-

Posts

239 -

Joined

-

Last visited

About itzgoten

- Birthday 05/06/1984

Contact Methods

-

AIM

itzg0ten

Profile Information

-

Gender

Male

-

Location

San Jose, CA

Recent Profile Visitors

6020 profile views

itzgoten's Achievements

Newbie (1/14)

11

Reputation

-

Arizona Z parking brake

itzgoten replied to m1noel's topic in Brakes, Wheels, Suspension and Chassis

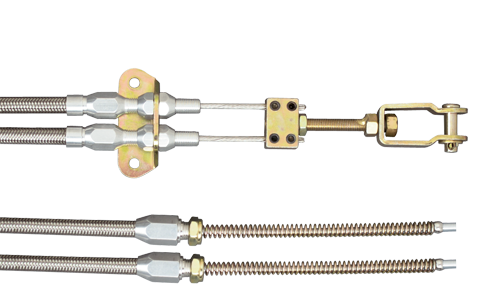

This is a CRAP pic but it's all I could find from 2015. I used a U bolt/clamp and had a bar welded upwards to hold the e-brake lines. You can see the OEM lines are bent too much, so this DOES NOT work. you will need to get longer aftermarket lines. The ends of the line must have a "spring return" or else the ebrake will not disengage after you pull it. I hope this helps. It sucks but I'm digging through old low quality cloud back ups of the pictures so it's not high res. The other pics were just google searches but it'll get you on the right track. -

Arizona Z parking brake

itzgoten replied to m1noel's topic in Brakes, Wheels, Suspension and Chassis

I'm not the original poster but I used his as a guide as well. You're going to need the longer parking brake lines. The way the caliper works it locks when being pulled back. Are you on facebook? I can message you quicker and share what resources I have. it's been a long time. I sold my Z a few years ago but I can help get you pointed in the right direction. -

Arizona Z parking brake

itzgoten replied to m1noel's topic in Brakes, Wheels, Suspension and Chassis

You do realize you're asking for pics from a 5 year old post? I was surprised I even got a notification still. Good luck on getting it all working! Shouldn't be too difficult once you have it all mocked up. -

jparker893, I didn't go with the Full-Race manifold even though it was a very high-end and super sexy manifold because of the way the turbo was clocked. It was pointed right at the strut tower and I wouldn't have been able to put on any intake piping. I had to return it at a loss and get a local shop to custom fab me a twin-scroll manifold. All swaps are different depending on where you mount the engine mounts. I had my mounts installed as far back as possible, engine almost up on the firewall. With that said the pre-made manifolds for a 240sx did not work. I would recommend getting something custom made. If the top mount is parallel with the motor you might be fine. Good luck!

-

You know, I'm no engineer so I can't give you an scientific answer. But from my personal opinion I felt it was a small hole to make so I was fine with it. I barely increasing the diameter. I didn't feel like it would be an issue. And compared to the small dinky looking stock one I think I'm better off anyway. Not sure hope much more steering angle you'll get but it's definitely more responsive.

-

I can't believe it's been over a year since I've updated anything. This will most likely be my last update since social media has been where things tend to go now a days. I enjoy reading on here but there really hasn't been much content lately. I really hope what I've done was able to help people around the globe who have done a similar build. I had a long and rough road but for the most part the car is in a good place. After the dash was flocked I purchased some nice wheels, custom re-valved stance coilovers, rear BBK from AZC with their e-brake option, AZC steering knuckles, T3 camber plates, tri-strut bar, outer tie rods, and C-pillar bar. Oh yea, I also switch to ARP Extended studs. The search for Nissan style threads were a hassle so I just went with the GM style pitch threads. I sold my trusty old suspension setup to another fellow Z buddy who wanted a plug and play option. I was running the Tokico shocks with the GC coils. But this new setup was just simply beautiful. No corners cut and we took our sweet time. The shop I took it to ordered me some custom 10k/8k coilovers which we adapted to collars that were more easily adjustable than the AZC setup. With that I had them adapted to also work with the T3 camber plates which were bolt-in no weld-in. I really preferred cutting and drilling over the whole cut and weld a new piece on. Just my preference I suppose. Here are some pictures. They were welded and then powder coated. Even though the suspension is adjusted down low it's very easy with these custom collars and a sweet little tool that Stance made. It snaps on to where the knob would go and extends them out with a flexible body. After the suspension was setup I had to figure out how to get the AZC knuckles adapted to the T3 outer tie rods. The struggle here was trying to taper off this spacer. Ended up taking quite a few hours of machine shop work but I couldn't think of any other way. This was the end result. I felt like it came together very nicely. The front arms are just so beefy now. The steering feedback is great and the steering wheel feels crisp with the shorter knuckles. I like it. The RCA also helps because I was getting really bad trailing issue (not sure what else to call it) when going over bumps on the road. Next were the extended studs and rear BBK. The studs were a pain. I'll admit I messed up. I had them press in on set and some how the were crooked as hell. This was such a pain because they decided to tap a small weld to save them from backing out. I ended up needing to source some extra scallops/hubs but the Z community came through and saved me. Here are the fronts. The rear BBK was a headache Install was fine but the problem is that I feel AZC really down plays how much BS it is to actually get the brakes working. It's definitely not "plug and play" that's for sure. It seems impossible with the current ebrake lines. Everything I've sourced online so far, people have purchased new brake cables and such to get it done. Even now I've taken the ebrakes off and wish I opted to save money and just get the hydro brake instead. I'll have to revisit this another time and get it done right. Till then, I'm just leaving the car in gear on level surfaces. We also had to grind down the parking brake to fit the wheels. It was re-sprayed with caliper paint after. Anyone reading this part.. just do the hydro line lock brakes unless you live in an area with lots in inclines... You're honestly looking at about $5-700 for ebrakes. The parking calipers are about $150 each. The brake cables I saw were about $280 plus your time and custom work. Screw it.. hah Last up were the wheels. I'm not a big wheel whore myself but no one loves you unless you're rocking some legit wheels right? LOL I absolutely love these CR-01s! They are just beautiful wheels. I will cry the day I scratch them. The wheels were A LOT wider than I had anticipated. I had to get rid of the old ZG flares and go WIDE ZG instead. Overall I'm extremely happy how things turned out. Here is how the car sits now. I really feel like it looks completely different! Not much else to do from this point.. 350z 6-speed tranny (which is in progress), MazWorx Intake Manifold, Q45 TB, ID2000 injectors, -10 AN fuel lines, redo my setup for dual fuel pumps w/ a surge tank. new ECU, FlexFuel, Rear chassis mounted GT wing, front splitter, rear diffuser.. and I think that's the end of it.

-

my goodness.. I haven't been on HBz for quite some time but that is one sexy intake manifold! Like VERY SEXY! Good job on the progress!

-

So again, I'll admit I have zero skill with doing this and part way I was going to say F* it and just sand everything flat and get a dash cover. But I stuck it out and yes.. WAY BETTER option and I'd say cheaper too after parts & shipping. I think if I got what I needed only I'd probably spend around $100.

-

I have their stage 3 ProCam. I believe 280deg IN / EX

-

Josel, I'm hardly ever on here now with social media making everything so damn accessible. Much easier to search for #240z on IG and look at cool cars. So car is back up and you're back on the road now right? I looked at your build thread and didn't see the updates on the carb rebuilds.

-

So I recently just finished re-doing my dash and flocking it. I've never done anything like this before and have ZERO skills. I just figured I'd try it out and see where it takes me. The project ended up being a success and for the most part I learned a lot and had a lot of fun. After removing the dash from the car I went and got some foam filler from the local hardware store (Orchard Supply Hardware "OSH") and picked up some epoxy resin there too. The idea was to cut out the cracks on the dash and make deep valleys and then fill it up with the foam filler and cover it with resin after and sand it all to a smooth surface. It didn't go as planned but I'll get to that later. I'm terrible with taking pictures so I'll narrate where I forgot to take pictures and document the process.. Here I've already cut into the cracks and made them into valleys. What I mean by that is the crack on the dash blistered upwards and if you were to cover it, it wouldn't be smooth. So some cutting had to happen in order to get the right smoothness on the final product. After I fill it with the foam and let it rise and fill the gaps After the foam cured/settled (please excuse my poor choice of words here, not my area of expertise) I used a razor blade to cut off the excess and prepped the area to lay down some resin. After the surface was prepped I used that crappy store bought epoxy and laid it down and covered the entire area. In my head I was thinking that it'd be easier to sand away the stuff I didn't need since I had an air sander practically unlimited sand paper. So... what went wrong with the epoxy? Well it sucked. It was the kind that came in a syringe and has two tubes. When it cured it wasn't hard enough and in that last picture it didn't cure at all and ended being super gummy. I had to rub the gum off by hand and it took away precious foam that gave that bezel area its shape. I ended up getting a bunch of the foam filler and sprayed it on my hand and smeared it over that area and shaped it how i wanted it to look. Kind of like you do with bondo. After that I sanded it nicely and made it round. I found the epoxy I need at TAP Plastics. Pretty damn awesome hobby store. It was my first time setting foot into one and it has a lot of useful stuff for crafting. They even had carbon kevlar sheets which I thought was amazing! Anyway, I got the hardest marine epoxy they had and bought the biggest bottle, I bought the hardener as well along with some mixing cups and mixing sticks.. I forgot to take pictures after I started epoxying again. Word of advice though. When you pick up the epoxy from the hobby store see if the have a sheet of MYLAR there. You'll want the 2mill thickness. I went and got the 5mil and found it was too think to work on and it took awhile to get the results I wanted. What happens is that the epoxy does not stick to the mylar. So you lay your epoxy in the foam area and use little strips of the mylar to lay it on top of the foam area like a paper machet [sp?] or tint. After it cures overnight you peel the mylar off and the cracks now have a super smoother surface. Don't try to use one big ass sheet to cover an area it gets really messy an you're prone to air bubbles. Before using the mylar sheets the resin would fill the holes of the foam and I'd have these depressions over the foam area. So here is the sanded dash after some work. I don't believe I've learned about the mylar sheets in these pictures but I don't remember taking any pictures of them after the fact either.. so we'll have to make do. Here you can see how NOT using the mylar sheets would be.. the resin just goes right into the foam and has depressions which sucks.. The final product after laying down epoxy and sanding for about 2 or 3 other sessions I ended up with this.. Everything was smooth to the touch and felt amazing. I was happy with the outcome and the feel of it was just right. I could finally see light at the end of the tunnel! NOW THE FUN BEGINS and the next step is to flock the dash! I had no idea how the process worked but it was very straight forward and very easy to do. I am NOT a hands on guy and if I made it turn out AMAZING I know you can do this too. The flocking materials can be bought at www.flockit.com (I'll cover this at the end as well.) I picked up the Suede-Tex flock, Suede-Tex adhesive, and the mini flocker (looks like a bottle of Pringles chips) So how it works.. you get a paint roller (3" roller with 1/4" nap) and you roll/paint the adhesive on the dash. (Make sure you're masking off the areas you don't want to mess up.) Then you put the suede-tex flock in the pringles can (fill it about half way) and you pump the can and it dusts the flocking material on to the adhesive. Like sprinkling powered sugar on something. BE EXTREMELY LIBERAL. LAY THAT SH*T ON THERE. I'm dead serious. I skimped on the adhesive and I ended up getting some bald/thin spots. Going back and touching it up afterwards doesn't give it that nice sexy suede feel to it. So try to do it all in one go. Lots of adhesive and lots of flock. You'll have plenty of time to flock the entire dash so just roll the adhesive paint all over the dash. Again, really roll it on there. Also have a flashlight handy. Shining the light gives you contrast and you can see the shiny or dull spots. So you know you need to paint there or toss some flock on. Here I started to flock and you can see the matte area which has the flocking material on it.. If you look at the table you'll notice more and more of that black stuff on there. That is all of the fibers that fell off. If you wanted you can collect it and use it again. I had so much I just felt it was easier to toss most of it. Plus I didn't want other debris going back into my supplies. Sorry some of the pictures were blurry. I also did the glove box door and the dash trim as well. It's really hard to capture black in the light but it's much darker and matte looking in person. Here is the gauges after being installed back into them. and the glove door... You can see I missed some spots but for my first time I'm pretty damn happy. I hope this helps some of you and gives you the information you need to move forward and do this yourself! So to recap... What you'll need. Hardware store (OSH) Foam filler paint roller 3" with 1/4" nap (do not get sponge material) Paint brush (for touching up and small spaces/corners) (no sponge!) masking tape to block off you stuff paint roller tray for the adhesive Hobby store (TAP Plastics) hardest grade epoxy resin mylar sheet 2mil (depending on your dash. I bought 2 feet and used less than 1 foot) mask (the resin fumes and resin dust is so bad for you to breath in) mixing cups (get the small ones. I laid resin down with only 2oz at a time. It cures way too quickly) mixing sticks Flocking materials. www.Flockit.com Suede-Tex Adhesive Suede-Tex flock Mini flocker applicator Other flashlight rubber gloves tarp or something to cover your work area Total I spent about $200-250 on this project and about 10 hours of my time. The longest part was waiting for the resin to cure for 24 hours. Total I did about 5 sessions @ 2hrs each.

-

aww man. I tried to look through the non-tech area and couldn't find anything.. bummed out that it happened. I went to look for the guys profile but it seems as if it went back in time and he no longer exist as well. what a bummer.

-

Did something happen to the forum? I could have sworn I was talking to a fellow not too many weeks ago. I went to drop some updates and that whole conversation is gone.. totally odd...

-

Phantom Z Sport Wagon Unveiled at Z CON 2014!

itzgoten replied to JDM's topic in S30 Series - 240z, 260z, 280z

I appreciate the work and time it took to make this. I am not bashing on it whatsoever.. but it's just not for me. My personal opinion is that it's ugly.. -

Nice. What motor, fuel and setup you running?