnum and Bell for these (Modular pattern) engines. Coyote will be a tight fit between the towers, 1" on each side to spare. We'll see what other issues occur. I'm sure it will need a low profile oil pan amoung other things, probably front mount accessories. It should almost be a front mid-engine configuration. I hope it can be made to sound more european as I think they have Americanized it to keep traditional Mustang appeal, we'll see.

-

I have a 6.2L and 6L80E in my Jeep Wrangler you can see in my info. If you go that way I HIGHLY recommend getting a native paired engine/transmission. The communication is important for proper operation. Don't need the other modules if done right.I just have ECM & TCM. It is quite large in girth. A 6L90E is about 30mm longer than the 6L80E. If you're really serious about this I may be able to lift one up into my 240Z chassis as I am building a stroker 6.2/6.8 right now for the Jeep and the Trans is out. Don't expect double clutch manual type shifts from that unit. They're better than earlier autos to be sure and I LOVE it in the Jeep but no way is my 240Z getting an auto.

-

I am. Probably will do a Coyote now and then swap in the Voodoo when available. Changed my T56 magnum to the Ford version.

I think it will sound much better with the right exhaust. They appear to have "Americanized" the sound to not lose traditional mustang customers with the GT350. The GT350R, sans resonators sounds better. Aside from the exhaust, firing order and center crank pins are different But it still has the alternating bank flat plane.

I'm SO glad that I'm not the only dude who thought about this thread recently. The Ford flat plane crank is going to set the world on fire.... it's awesome.

So who's already planning a build with one?

Group Buy on SpeedHut Gauges

in Group Buys

Posted

Ok, PM'd two sets to you for prices, thanks!