-

Posts

149 -

Joined

-

Last visited

-

Days Won

5

Content Type

Profiles

Forums

Blogs

Events

Gallery

Downloads

Store

Posts posted by osirus9

-

-

So after talking with Haltech tech support I'm probably going to go with the sport 1000 because its got data logging and closed loop functionality. It can also do direct fire on a COP setup which is pretty slick. The thing costs a lot more but it looks worth it. Are you seeing any of these features as major issues with your sprint 500, or is the extra stuff a waste of money?

-

Great info! I will be using this knowledge when I set up my Haltech. I was considering using an MS setup too, but I've done a haltech e6k before and even though it was old as hell it worked very well.

2 questions though, I see the Sprint 500 does not support closed loop, so are you able to get good mileage? Do you use your car as a daily? (kinda off topic, sorry)

Also, and more on topic, can you use the VG30 wheel with the L28 engine somehow? Can you fit it in the 280ZX CAS for instance? I'd like to run wasted spark off of the distributor at least for now, then maybe upgrade to COP (same as direct fire?) later

-

How can you run in closed loop without an 02 sensor? There was no 02 sensor on the 78 correct?

And I'm sure my mileage will improve later with an aftermarket ecu, but in the mean time I was still curious about other people's experiences. It seems like half the folks here get over 25mpg pretty easily, while others can't get 20mpg to save their lives. It just seems like a pretty big gap to me is all.

-

Kuro is actually Christine

but yes, MSA still sells the 240 and 280 style xenon air dams

-

Welcome to the community!

So does your car run? Or have you inherited a work in progress? Either way that thing is gonna be FAST! And very similar to the setup I'm putting together for my own car. Good luck to ya

-

Good advice the both of you, I will try disconnecting the LCA at the diff side and moving it around to see if I can reproduce the noise.

-

You need to change that crossmember when changing the racks. While you have it out, put in your engine link to limit engine torqueover on accel-decel and keep soft mounts. I did mine with the car in the air on 4 jackstands, and a 5th under the tranny bellhousing holding up the engine while I dropped the K-Member and in fact, the whole front suspension!

Engine link? What is that?

-

when I first went to install the bushings the LCA was SUPER tight against the hub so I forced it on. One of the bushings was definitely damaged by that, but I thought it would be ok. It squeaked, so I cut off the loose "flap" of bushing. It was really quite small. That didn't seem to affect the squeaking at all though.

After I went and sanded and squared the hubs the LCA slides right on no problem, so I'm assuming that that was the issue all along? Unless it could be something else?

-

huh, well I know my timing is fine, I already checked that. I'm using some unknown injectors though. You'd think they would flow less over time instead of more though?

Any options to check them without having to send them away?

-

Hmmm, I have a factory black car, but I was planning on getting the outside painted dark green w/ a black air dam/overfenders/tail light panel. I was just going to leave the engine bay black, but now I'm wondering if that is wise... sigh, I suppose I could pull the engine and trans and have the car towed to the paint shop. but just for the engine bay, that seems extreme to me. I'll probably just leave it black and if it really bothers me I can have it painted when I have the engine out later when I swap to a turbo motor.

-

I've got the stock 5-speed 280Z Trans and an air dam too. I figured the 3.7 rear end would hurt mileage some, but this seems extreme to me.

Its odd that some people get over 25mpg and others are stuck below 20. What gives?

I know I had a bad coolant temp sensor on a previous car that was causing a rich condition, so I replaced the one on the Z, but apparently there are 2 on this car? I replaced the small, single wire one. It's not really a huge deal since next year I will be going turbo and converting to a MS ECU, but if there is something simple and cheap I can try in the mean time I'd definitely do it. Premium is expensive!

-

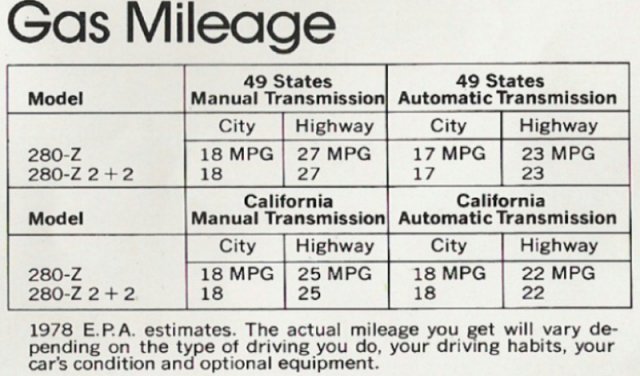

So after searching around I couldn't find anything on this site related to gas mileage. So I went to google and found that the 280z is rated about 18mpg city and 27mpg highway!

Well I'm running a mostly stock 280z (just intake and 2.5" straight exhaust) and I'll get 16-18mpg cruising 50% highway at 70mph @ ~3800RPMS, and most of the rest on country roads at 55mph @ 2500RPMS. I think the only other things affecting mileage would be wider sticky summer tires (225s) and a 3.7 rear diff, but would that really kill my mileage that much? I have new plugs and wires as well, and my car idles rock solid at 750rpms, but I don't have a wideband (yet) to check my AFRs

Are other people getting similar mileage, or is my car running too rich for some reason?

-

Thanks for explaining that madkaw, it makes sense to me now. I haven't had time to mess with the car much lately, but I ordered a new set or LCA bushings (mine were a little shredded on the hub side) and when those come in I will take both LCAs out of the car completely, install new bushings again and grease the hell out of them. Gonna pray I just derped on a step and doing it over again will fix it. Also going to make sure to concentrate on greasing the bushing instead of the metal sleeve now that I know it isn't supposed to move. I'm thinking that, combined with my messed up hubs is the issue here.

-

I've got a 3.7 LSD with the early Z 5 speed and I have to agree, 1st is way too short, and 4th and 5th are almost the same gear. Highway cruising at 80mph is almost 4k rpms and I'm at 2500rpms in 5th going 55mph. I was always considering a trans swap, but not sure if the T5 or the ZX was right for me, especially since I am planning to turbo the car. Seems like the general consensus here is the ZX which seems odd to me since the T5 has taller gearing and is stronger, unless I'm horrifically mistaken.

-

OK, so this weekend I took both spindle pins out and their bushings. I checked the hubs with a square and they were a pretty far cry from squrae. They also had some dents and machine marks on them that I had't sanded down apparently. I was in a rush to get the car running last time so I overlooked the hubs, assuming that the shop had done a decent job.

Anyway, I squared them as best as I could without a lathe, but they still have some minor depressions in them. I'd say at least 80% of the surface is flat and mirror smooth. I then regreased the pins and the inside of the metal bushing sleeve and replaced the spindle pins. At first this helped a lot and I thought I had figured out my problem, but after 30 miles the squeaking is back the same as last time! I got some more grease today finally, but I was wondering, which part of the LCA bushing actually moves? The spindle pin stays still obviously, but does the inner metal bushing sleeve move against the pin, or does the bushing move against the inner metal sleeve and the sleeve and the pin remain locked together?

So I guess my next step will be to remove the sway bar and see if that's the culprit. Grrr... I hate doing the same job more than once...

-

My 78 is not slanted, and I don't have any storage bins either. There is just a bunch of wasted space where the rear deck is raised up.

-

Lookin good! So does this rad cool as well as the stock unit?

-

I had the spindle pin bushings and the spindle pins pressed out at a local shop, so its possible they bent the LCA. They said they broke their press! And the hub was pretty banged up where the LCA bushing touches it. I had to take a grinder to it and then some sandpaper to get it as smooth and straight as possible. I'm no machinist though, so it was kinda just eye-ball straight unfortunately.

I use this car as my daily and I put like 60 miles on it every day, so I haven't had the chance to take it apart yet. But tomorrow I should have some time. How can I test if my LCA is bent? Wouldn't it be hard to get the spindle pin in or to bolt it up if it was bent? I had no such issues.

This noise used to happen on acceleration for a week straight, but now its only when the car is cold in the morning and when turning and braking. I was able to reproduce it in the parking lot at work finally, since before now I had to basically pile drive the car to get it to make noise it was too dangerous to stick you head under. Anyway, this time I stuck my head under there and as best as I can tell, it sounds like the LCA where it attaches to the hub.

So tomorrow I'm gonna take both (brand new) spindle pins out, bathe them in a tub of bushing grease, and then see what happens. Last week when I took them out they had some pretty noticeable scratch marks from the inner metal sleeve of the LCA bushings, is that expected? Maybe I'll lightly sand them smooth with some 220 grit while I have them out.

-

I haven't gotten a chance to try disconnecting the swaybar yet, but as an update:

I filled up my gas tank and I had a passenger and some bags in the back and the noise is now happening when I brake, or just all the time. It kinda changes when it feels like it... but its definitely worse than when there was less weight in the car.

-

As far as lubricants go, when I installed the sway bar I had really bad squeaking, the end all solution was to use teflon tape to wrap the sway bar where the bushings went, no problem after that. I don't think sanding the bushings was the right choice, the extra movement can add to the squeaking. Making sure to grease one of the contact points is also an overlooked spot, the bushing essentially stays still while the suspension piece moves in the inner tube or against the bushing, if that area isn't greased or wrapped or what not, you are going to get a very pleasant metal on metal screech. If the bushing in question is supplied with an inner tube that will be held in place, lube the outside of the tube before inserting into the polyurethane sleeve, (lubing the inside doesn't hurt either), if no inner tube is supplied grease the suspension piece that goes through it.

During hard acceleration, the parts stressed starting with the suspension, is the strut top insulator, the spring seat, the spring, the bottom spring seat, the wheel bearing, the wheel hub, the wheel, the tire, the half shafts, the diff, the diff mount front and rear, the drive shaft angle changes a bit, the transmission mount, and the engine mounts.

I would check the strut top insulators see if they are intact, make sure the spring is seated in the perches top and bottom, take a look at the e-brake routing, inspect the rear wheel bearings, liberally grease up the bushings, and tighten down the LCA captive bolts (the giant bolt front and back on the inner side of the LCA). Granted I really think liberal application of grease is the answer.

Regarding the preload thing, I've been told opposite, that you shouldn't pre-stress the bushings until they are compressed and supporting the car, or else you risk mushrooming the bushing or worse bending/stressing a suspension component, end links, etc etc. I make sure the pieces are all in their correct spots, hand tighten, or take up slack on the lock washers, lower the car onto blocks or ramps, compress suspension and then torque the bolts.

Thanks for the info, I will try disconnecting the rear swaybar and tying it out of the way to see if that is the culprit!

I sanded the bushings down the tiniest amount. Really it was just to get the pieces to fit together without excessive force being applied. If you think of the bushings as little mushrooms, I sanded the top and the bottom less than a millimeter in total. Before I did that I was having a really hard time getting the LCA to fit against the wheel hub so putting the spindle pin in was a nightmare. After sanding I was able to fit them together much more easily. This may have been because my wheel hub was slightly damaged when the shop pressed my spindle pins out, so I had to sand the metal there flat as well.

Also I may have described my pre-stressing steps unclearly, because I meant exactly what you described. So good to know I did that right haha.

-

hmmm, yea I used a bunch of that nasty lube on the bushings. I replaced the front diff mount with a brand new one from courtesy nissan. I can try tightening the mustache bar bolts again, but I've been down there several times and even tightened the bolts down when the car was on a lift so they were "pre-stressed". My mechanic told me that was important, I've personally never heard of that before. I've replaced the bushings with urethane ones on my old rx7 before, and I didn't have any squeaking issues then, so I don't know what I could have done differently this time...

Why do you think it sounds like it is coming from the strut tower? Is that just acoustics playing tricks on me? Why only on acceleration? Which parts of the suspension are stressed/unstressed at that time?

-

I have already searched this problem, that's how I knew to try the common solutions. They helped some of the squeaking sound, but I can't figure out what is causing this last squeak. I was more asking if anybody else has had this problem of acceleration causing a rear end squeak, and if they were able to find a solution.

Also, is it possible that my springs are causing this noise by scraping against their spring perch? It sounds like it is coming from the rear driver's shock tower, and I recently installed camber plates there (the peasant, bolt on kind) and replaced the struts with KYBs. I've checked over that area multiple times and everything is torqued to spec etc...

-

So I have a really loud and awful sounding squeaking noise coming from my rear suspension. it is happening only when I either go over a large bump, or I accelerate.

It is BY FAR worse when accelerating, its almost constant squeaking/metal on metal? screeching sound.

I'm having a lot of trouble trying to narrow down what could be causing it because I recently replaced all my bushings with urethane bushings, and replaced the struts.

I have tried spraying my bushings with silicone spray, but that doesn't really help. I have tried having a passenger crawl back there and see if they can narrow down the problem area while I was driving but met with no success that way. I've tried taking out all the rear interior and driving with the hatch open but that did nothing. I've tried pulling the driver's side LCA (I'm convinced its on the driver's side... at least mostly) and re-greasing and sanding down the bushings to make them fit better, but that did nothing either.

What could be causing a squeak under acceleration? Which bushings should I look at?

Is it possible its the springs scraping the spring perch? Is there supposed to be some kind of pad between the two?

Its SO BAD when accelerating, even like 1/8th gas it will do it. But cruising and braking it is silent.

Any insight would be much appreciated. I apologize if this is in the wrong section, but I figure that since I have a 280z, this issue would be specific to that car, Mods please move if this is in the wrong section.

-

OK, that makes sense, so if you still had a heater would it be safe to just route the coolant into the coolant line that runs along the passenger side of the engine to the pump inlet? Being that it is the exit of the heater shouldn't disrupt its function even if the heater is on or off correct? And for that matter, would it make sense to route the bypass to the heater core inlet? That way the coolant would be cooled a little if the heater was on, but where would it go if the heater was off.. back into the head? Or is that idea just retarded.

Help fix my heater?

in S30 Series - 240z, 260z, 280z

Posted

Mine does this sometimes. The stock vacuum lines are TINY, and get cooked in the engine bay over time. The PO in my car thought he was helping and replaced all the under the hood hoses, and then used a plastic 2 barbed connector to join the new hoses to the original at the firewall. Well that joiner is a little too big for the stock lines and they like to split right there and leak air. I literally just wrapped it in electrical tape and my heat works perfectly. Some day I'll find the proper adapter...